Parameterized bus bridge model design and modification method

A model design and busbar bridge technology, applied in the field of busbar bridges, can solve the problems of heavy design workload, low design efficiency, and heavy workload, and achieve the effects of reducing labor intensity, improving design efficiency, and ensuring design quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them.

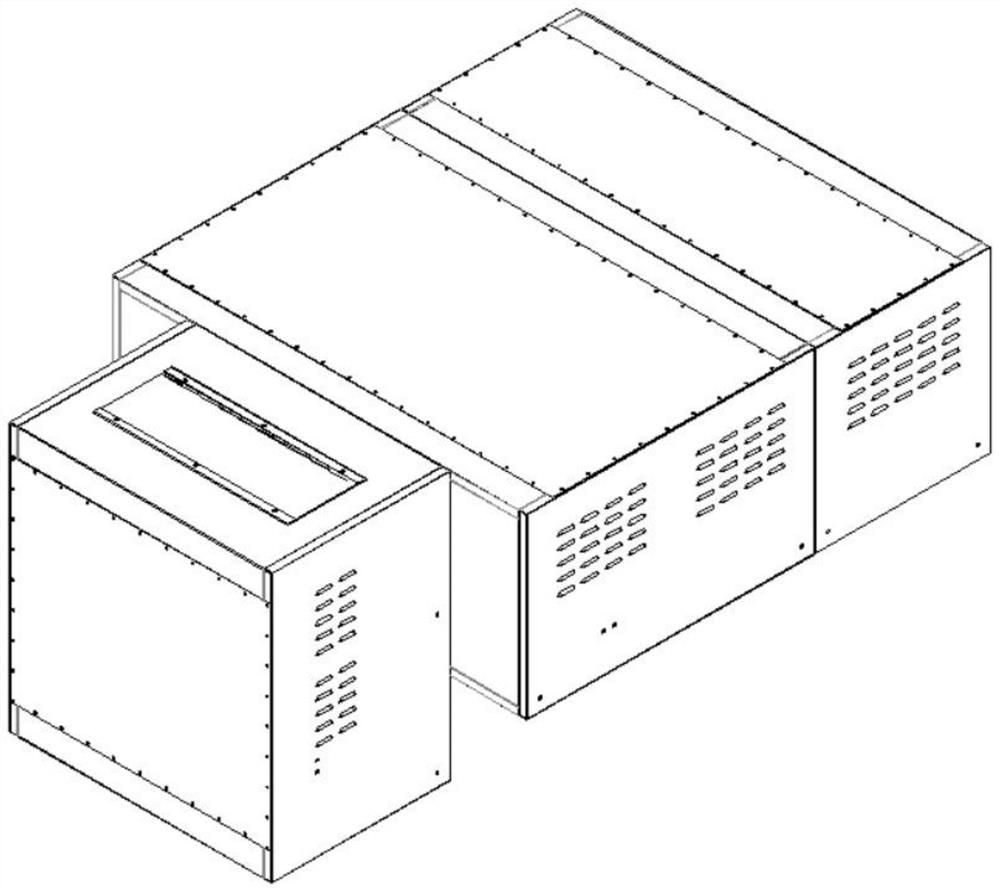

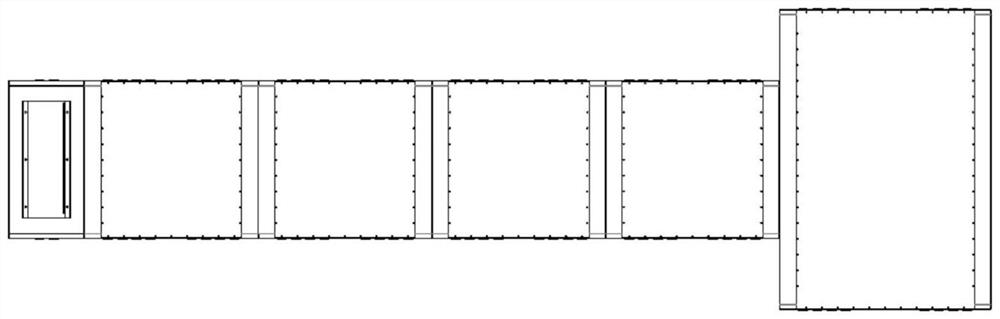

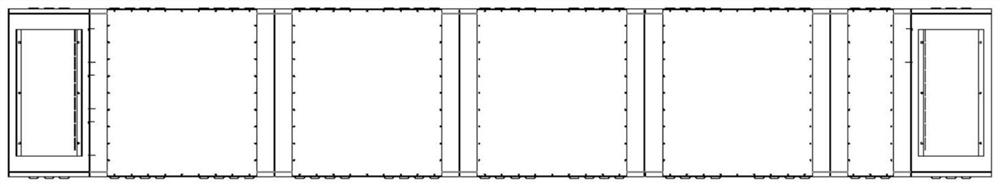

[0031] In the present invention, refer to Figure 1-7 , the application of SolidWorks overall parametric layout in busbar bridge design, and the shortcut form of SolidWorks in parametric design.

[0032] 1. Carry out the overall layout of the busbar bridge, according to the direction of the copper bars in the busbar bridge, make an overall layout of the structural position of the busbar bridge shell through the 3D sketch of SolidWorks, and add correlation equations to its main parameters, and control the main dimensions through the parameters.

[0033] 2. After completing the 3D sketch layout of the busbar bridge structure, set the datum plane with the help of the point lines of the 3D layout, and determine the specific position in space f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com