Parametrization design method of first-level member of beam, wall and rib type parts of airplane

A parametric design and parametric technology, applied in the parametric design of aircraft beams, rib parts, first-level components, and walls, which can solve problems such as inconsistency of geometric types, affecting the seamless connection between CAD and CAE, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A first-level component parametric design method for aircraft beams, walls, and ribs used in the aircraft structure design method based on parametric components. Its technical basis is the aircraft structure design method based on parametric components. For related content, please refer to the "Contents of Invention" in the manual.

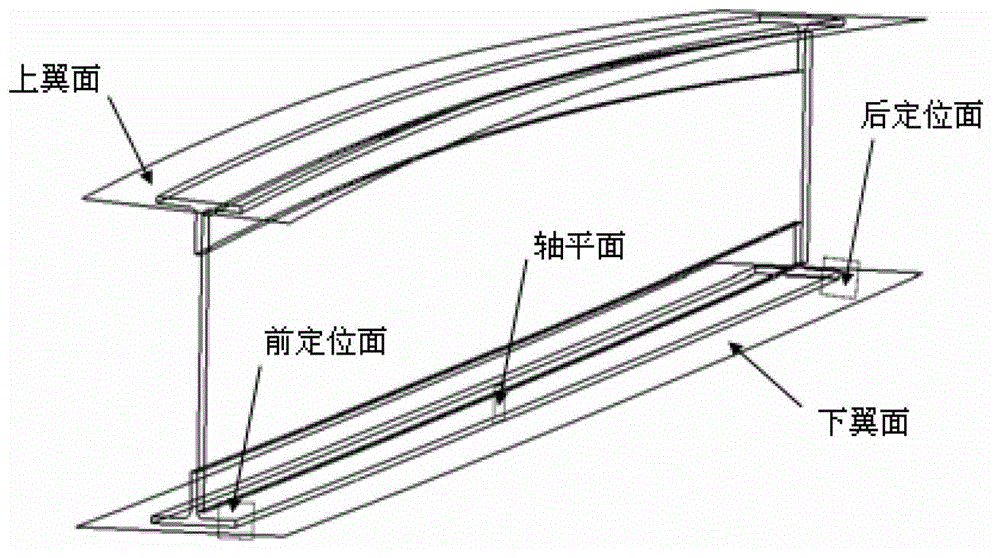

[0079] The focus of this embodiment relates to a parametric design method for first-level components of aircraft beams, walls, and ribs: use parametric components to describe beams, walls, and ribs in aircraft structures, and aircraft beams, walls, and ribs 1 The parametric expression of level components specifically involves the following four parts: "basic properties", "geometric properties", "non-geometric properties", and "two-dimensional cross-section diagram"; where:

[0080] "Basic attributes" specifically include: component name, version number, creation time, component description, manufacturing process, remarks;

[0081] The "geo...

example

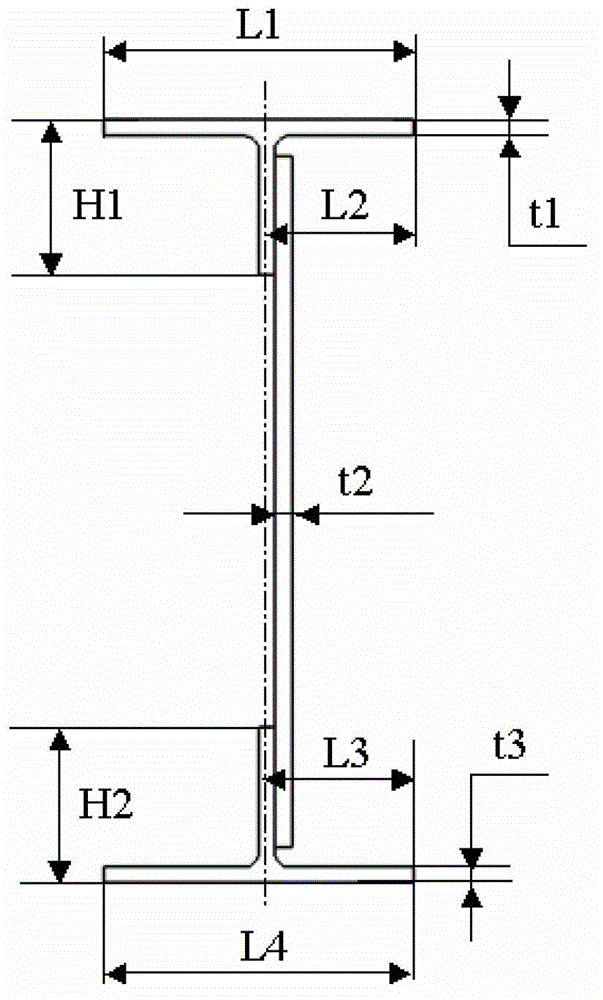

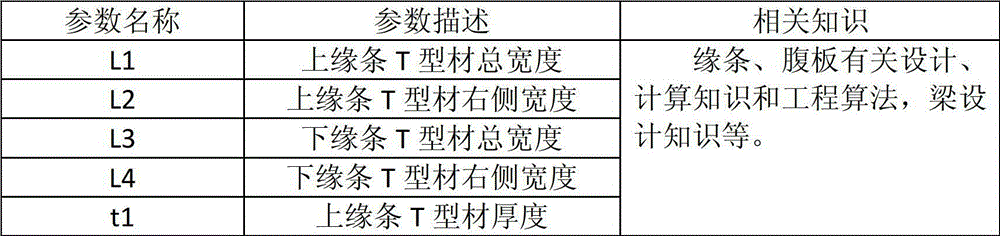

[0085] Example: For composite beam-wall members whose upper and lower flanges are T-shaped extruded profiles, they can be decomposed into upper and lower flanges and webs. For the upper edge strip, see Table 2 for the simplified unit and computed attribute table.

[0086] Table 2 can be simplified as member calculation properties and associated formulas of bar and beam elements

[0087]

[0088] For the lower edge, the simplified elements and calculation properties are the same as the upper edge, the difference is that the parameters of the associated formula are different.

[0089] For the web, the simplified elements and calculated properties are shown in Table 3.

[0090] Table 3 can be simplified to the calculated properties of members of various plate units

[0091]

[0092] "Two-dimensional section view": it is used for the user to correctly understand the physical meaning of each parameter of the component when the component is instantiated.

[0093] The parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com