Patents

Literature

38 results about "Error field" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

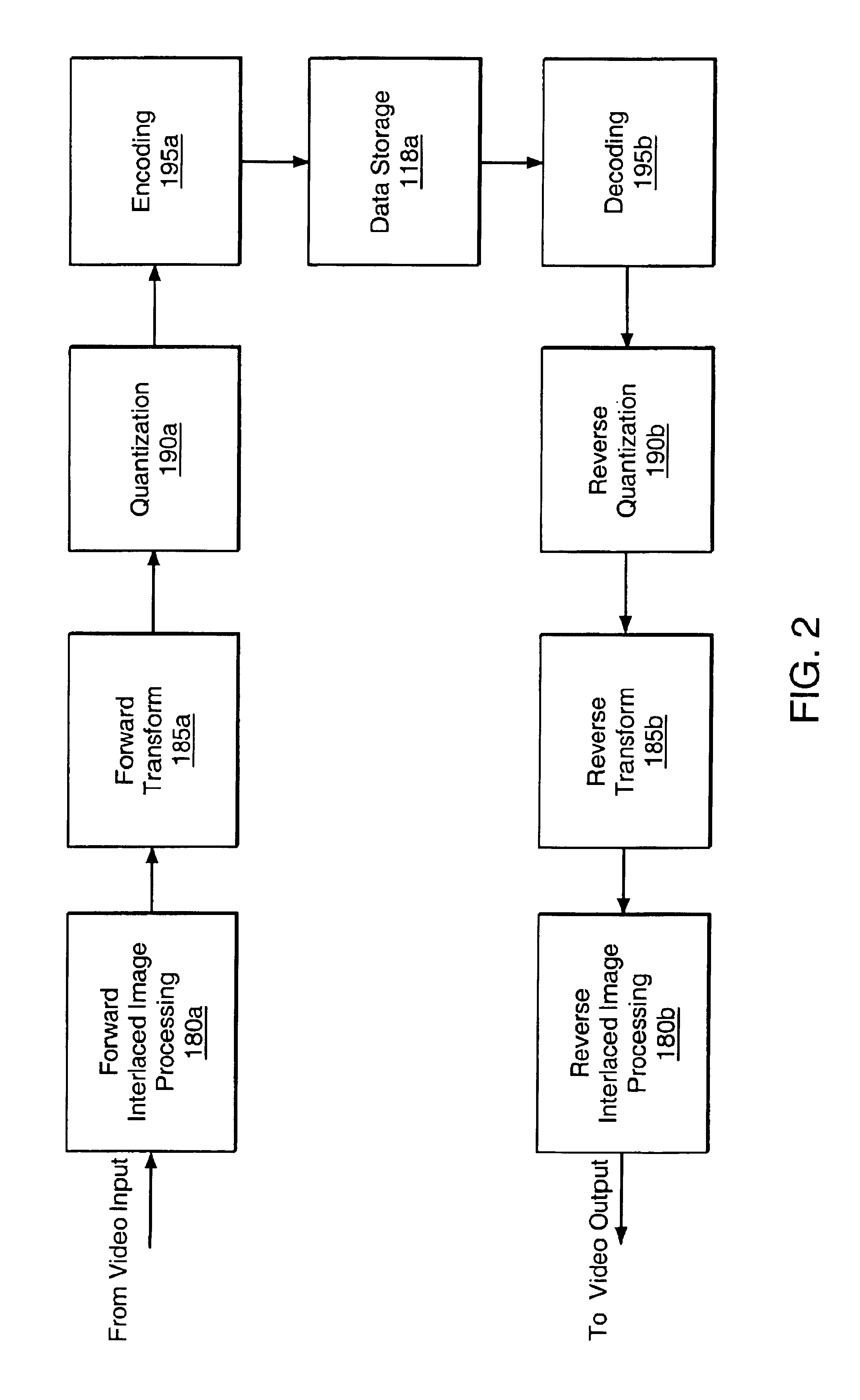

Apparatus and method for optimized compression of interlaced motion images

InactiveUS6289132B1Easy to compressAvoid inefficiencyPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningImaging processingInterlaced video

Owner:QUVIS +1

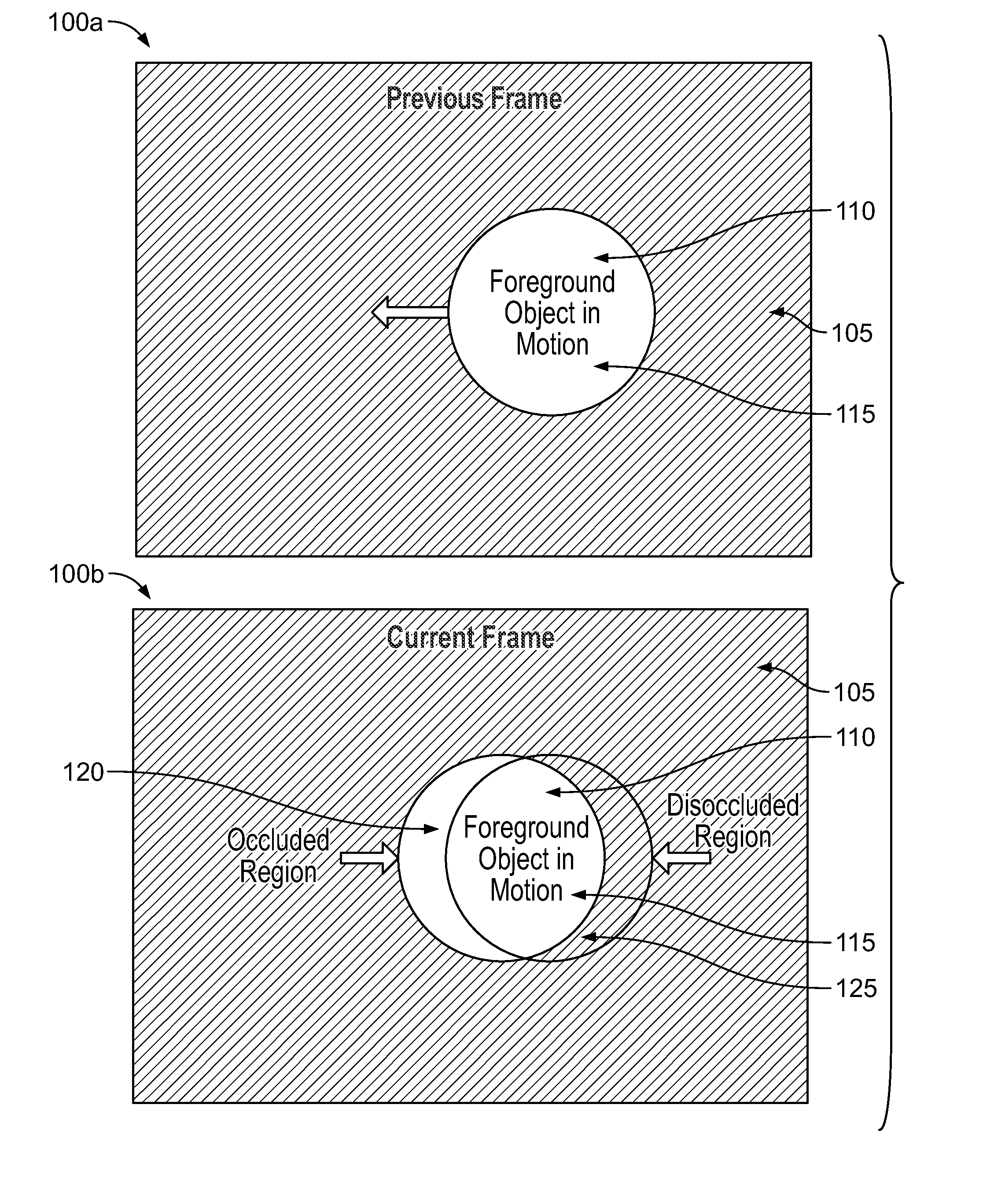

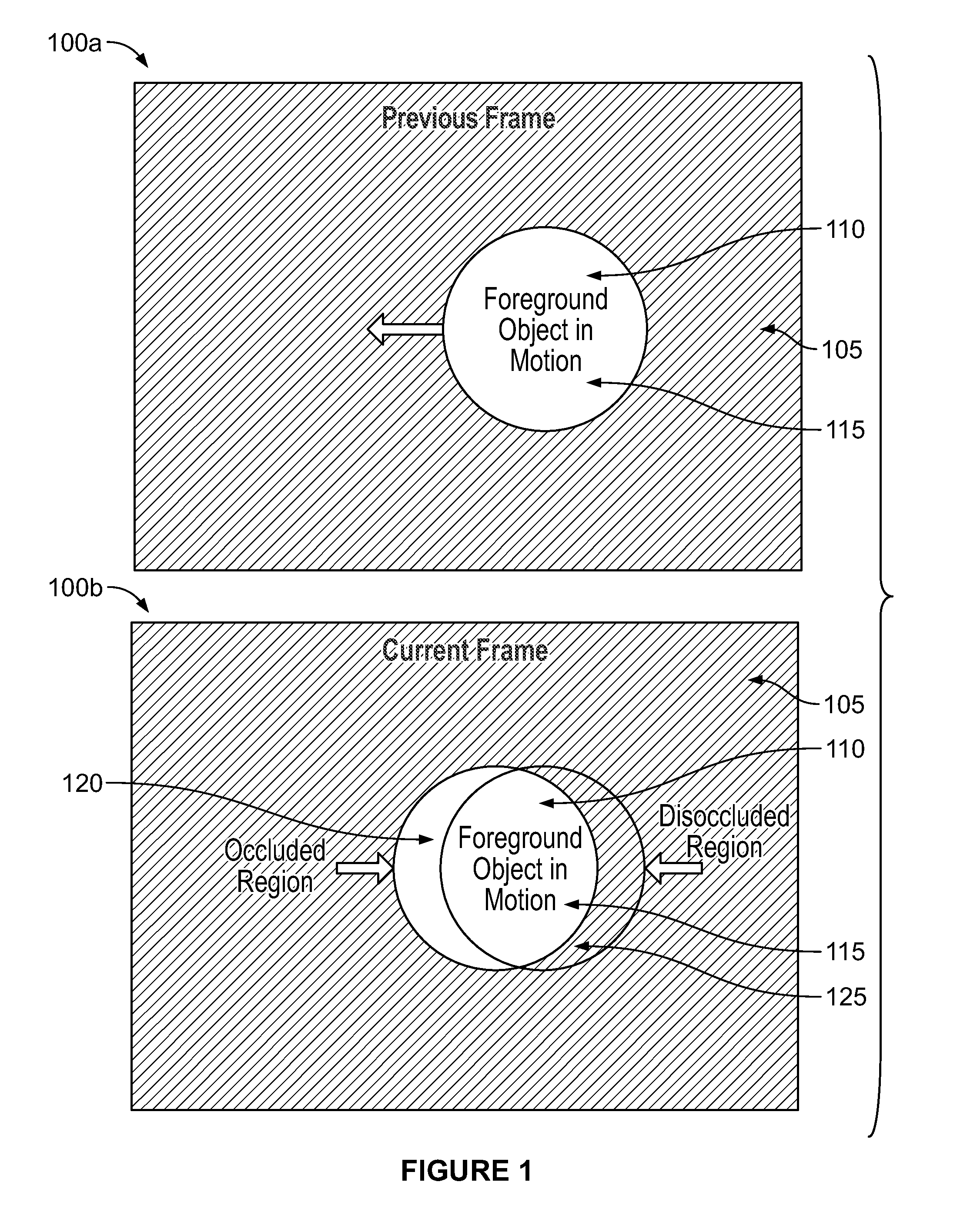

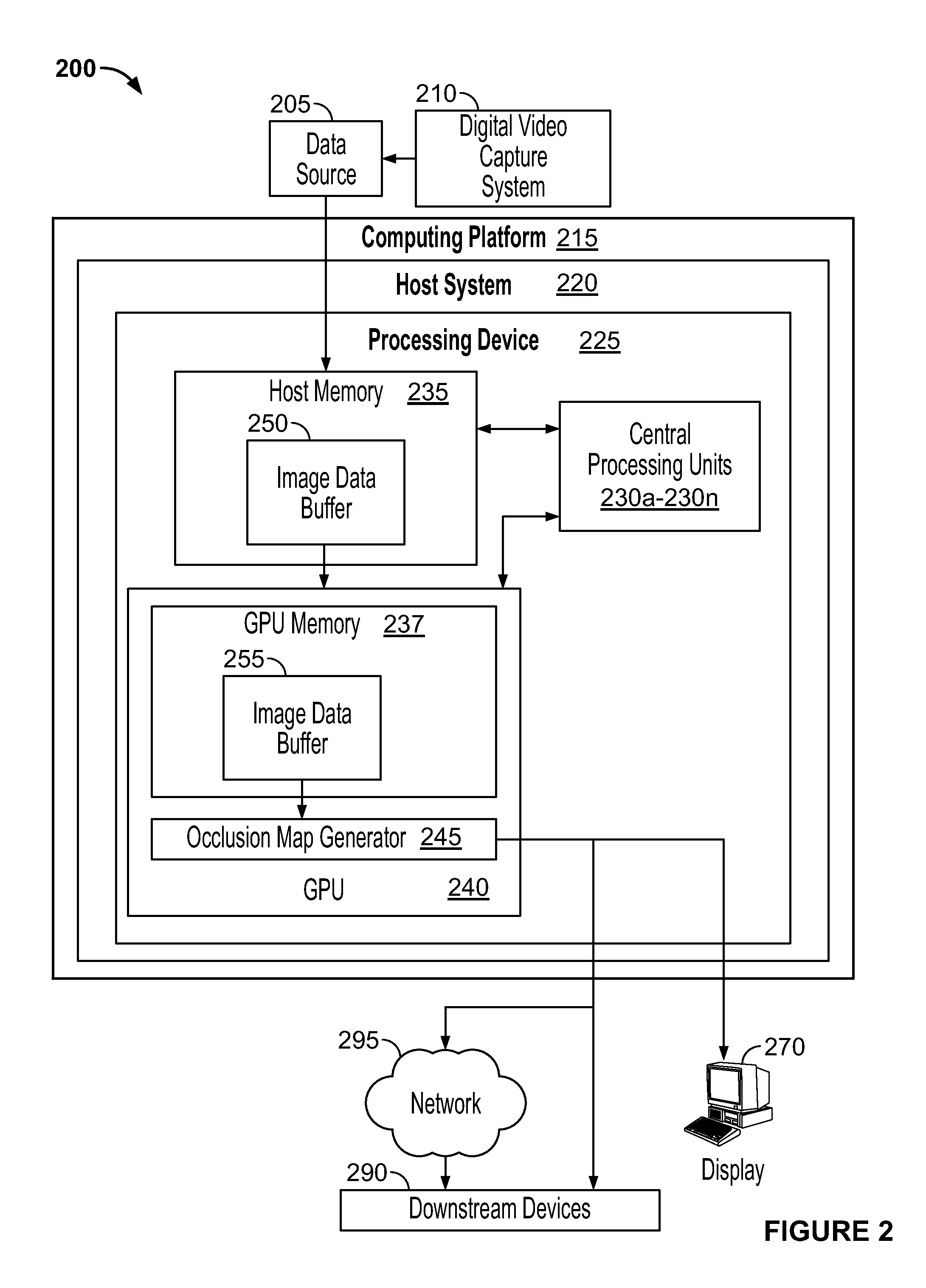

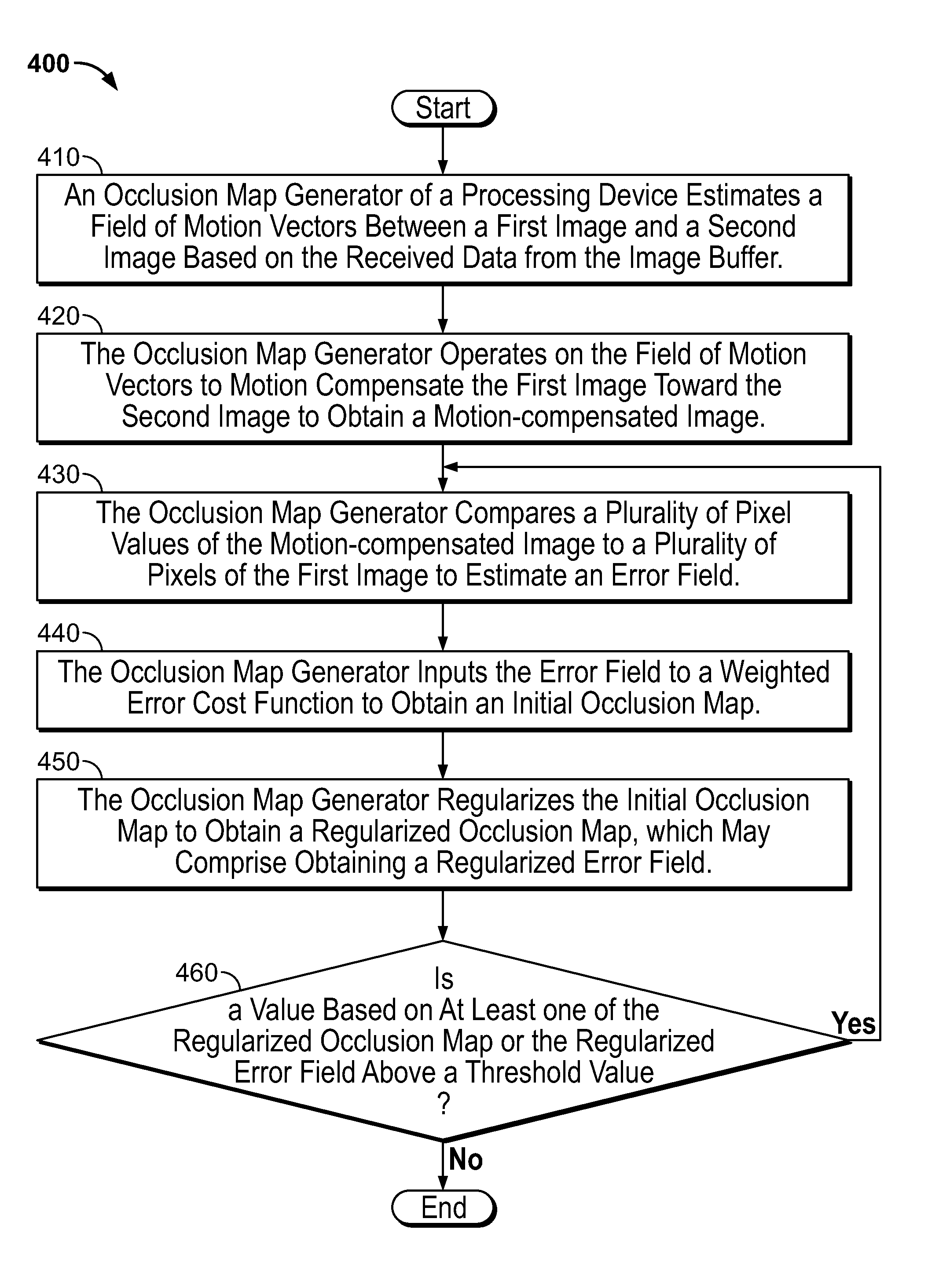

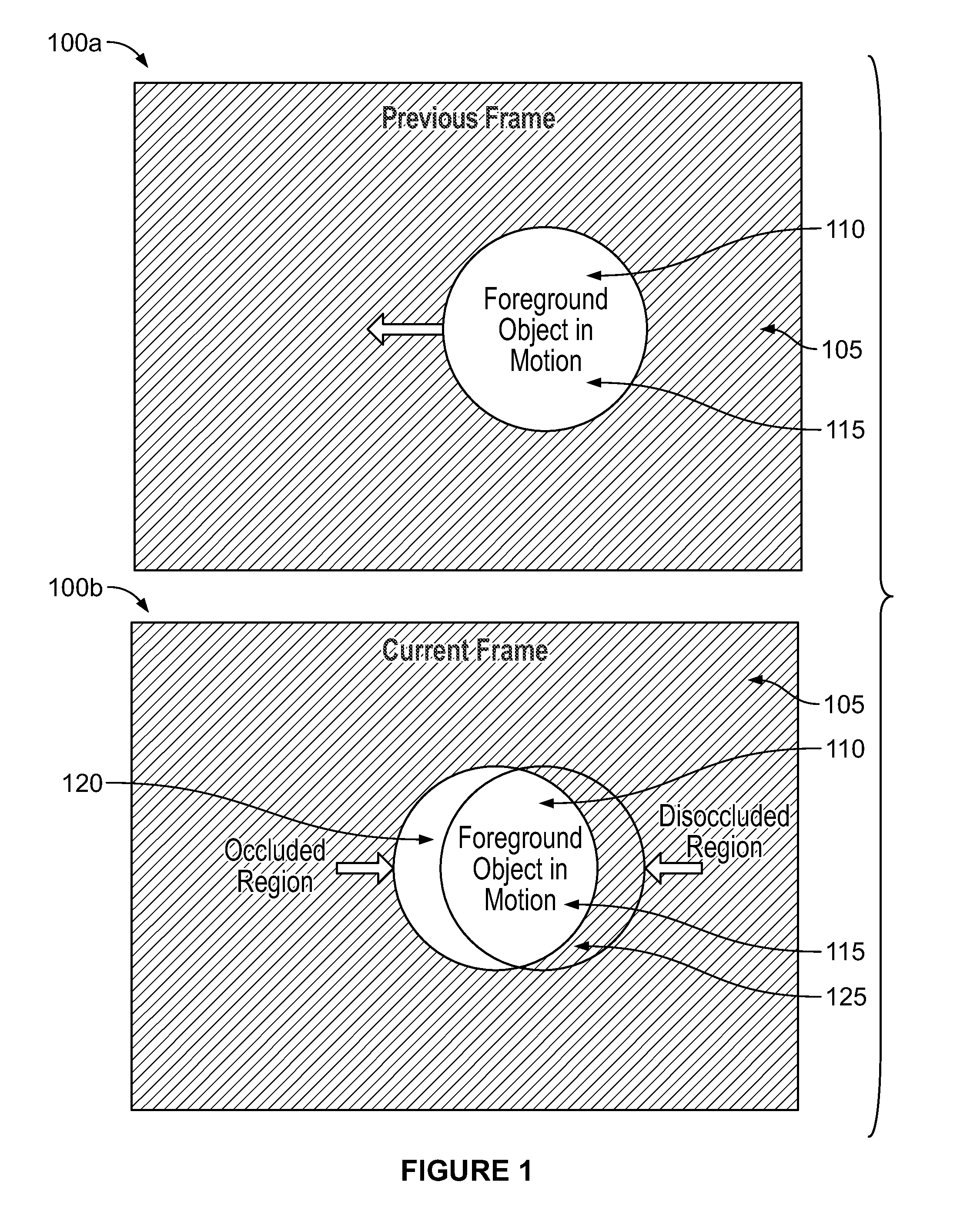

Digital processing method and system for determination of object occlusion in an image sequence

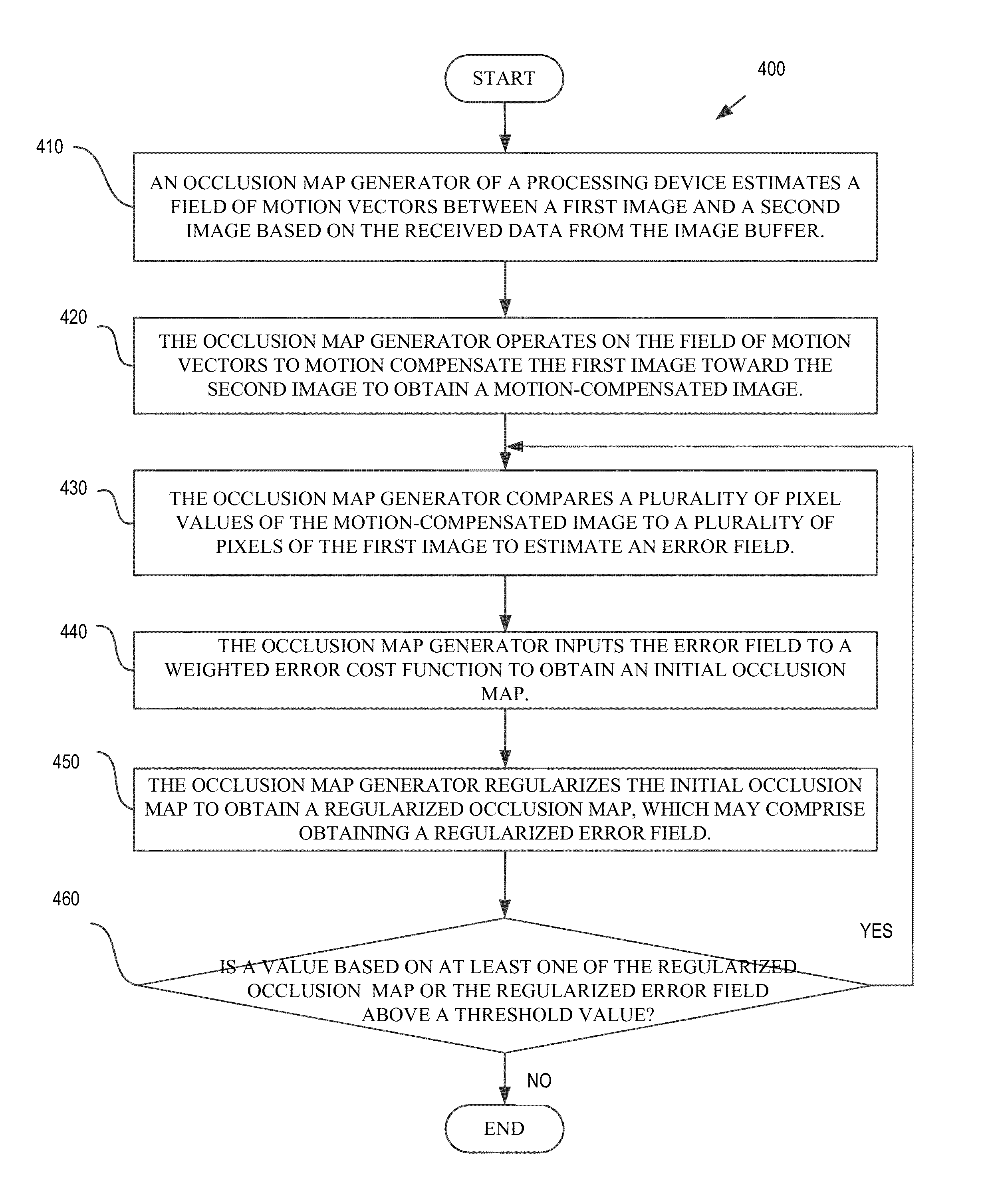

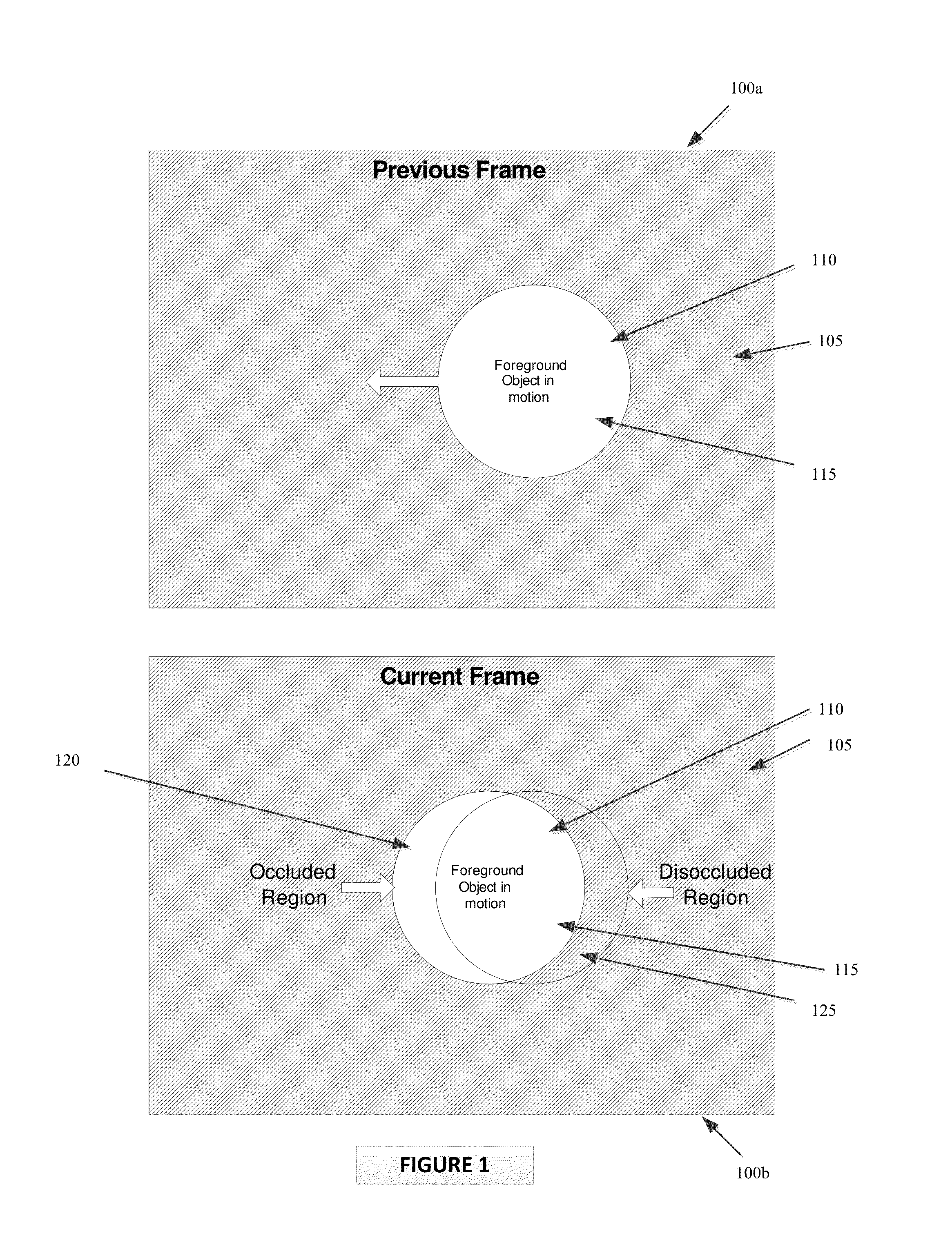

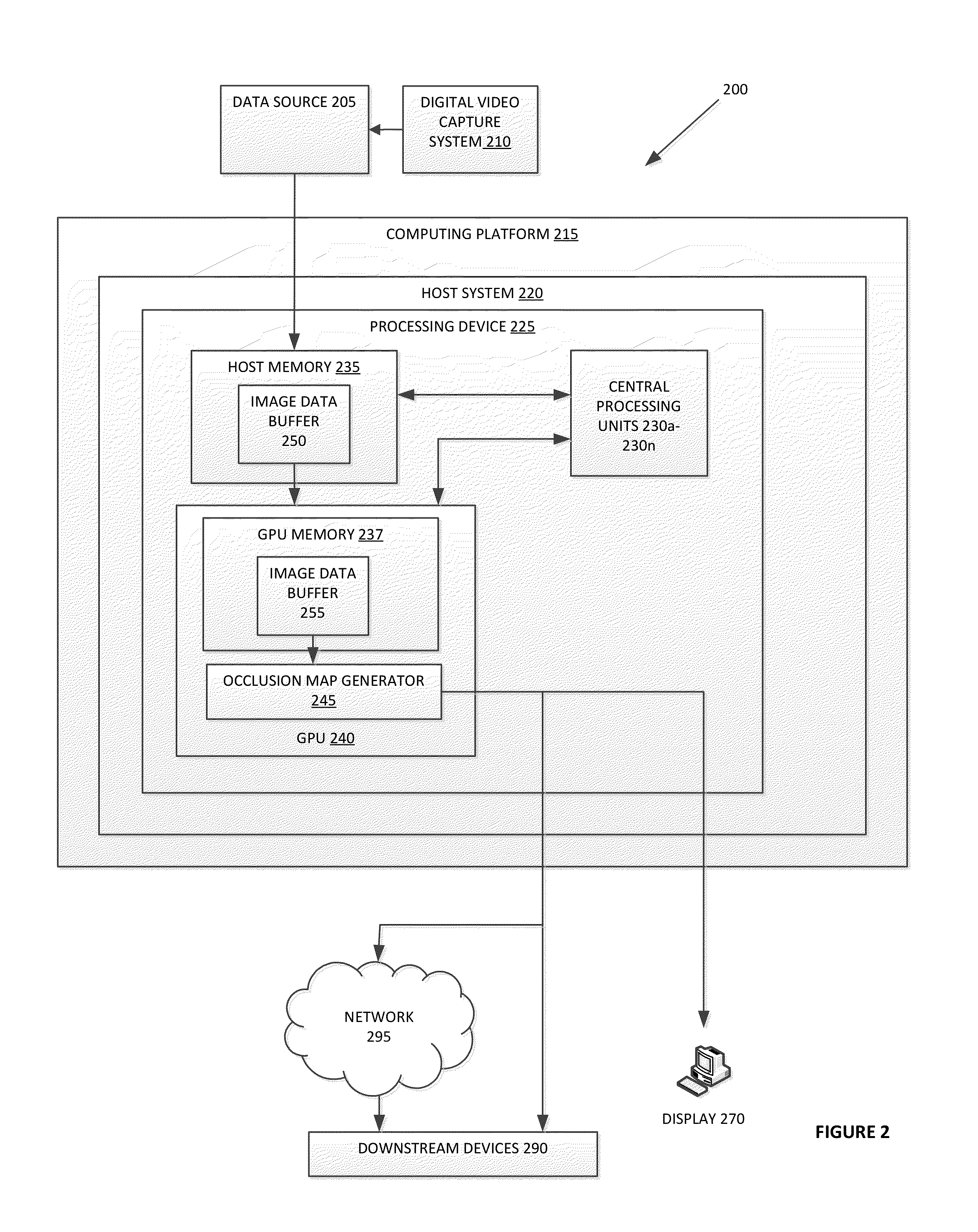

A method and system for occlusion region detection and measurement between a pair of images are disclosed. A processing device receives a first image and a second image. The processing device estimates a field of motion vectors between the first image and the second image. The processing device motion compensates the first image toward the second image to obtain a motion-compensated image. The processing device compares a plurality of pixel values of the motion-compensated image to a plurality of pixels of the first image to estimate an error field. The processing device inputs the error field to a weighted error cost function to obtain an initial occlusion map. The processing device regularizes the initial occlusion map to obtain a regularized occlusion map.

Owner:CHEYTEC TECH LLC

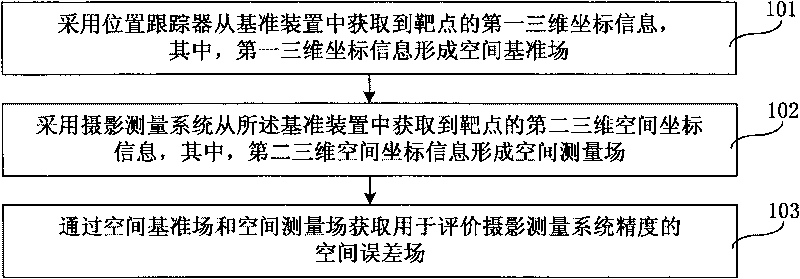

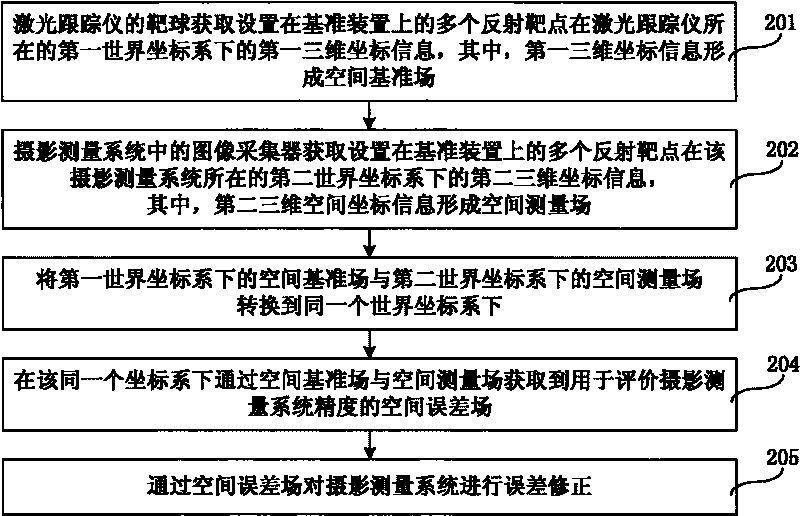

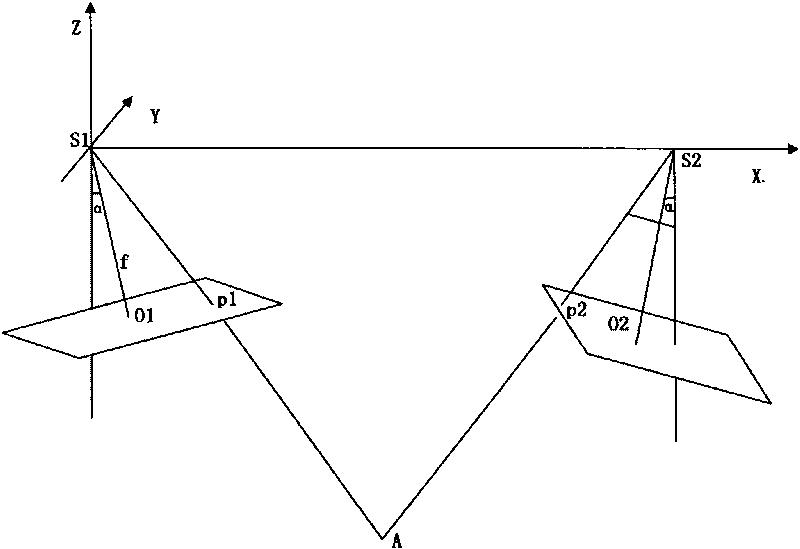

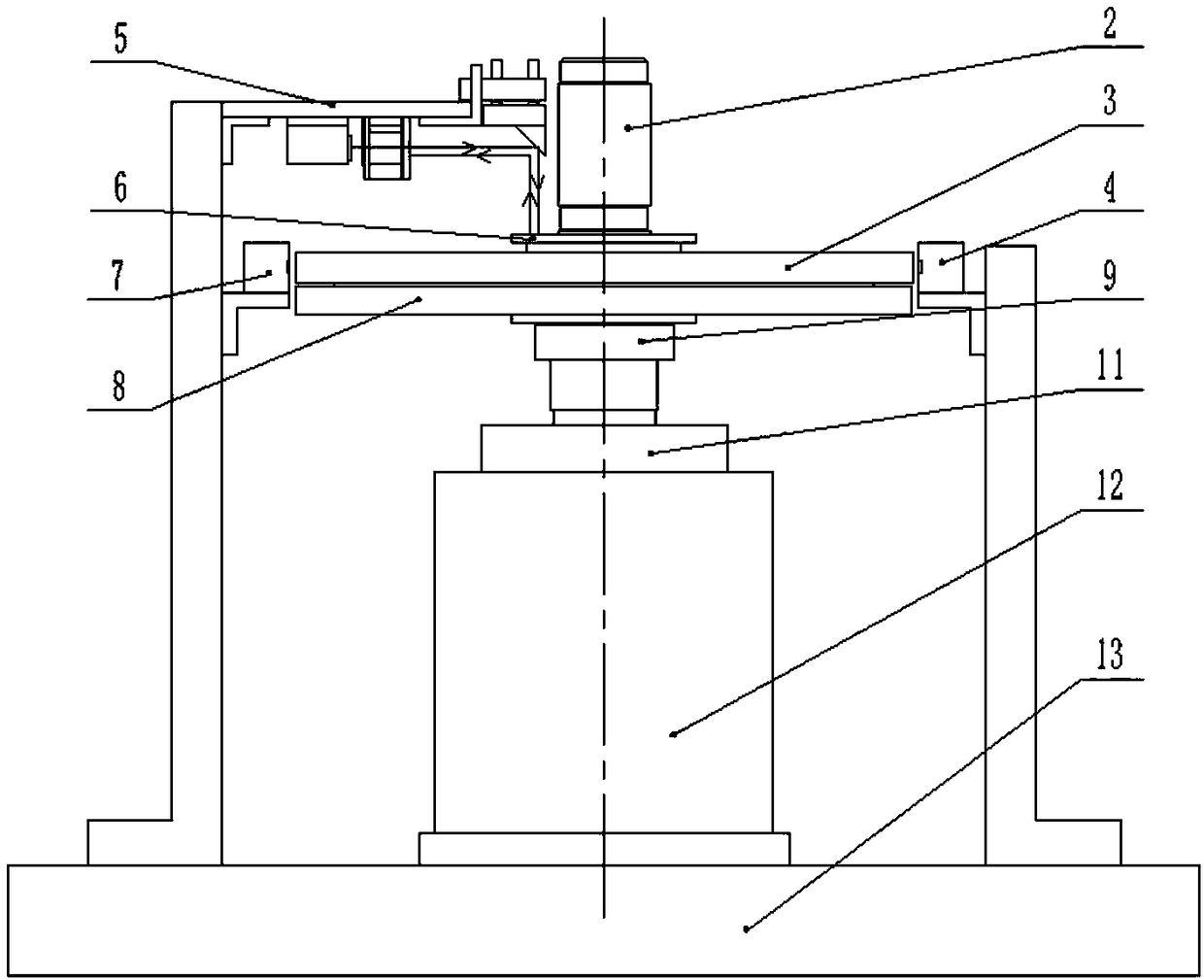

Method for evaluating precision of large-scale industrial photogrammetry system and benchmark device

InactiveCN101694370AHigh measurement accuracyPhotogrammetry/videogrammetryUsing optical meansThree-dimensional spaceReference device

The invention discloses a method for evaluating the precision of a large-scale industrial photogrammetry system and a benchmark device. The method comprises the following steps: obtaining first three-dimensional coordinate information of a reflection target spot from the benchmark device by using a laser tracker, wherein the first three-dimensional coordinate information forms a space benchmark field; obtaining second three-dimensional coordinate information of the reflection target spot from the benchmark device by using the photogrammetry system, wherein the second three-dimensional coordinate information forms a space measurement field; and obtaining a space error field by the space benchmark field and the space measurement field. The method for evaluating the precision of a large-scale industrial photogrammetry system and the benchmark device obtain the space error field by the space benchmark field and the space measurement field, and analyze the error sources in the photogrammetry system by the space error field and further enhance the measurement precision of the photogrammetry system in large-scale industrial photogrammetry.

Owner:BEIJING INFORMATION SCI & TECH UNIV

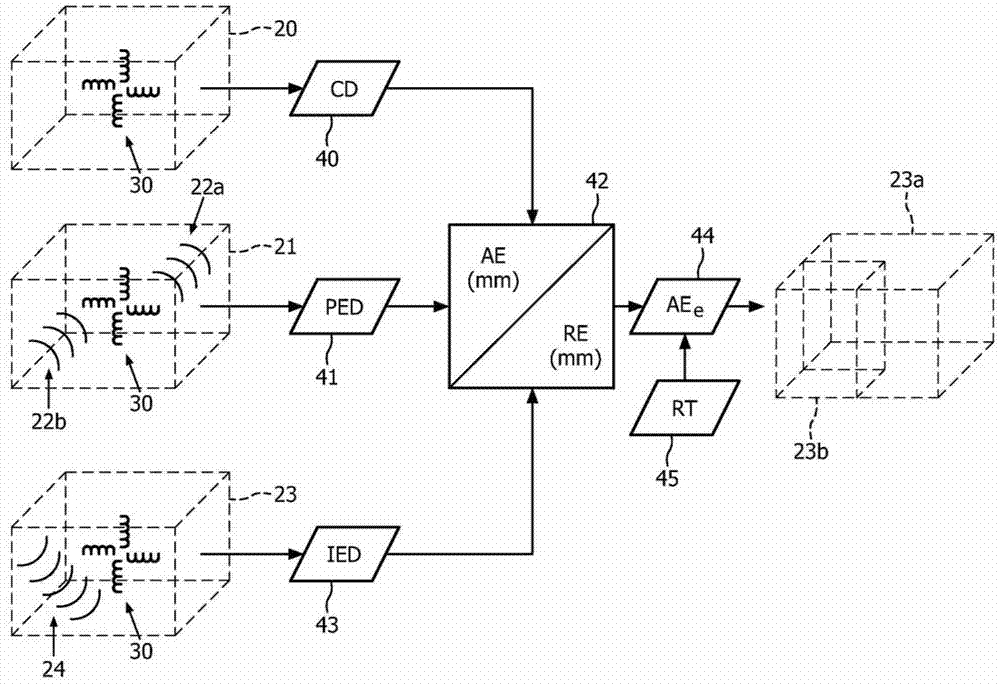

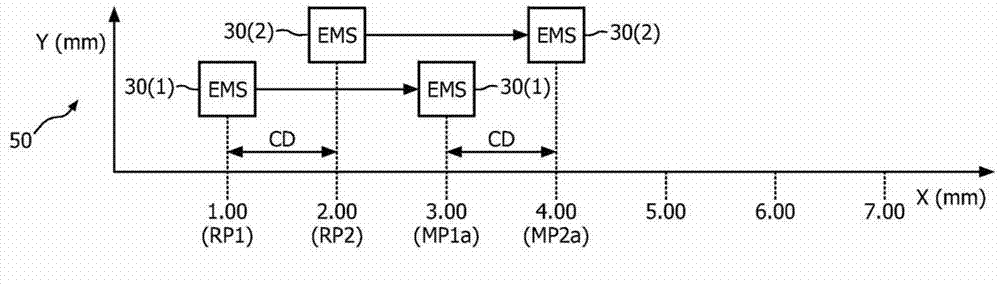

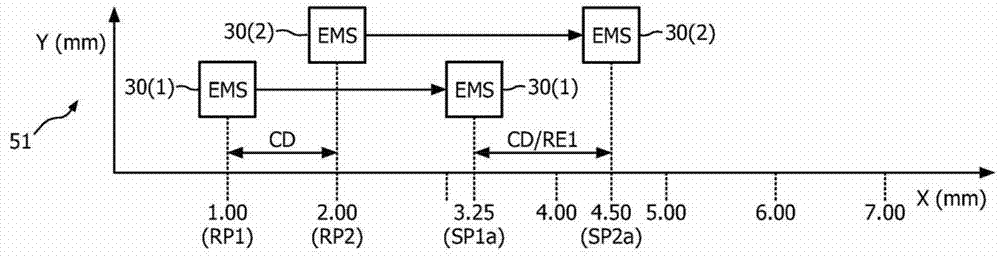

Method and system for characterizing and visualizing electromagnetic tracking errors

A calibration / surgical tool (90, 160) includes an electromagnetic sensor array (30) of two or more electromagnetic sensors in a known geometrical configuration. Electromagnetic tracking errors are characterized by a mapping of pre-operative absolute and relative errors based on a movement of a calibrated calibration / surgical tool (90, 160) through a pre not operative electromagnetic field. Using statistical mapping, a desired absolute error field (46) is measured either in the clinic as the part of daily quality control checks, or before the patient comes in or in vivo. A resulting error field (46) may be displayed to the physician to provide clear visual feedback about measurement confidence or reliability of localization estimates of the absolute errors in electromagnetic tracking.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

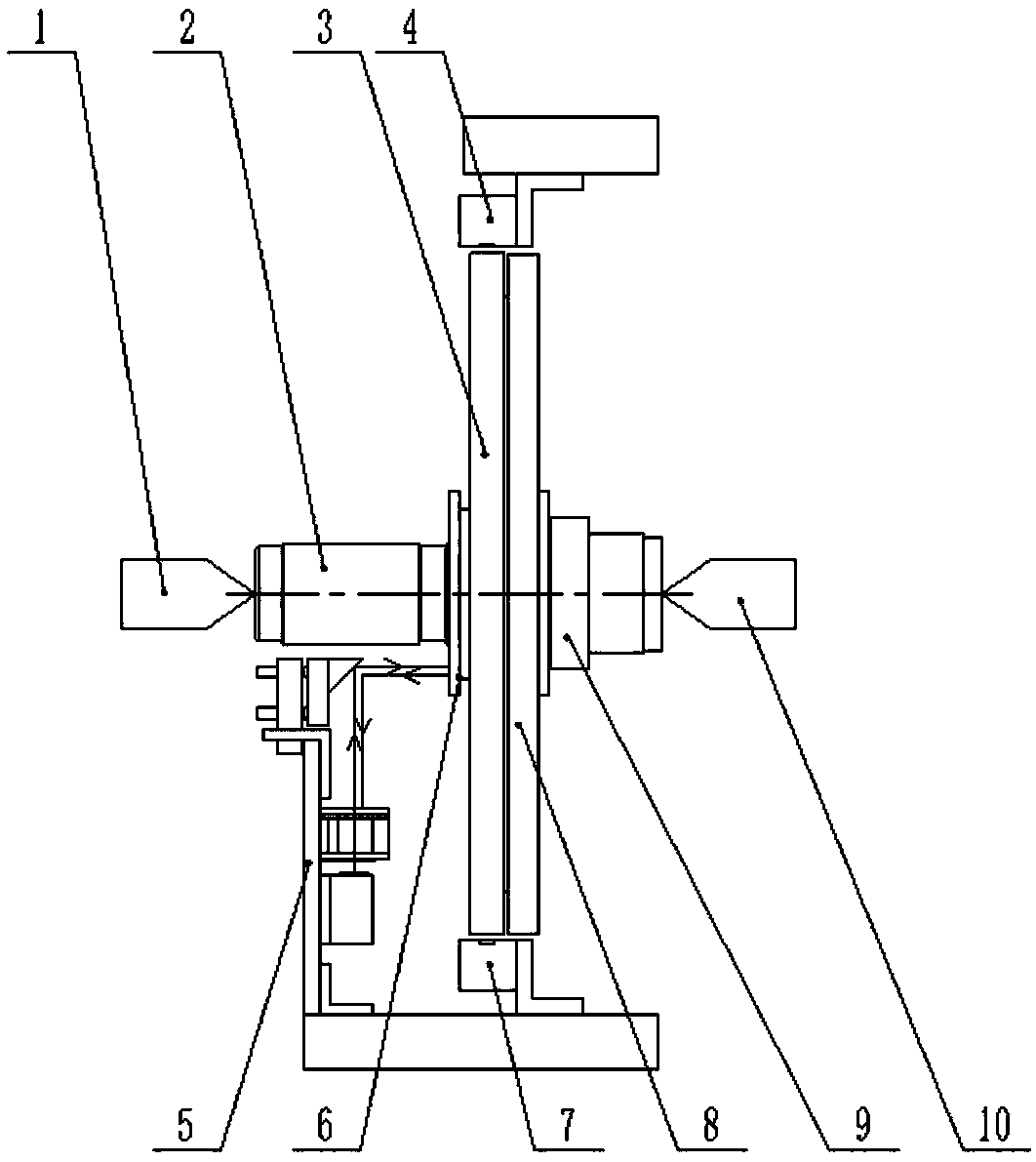

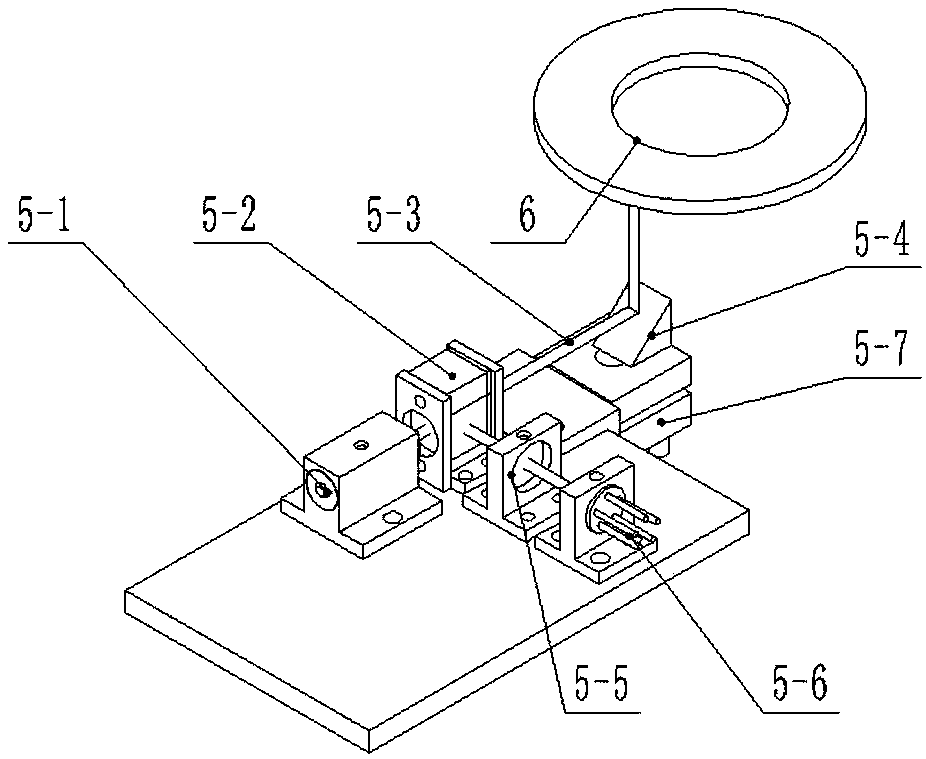

Device and method for measuring main shaft rotation error by using circular gratings and autocollimators

ActiveCN108981614ARealize high-precision positioningEliminate the effects ofUsing optical meansRadial motionGrating

The invention belongs to the precision mechanical error field and displays a device and a method for measuring a main shaft rotation error by using circular gratings and autocollimators. The measuringdevice is formed by a set of double reading head circular gratings installed on a main shaft, a plane mirror attached to a shaft bottom end and a set of self-made autocollimators. When the main shafthas a radial rotation error, a radial motion error measured by the circular gratings and a deflection error measured by the autocollimators are combined to calculate the radial rotation error at anypoint on the shaft, and then, the motion state of the shaft during a rotation process is analyzed. By using the structure of the invention, the influences of a main shaft circularity, surface roughness and the changes of a load on the main shaft on a measurement result can be eliminated. And simultaneously, the device can be used to realize the high precision positioning of a main shaft rotation angle.

Owner:DALIAN UNIV OF TECH

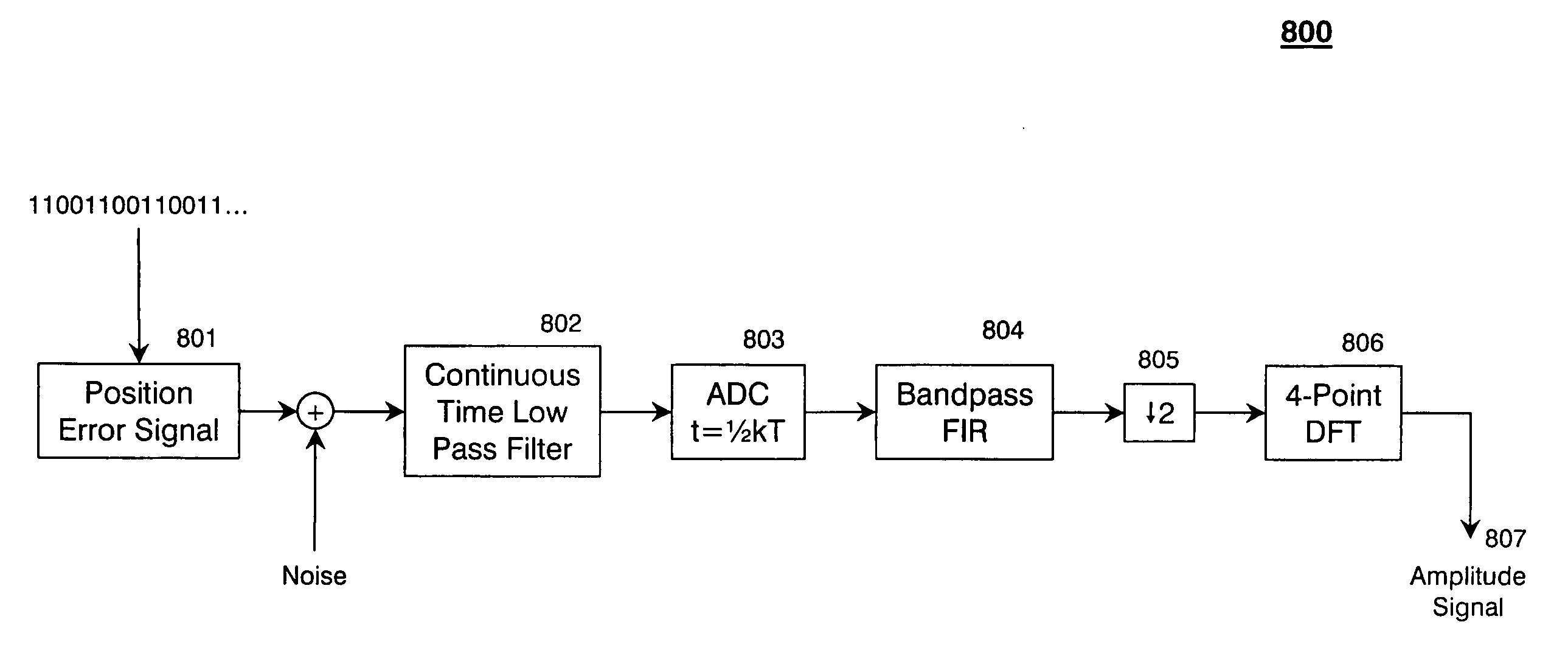

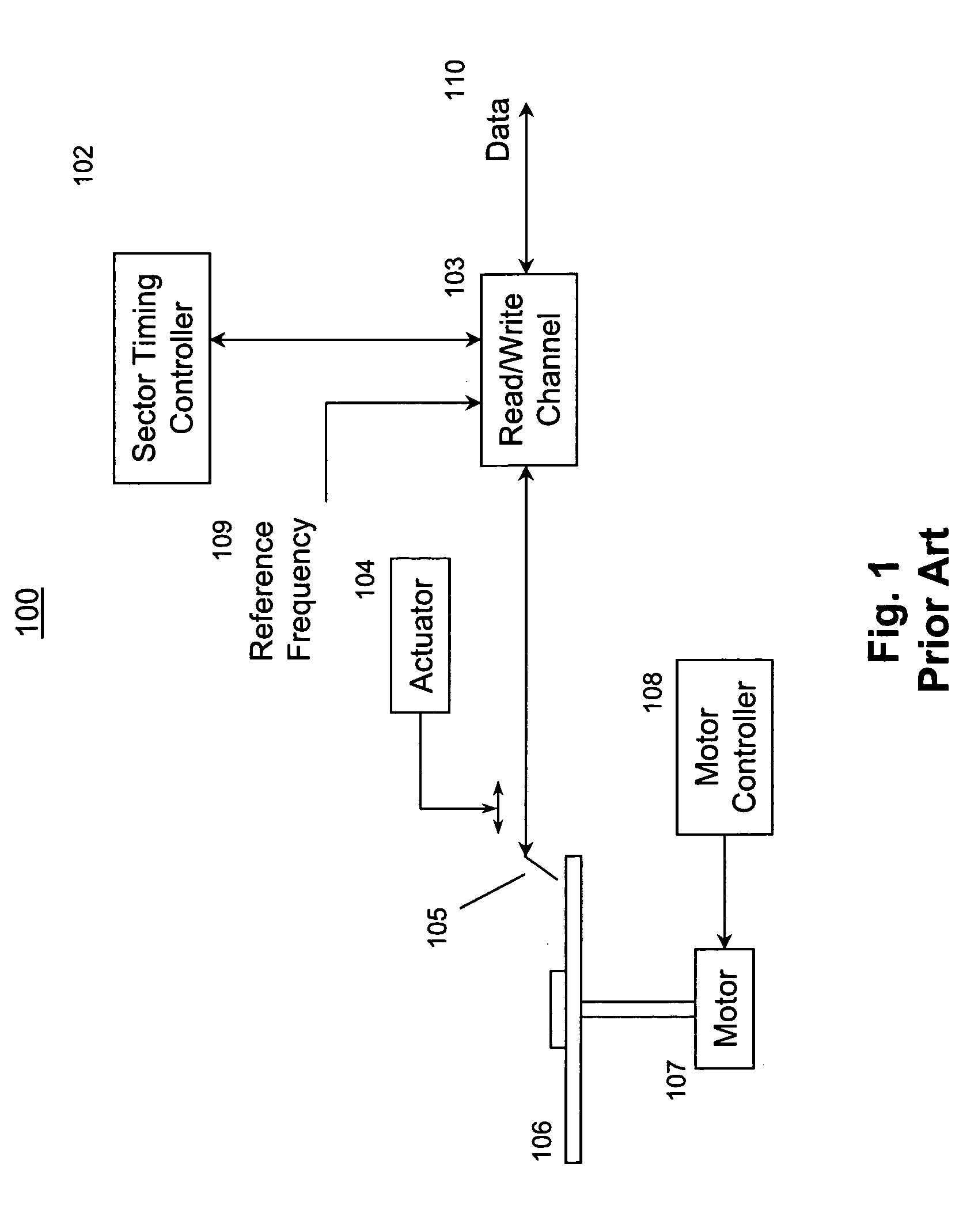

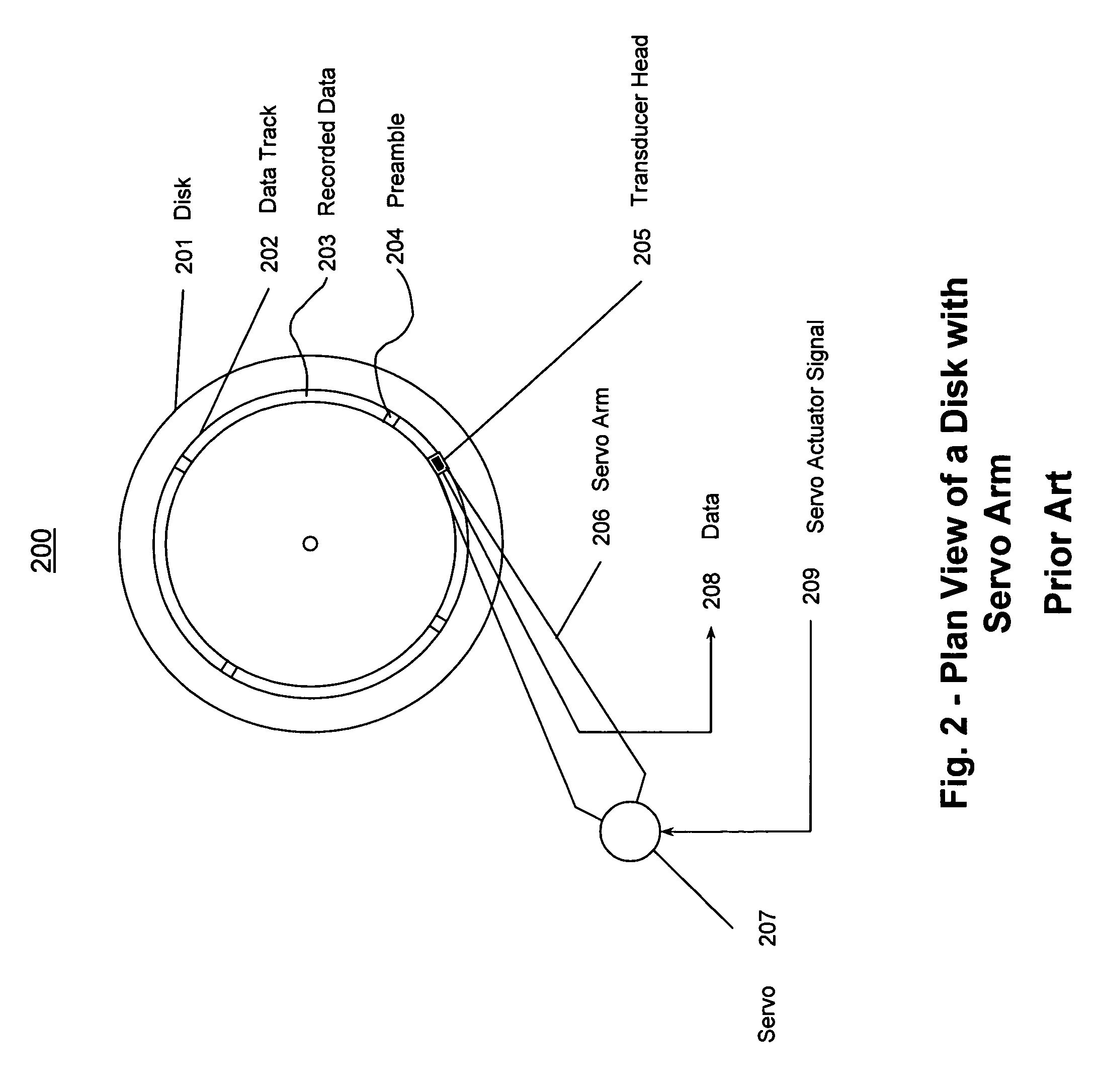

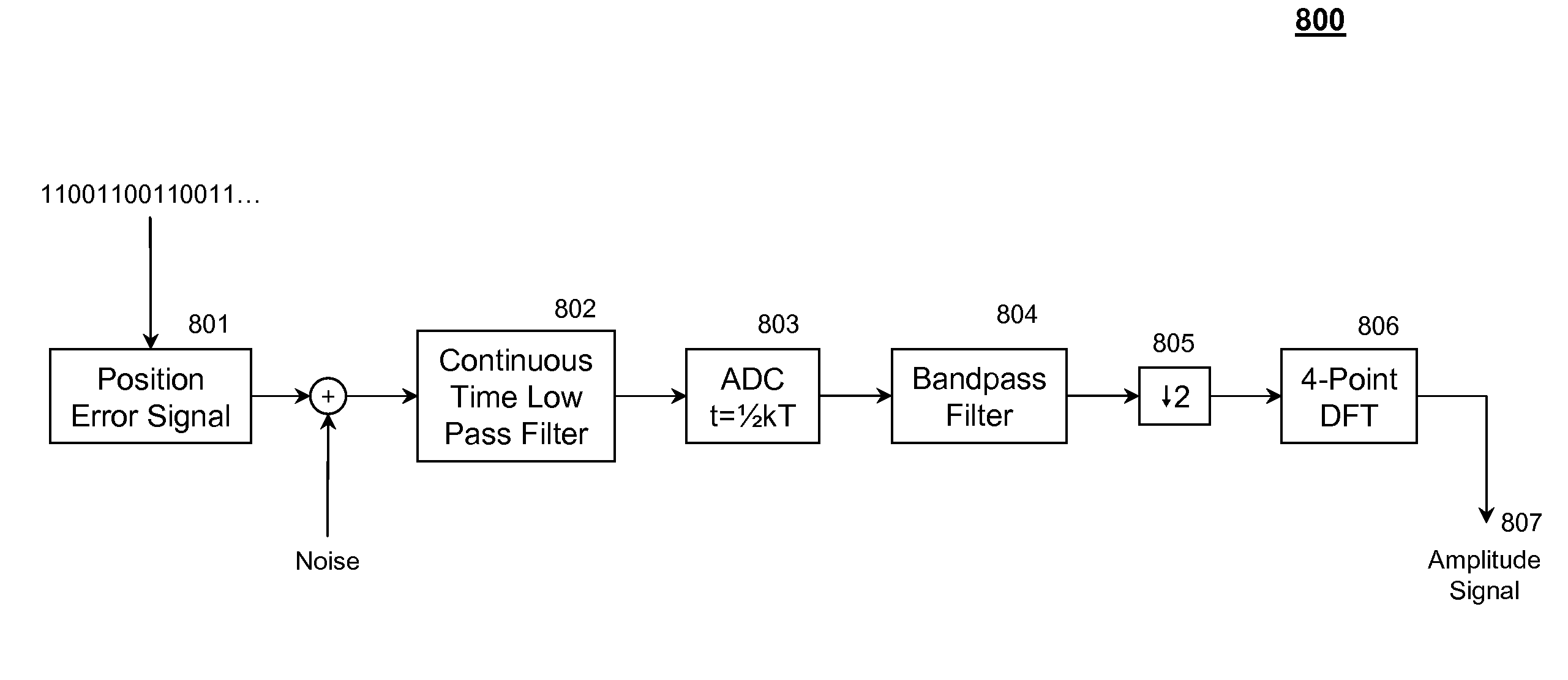

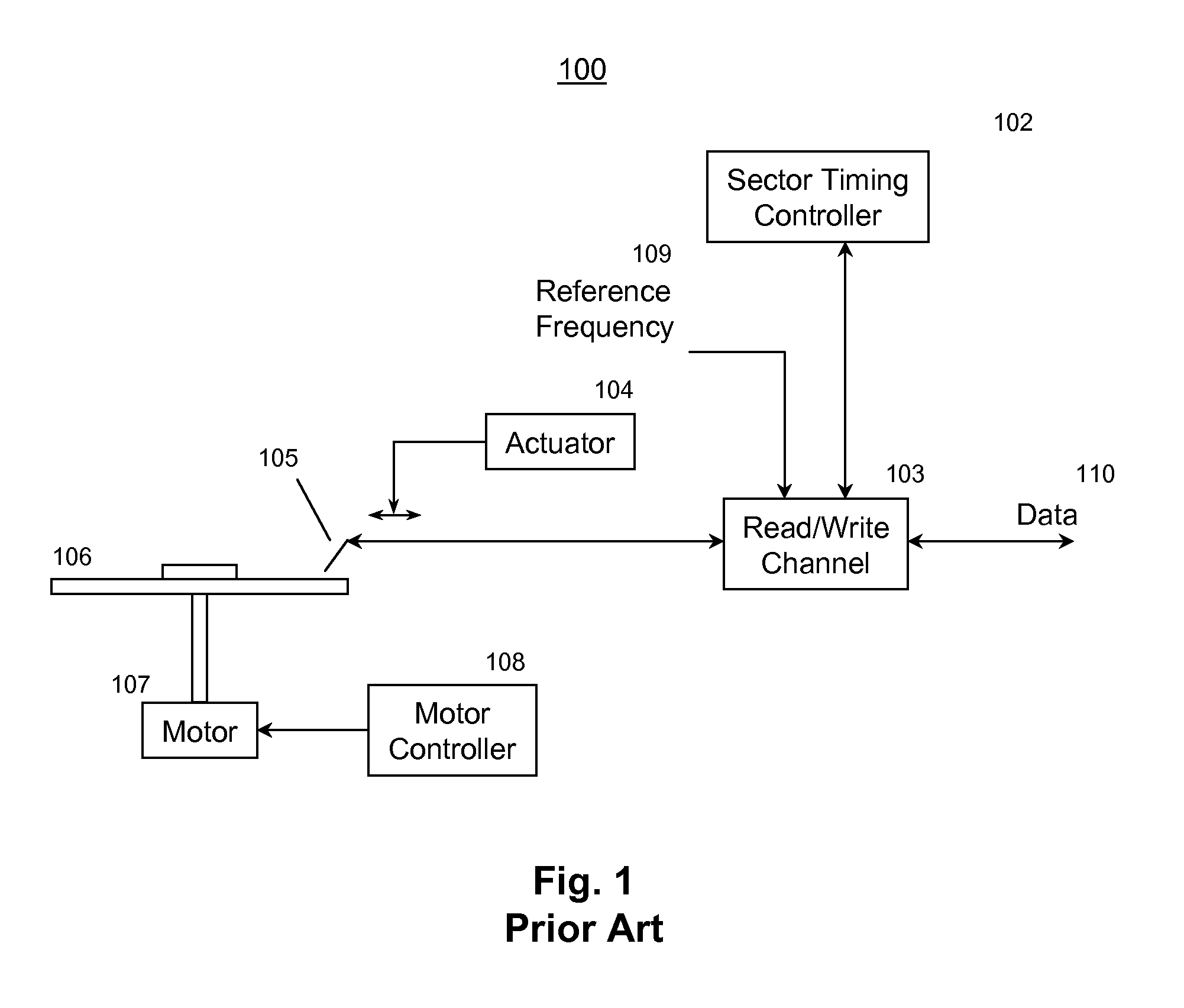

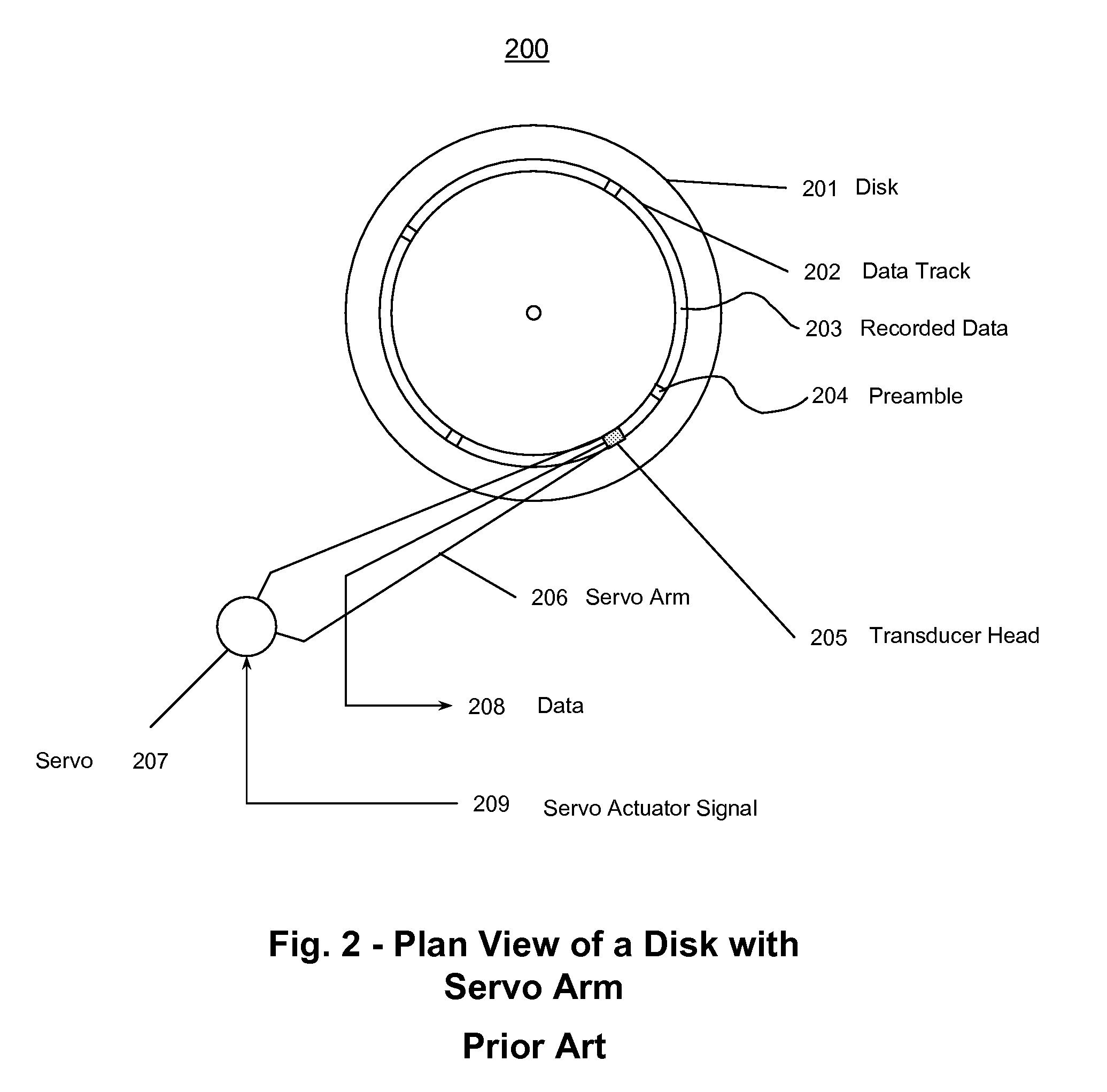

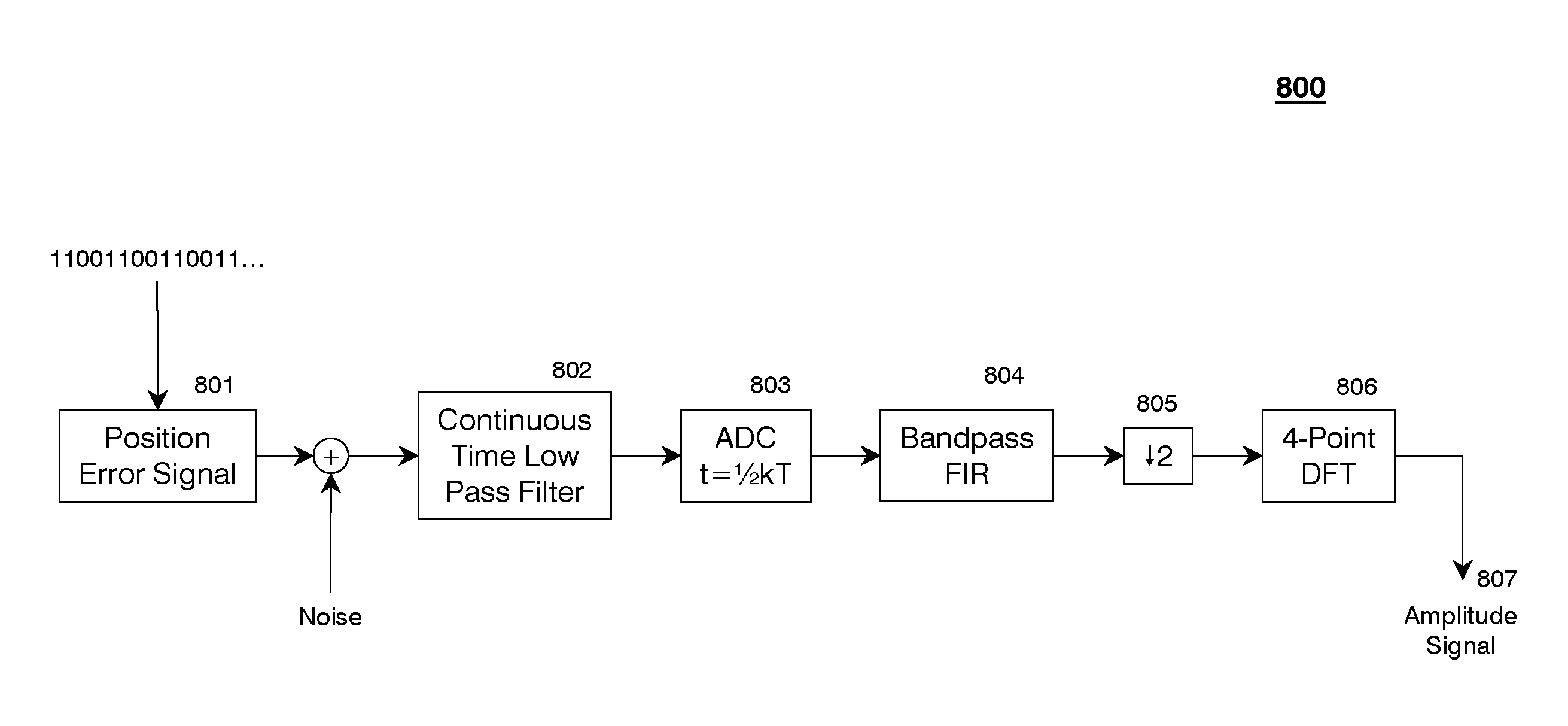

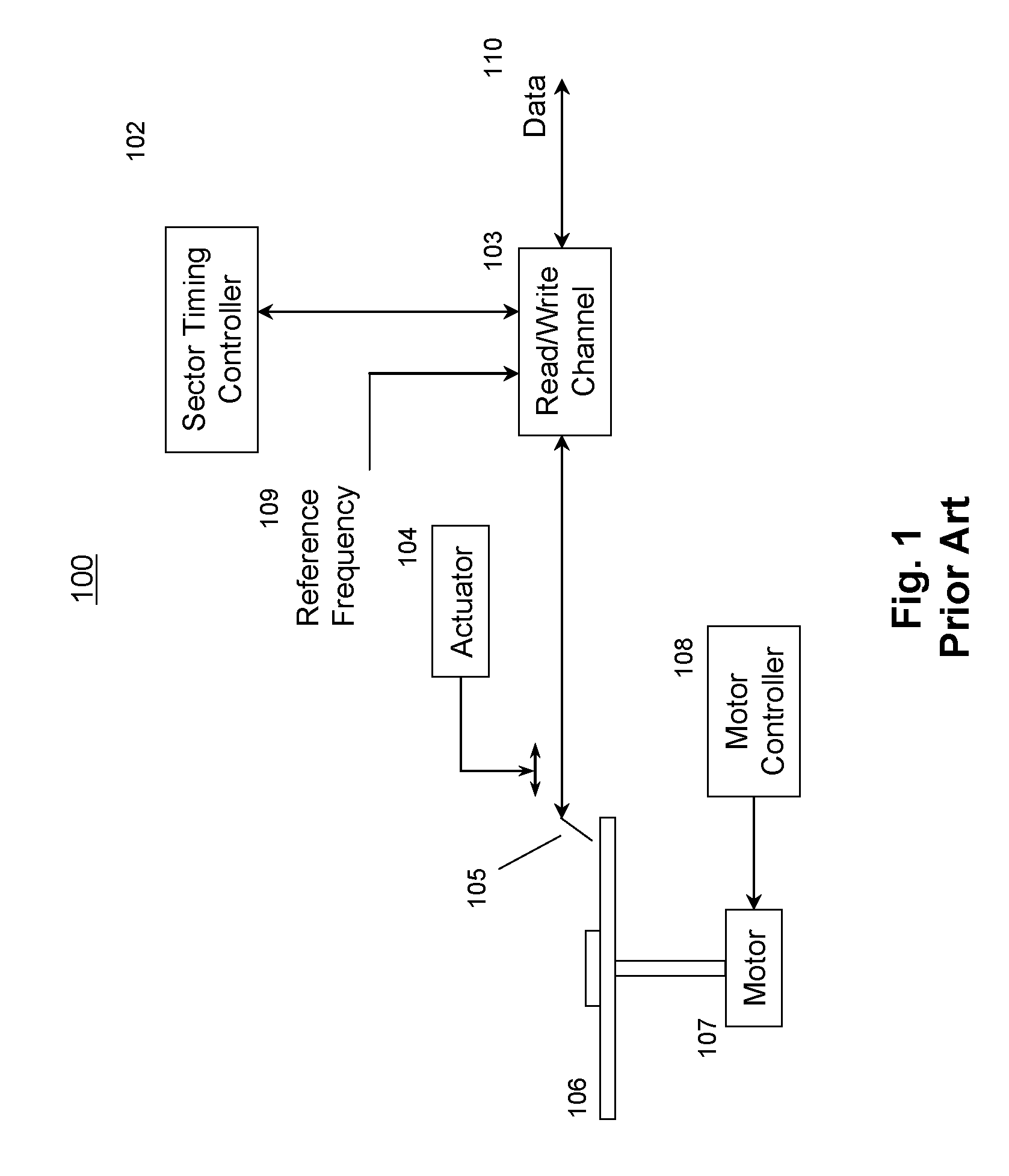

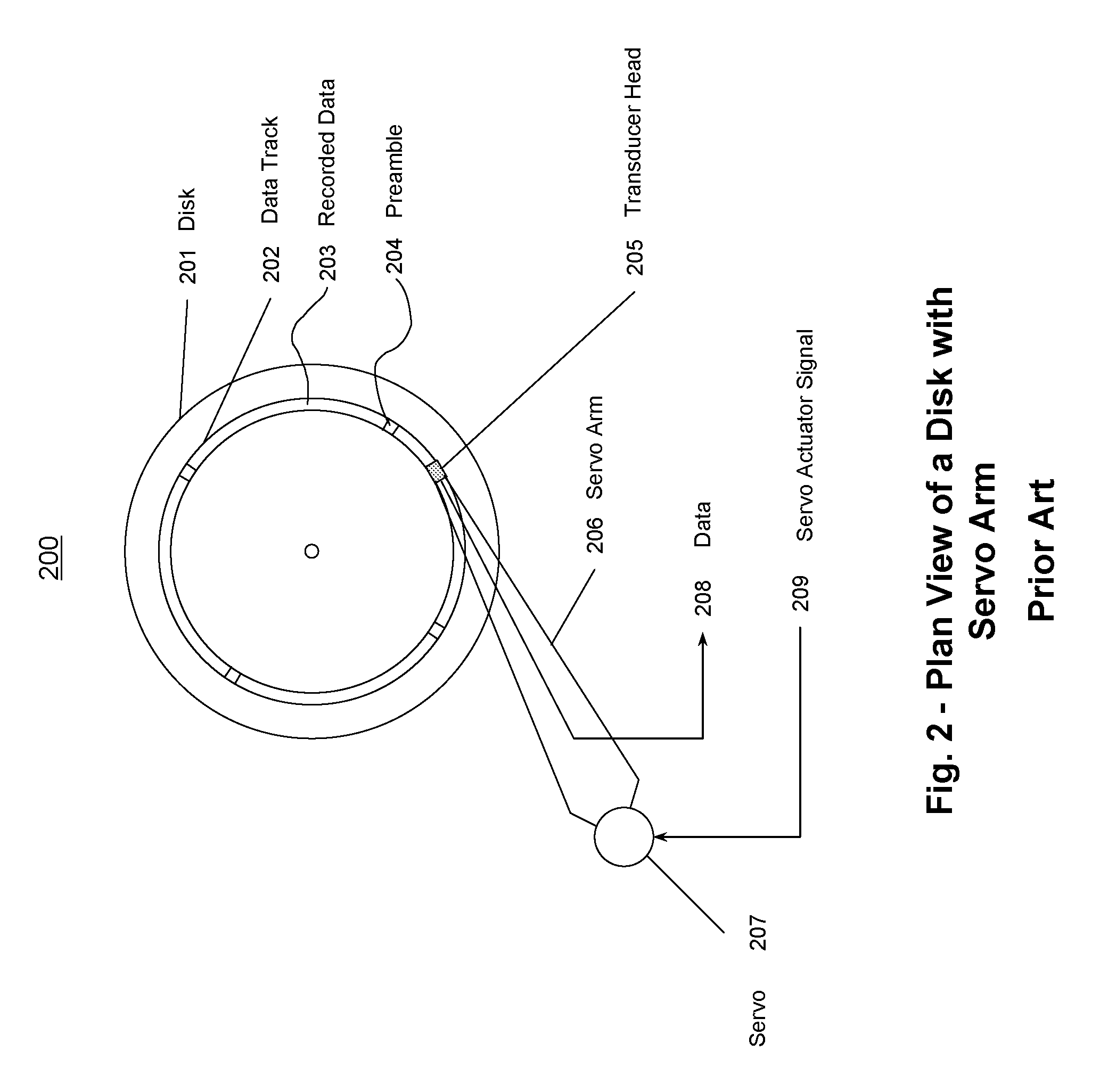

Up-sampled filtering for servo demodulation

InactiveUS7158333B1Need can be addressedRecord information storageAlignment for track following on disksHard disc driveHarmonic

An apparatus, method, and system for providing a fine adjustment for transducing head positioning in a hard disk drive (HDD). The apparatus, method, and system include reading a positioning error field wherein the resulting signal is a substantially sinusoidal position error signal (PES), filtering the PES to remove low frequencies and attenuate high frequencies, sample the filtered PES at a multiple of the channel frequency, filter the higher frequency harmonics, down sample the PES, and provide a signal proportional to the amplitude of the down sampled PES. This signal is the reference signal to the head positioning servo.

Owner:MARVELL INT LTD

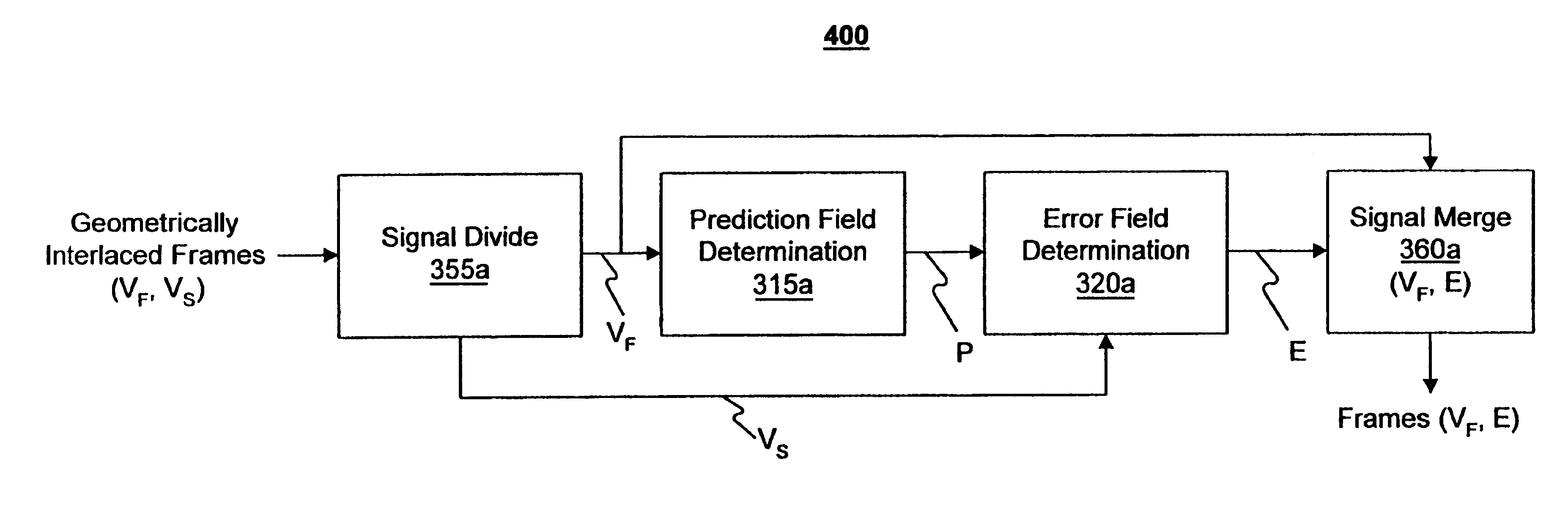

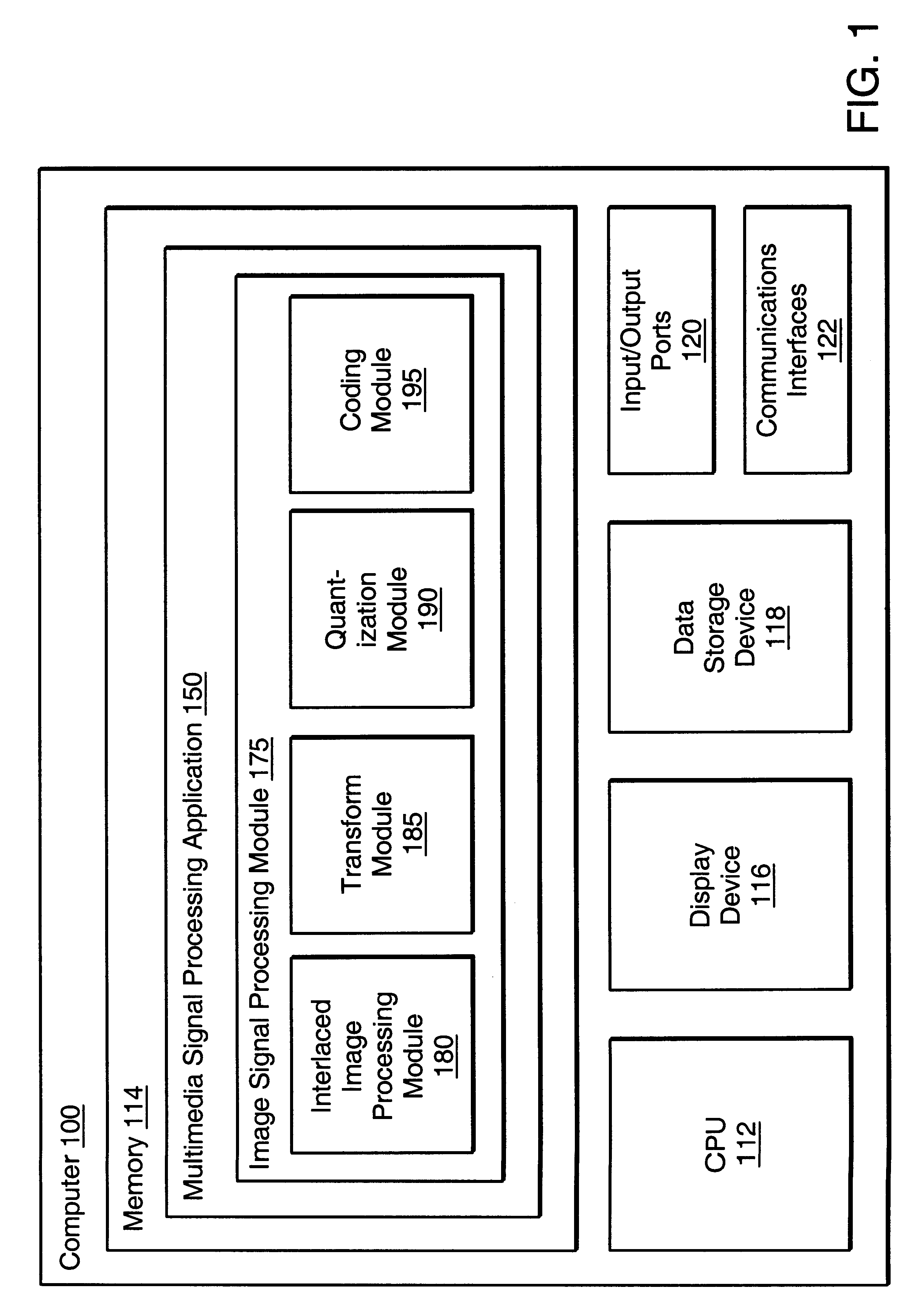

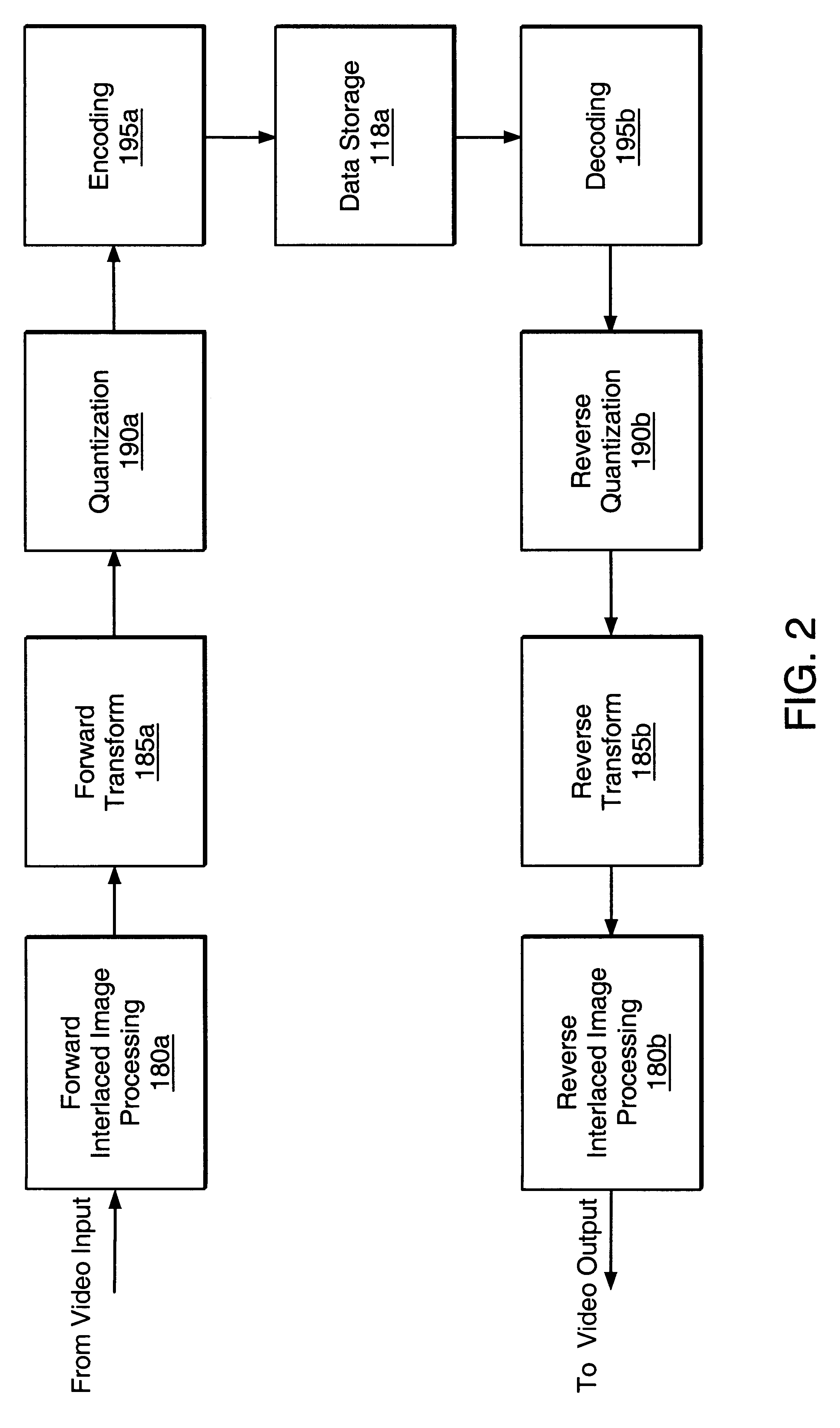

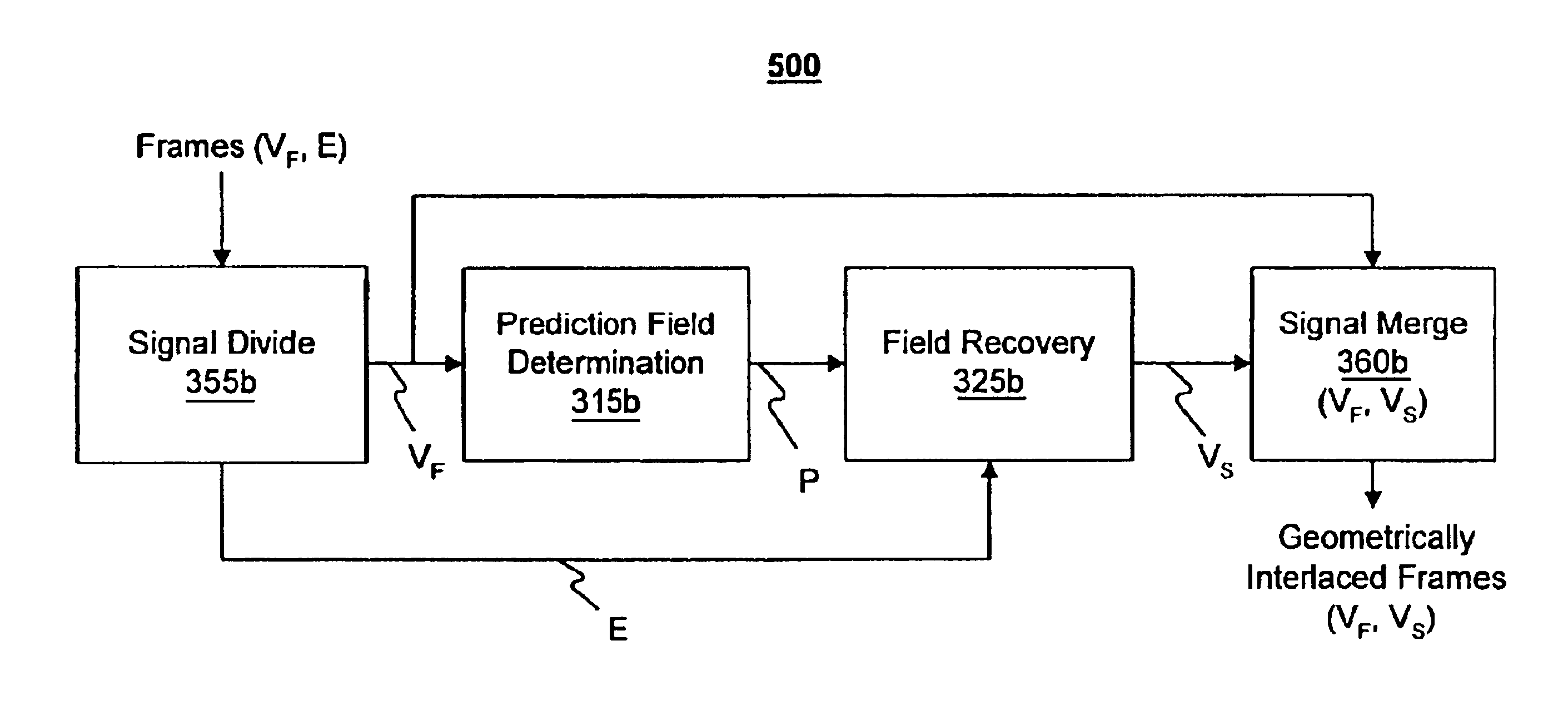

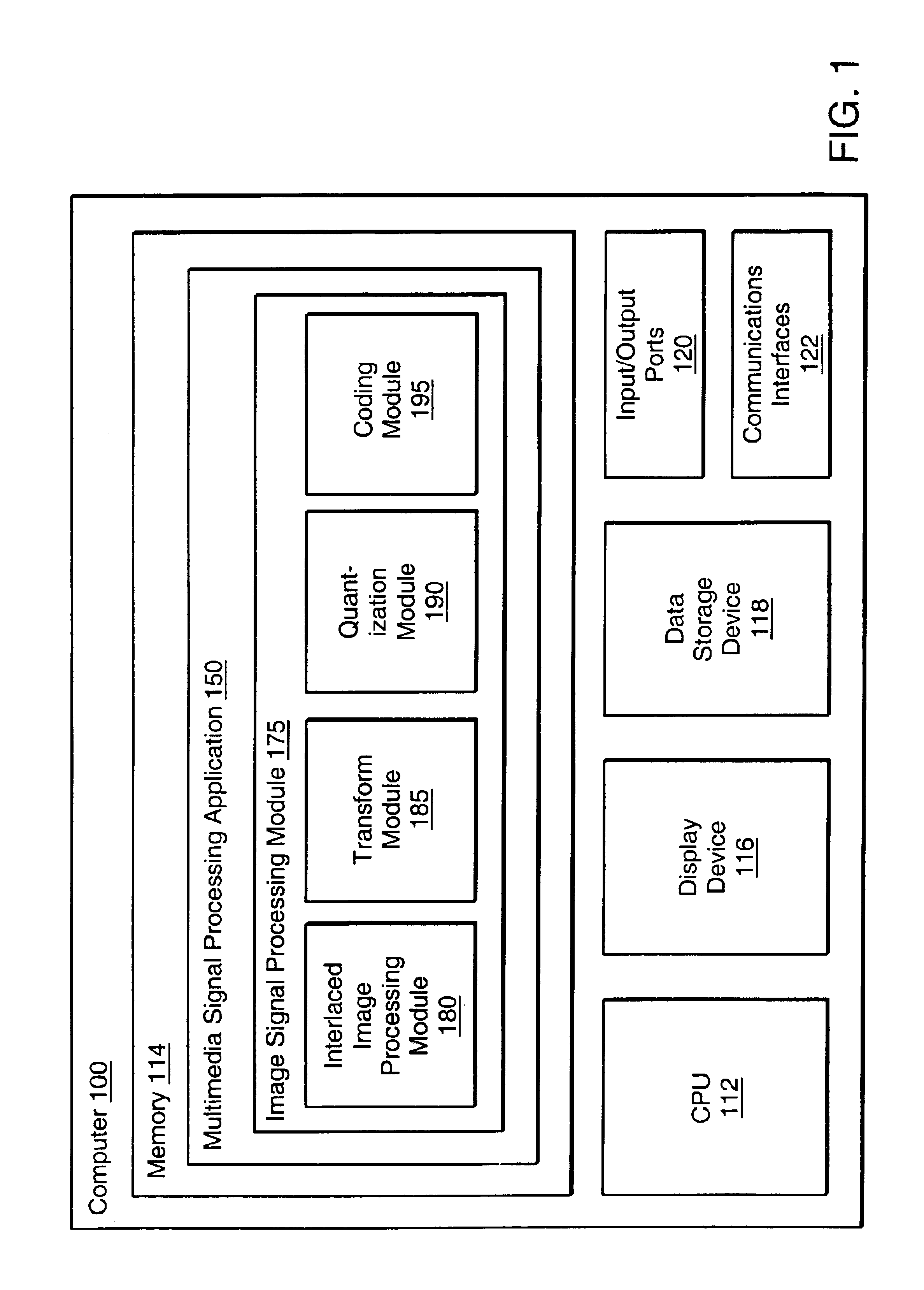

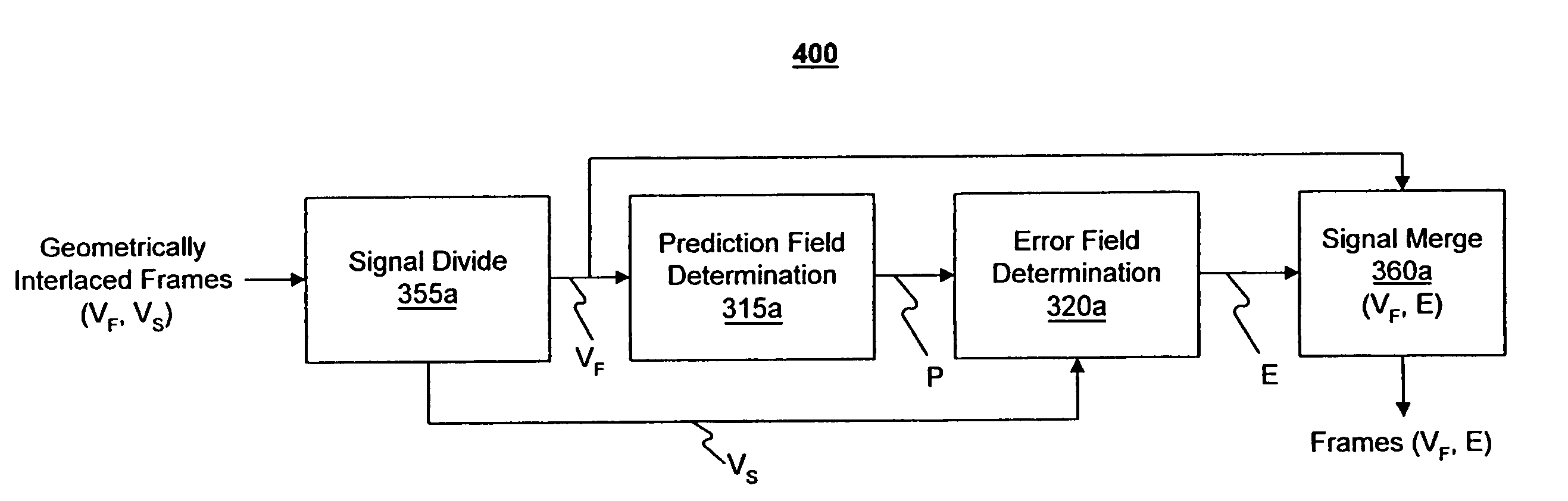

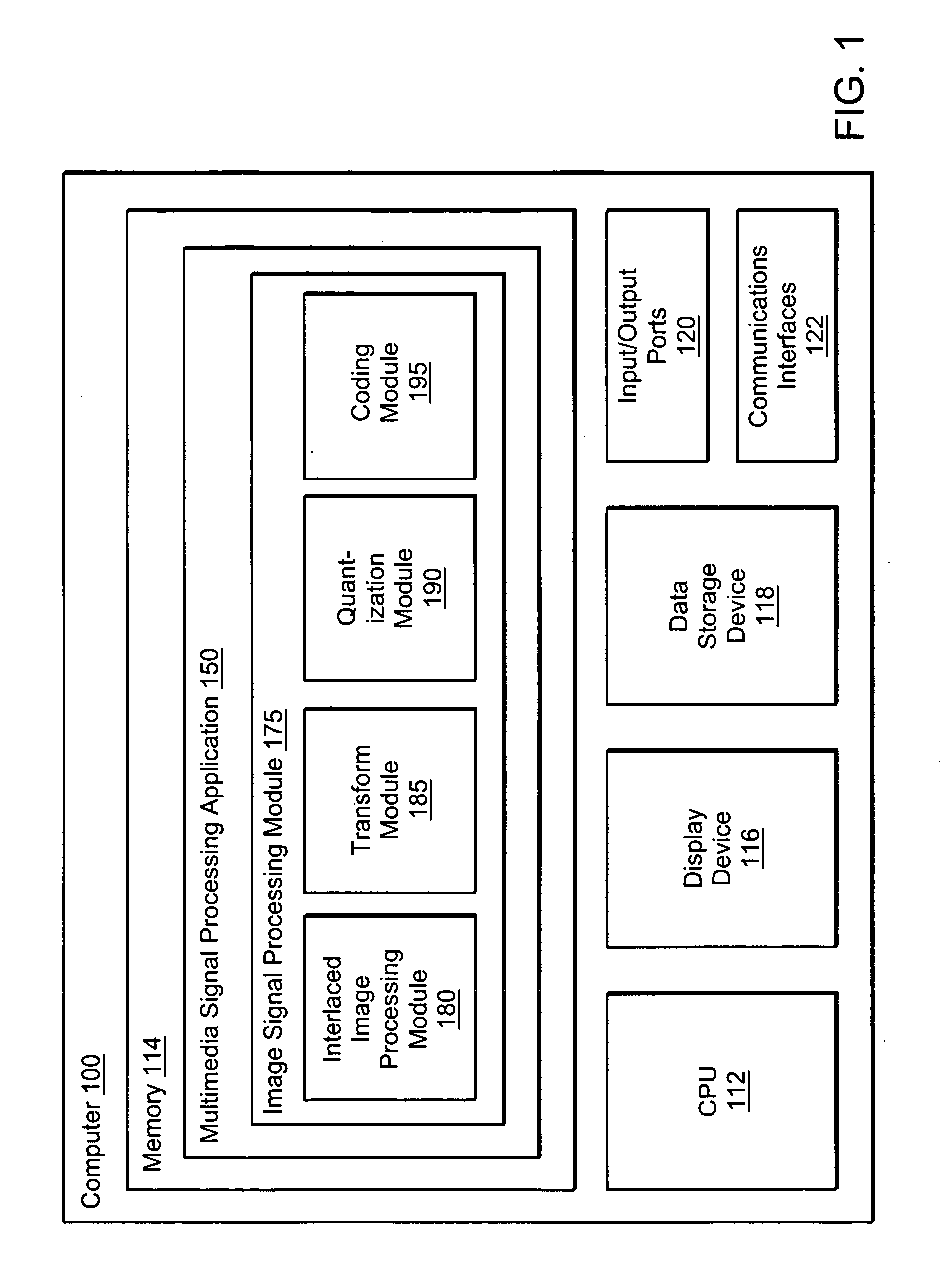

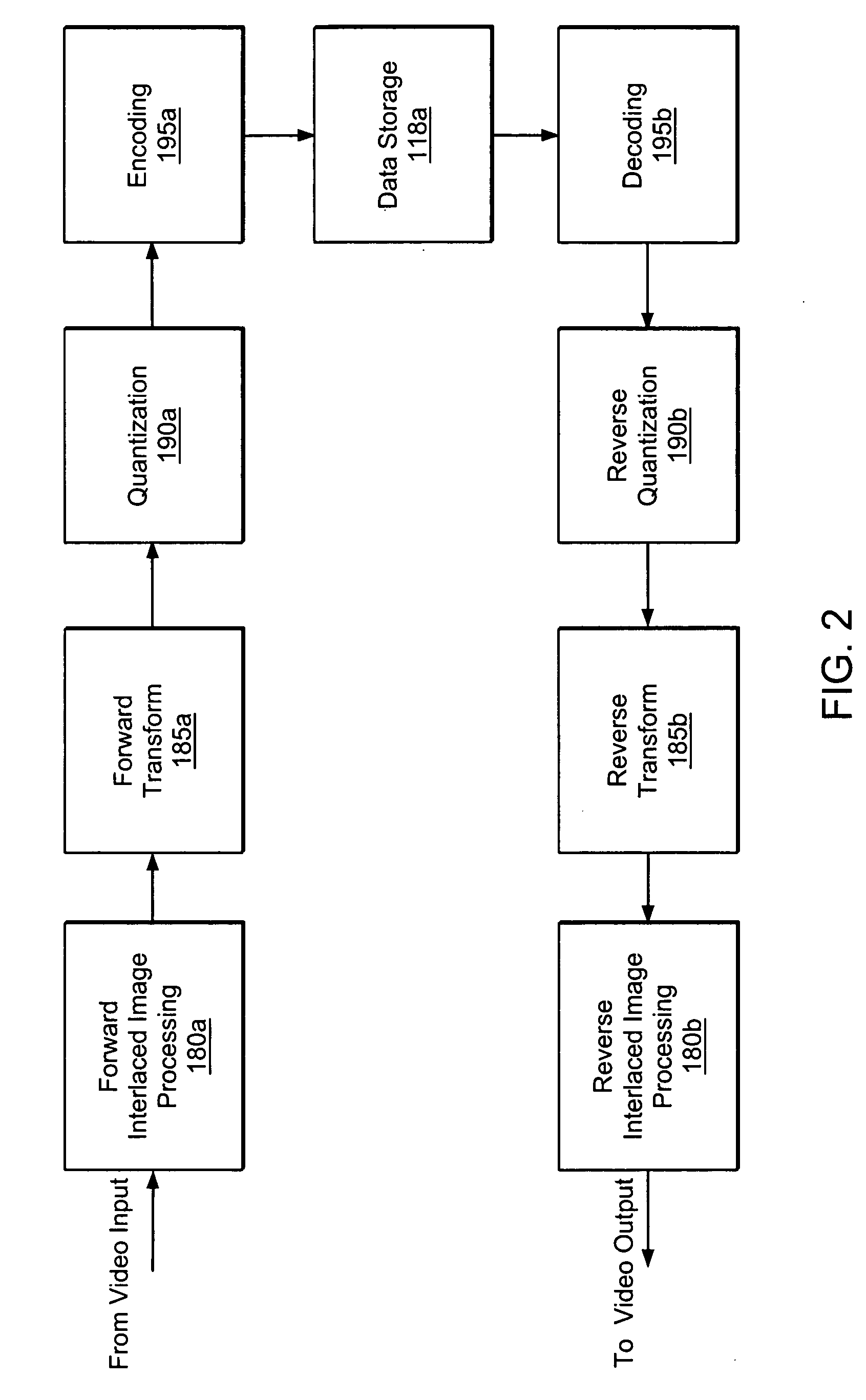

Apparatus and method for improved interlace processing

InactiveUS6928191B2Easy to compressAvoid inefficiencyCharacter and pattern recognitionImage codingInterlaced videoImaging processing

An interlaced image processing module and corresponding method facilitate improved processing of interlaced motion images. In one embodiment, the interlaced image processing module receives image data frames having interlaced first and second fields and produces a reference field and error field. The reference field corresponds to the still image content of the interlaced frame, whereas the error field corresponds to the motion content of the interlaced frame, particularly the motion between fields. Motion between fields is thus represented in the error field, without redundant representation of the still image content provided by the first field. Where there is little motion between fields, the error terms will be small so the predictor preserves the coding efficiency provided by any auto-correlation in the image.

Owner:QUVIS TECH +1

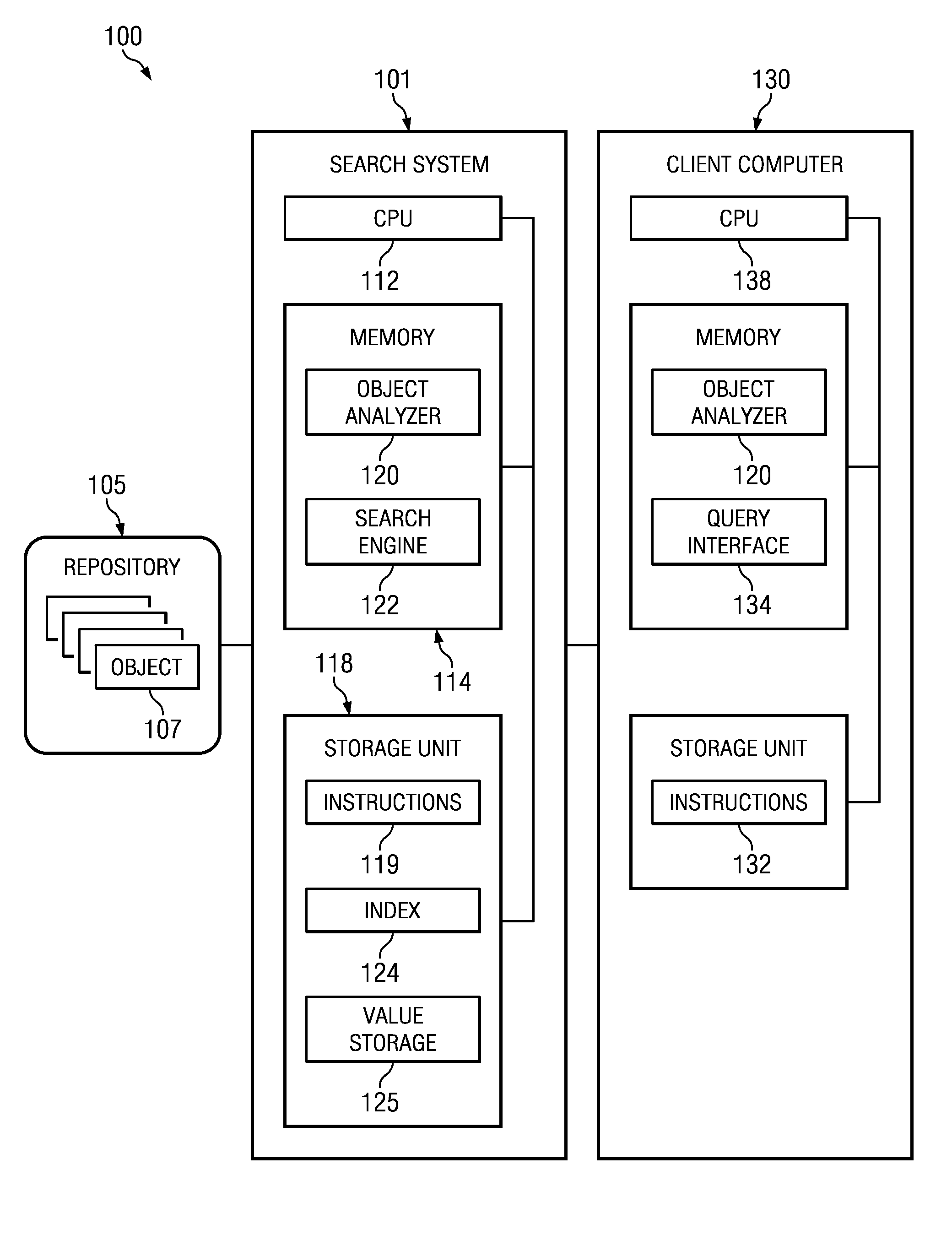

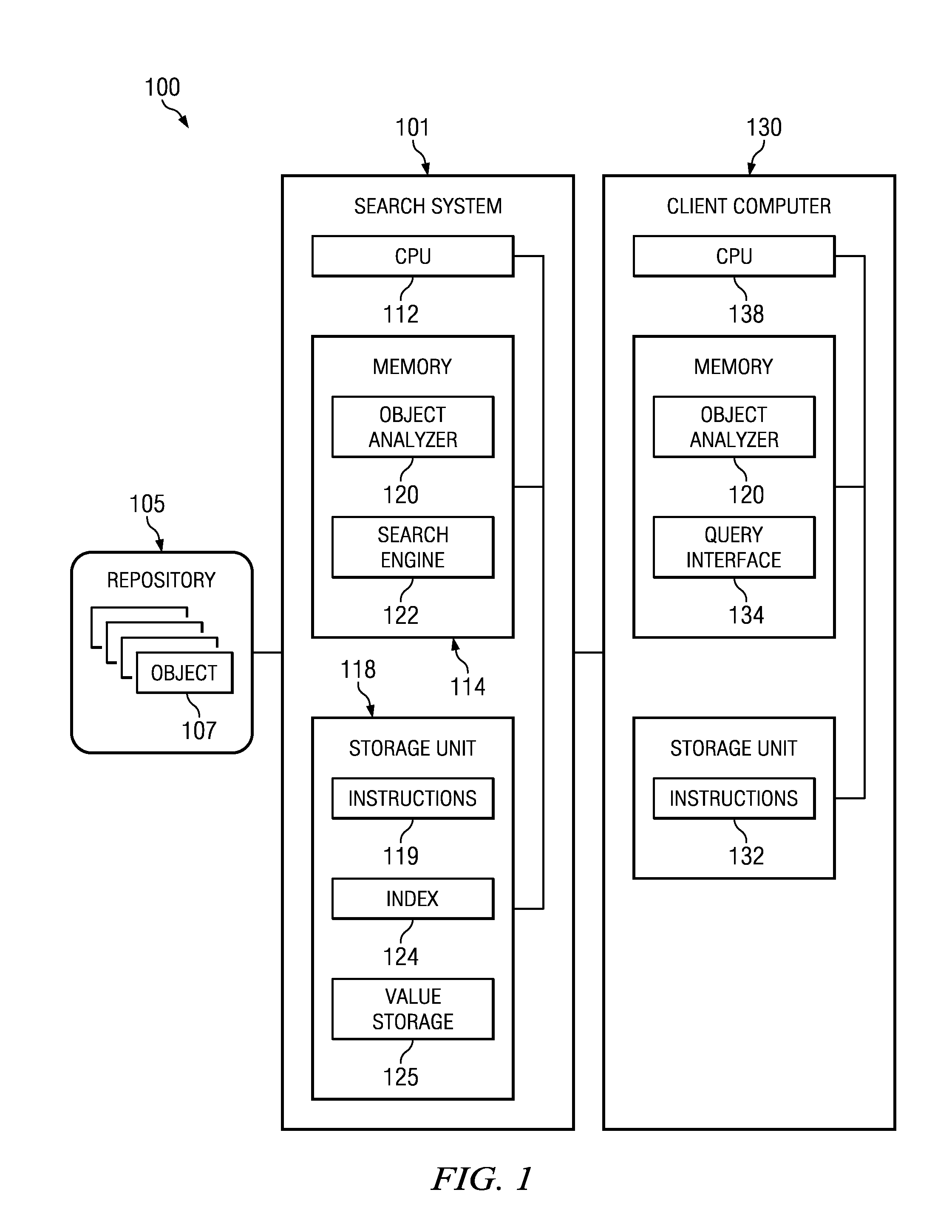

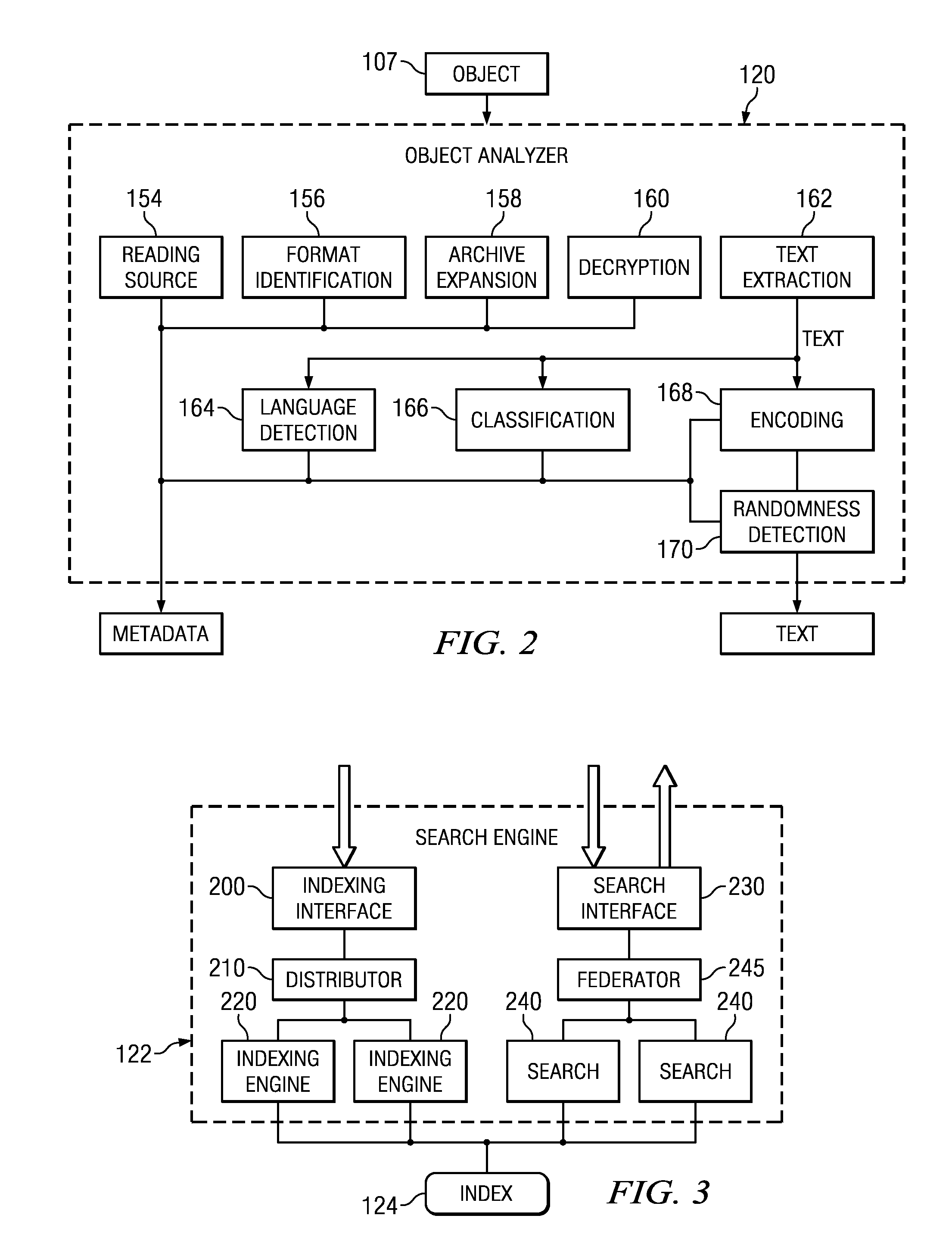

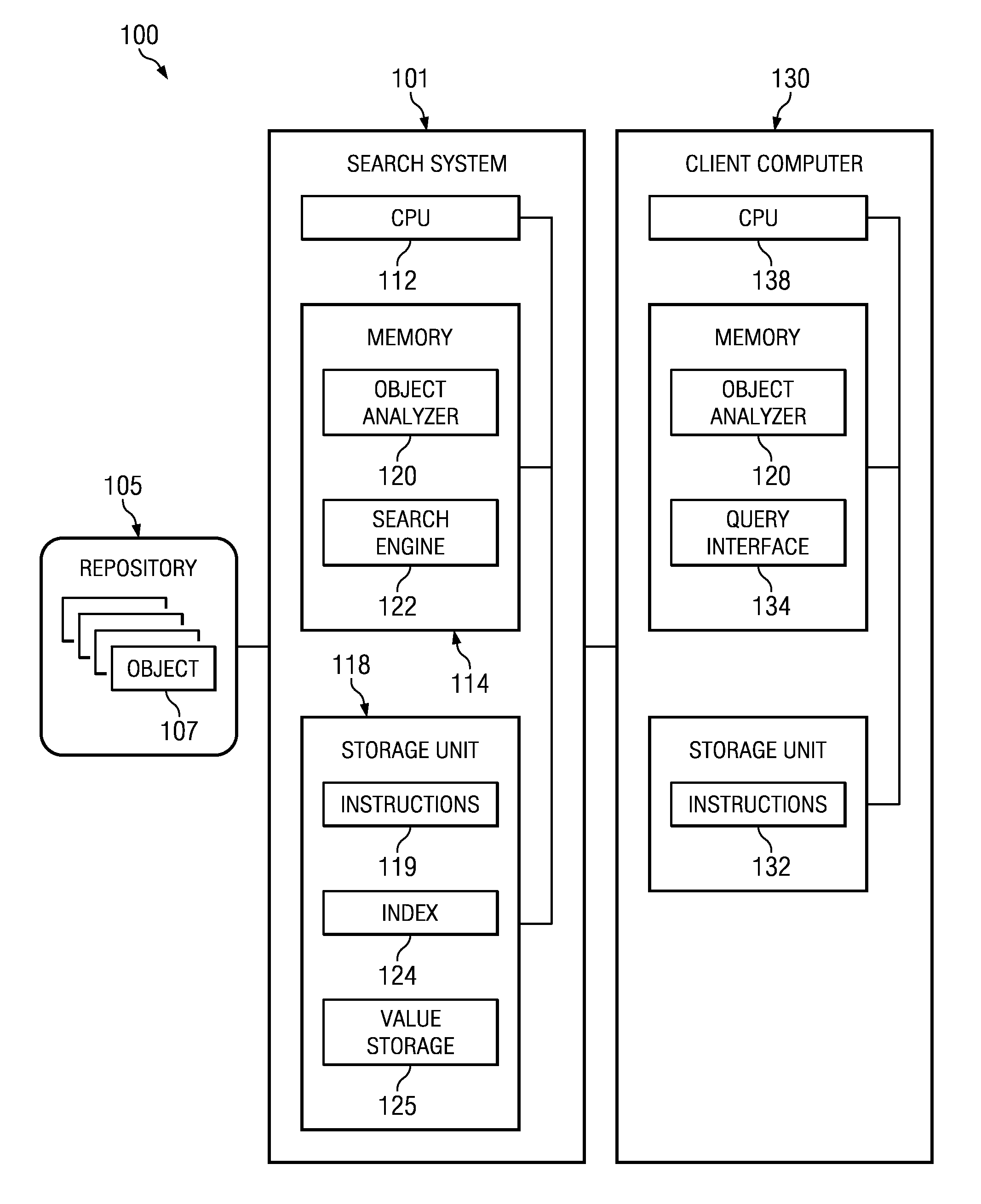

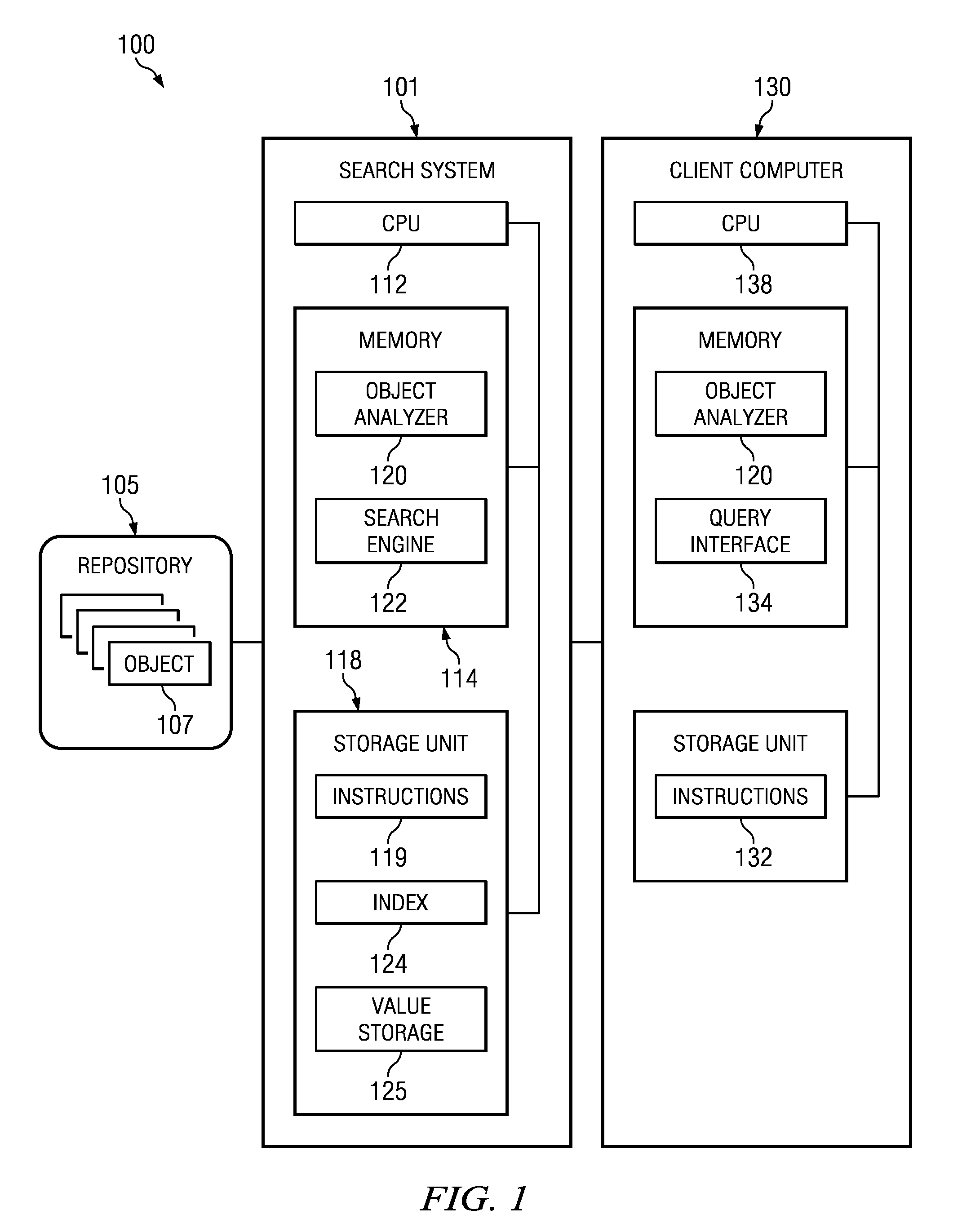

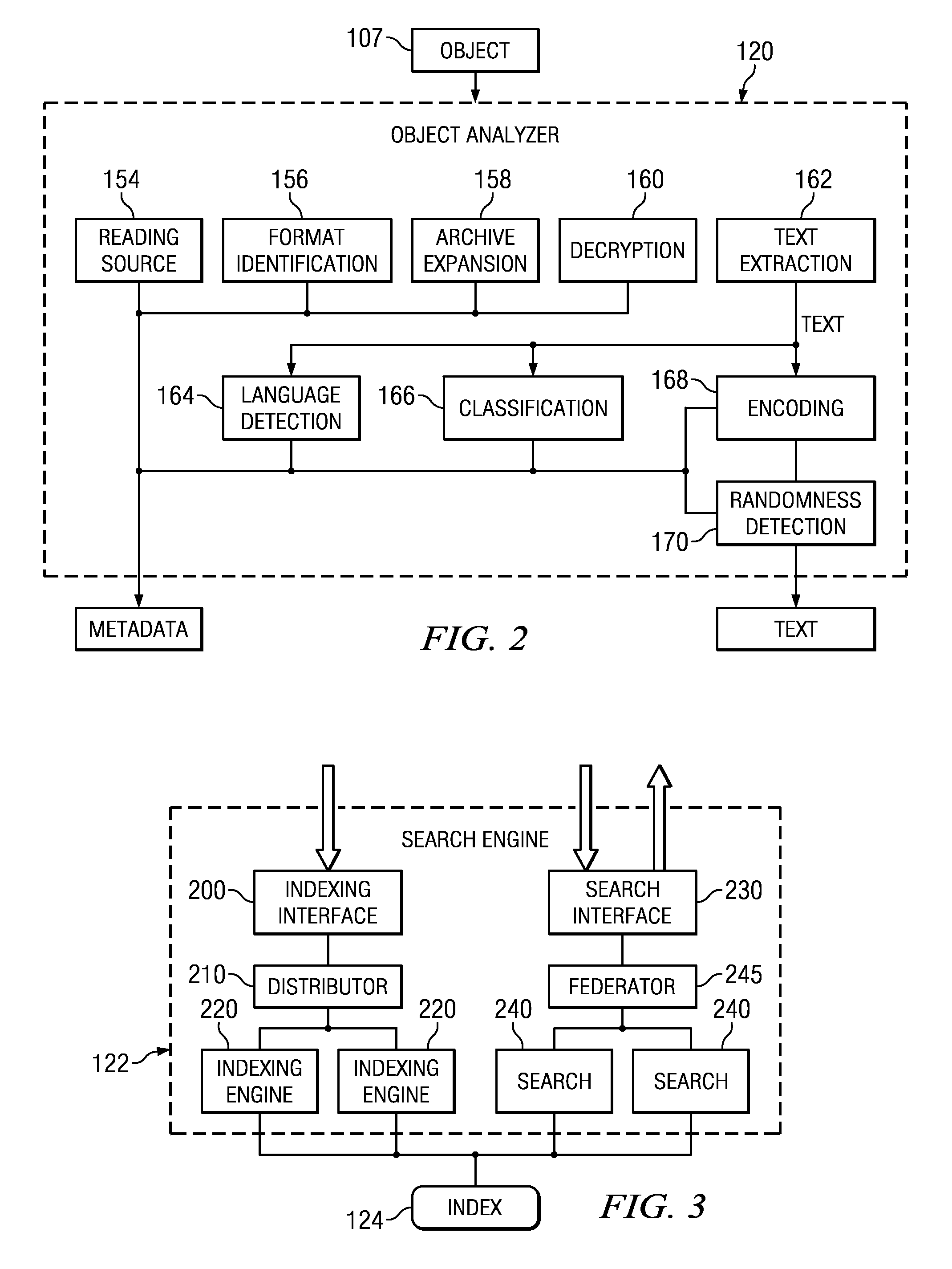

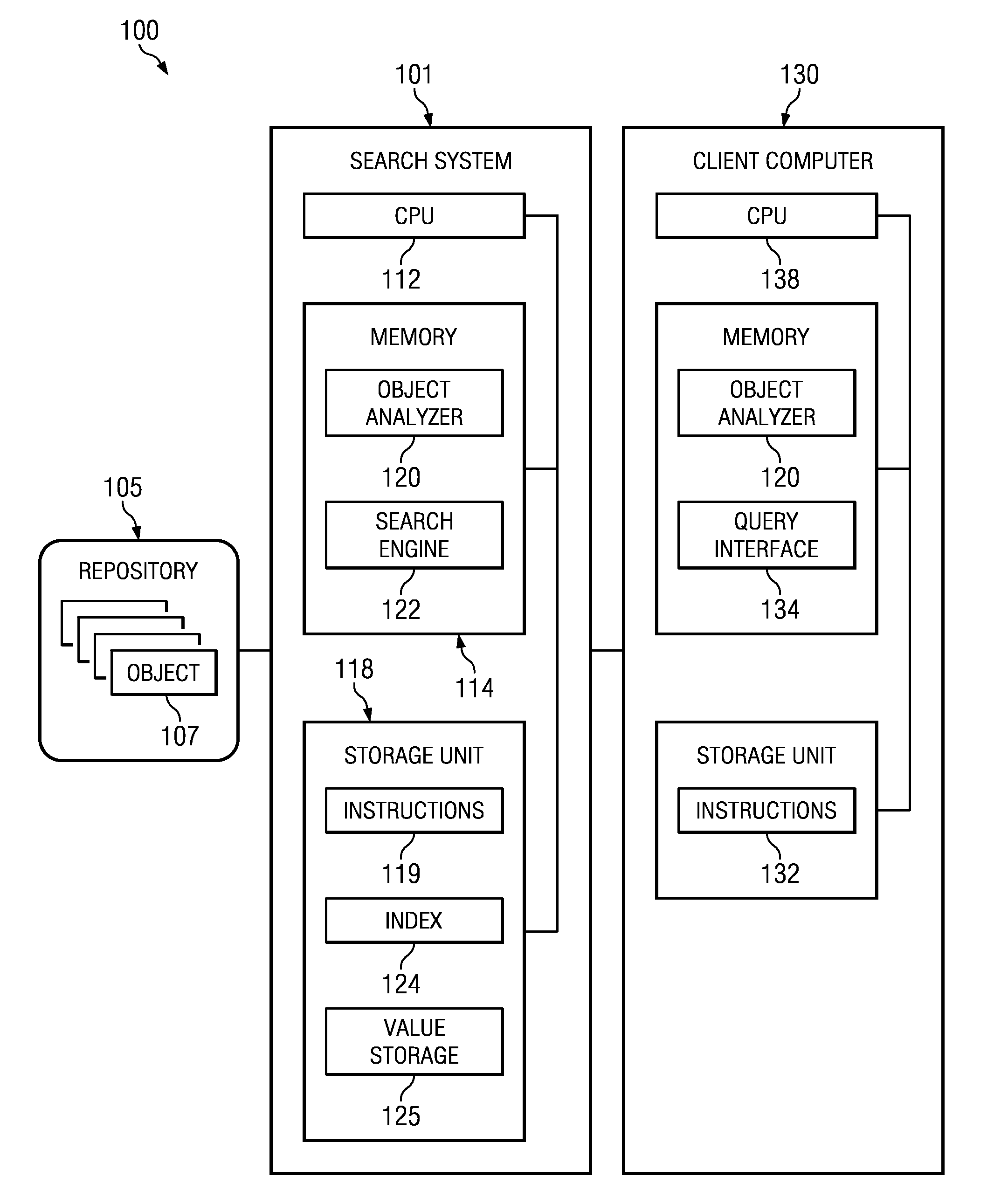

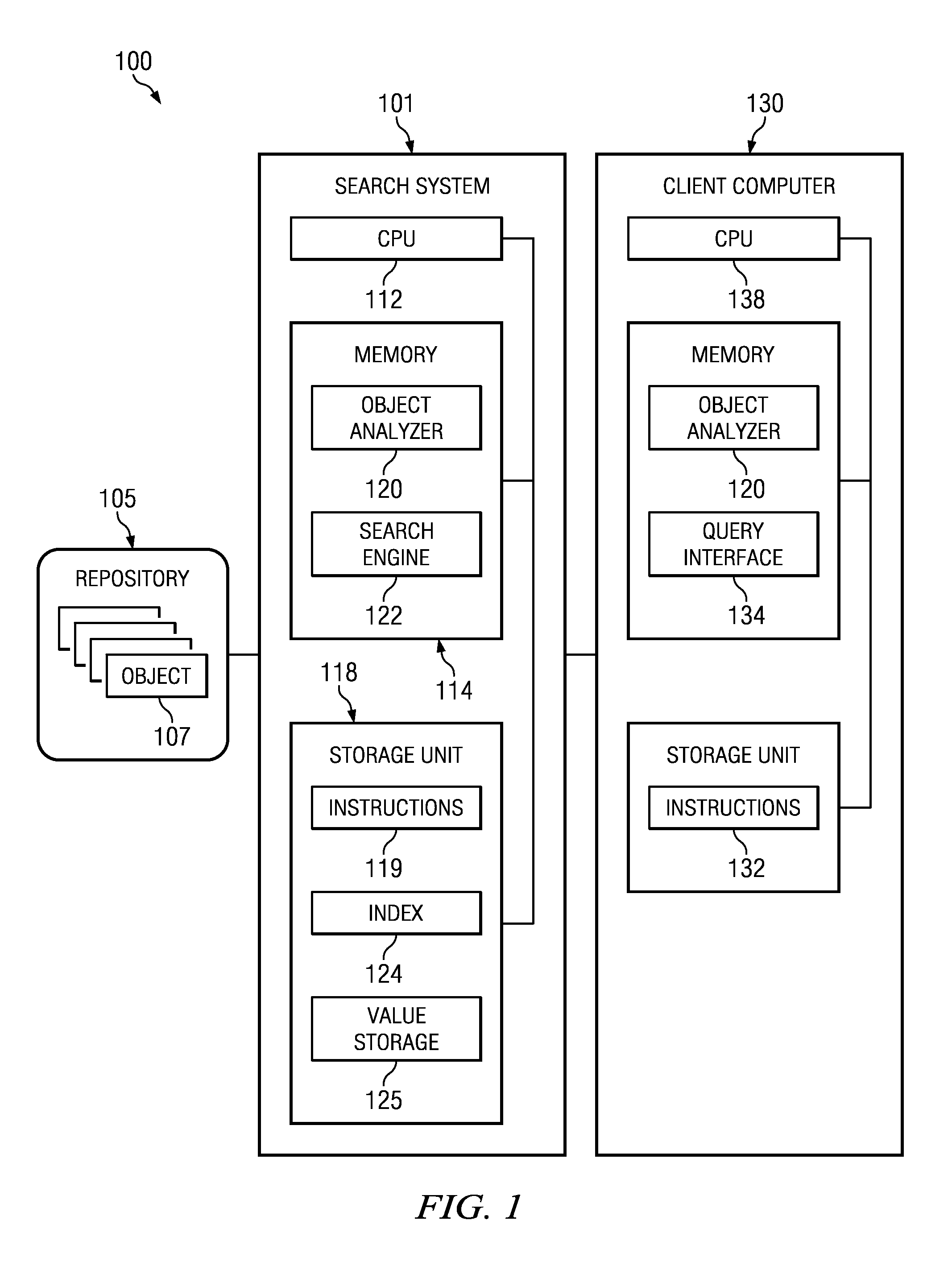

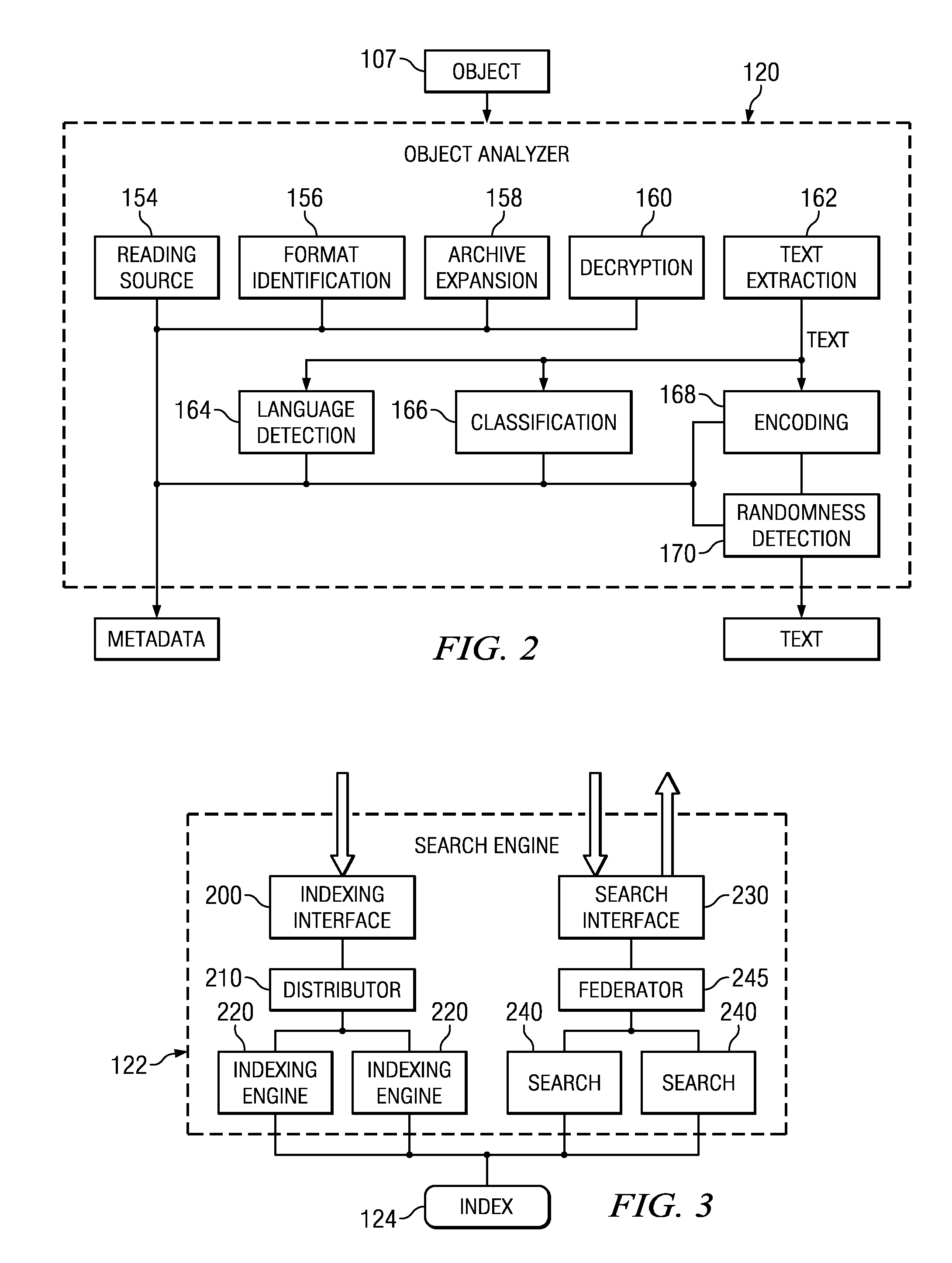

System and method of quality assessment of a search index

ActiveUS20140181056A1Digital data processing detailsWebsite content managementIndex systemQuality assessment

Systems, methods, and computer program products for enabling assessment of the quality of a search index. In one embodiment, objects are processed to produce corresponding text that is stored and indexed. The objects are also processed to identify and store corresponding metadata values for indexing. Error conditions that are detected during the processing of objects to generate corresponding text are tracked and compared to determine the most severe of the error conditions. An indication of the most severe error condition is stored in a first consolidated error field. Errors that are encountered in the identification and storage of metadata values are counted and this count is stored in a second consolidated error field. Both of the consolidated error fields are indexed in the same manner as the text and metadata for the objects, so that the stored error information can be used in queries of the search index.

Owner:OPEN TEXT SA ULC

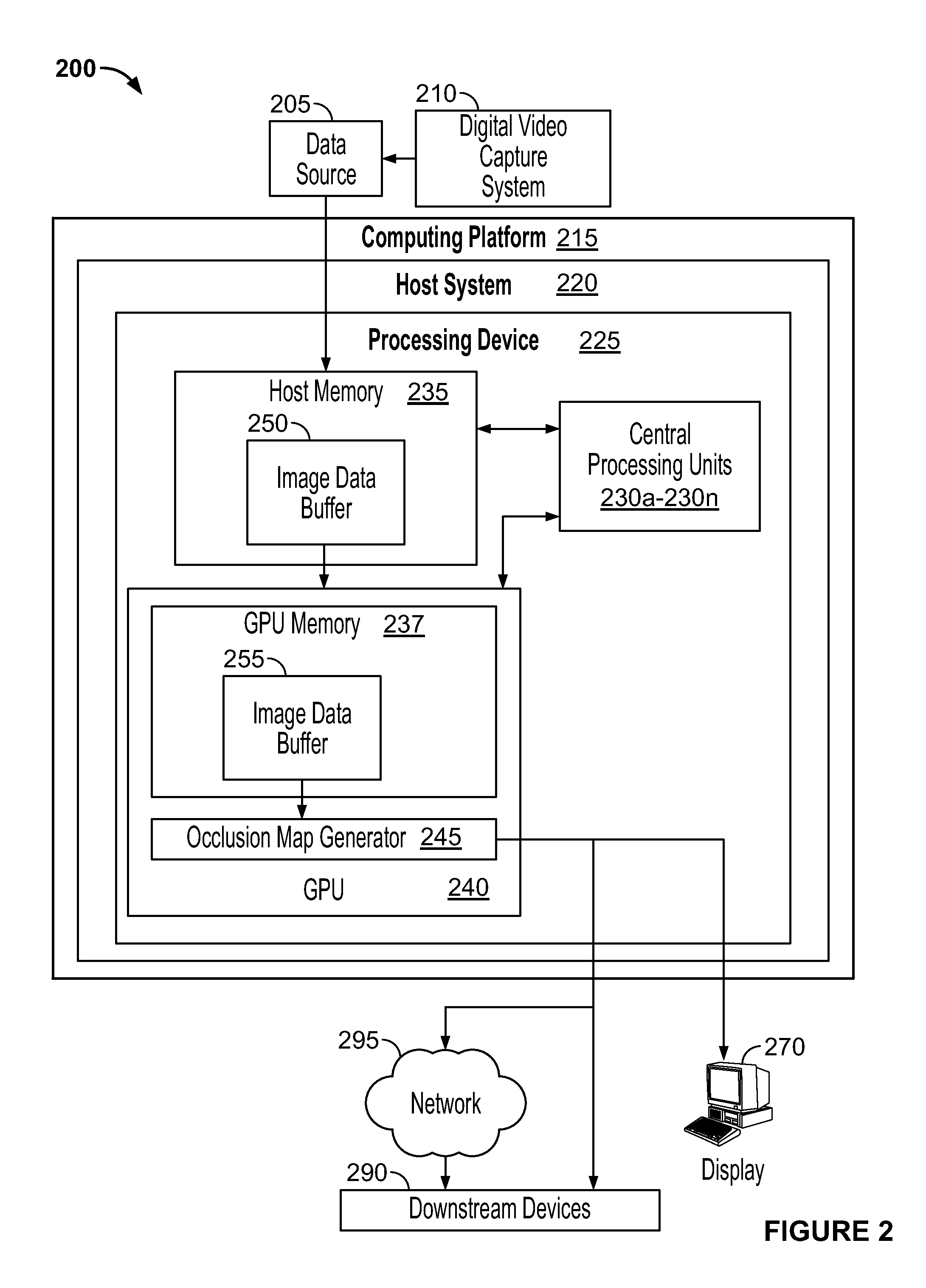

Digital processing method and system for determination of object occlusion in an image sequence

InactiveUS8718328B1Color television with pulse code modulationImage analysisMotion vectorError field

A method and system for occlusion region detection and measurement between a pair of images are disclosed. A processing device receives a first image and a second image. The processing device estimates a field of motion vectors between the first image and the second image. The processing device motion compensates the first image toward the second image to obtain a motion-compensated image. The processing device compares a plurality of pixel values of the motion-compensated image to a plurality of pixels of the first image to estimate an error field. The processing device inputs the error field to a weighted error cost function to obtain an initial occlusion map. The processing device regularizes the initial occlusion map to obtain a regularized occlusion map.

Owner:CHEYTEC TECH LLC

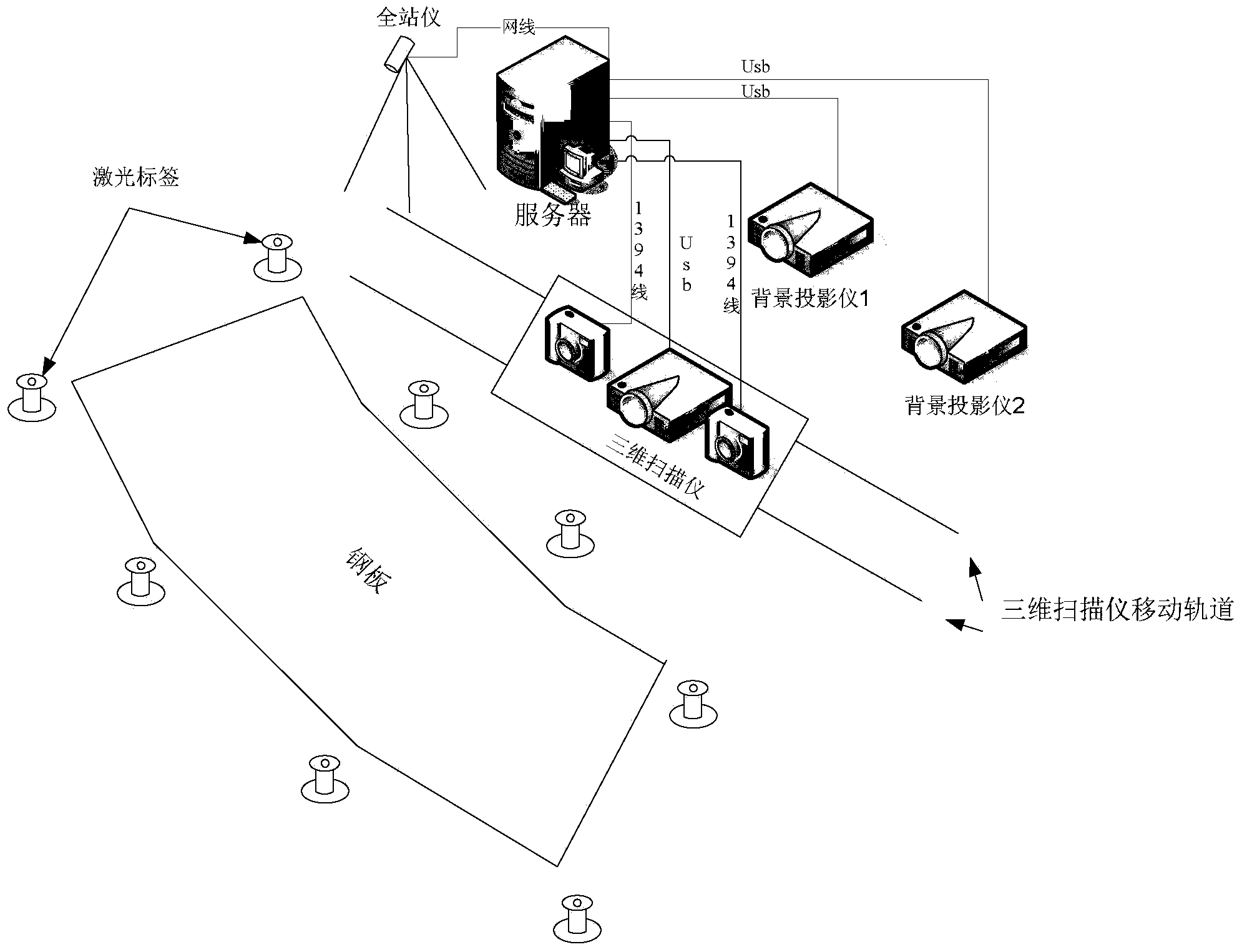

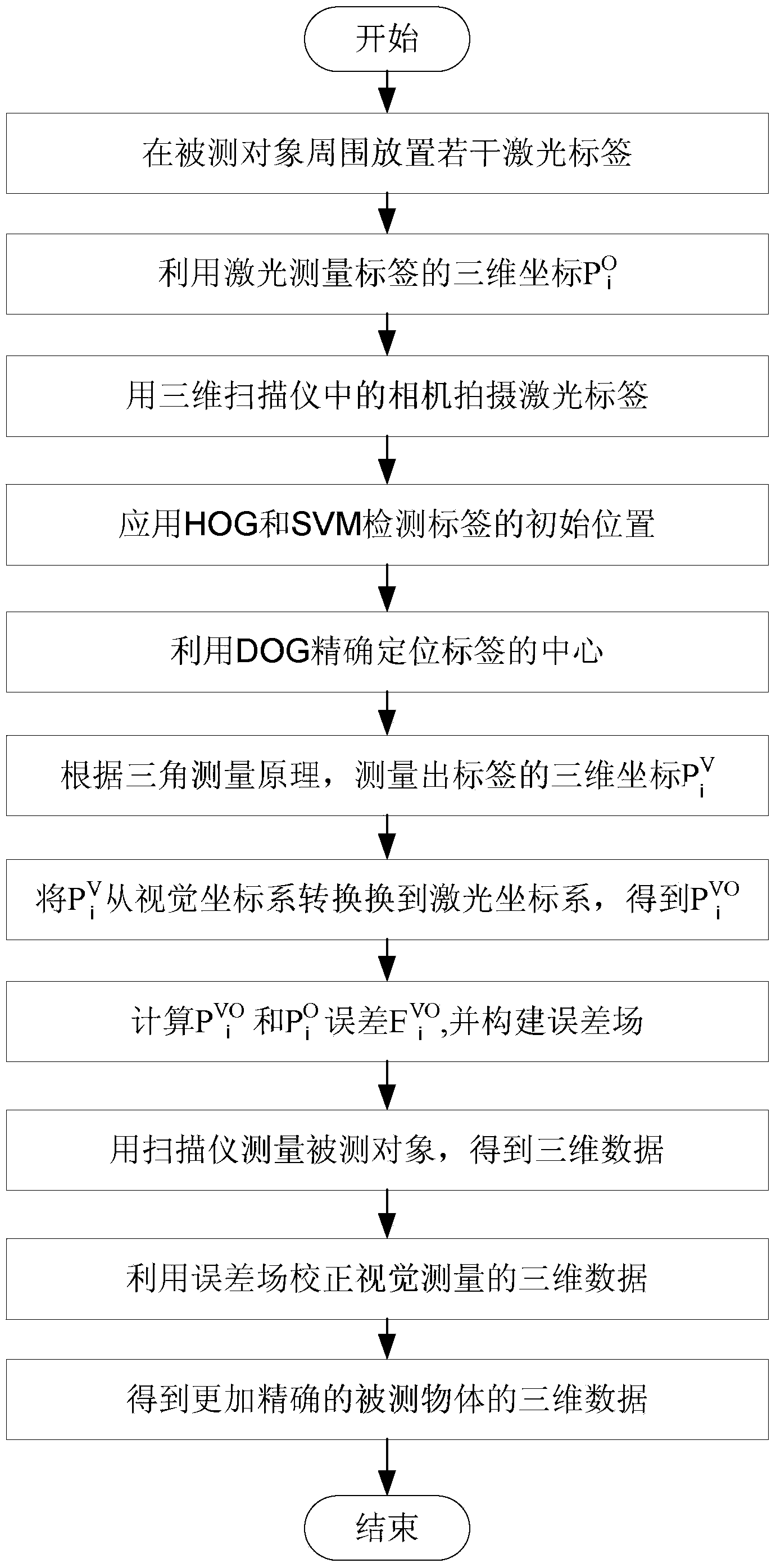

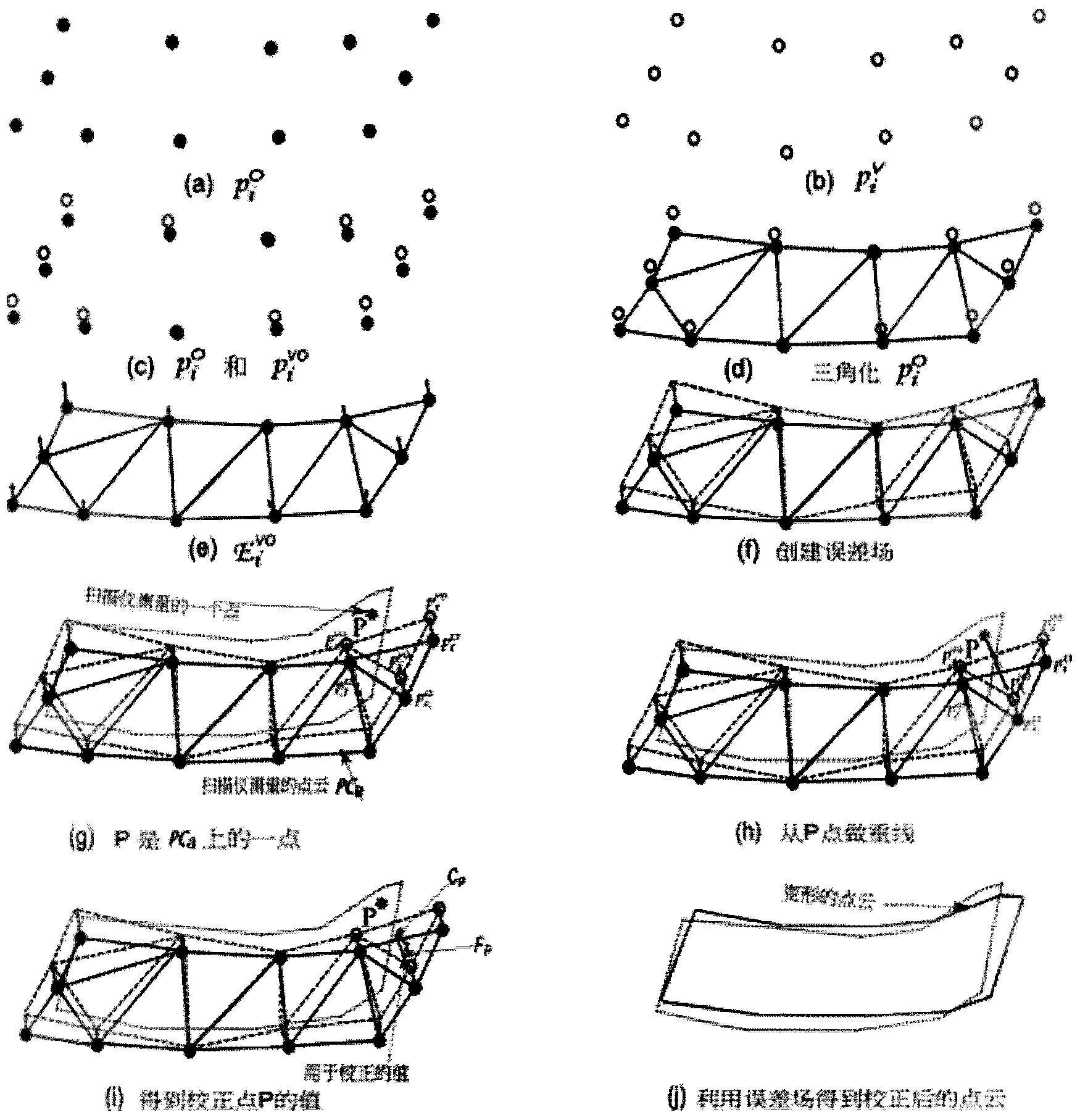

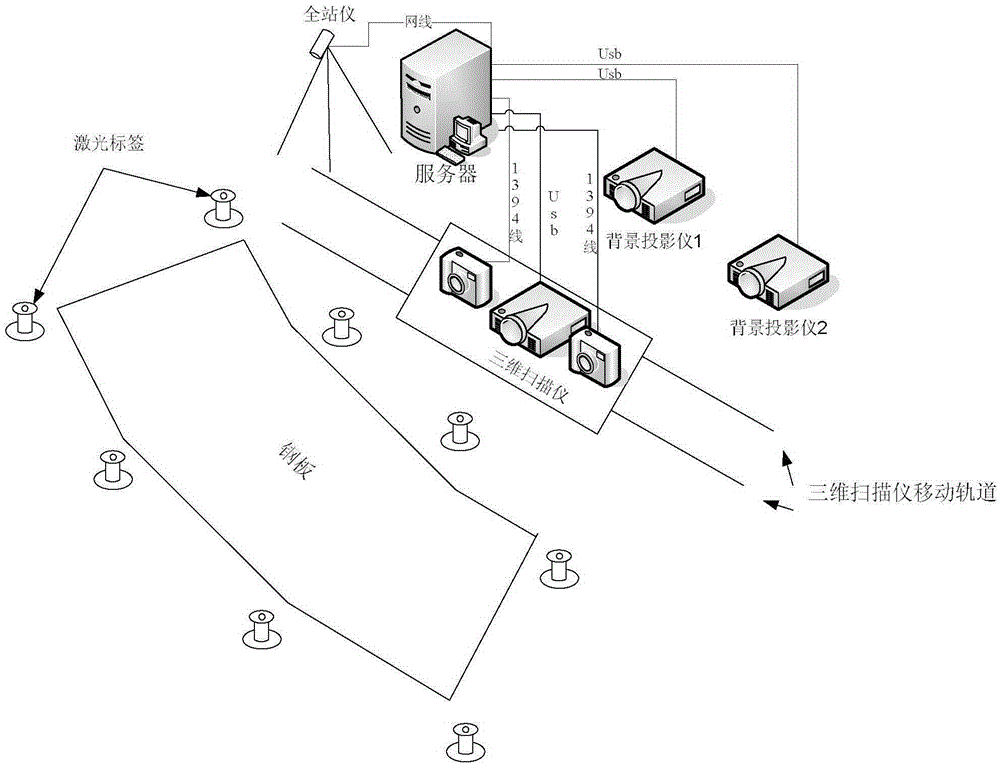

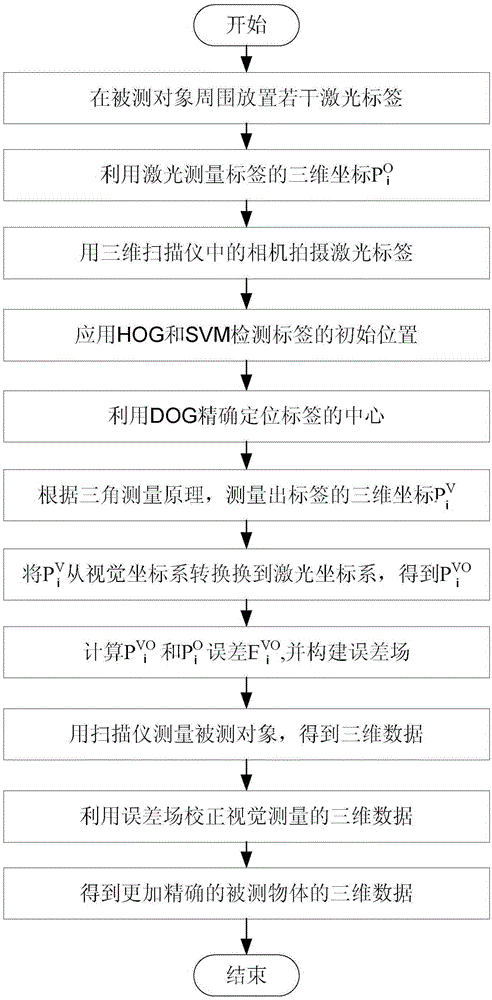

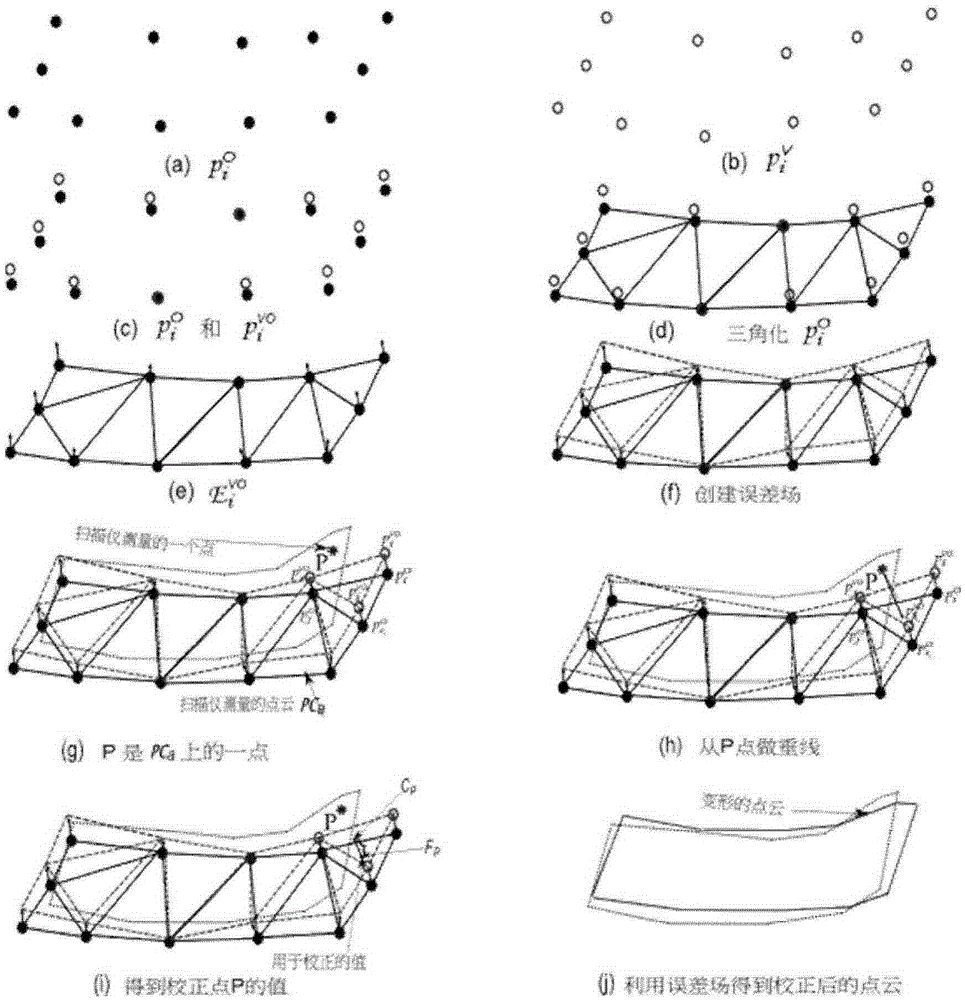

Three-dimensional measurement system and three-dimensional measurement method for steel plate with lasers and vision combined

InactiveCN103438826A3D measurement fastAccurate 3D measurementUsing optical meansThree dimensional measurementTotal station

The invention discloses a three-dimensional measurement system and three-dimensional measurement method for a steel plate with lasers and vision combined. The system is mainly composed of two background projectors, a total station, a three-dimensional scanner and a GPU server. The background projectors, the three-dimensional scanner and the total station are all connected to the server. The method comprises the steps that a plurality of laser labels are placed around the steel plate to be measured; the lasers are used for measuring the three-dimensional coordinates of the labels, and two cameras in the three-dimensional scanner are used for shooting the laser labels; an HOG and an SVM are used for detecting the original positions of the labels; a DOG is used for precisely locating the center of the labels; the three-dimensional coordinates of the labels are measured, the coordinates are converted into a laser coordinate system from a visual system, the errors of a calculation sum are obtained, and an error field is constructed; the scanner is used for measuring the steel plate to be measured to obtain the three-dimensional data of the steel plate; the error field is used for correcting the three-dimensional data of the steel plate to obtain the more accurate three-dimensional data of the steel plate. Laser measurement and vision measurement are combined, and the errors of the vision measurement can be greatly reduced.

Owner:JIANGSU UNIV OF SCI & TECH

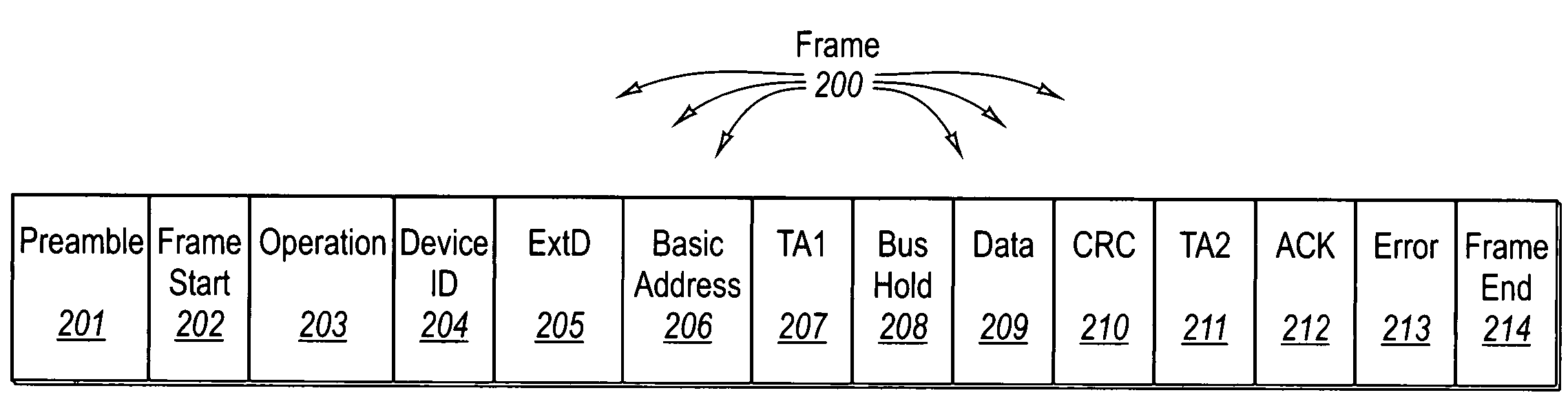

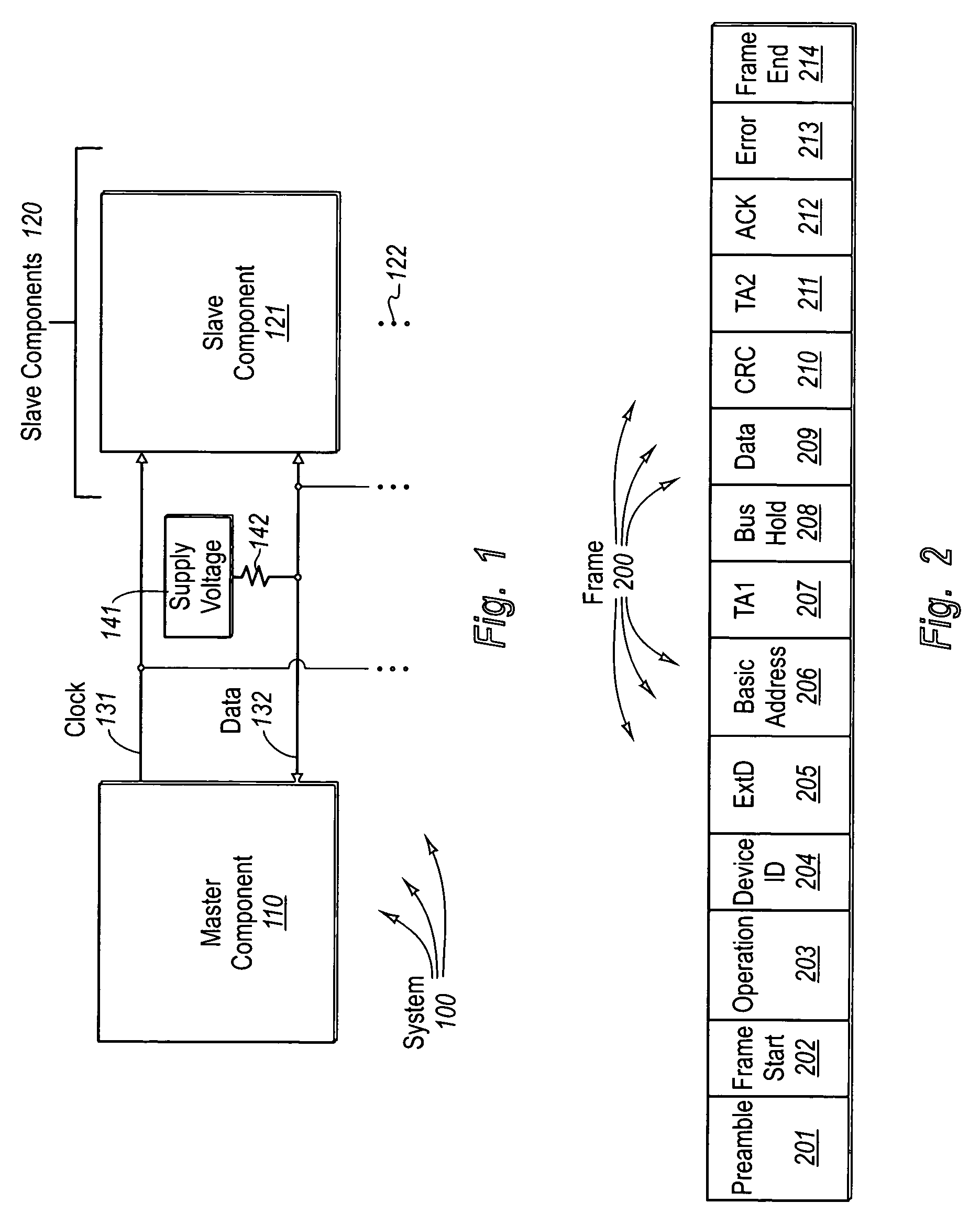

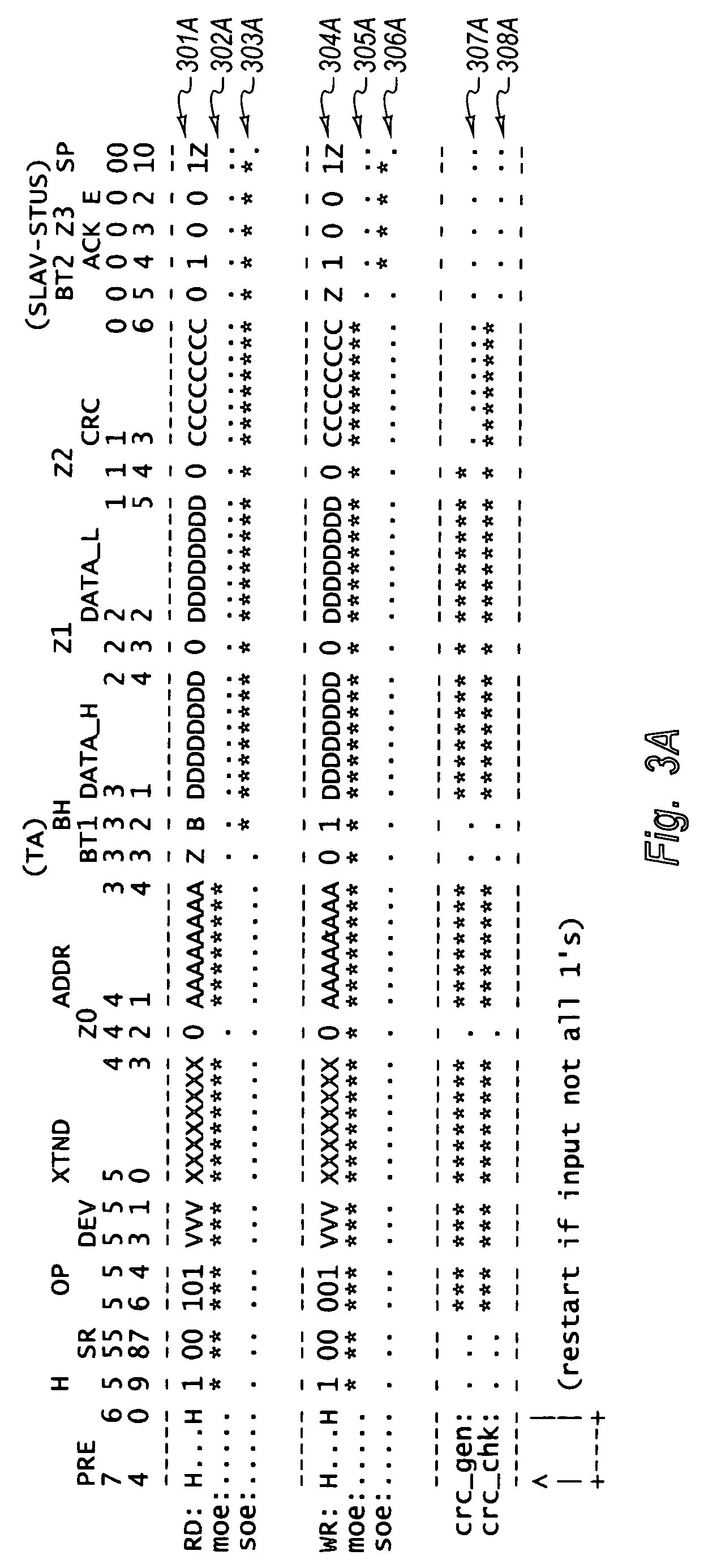

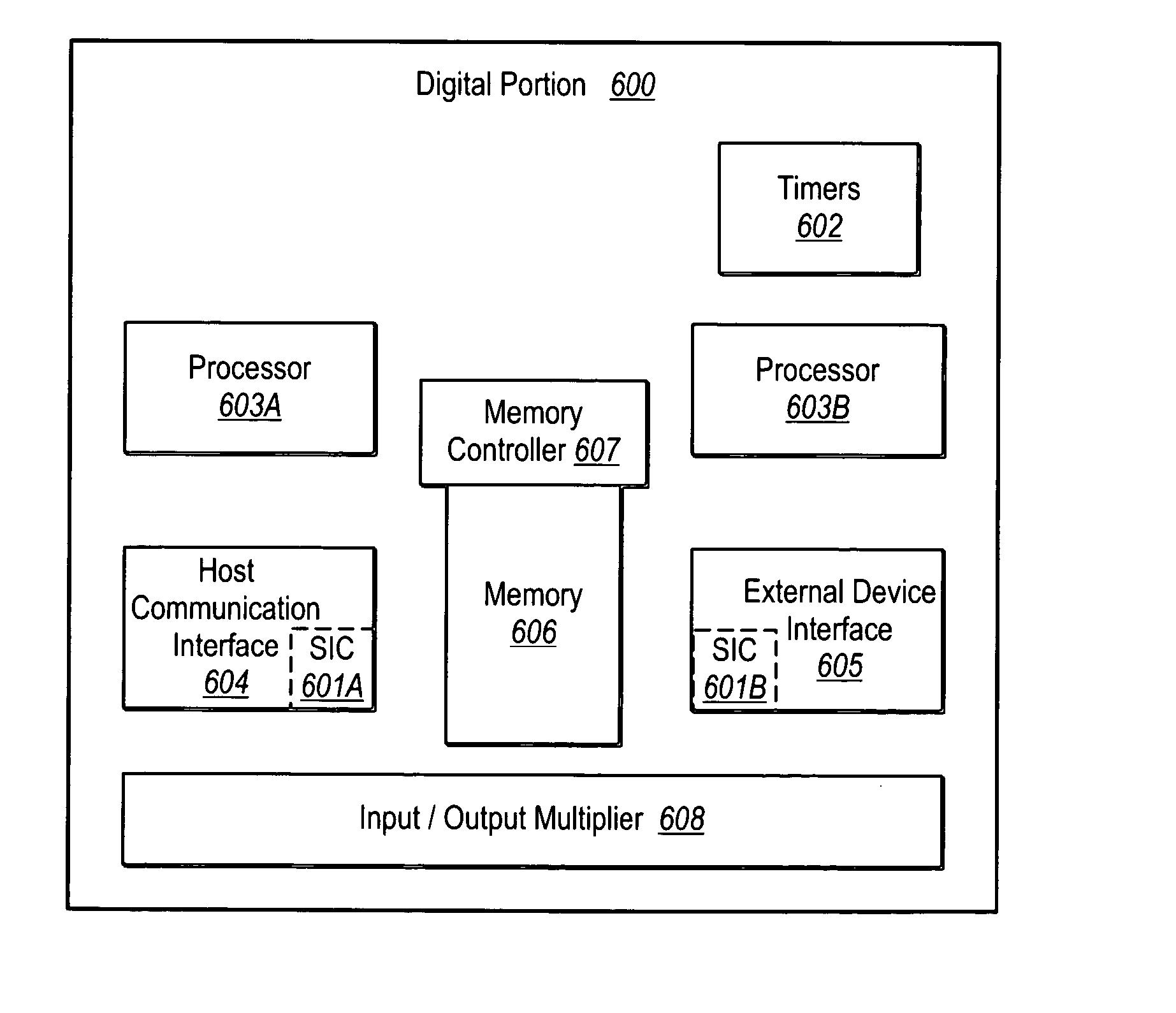

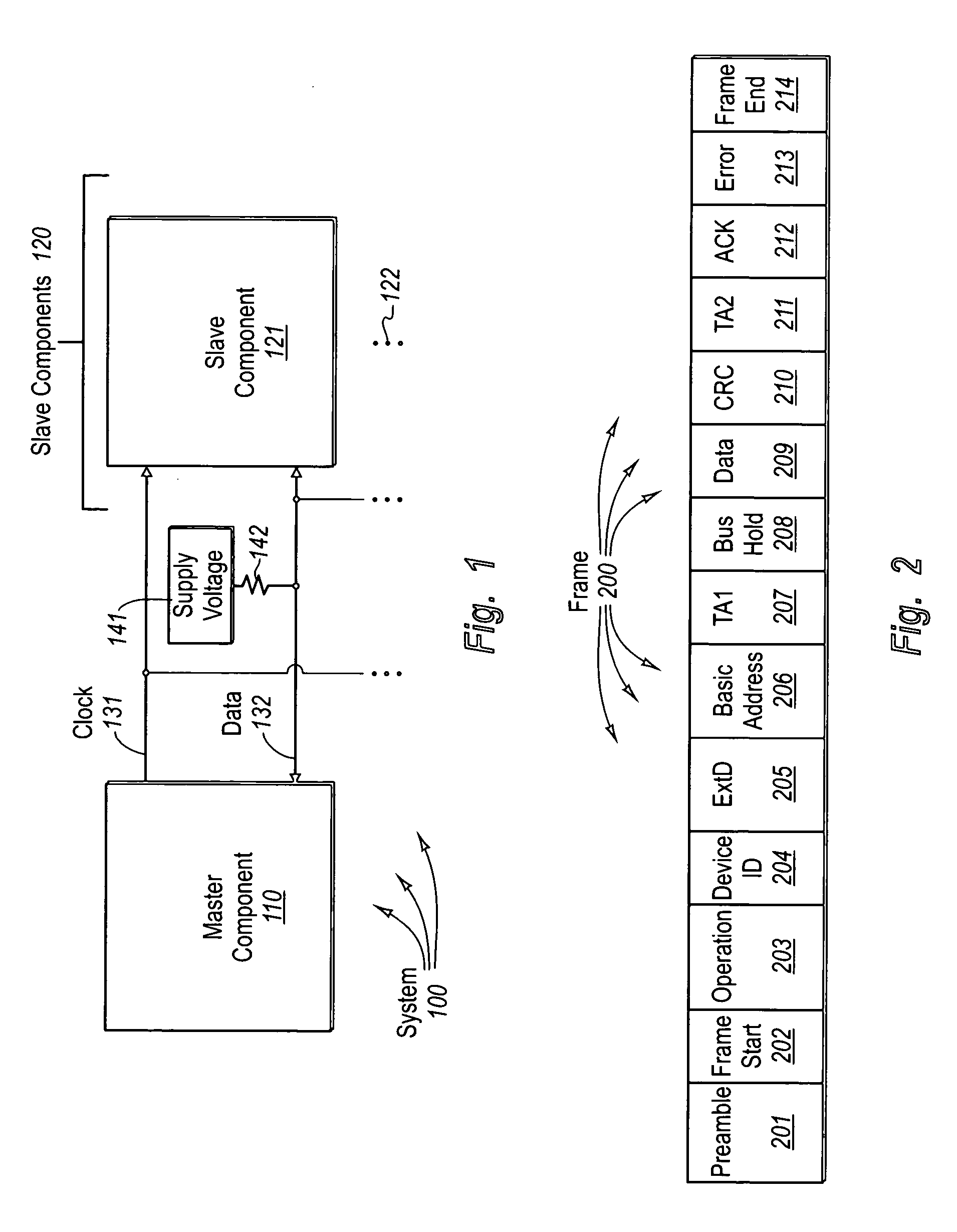

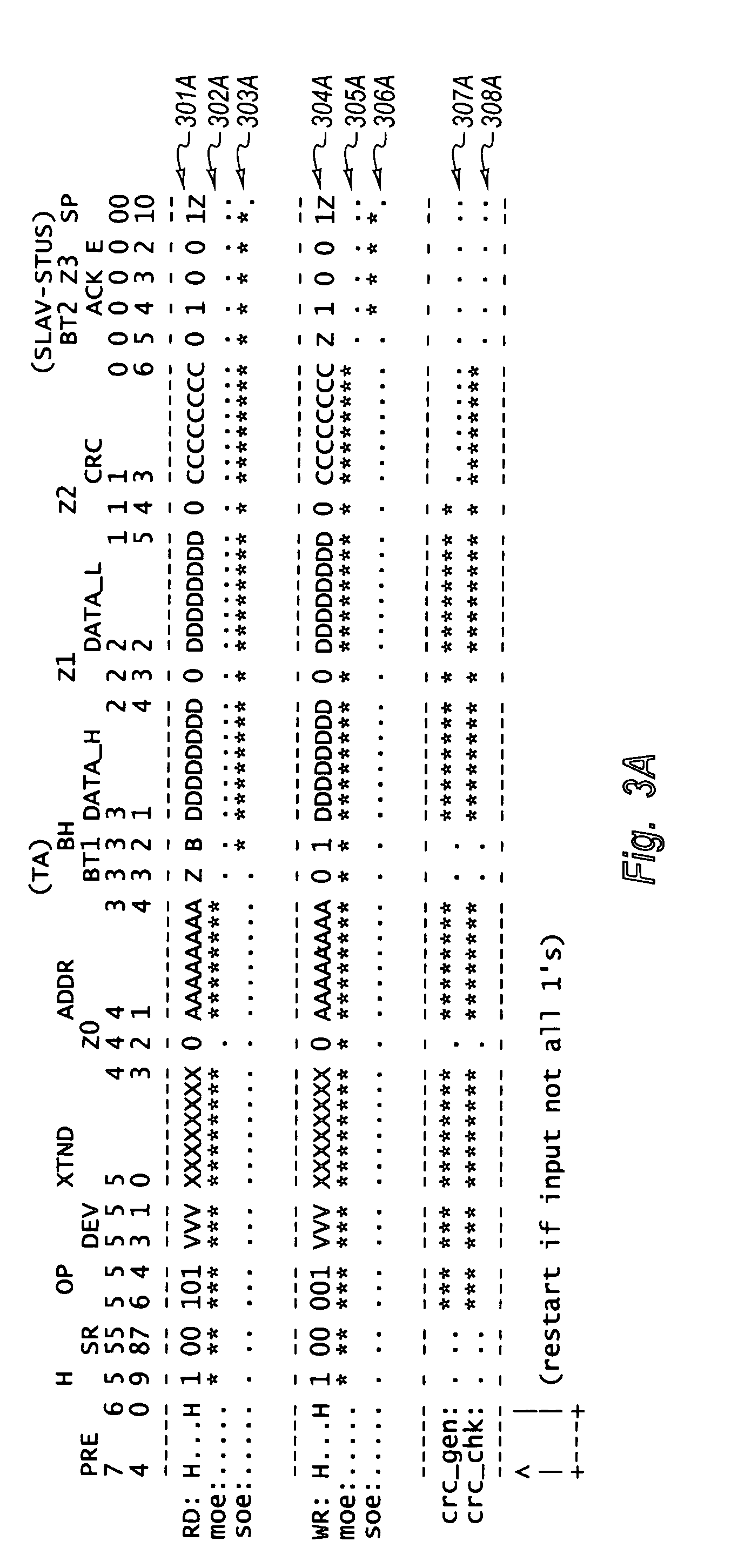

Two-wire interface having dynamically adjustable data fields depending on operation code

A guaranteed two-wire interface in which upon determining that an operation is to be performed on a slave component, a master component transmits at least a portion of a corresponding frame to the slave component over the data wire. The master component repeats this detection and transmission each time it determines that an operation is to be performed on a slave component, whether the same component or a different slave component as the slave component previously communicated with. The frame structure itself may change depending on the operation to be performed. For example, one frame might include an extended address data field that includes extended address information that goes beyond a basic address field included in another frame. One frame may include reliability fields (such as cyclic redundancy checking field, an acknowledgement field, and / or an error field), whereas another frame having a different operation may not.

Owner:II VI DELAWARE INC

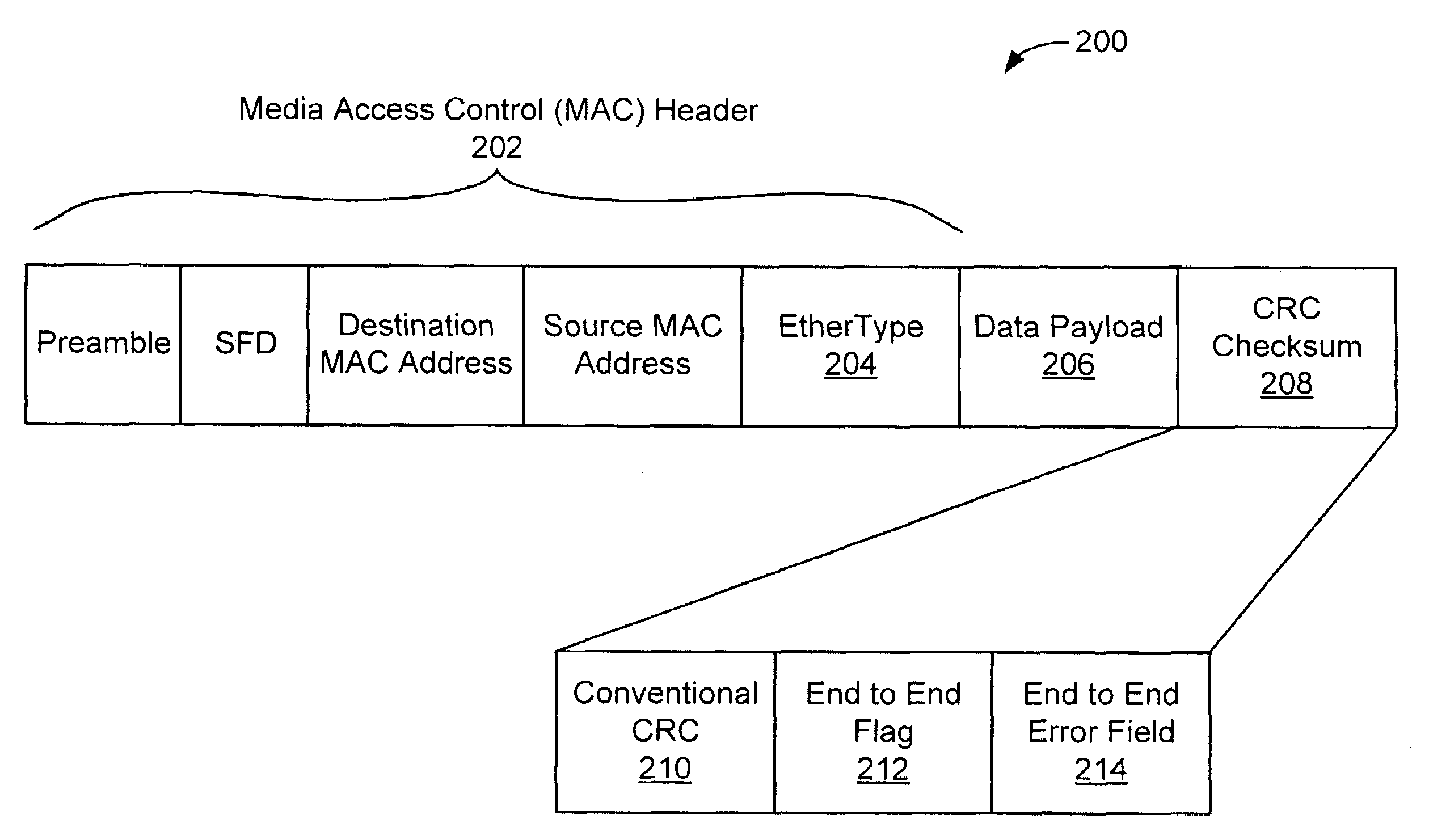

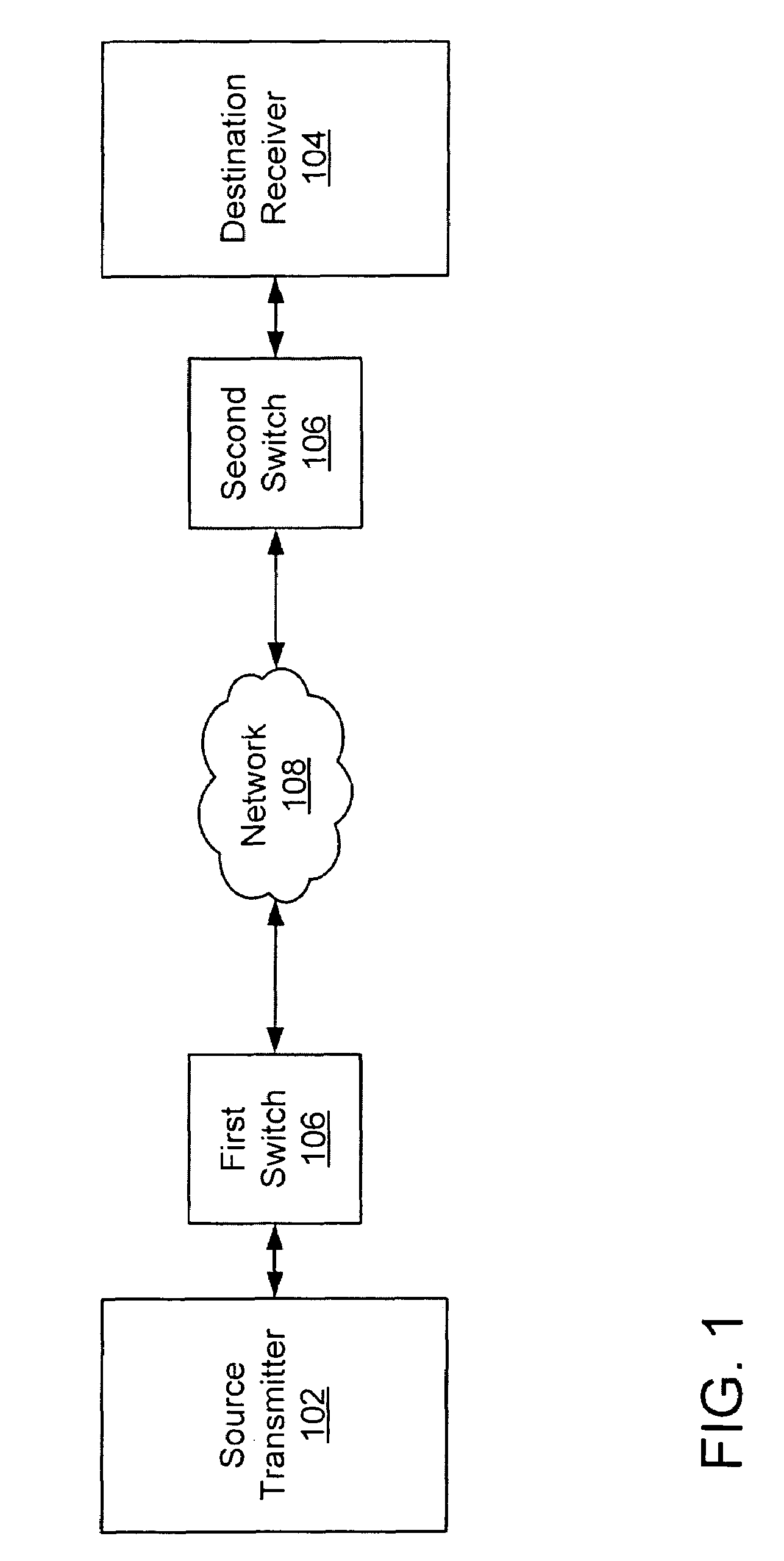

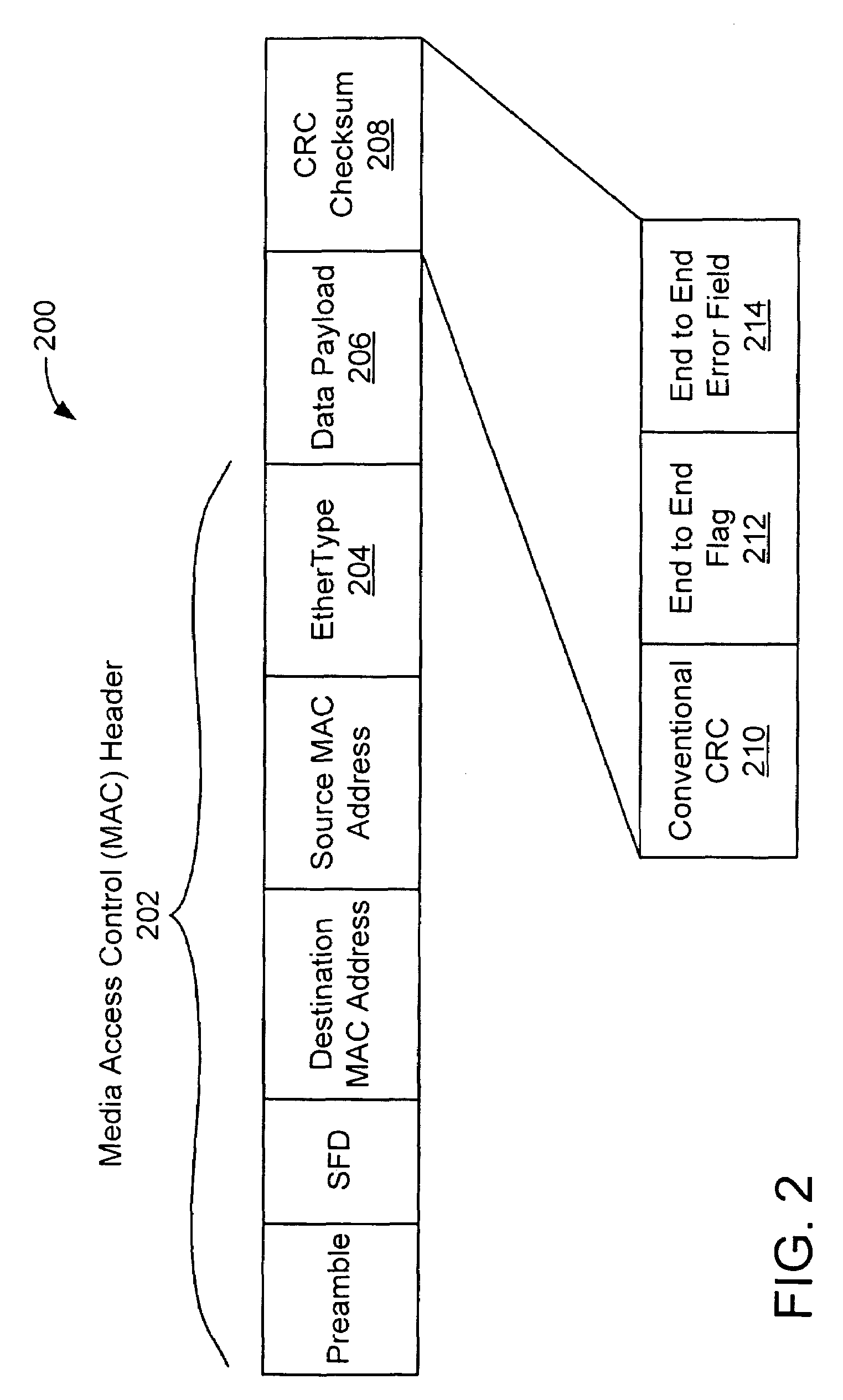

Method, system and computer program product for end to end error checking in ethernet

A method for network protocol error correction comprising, generating a data packet including a cycle redundancy check (CRC) field, an end to end error field that remains unchanged as the data packet is sent over a network, for use in performing error detection in one or more field of the data packet, and a flag field associated with the end to end field to indicate that the end to end error field contains error correction data, and sending the data packet over a network via an Ethernet protocol.

Owner:IBM CORP

Two-wire interface having dynamically adjustable data fields depending on operation code

ActiveUS20050132114A1Overcome problemsMultiplex system selection arrangementsError preventionAction CodeData field

A guaranteed two-wire interface in which upon determining that an operation is to be performed on a slave component, a master component transmits at least a portion of a corresponding frame to the slave component over the data wire. The master component repeats this detection and transmission each time it determines that an operation is to be performed on a slave component, whether the same component or a different slave component as the slave component previously communicated with. The frame structure itself may change depending on the operation to be performed. For example, one frame might include an extended address data field that includes extended address information that goes beyond a basic address field included in another frame. One frame may include reliability fields (such as cyclic redundancy checking field, an acknowledgement field, and / or an error field), whereas another frame having a different operation may not.

Owner:II VI DELAWARE INC

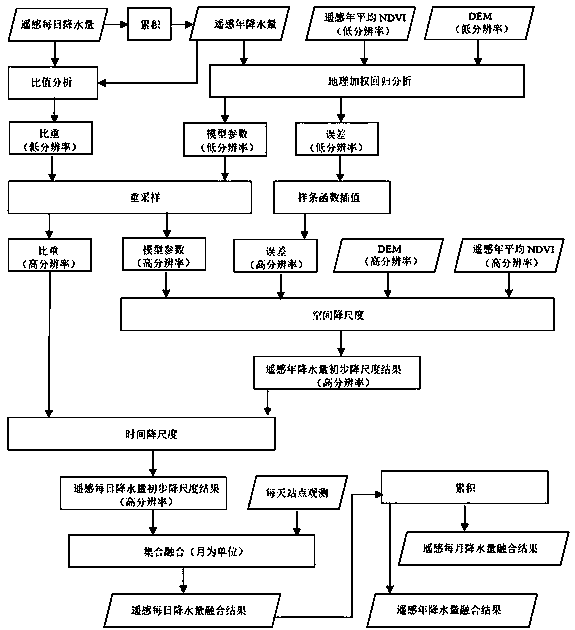

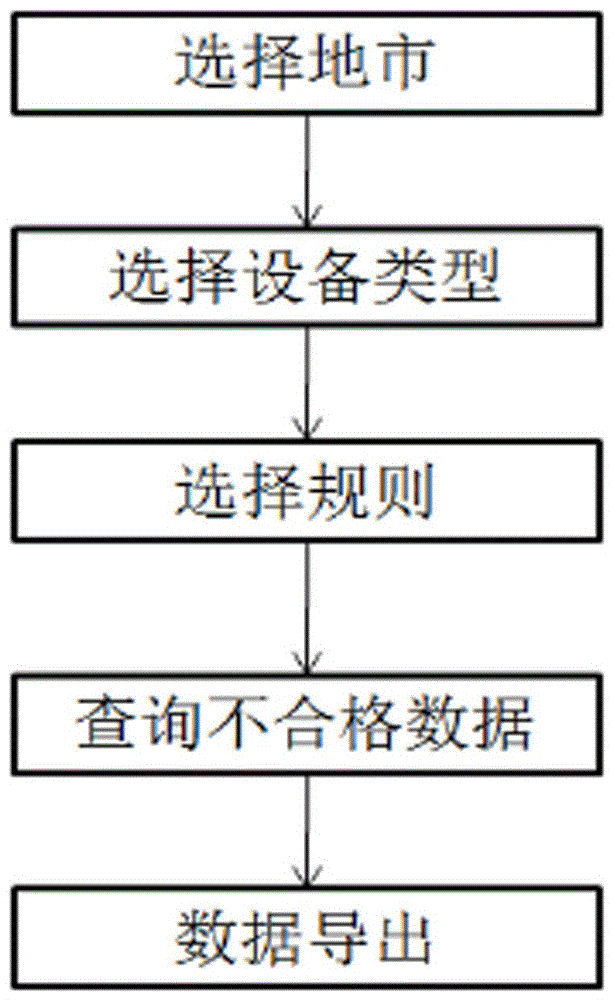

A spatial downscaling method for remotely sensed daily precipitation data

ActiveCN109325540AImprove monitoring effectImprove spatial resolutionCharacter and pattern recognitionImage resolutionSpacetime

A spatial downscaling method for remotely sensed daily precipitation data comprises the following steps of firstly using a temporal-spatial downscaling scheme to indirectly realize downscaling of theremotely sensed daily precipitation data, and obtaining a preliminary downscaling result of the remotely sensed daily precipitation; secondly using an ensemble fusion method to obtain the result of daily precipitation fusion based on the monthly data, which integrates the results of daily precipitation downscaling of all remote sensing stations and daily observation in the month; then accumulatingthe daily precipitation fusion results to generate monthly or annual precipitation fusion results. The method of the invention can overcome the limitation of the prior art, considers the spatial non-stationary relationship between precipitation and auxiliary environmental factors and the temporal variation of daily precipitation, at the same time, the spatial resolution and precision of daily precipitation can be greatly improved by taking full account of the whole error field of the preliminary downscaled results of daily precipitation. In addition, the capability of detecting precipitationand non-precipitation areas can be significantly improved.

Owner:HENAN UNIVERSITY

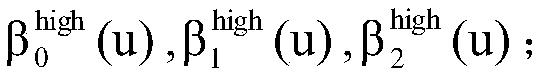

Production management system distribution network equipment machine account intelligent inspection system

InactiveCN105678646AHigh speedImprove integrityData processing applicationsInformation technology support systemTerra firmaData integrity

The invention belongs to the electric power technical field, especially a production management system distribution network equipment machine account intelligent inspection method based on technical parameter relevance. The method comprises: based on distribution network equipment theoretical knowledge and in-depth knowledge of parameters, stipulating the parameter scope of distribution network equipment machine account fields; according to the relevance among fields, employing a DELPHI programming curing formula to automatically inspect machine accounts; describing error causes of error fields in displayed results; and running statistics on the error rate of each city bureau. The method can save manpower and material resources, avoid leakage of inspection and inaccurate inspection in a manual machine account inspection process, improve distribution network equipment machine account data integrity and accuracy, and lay a firm foundation for advanced application development of distribution network equipment in a PMS (production management system). The method increases a machine account inspection speed, guarantees advanced application development of equipment such as a transformer in a PMS, and promotes PMS stable and efficient operation.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +1

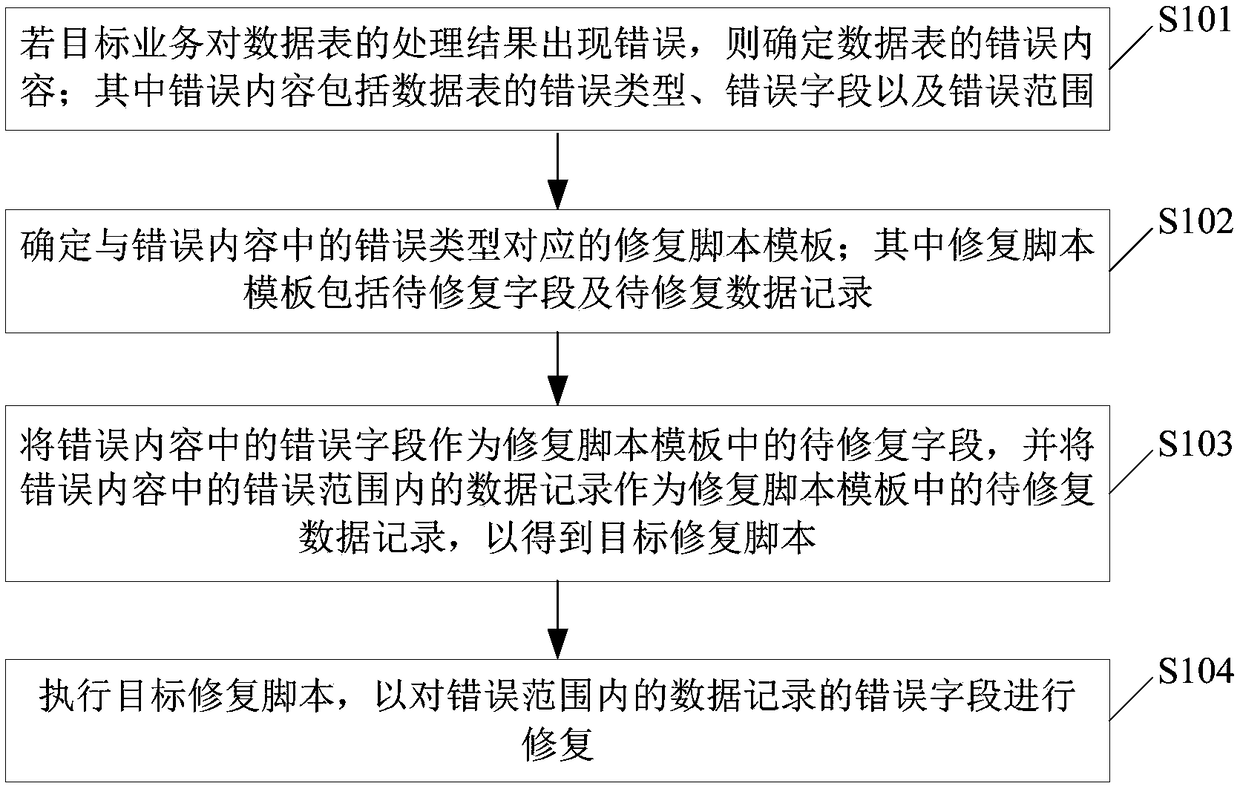

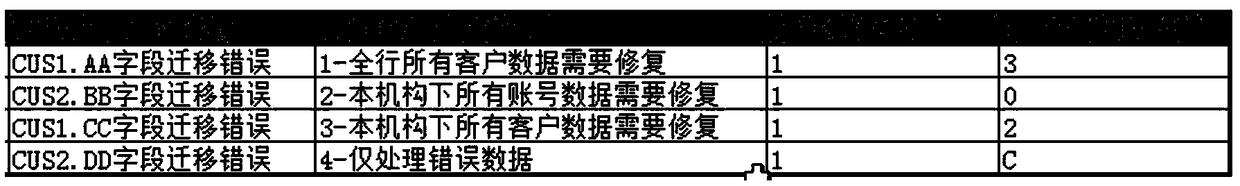

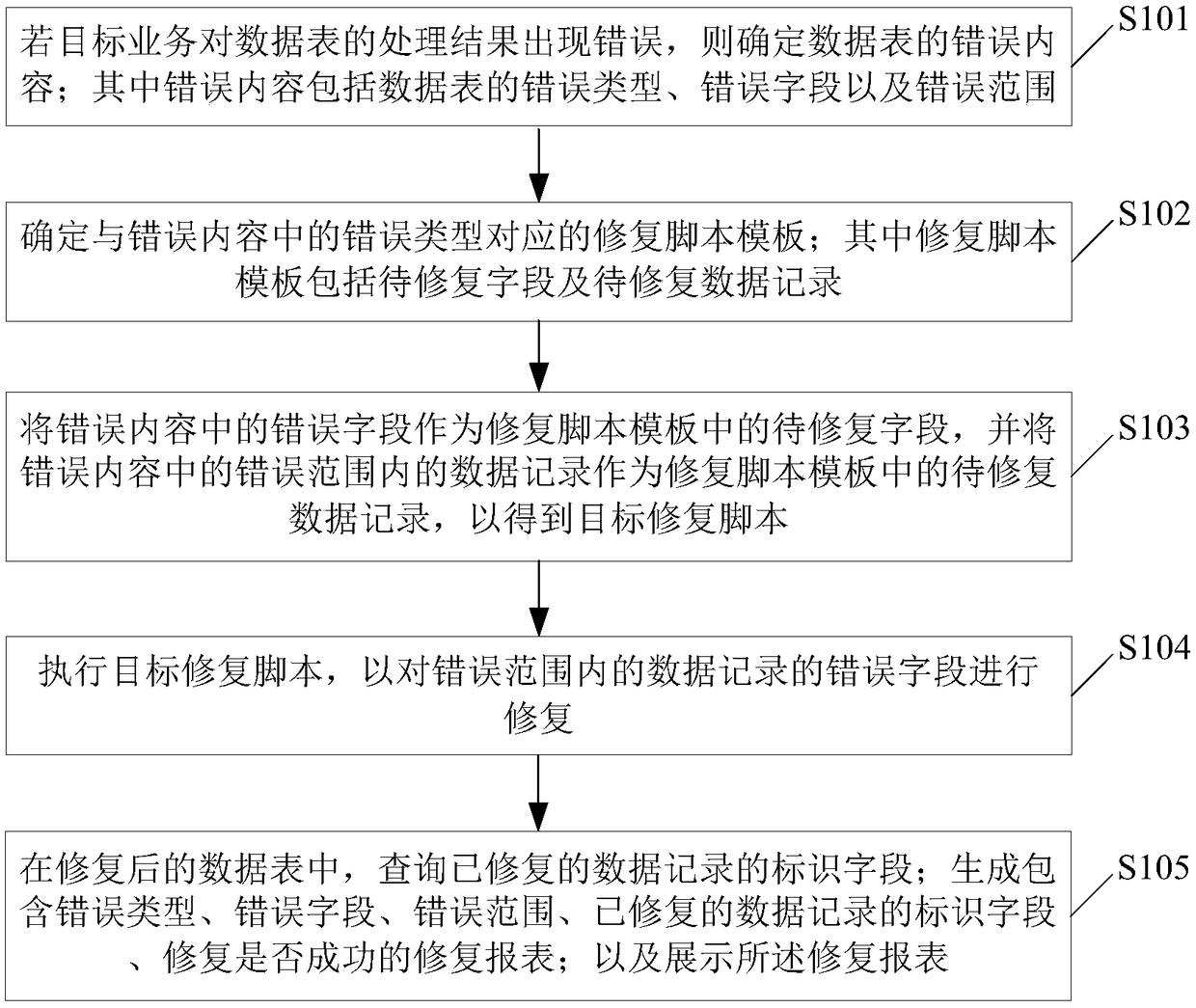

Data regulation method and device

The invention provides a data regulation method. The method comprises the following steps that: when the processing of a data table by target business has errors, determining the error contents of thedata table; then, according to error types in the error contents, determining a repairing script template, wherein the repairing script template comprises a field to be repaired and a data record tobe repaired; taking an error field in the error contents as the field to be repaired, and taking the data record contained in an error range in the error contents as the data record to be repaired soas to obtain a target repairing script; and executing the target repairing script to repair the error field of the data record in the error range. Obviously, by use of the method, the data with errorsafter migration can be repaired, and in addition, the repairing method can use the preset repairing script template so as to be convenient and quick. The invention also provides a data regulation device which is used for guaranteeing the application and the implementation of the method in practice.

Owner:BANK OF CHINA

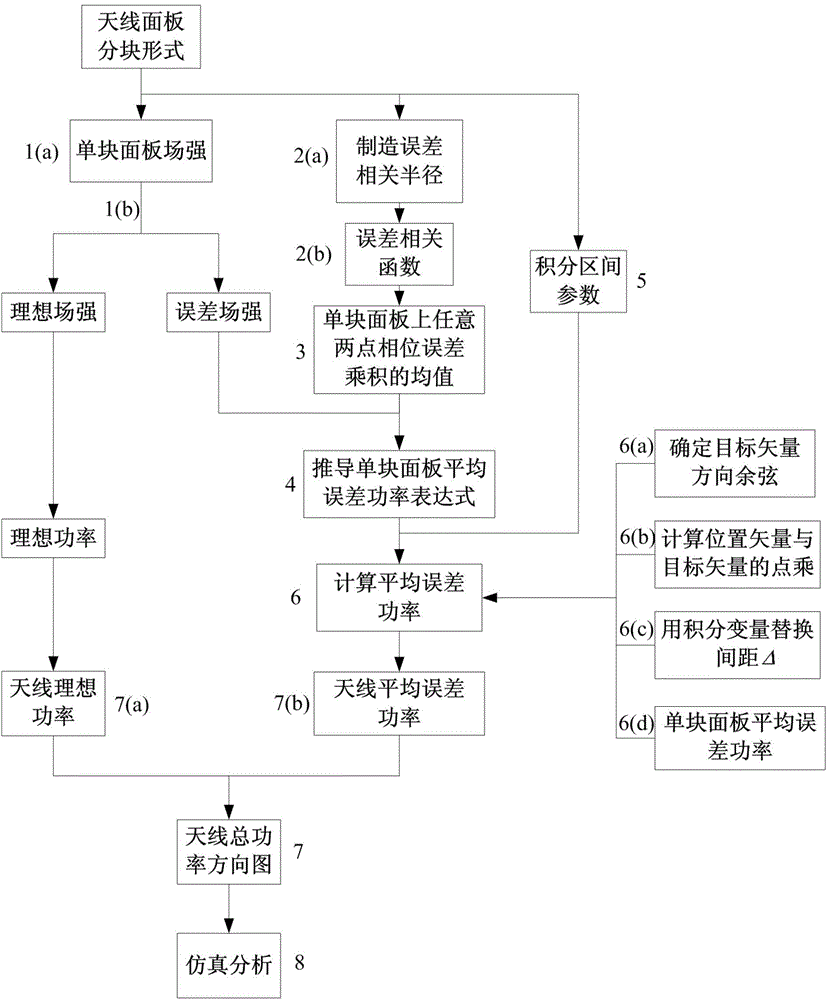

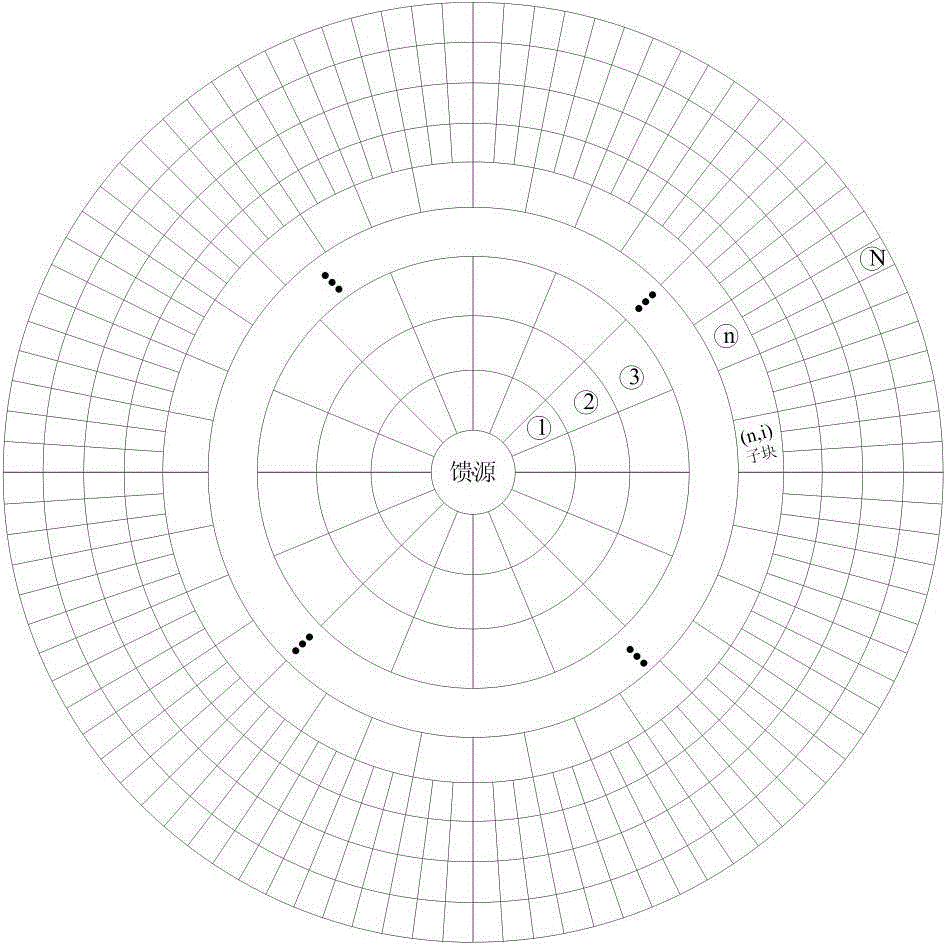

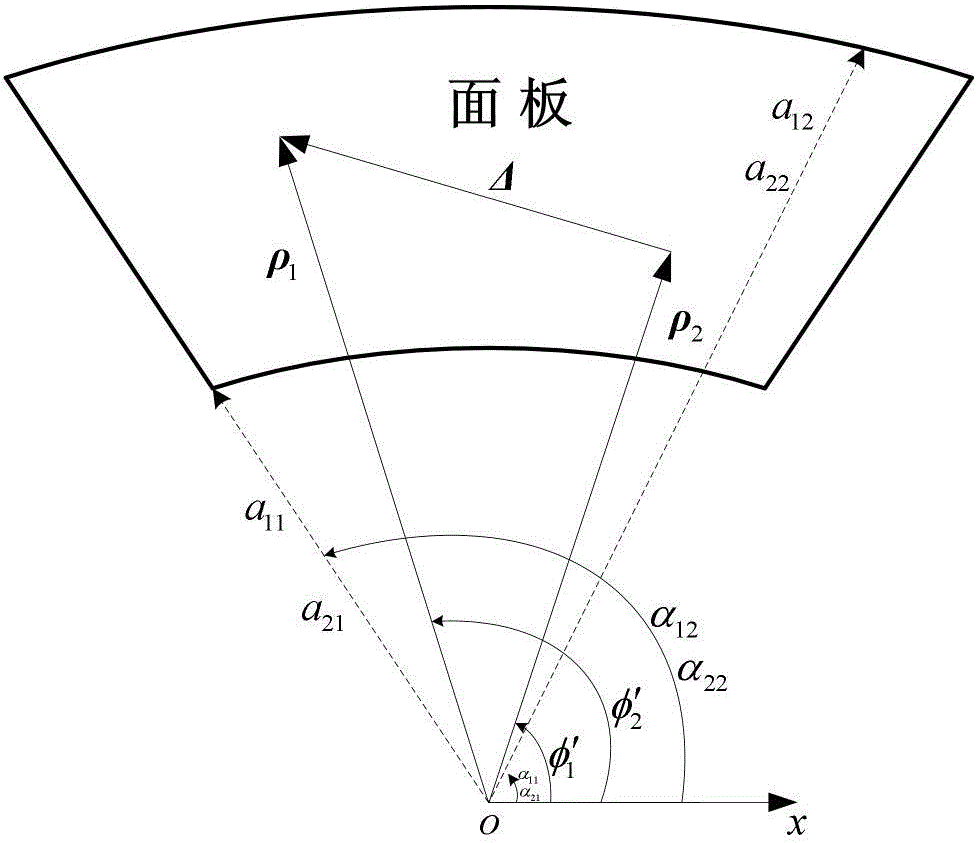

Method for calculating influence of panel machining errors to electrical property based on partitioning mode

InactiveCN104063587ASmall amount of calculationAvoid defects that cannot be fully representedSpecial data processing applicationsElectricityLimit value

The invention relates to a method for calculating influence of panel machining errors to electrical property based on a partitioning mode, and is used for guiding panel surface machining and simulation analysis and evaluation on the electrical property of an antenna. A distant field influenced by surface error is expressed as the sum of an ideal field and an error field, when the average power of the antenna is solved, error power between different panels is simplified to be zero for processing, and the calculation amount is reduced; according to the actual partitioning mode of the antenna, the influence of surface machining errors to the electrical property is calculated and is closer to engineering practice; the average error power of a single panel is solved by accurate four numerical integration, and the defect that in the prior art, an integral time distance vector delta cannot be completely expressed is avoided; an upper limit value of a surface error root-mean-square is obtained by simulation analysis, the excessive accuracy requirement made by experience is avoided, and electrical property indexes are satisfied while the machining difficulty is reduced.

Owner:XIDIAN UNIV

System and method of quality assessment of a search index

ActiveUS8983920B2Digital data processing detailsWebsite content managementIndex systemQuality assessment

Owner:OPEN TEXT SA ULC

Apparatus and method for improved interlace processing

InactiveUS20060002480A1Easy to compressAvoids inefficiency and inadequacyColor television with pulse code modulationColor television with bandwidth reductionInterlaced videoImaging processing

An interlaced image processing module and corresponding method facilitate improved processing of interlaced motion images. In one embodiment, the interlaced image processing module receives image data frames having interlaced first and second fields and produces a reference field and error field. The reference field corresponds to the still image content of the interlaced frame, whereas the error field corresponds to the motion content of the interlaced frame, particularly the motion between fields. Motion between fields is thus represented in the error field, without redundant representation of the still image content provided by the first field. Where there is little motion between fields, the error terms will be small so the predictor preserves the coding efficiency provided by any auto-correlation in the image. Further, the interlaced image processing method does not rely upon pixel group classification, and thus avoids classification errors, and the loss of coding efficiency from still image content in motion classified blocks. Finally, problems presented by relative motion between fields are avoided, as are local artifacts. Another embodiment transforms the interlaced fields into frame data having a high frequency field and a low frequency field.

Owner:QUVIS

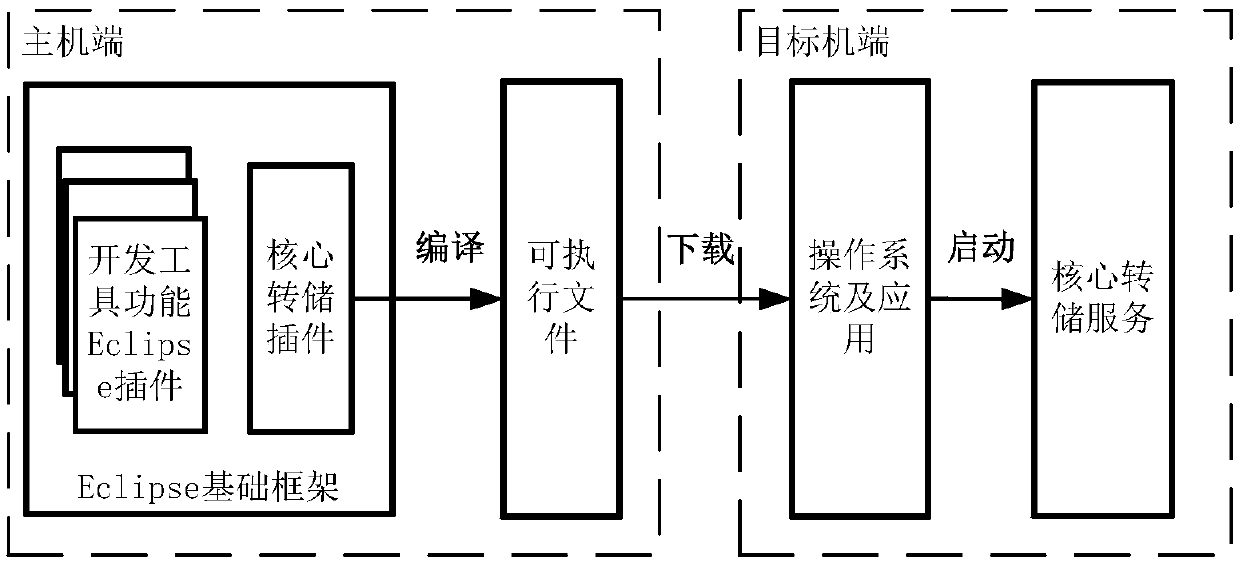

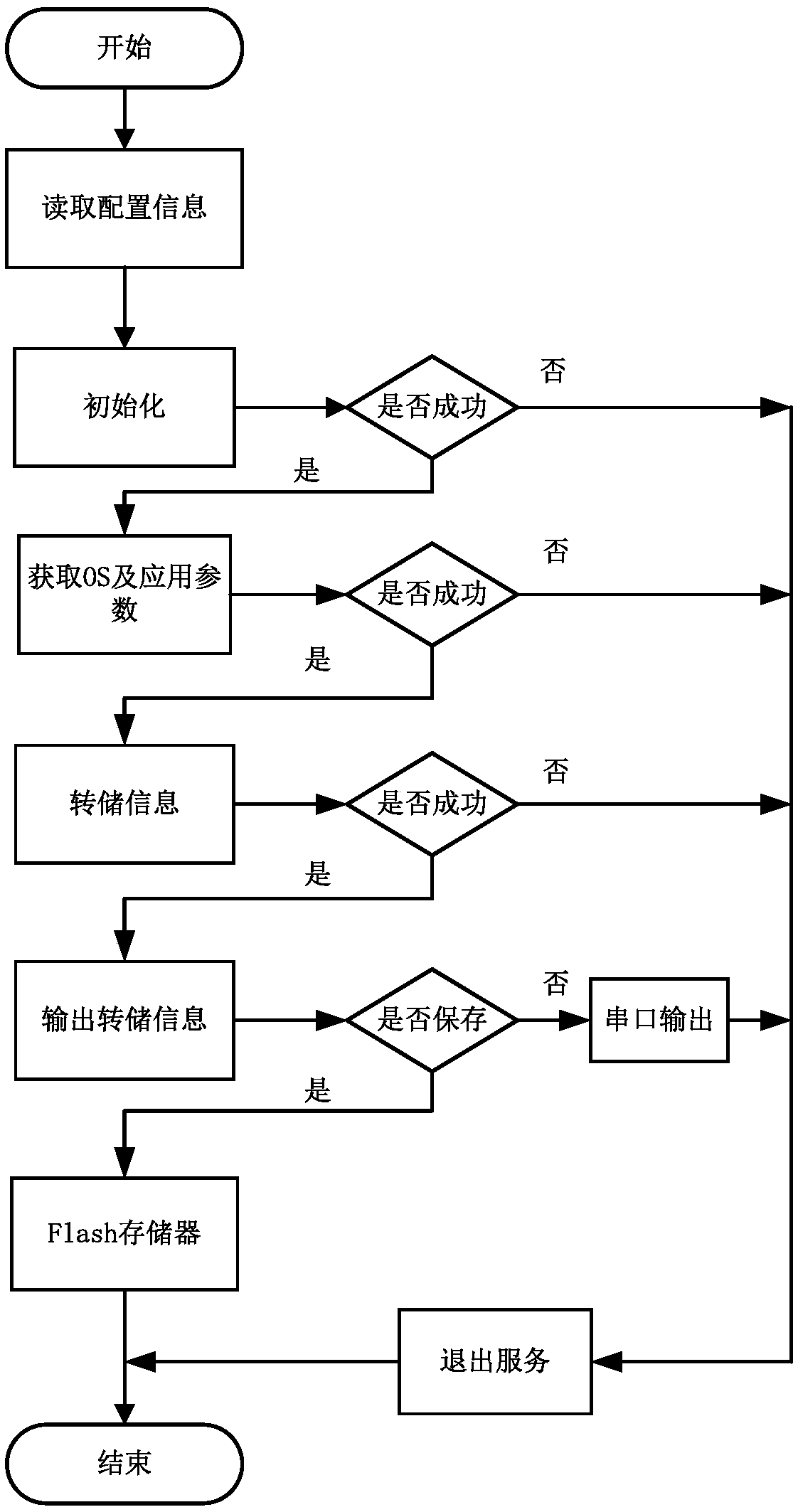

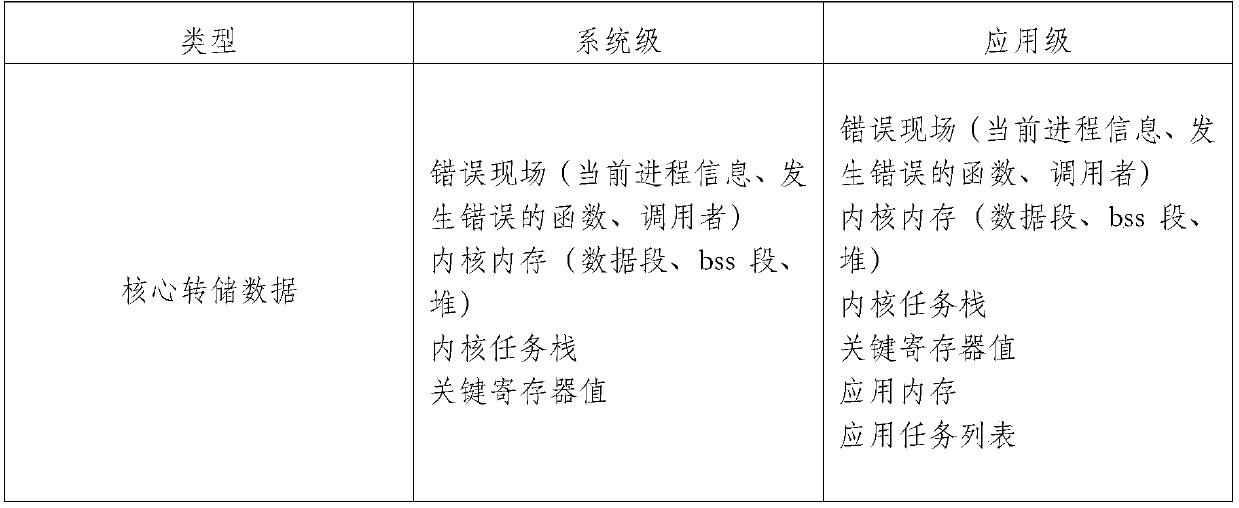

An embedded system core dump method

ActiveCN109582542AResolve error field captureResolve error message storageHardware monitoringCall stackCore dump

The invention belongs to the technical field of computer system software specialty. Based on an embedded development environment, by use of a software structure which is configured by a host end and achieved on a target machine end, acquisition of system memory and program information is supported according to a core dump type, corresponding core dump information is generated and stored, and the problems of error field capture, error information storage, error analysis difficulty and the like of an embedded system are better solved. According to the invention, the graphical configuration of the system is supported, and the graphical configuration interface is provided at the host end, so that the usability and the intuitiveness of the core dump configuration are improved; Core dump information is supported to be acquired from an operating system and specifically comprises a memory, a register state, a stack state, memory management information and various function call stack information during program running, so that the reliability and integrity of acquiring the core dump information are improved; Storage of the output core dump information is supported, the safety of the core dump information is improved, and then the error positioning and troubleshooting efficiency is improved.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

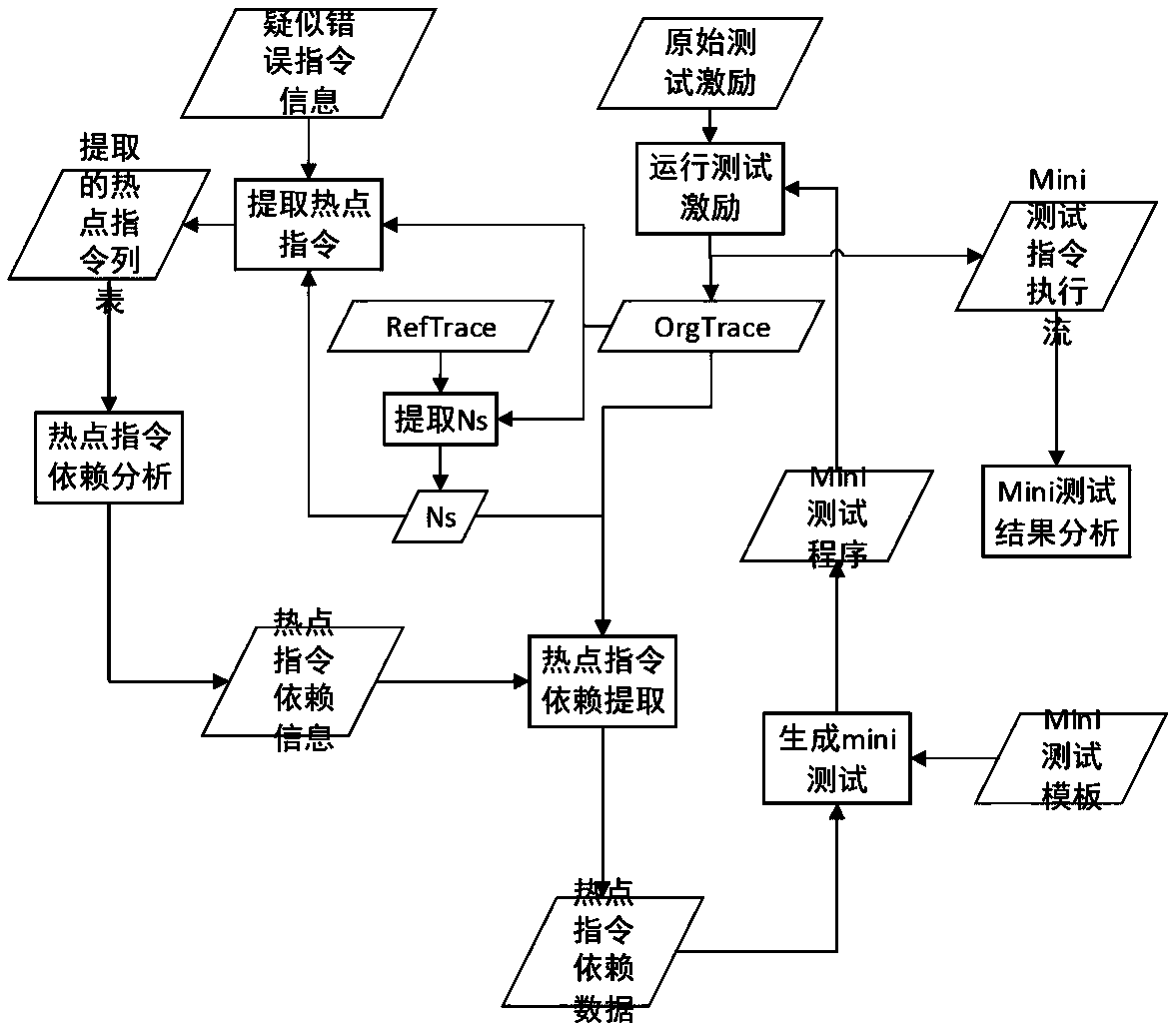

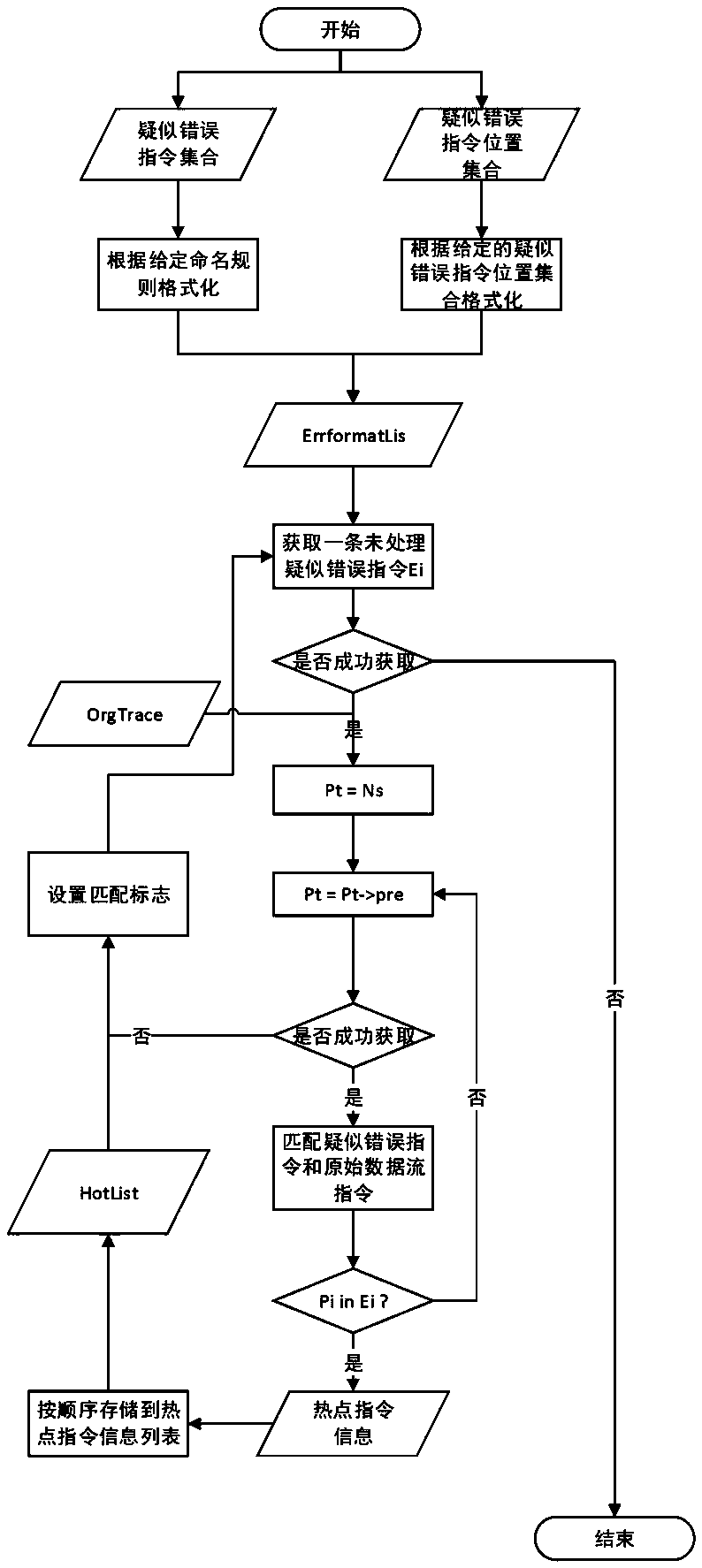

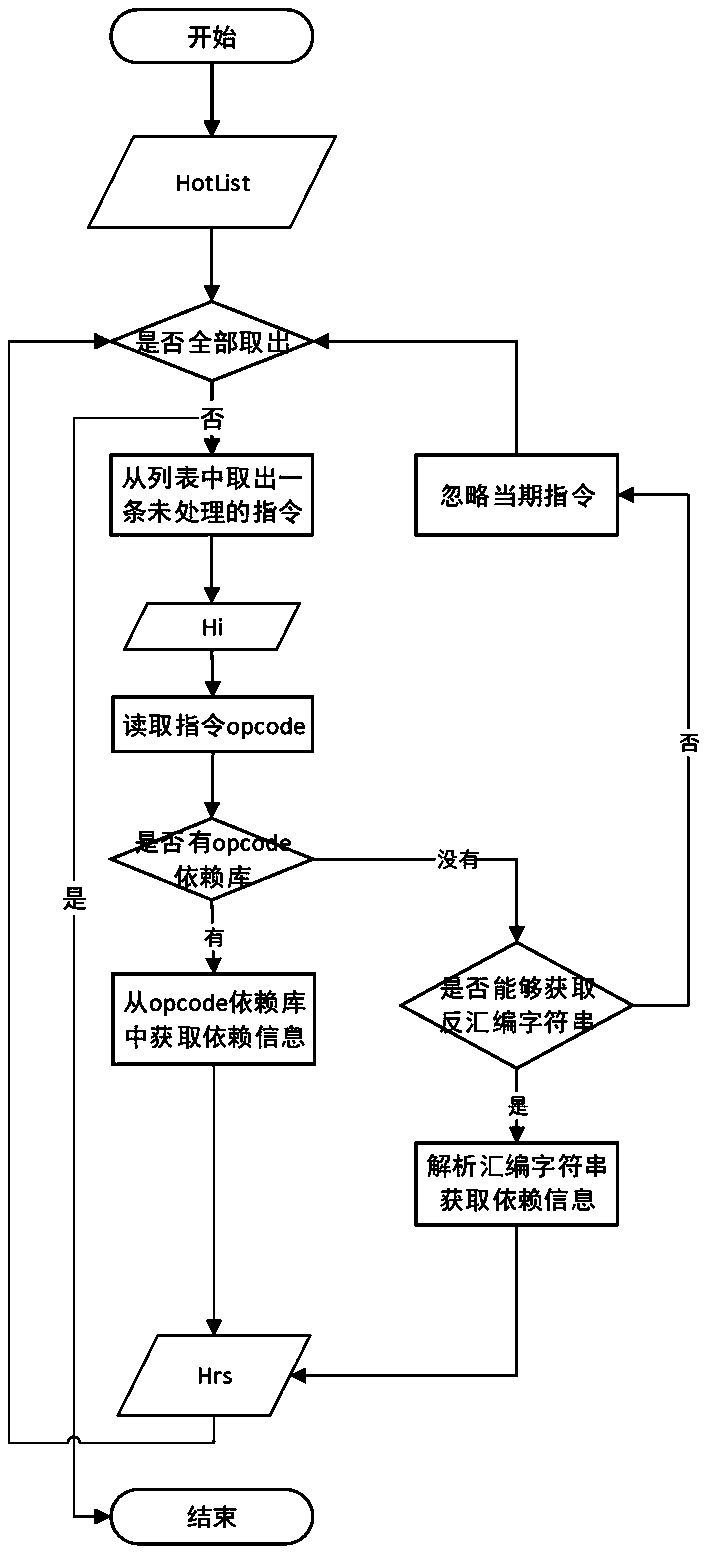

A processor debugging method for extracting fault field feature test excitation

The invention discloses a processor debugging method for extracting error field characteristic test excitation. The method comprises executing the original test excitation and records the original execution data stream in the running environment; according to the information of the designated suspected error instruction, searching the original execution data stream to obtain the hot instruction and obtaining the hot instruction list; the hot instruction list being analyzed one by one to retrieve the register information that the instruction depends on; searching data corresponding to all dependency information of all hot-spot instructions in the original execution data stream; converting hot instructions and corresponding dependency data into test code and compiling to generate executablefeature test excitation; running feature test incentives in the test environment, recording the running status of running feature test incentives or using debugging methods for debugging. The invention reduces the time for finding error points and reproducing errors in the debugging process by automatically extracting characteristic test incentives from the original incentives through a given flowand information, thereby reducing the time and energy spent in the whole debugging process.

Owner:PHYTIUM TECH CO LTD

Up-sampled filtering for servo demodulation

InactiveUS7583469B1Record information storageAlignment for track following on disksHard disc driveHarmonic

An apparatus, method, and system for providing a fine adjustment for transducing head positioning in a hard disk drive (HDD). The apparatus, method, and system include reading a positioning error field wherein the resulting signal is a substantially sinusoidal position error signal (PES), filtering the PES to remove low frequencies and attenuate high frequencies, sample the filtered PES at a multiple of the channel frequency, filter the higher frequency harmonics, down sample the PES, and provide a signal proportional to the amplitude of the down sampled PES. This signal is the reference signal to the head positioning servo.

Owner:MARVELL INT LTD

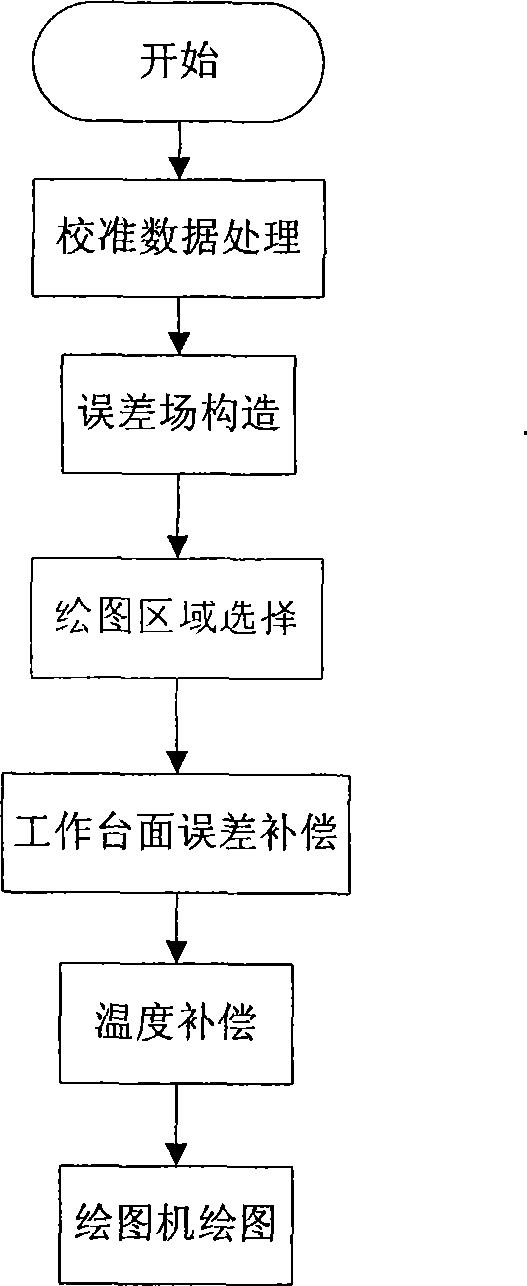

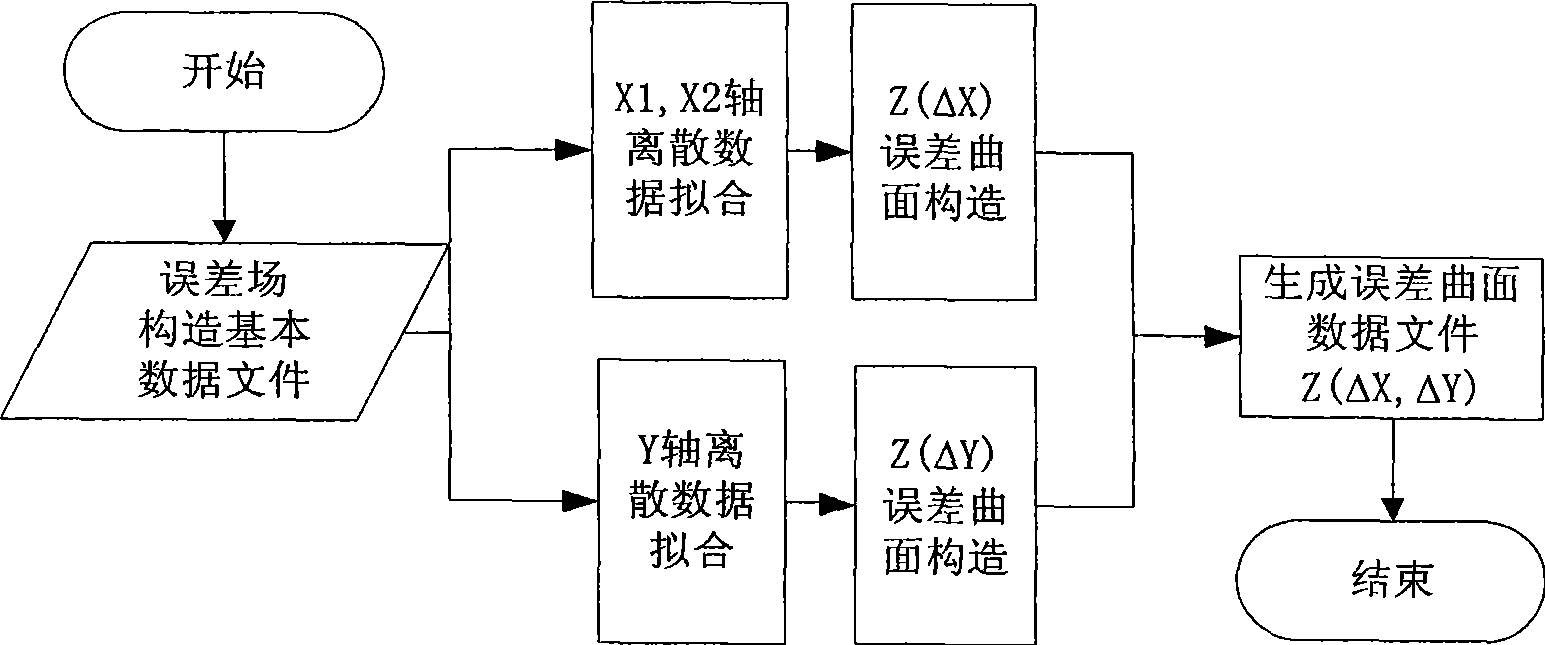

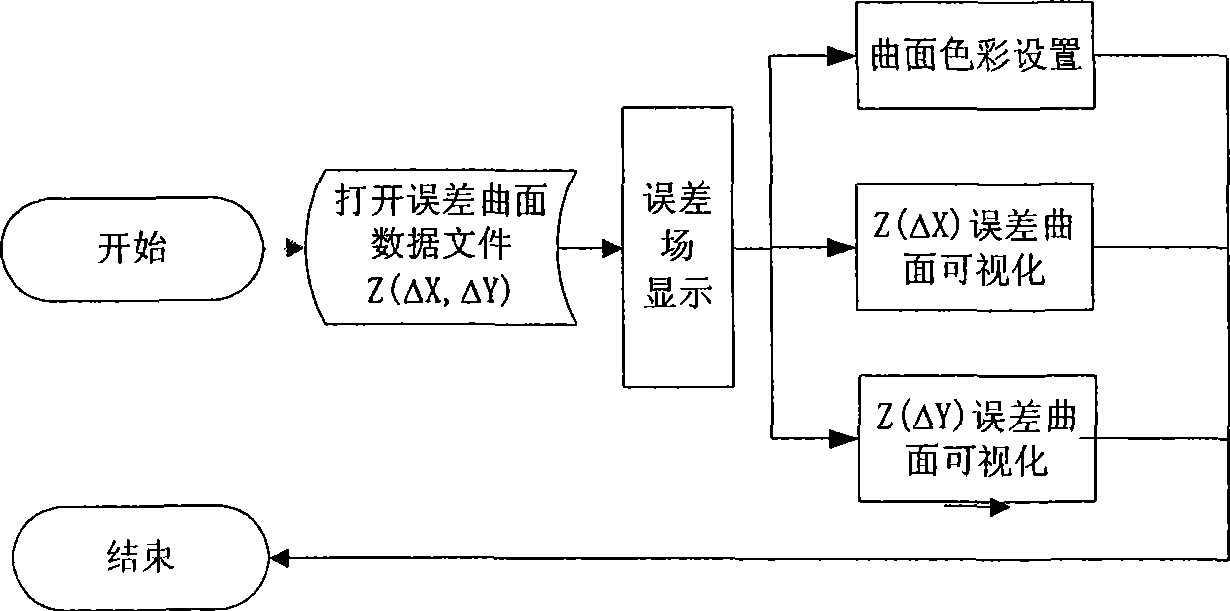

Precision compensation method for pen type graph plotter based on error field

InactiveCN101544150AOptimize workflowEliminate the effect of drawing precisionWriting aidsGraphicsTemperature difference

The invention discloses a precision compensation method for a pen type graph plotter based on an error field. The method comprises the following steps: basic data of a structure of the error field is input through a calibration graph plotter, and an error distribution field of a working table of the graph plotter is constructed; all the geometric graph elements needed to be drawn are extracted to determine the size of a mapsheet, and one drawing work area which can contain all the graph elements is selected according to distribution of the error field to ensure that error distribution at the position is the least; according to a starting point, an end point and the geometric graph of each graph element, error compensation is respectively carried out, a deformation error of the working table generated by temperature difference between field temperature and calibration temperature is comprehensively considered to carry out temperature compensation at the same time; and subsequent format conversion and drawing plotting are carried out on a file after being compensated twice. The invention basically eliminates influence of aging of the graph plotter and working field temperature to the drawing accuracy, enhances the drawing efficiency of the graph plotter, prolongs the service life of the graph plotter, and reduces the maintenance cost and the repair cost of the graph plotter.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Three-dimensional measurement system and method of steel plate combined with laser and vision

InactiveCN103438826B3D measurement fastAccurate 3D measurementUsing optical meansThree dimensional measurementTotal station

The invention discloses a three-dimensional measurement system and three-dimensional measurement method for a steel plate with lasers and vision combined. The system is mainly composed of two background projectors, a total station, a three-dimensional scanner and a GPU server. The background projectors, the three-dimensional scanner and the total station are all connected to the server. The method comprises the steps that a plurality of laser labels are placed around the steel plate to be measured; the lasers are used for measuring the three-dimensional coordinates of the labels, and two cameras in the three-dimensional scanner are used for shooting the laser labels; an HOG and an SVM are used for detecting the original positions of the labels; a DOG is used for precisely locating the center of the labels; the three-dimensional coordinates of the labels are measured, the coordinates are converted into a laser coordinate system from a visual system, the errors of a calculation sum are obtained, and an error field is constructed; the scanner is used for measuring the steel plate to be measured to obtain the three-dimensional data of the steel plate; the error field is used for correcting the three-dimensional data of the steel plate to obtain the more accurate three-dimensional data of the steel plate. Laser measurement and vision measurement are combined, and the errors of the vision measurement can be greatly reduced.

Owner:JIANGSU UNIV OF SCI & TECH

System and method of quality assessment of a search index

ActiveUS20150154245A1Digital data processing detailsWebsite content managementIndex systemQuality assessment

Owner:OPEN TEXT SA ULC

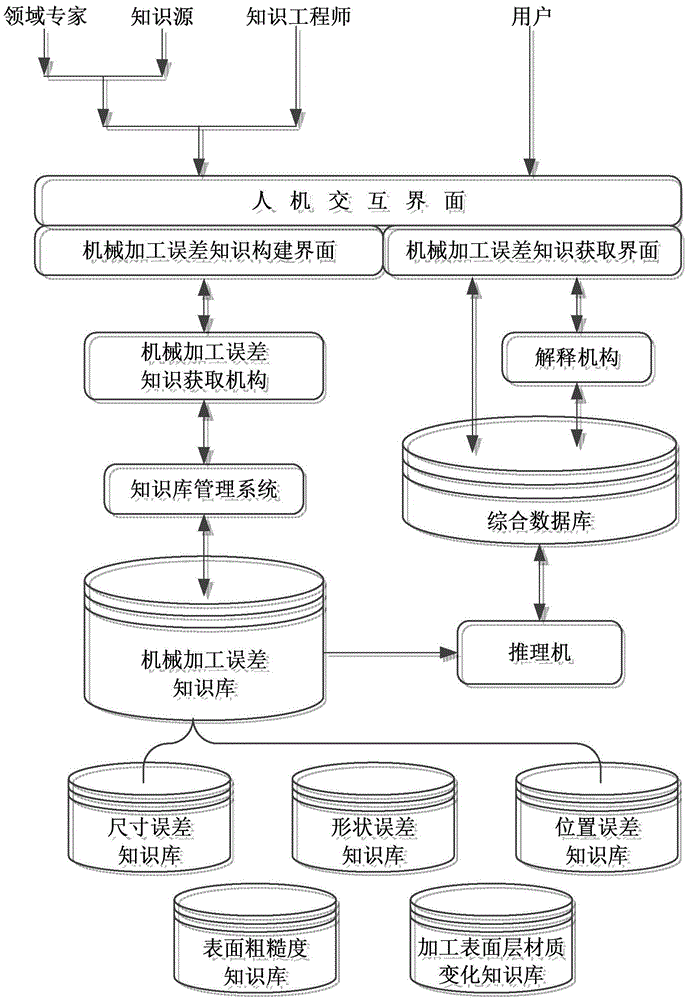

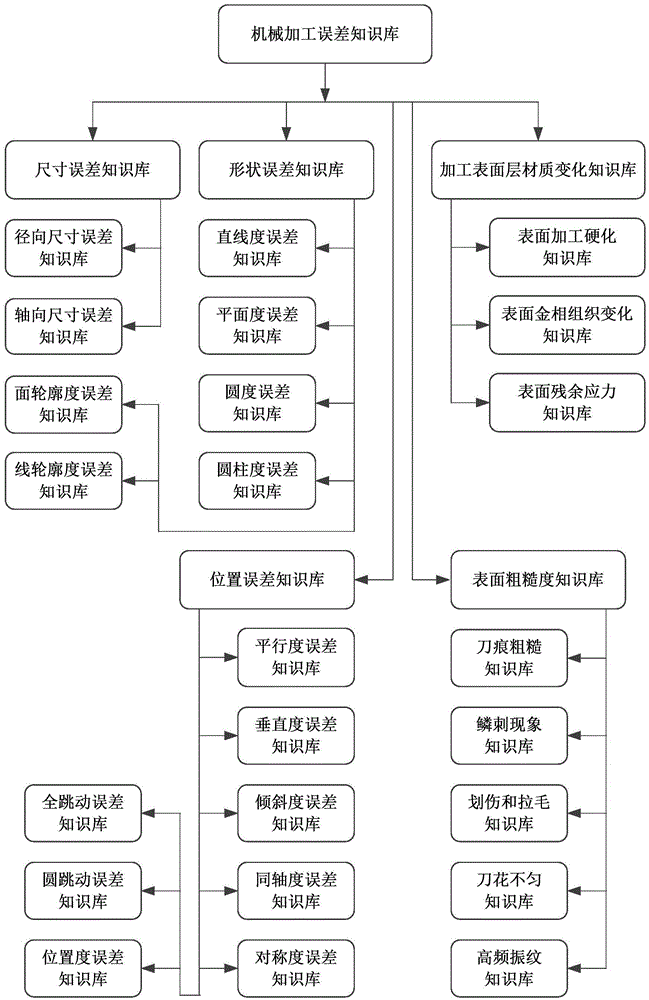

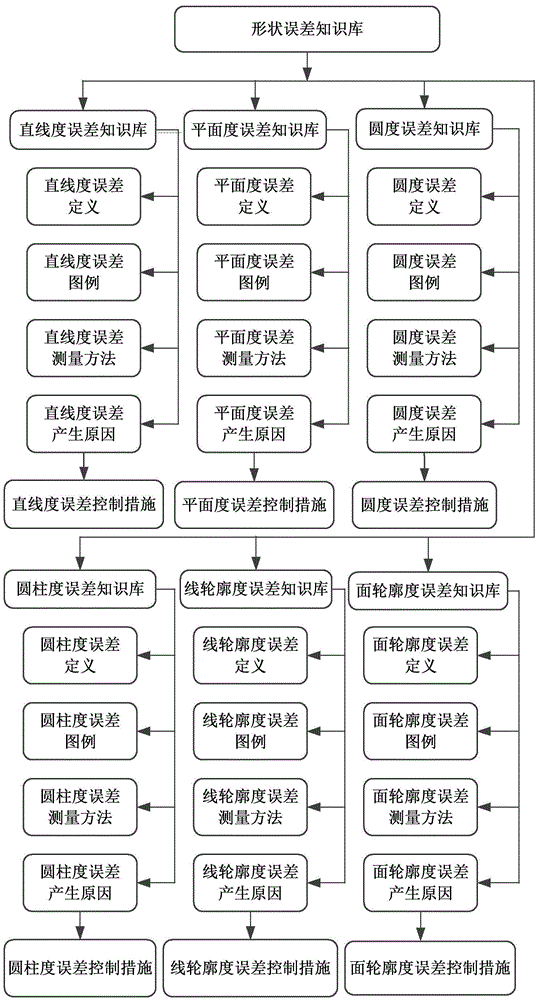

Machining error knowledge base system

InactiveCN105528462AImprove organizationEasy maintenanceSpecial data processing applicationsDatabase design/maintainanceKnowledge sourcesInteraction interface

The invention relates to a machining error knowledge base system. The machining error knowledge base system comprises a human-computer interaction interface; the human-computer interaction interface comprises a machining error knowledge construction interface and a machining error knowledge acquisition interface; an expert from a machining error field and knowledge from a machining error knowledge source are converted into a production rule by using a machining error knowledge acquisition mechanism; the production rule is stored into a machining error knowledge base through a knowledge base management system; a user submits a machining error fact to a synthesis database through a machining error knowledge acquisition interface of the human-computer interaction interface; an inference machine is used for carrying out matching processing on the machining error fact submitted by the user in the synthesis database and an antecedent of the production rule in the machining error knowledge base, and then a consequent of a found matched rule is considered as an inference conclusion which is then stored to the synthesis database; the user acquires the inference conclusion through the machining error knowledge acquisition interface. The machining error knowledge base system has the advantages of favorable reliability, expandability, intelligence and the like.

Owner:XIJING UNIV

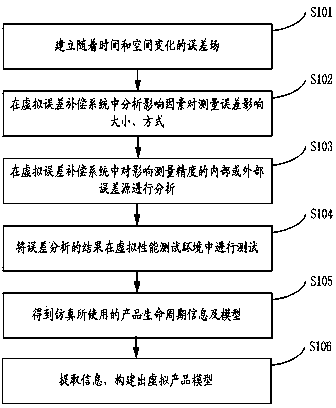

Method for creating virtual prototype product of CMM (coordinate measuring machine)

InactiveCN103646142ASpeed up the design processImprove performanceSpecial data processing applicationsObservational errorCoordinate-measuring machine

The invention discloses a method for creating a virtual prototype product of a CMM (coordinate measuring machine). The method comprises the steps as follows: an error field changing with time and space is established; the magnitude and the manner of an influence of an influence factor on a measuring error are analyzed in a virtual error compensation system; an internal or external error source influencing the measurement accuracy is analyzed in the virtual error compensation system; a result of error analysis is tested in a virtual performance test environment; product life-cycle information and a model which are used during simulation are obtained; and the information is extracted to create a virtual product model. According to the method, the high cost is reduced, and the time for tests is shortened. A CMM design process is accelerated, and the performance of the CMM is improved. Finally, CMM developers can reflect market changes promptly.

Owner:XIAN TECH UNIV

Up-sampled filtering for servo demodulation

InactiveUS7764458B1Record information storageAlignment for track following on disksHard disc driveHarmonic

An apparatus, method, and system for providing a fine adjustment for transducing head positioning in a hard disk drive (HDD). The apparatus, method, and system include reading a positioning error field wherein the resulting signal is a substantially sinusoidal position error signal (PES), filtering the PES to remove low frequencies and attenuate high frequencies, sample the filtered PES at a multiple of the channel frequency, filter the higher frequency harmonics, down sample the PES, and provide a signal proportional to the amplitude of the down sampled PES. This signal is the reference signal to the head positioning servo.

Owner:MARVELL INT LTD

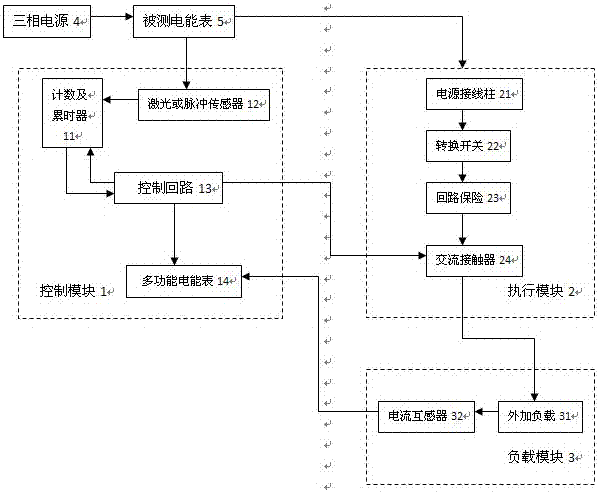

On-the-spot tester for error of electric energy meter with external load of beam pumping unit

InactiveCN104635195BRealize fully automatic controlHigh precisionElectrical measurementsComputer moduleTester device

The present invention provides a beam pumping unit external load electric energy meter error field tester, the beam pumping unit external load electric energy meter error field tester includes a control module, an execution module and a load module, the load module is connected to The control module measures the current signal of the load inside and outside the load module, and transmits the current signal to the control module, the execution module is connected to the control module and the load module, and the execution module is under the control of the control module, Control the switching operation of the external load, the control module controls the operation of the execution module, calculates the number of revolutions of the electric energy meter under test and the time it takes to run, and obtains the current signal when the external load is working, so as to measure the power of the external load power and electricity consumption. The beam pumping unit added load electric energy meter error on-site tester can detect the error of the beam pumping electric energy meter and the current transformer on the spot.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com