Automatic special-shaped ceiling modeling method

A ceiling-mounted, automatic technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of complex design process, low design efficiency, and many repetitive tasks, and achieve the goal of ensuring design quality and improving design efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] The special-shaped suspended ceiling automatic molding method of the present invention comprises the following steps:

[0039] 1) Establish initial data templates, parts templates, engineering drawing templates and bill of materials templates;

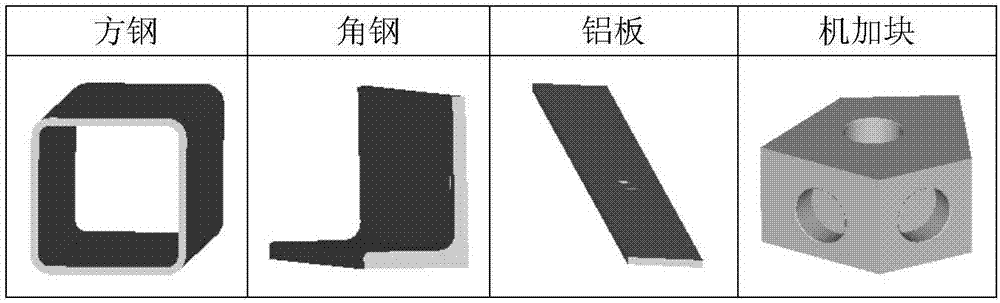

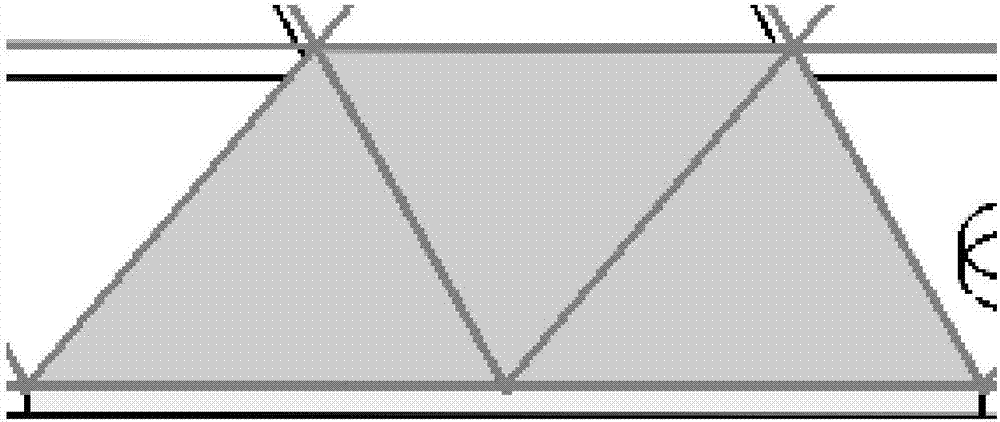

[0040] For regular ceiling units (the angle between the top surface and the bottom surface is less than 15 degrees, triangular or convex quadrilateral units that do not include special holes such as air-conditioning holes and inspection ports), an initial data template for triangular units, an initial data template for approximate trapezoidal units, and angle steel are designed. Part templates (engineering drawing templates) and bill of materials templates for four parts, square steel, aluminum plate, and machined block, such as figure 1 shown.

[0041] The initial data template is used to operate with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com