Design and processing method suitable for extremely light mass delivery model

A processing method and model technology, applied in the aviation field, can solve the problems of time-consuming and labor-intensive, inapplicability, model design and processing quality experience have a great influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

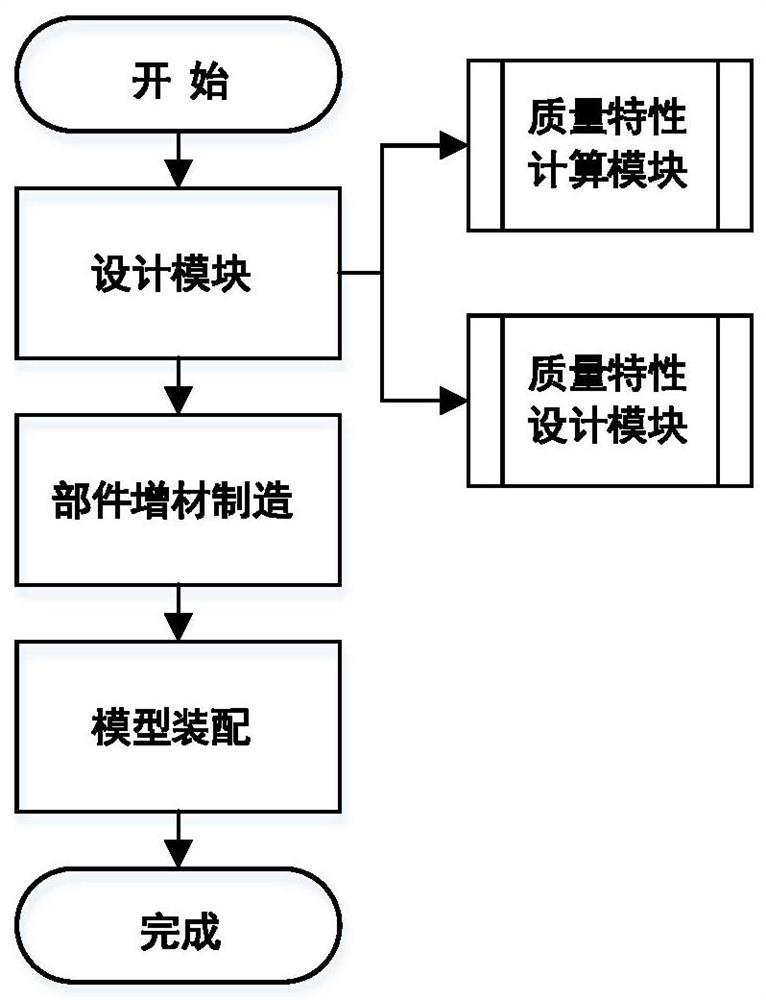

[0071] The flow sequence of the whole method is design module-component additive manufacturing-component assembly. The design module includes two subroutines, the mass characteristic calculation module and the mass characteristic design module.

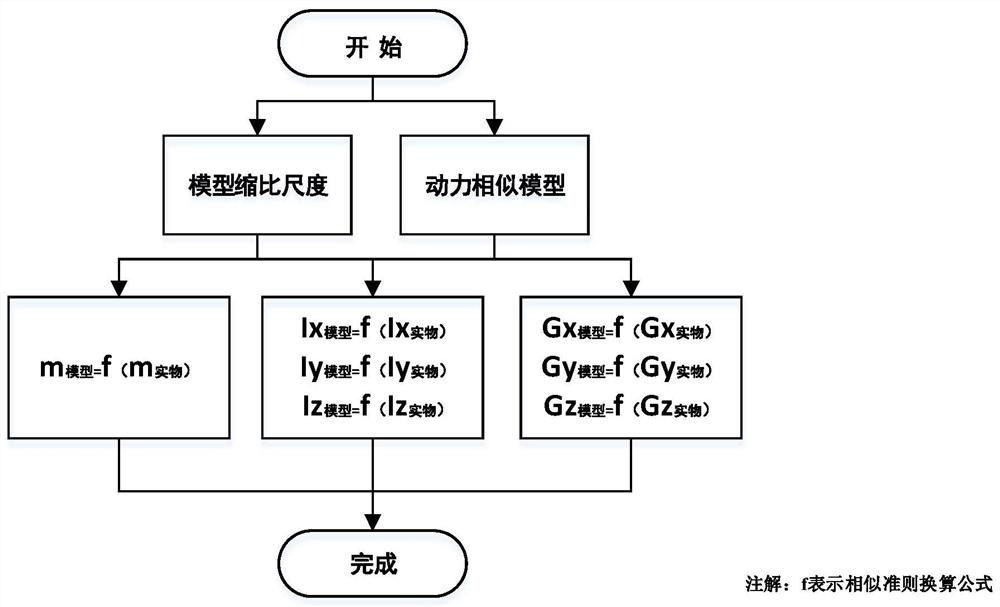

[0072] The mass characteristic calculation module calculates the weight, center of gravity and moment of inertia of the model according to the model scale ratio and dynamic similarity criterion, and uses the calculated weight, center of gravity and moment of inertia as the target parameters of the mass characteristic design module.

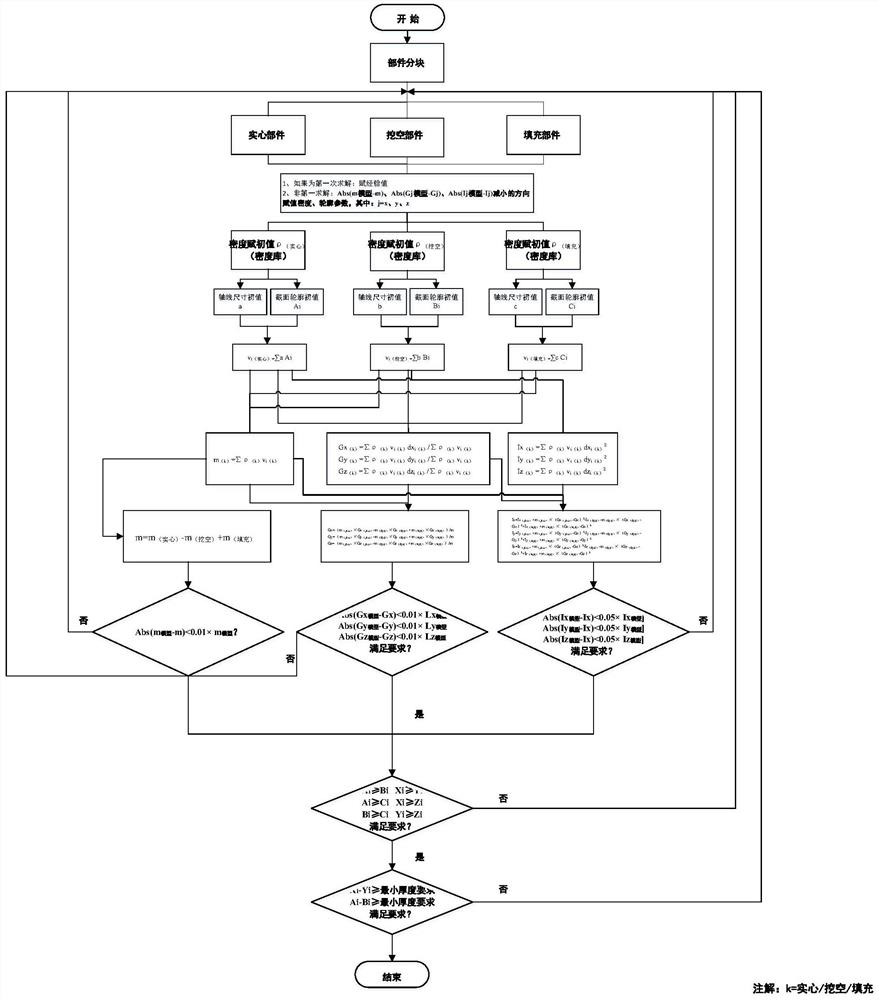

[0073] The core idea of the mass characteristic calculation module is: hollow out the middle of the solid body model to form a shell, and the hollowed out part is continuous, and the basic thickness requirements of the shell must be guaranteed, and its shape is not limited. Place the filling part inside the hollowed part. The filling part can use materials of different densities. The filling part is con...

Embodiment 2

[0083] A design and processing method suitable for an extremely light mass delivery model, characterized in that it includes design and processing steps, and is characterized in that it manages to include the following modules: mass characteristic calculation module, mass characteristic design module, component additive manufacturing and model assembly, Its design method steps are as follows:

[0084] (1) First divide the parts into blocks, define the model entity without any operation as a solid part, define the excavated part as a hollow part, and define the filled part as a filled part;

[0085] (2) Then the cross-sectional profile and axial profile of the solid part are described by the profile formed by point Ai and the profile formed by point a respectively, and the cross-sectional profile and axial profile of the hollowed out part are described by the profile formed by point Bi and point b respectively Formed profile description, the cross-sectional profile and axial pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com