Transverse electromagnetic (TEM)-mode coaxial dielectric ceramic filter and manufacturing method for same

A technology of dielectric ceramics and filters, which is applied in the structural field of TEM-mode coaxial dielectric ceramic filters, and can solve problems affecting batch consistency of final products, long production cycle, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

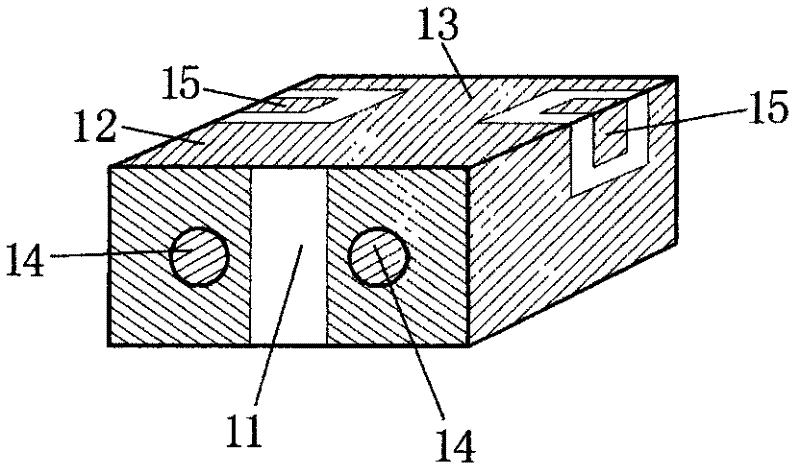

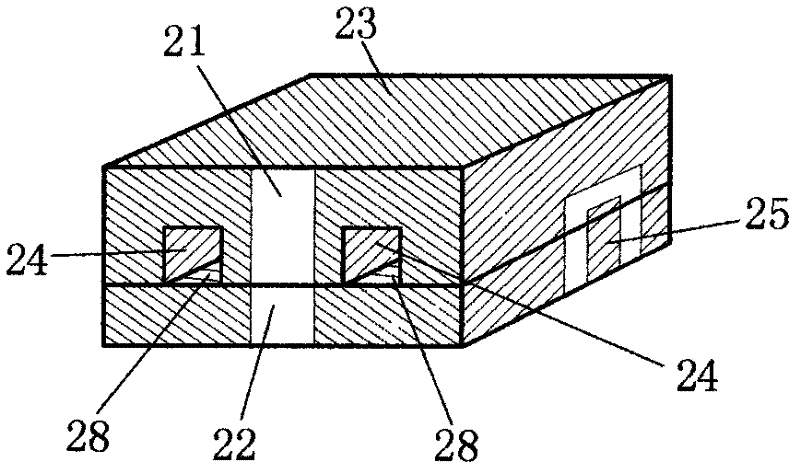

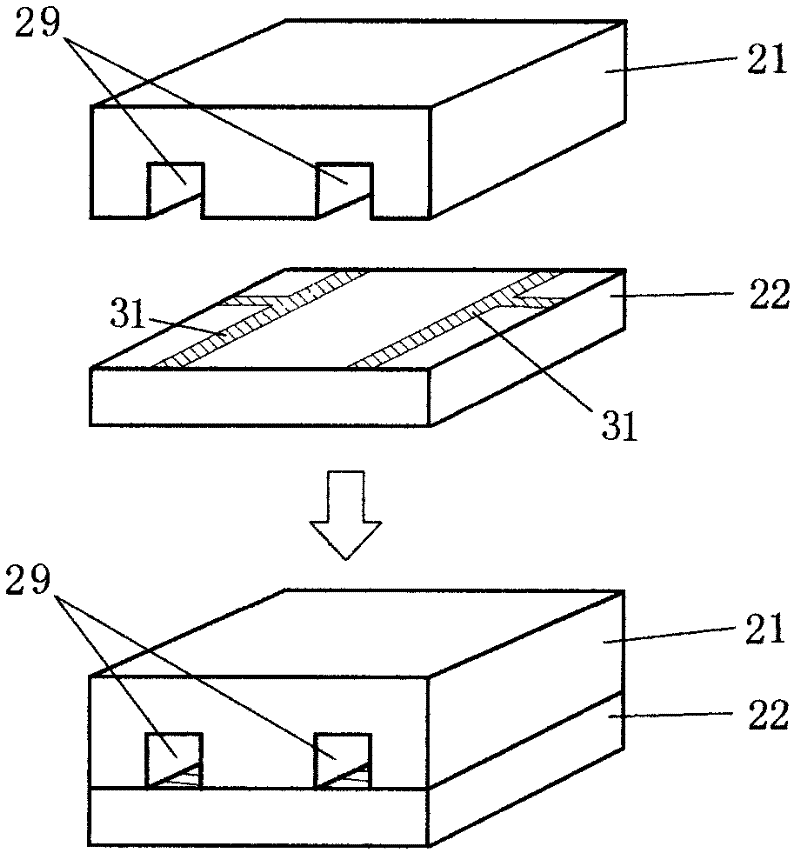

[0024] like figure 2 As shown, this TEM mode coaxial dielectric ceramic filter includes a cube-shaped dielectric ceramic block and a surface metal layer. There are two in the center of the end face of the dielectric ceramic block. Through the cavity 24 (coupling hole), the surface metal layer includes input and output electrodes 25 and surface electrodes 23, wherein the surface electrodes 23 are distributed on the upper and lower surfaces of the dielectric ceramic block, both sides, the inner surface of the cavity and the surface of the cavity. on one end face. like image 3 As shown, the dielectric ceramic block is formed by bonding and sintering two dielectric ceramic bodies 21, 22 with glass paste, and one of the dielectric ceramic bodies 21 has two rectangular cross-sections on the bonding surface. Groove 29, the above-mentioned groove becomes the cavity 24 after the two dielectric ceramic bodies are bonded together. Another piece of dielectric ceramic body 22 is a fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com