Visual servo feeding special-shaped spiral curved surface screw abrasive belt polishing device and method

A helical curved surface and visual servo technology, which is applied in the direction of abrasive belt grinder, grinding/polishing equipment, workpiece feed movement control, etc., can solve the problem that it is difficult to adapt to the variable-lead special-shaped screw, which affects the polishing path and CNC machining accuracy, Affect production efficiency and economic benefits and other issues, to achieve the effect of enhancing processing flexibility and continuous production capacity, improving polishing accuracy and processing quality, and improving process design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

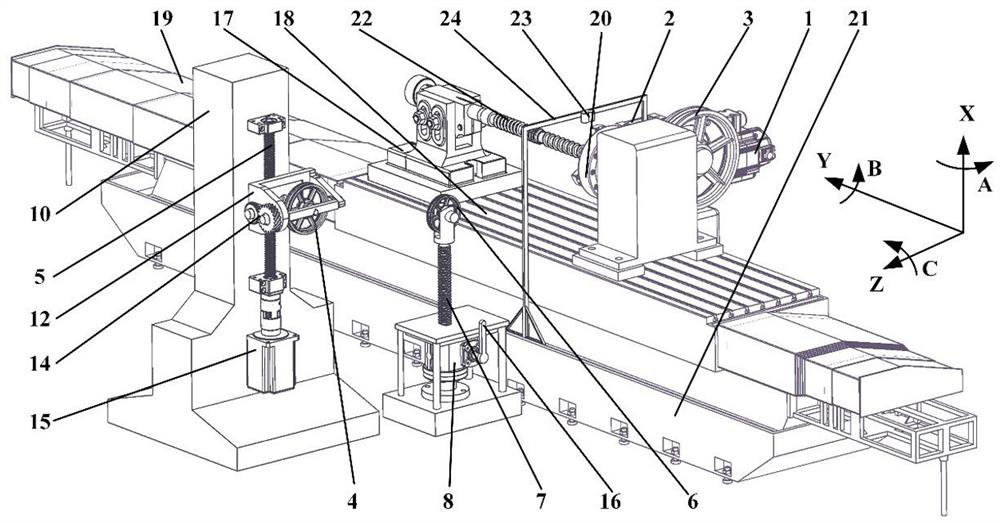

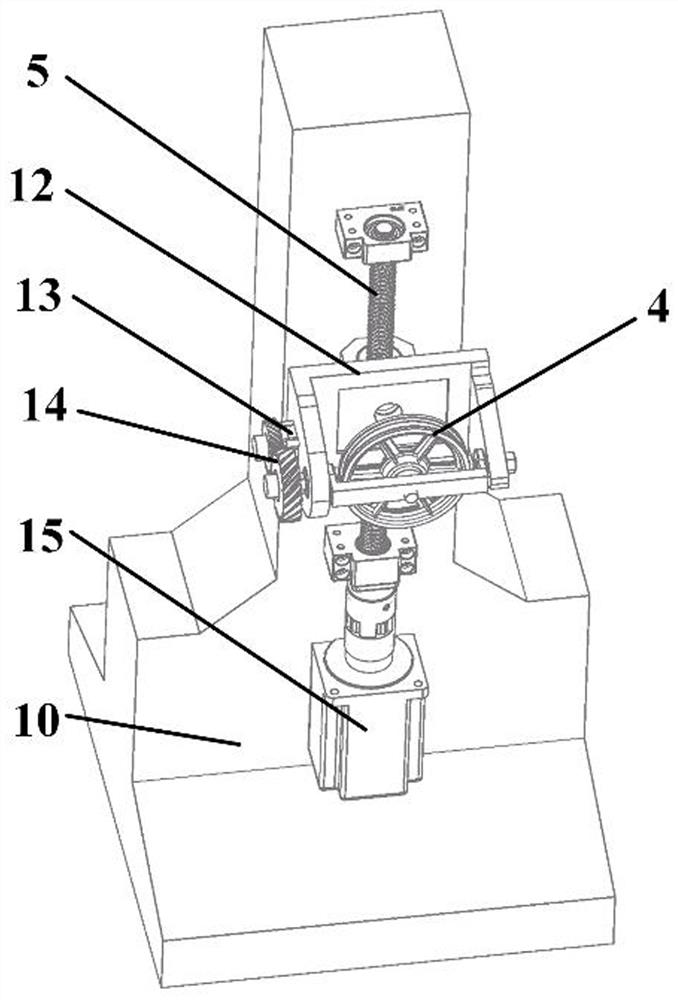

[0033] Such as figure 1 The shown a visual servo feeding special-shaped spiral curved surface screw abrasive belt polishing device includes a bed 21, and also includes an abrasive belt drive mechanism, a screw feed mechanism, a binocular vision acquisition mechanism and a data processing unit; the abrasive belt drive mechanism is fixed Installed on both sides of the bed 21, the screw feed mechanism is installed on the bed 21, the binocular vision acquisition mechanism is fixed on the bed 21 through the support mechanism, and the collected data is transmitted to the data processing unit; the abrasive belt drive mechanism includes A driving wheel mechanism, a driven wheel mechanism and a tensioning wheel mechanism; the driving wheel mechanism, the driven wheel mechanism and the tensioning wheel mechanism are sequentially connected through an abrasive belt.

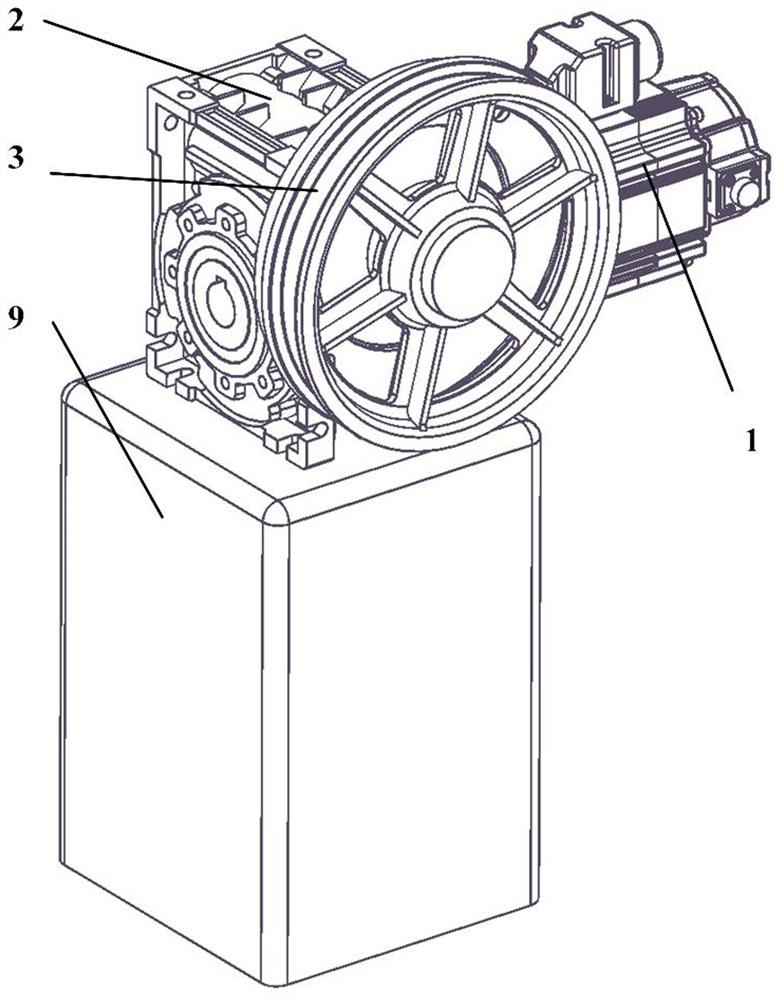

[0034] Such as figure 2 As shown, the driving wheel mechanism includes a driving motor 1, a reducer 2 and a driving whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com