Assembled steel pipe concrete-wood composite wall for building house and manufacturing method thereof

A concrete-filled steel tube and prefabricated technology, which is applied in building structures, buildings, building components, etc., can solve problems such as impact, and achieve the effects of reducing pollution, increasing usable area, and enhancing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings.

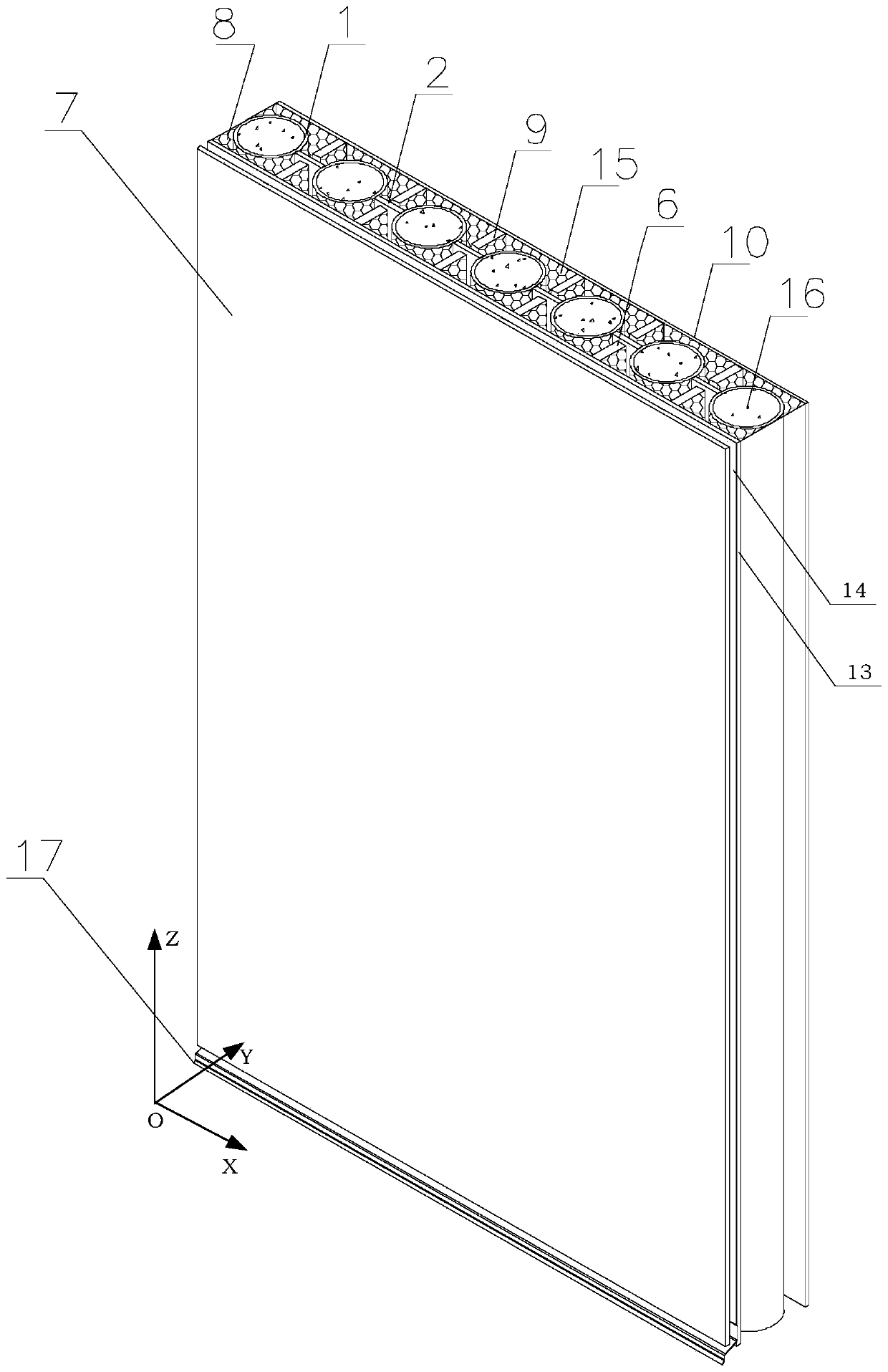

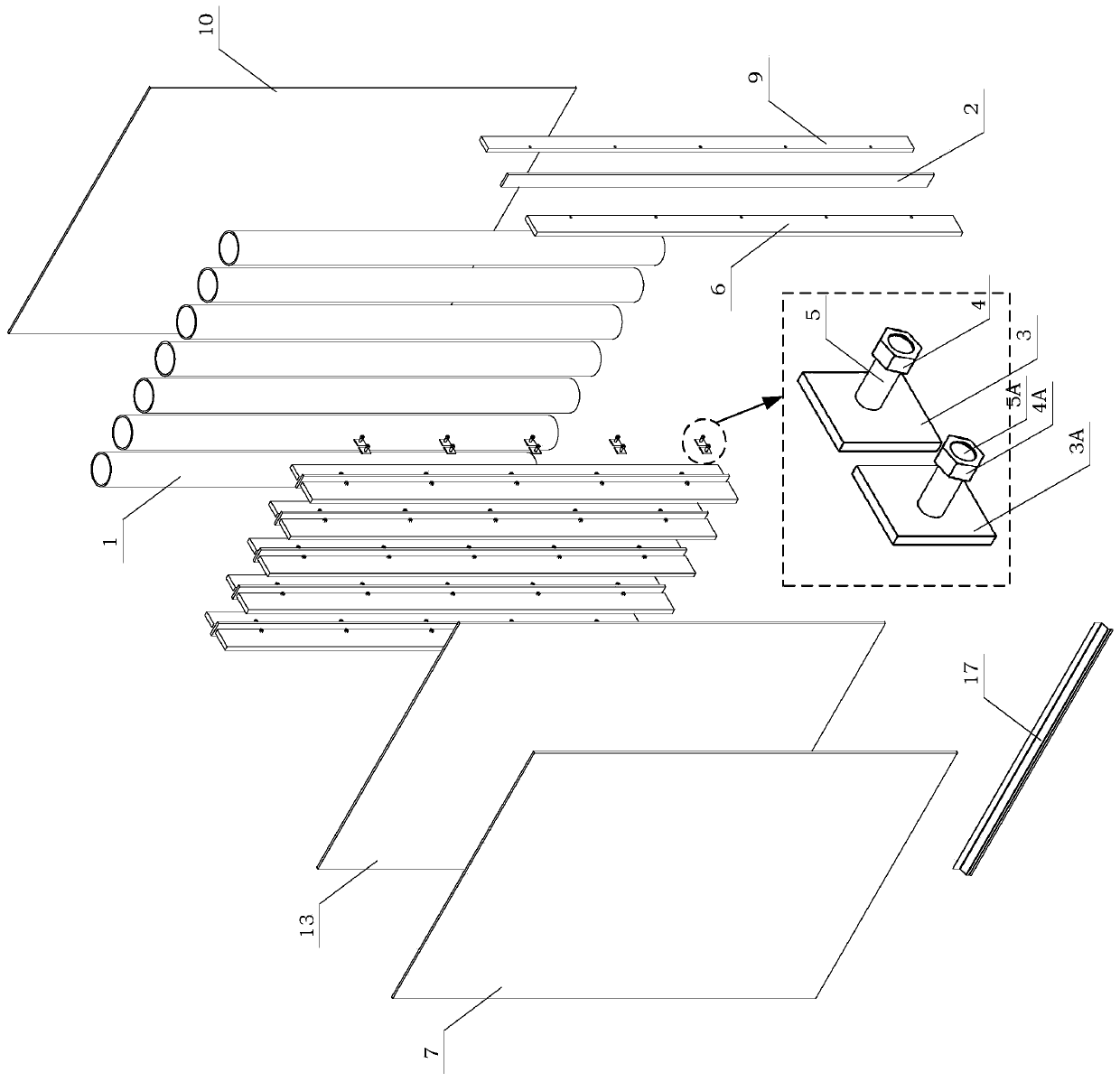

[0061] The assembled steel bar-concrete-wooden-modular wall device (abbreviated as steel civil engineering modular wall) designed by the present invention includes wall panels 7, wall panels 13, prefabricated parts, interior decorative panels 10 and dripping water 17; wall panels Between 7 and the wall panel 13 is an air pressure balance layer 14; between the wall panel 13 and the interior decoration panel 10 is a prefabricated part; the lower end of the wall panel 7 and the wall panel 13 is installed on the dripping water 17;

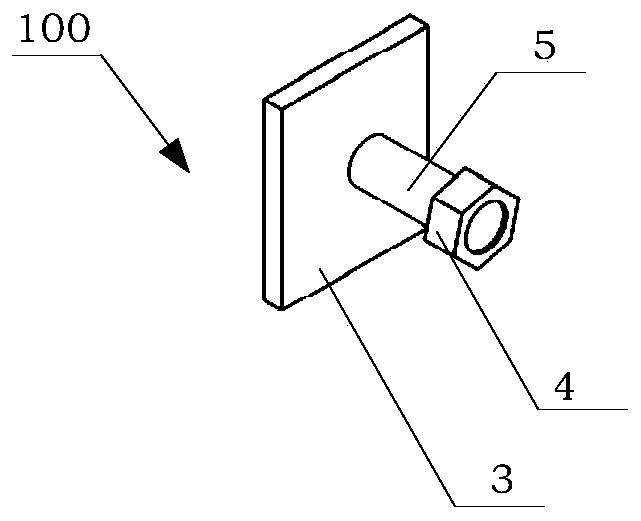

[0062] The prefabricated part includes a round steel pipe 1, a panel 2, an outer wall bone column 6, an inner wall bone column 9, thermal insulation and sound insulation materials 8, pipeline channels 15 and connectors 100 (such as Figure 1B shown); the pipeline channel 15 is arranged in the thermal insulation material 8; the patch p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com