Deep drawing die structure generating method and system

A deep drawing die and die technology, applied in the field of deep drawing die structure generation method and system, can solve the problems of time-consuming and labor-intensive change process, unreasonable die structure, low standardization degree, etc., to reduce duplication of labor, shorten die design cycle, The effect of increasing the degree of standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

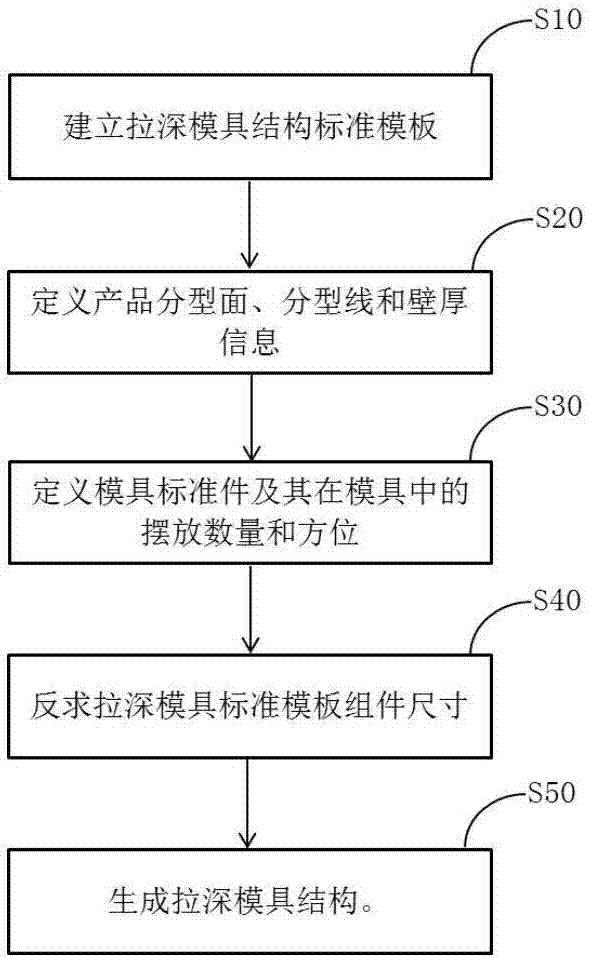

[0037] figure 1 Shown is the process flow of the method for generating the drawing die structure in this embodiment, including the following steps:

[0038] Step S10, establishing a drawing die structure standard template;

[0039] Step S20, defining product parting surface, parting line and wall thickness information;

[0040] Step S30, defining mold standard parts and their placement quantity and orientation in the mold according to product size specifications;

[0041] Step S40, reversely calculate the size of each part of the standard template through the product information and the standard part information;

[0042] In step S50, a drawing die structure is generated according to the reverse obtained standard template and standard part information.

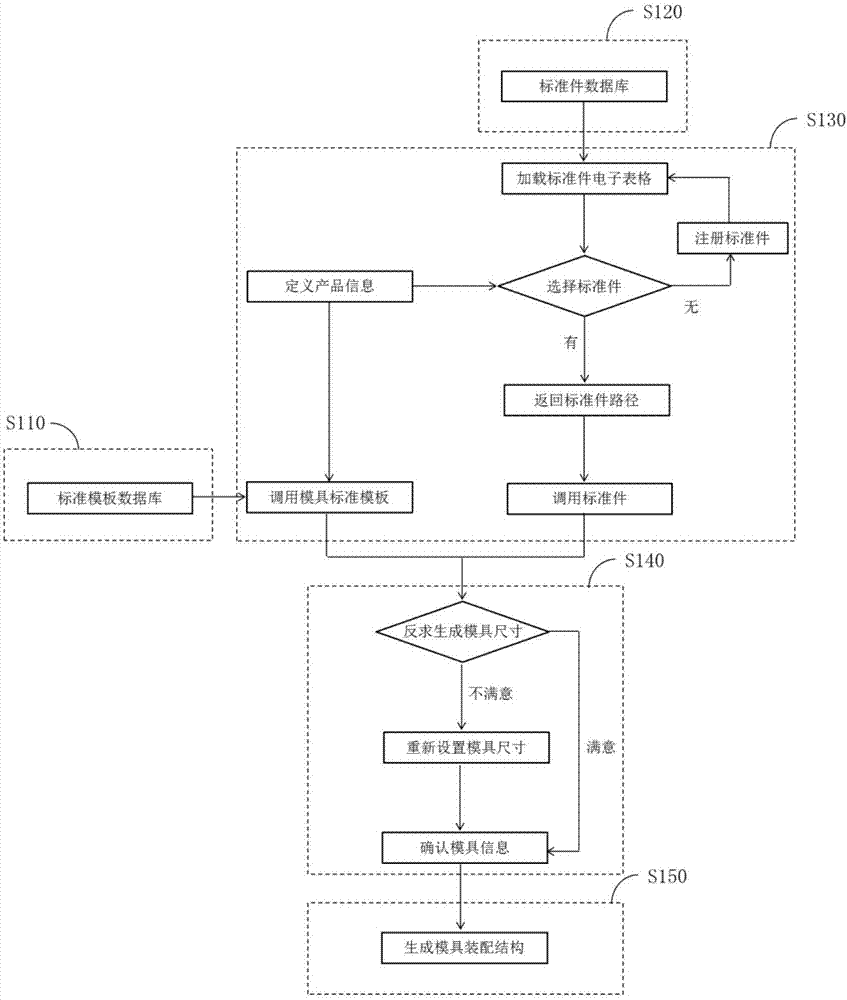

[0043] In step S10, the standard template includes a punch part, a die part, a blank holder part and a formwork part, and the dimensions of each part are related to each other, and when a part of the size is changed, the as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com