Three-dimensional measurement system and three-dimensional measurement method for steel plate with lasers and vision combined

A three-dimensional measurement and combination technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high measurement accuracy, slow measurement speed, and low measurement accuracy, and achieve the effect of accurate three-dimensional measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with specific embodiment, further illustrate the present invention, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various equivalent forms of the present invention All modifications fall within the scope defined by the appended claims of the present application.

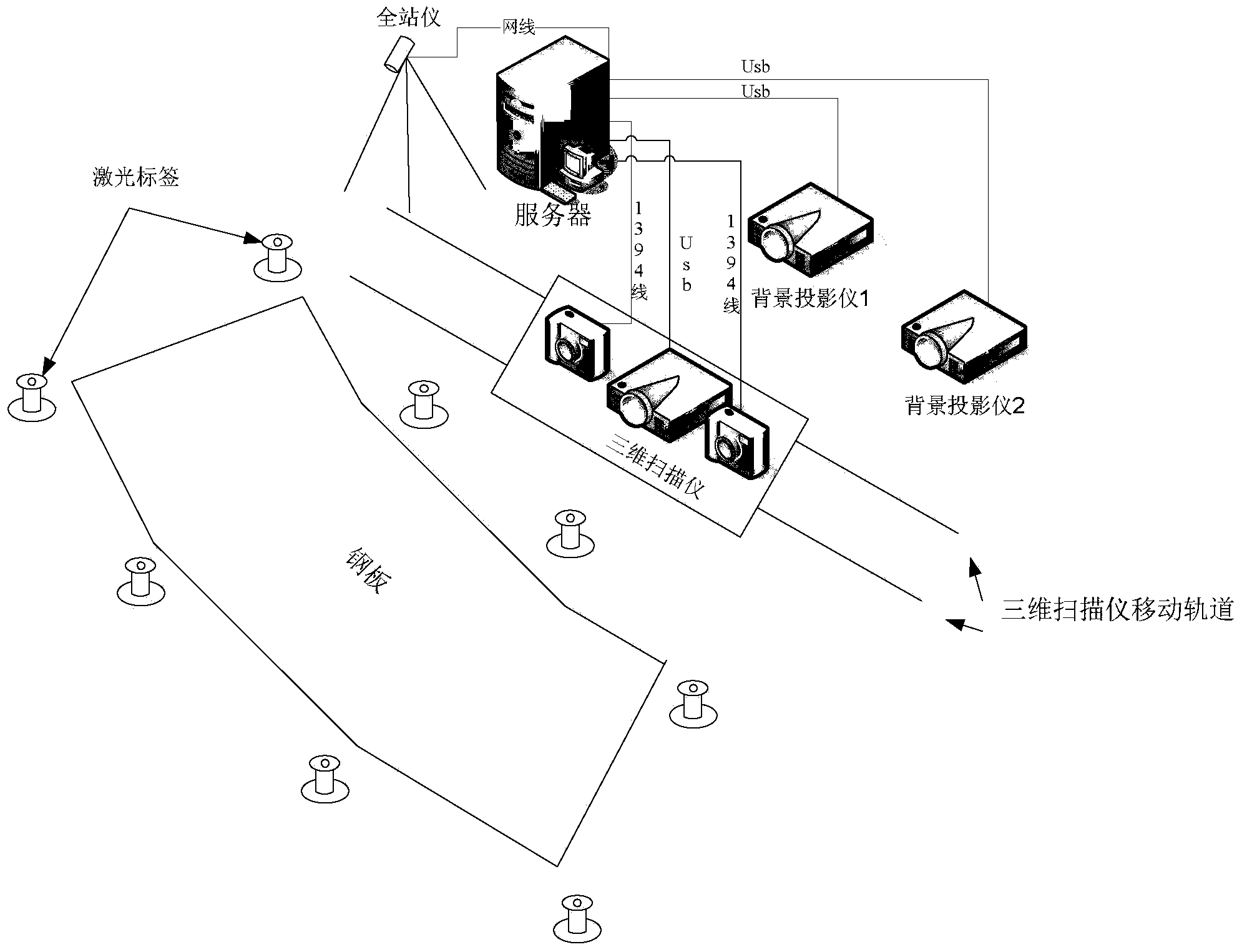

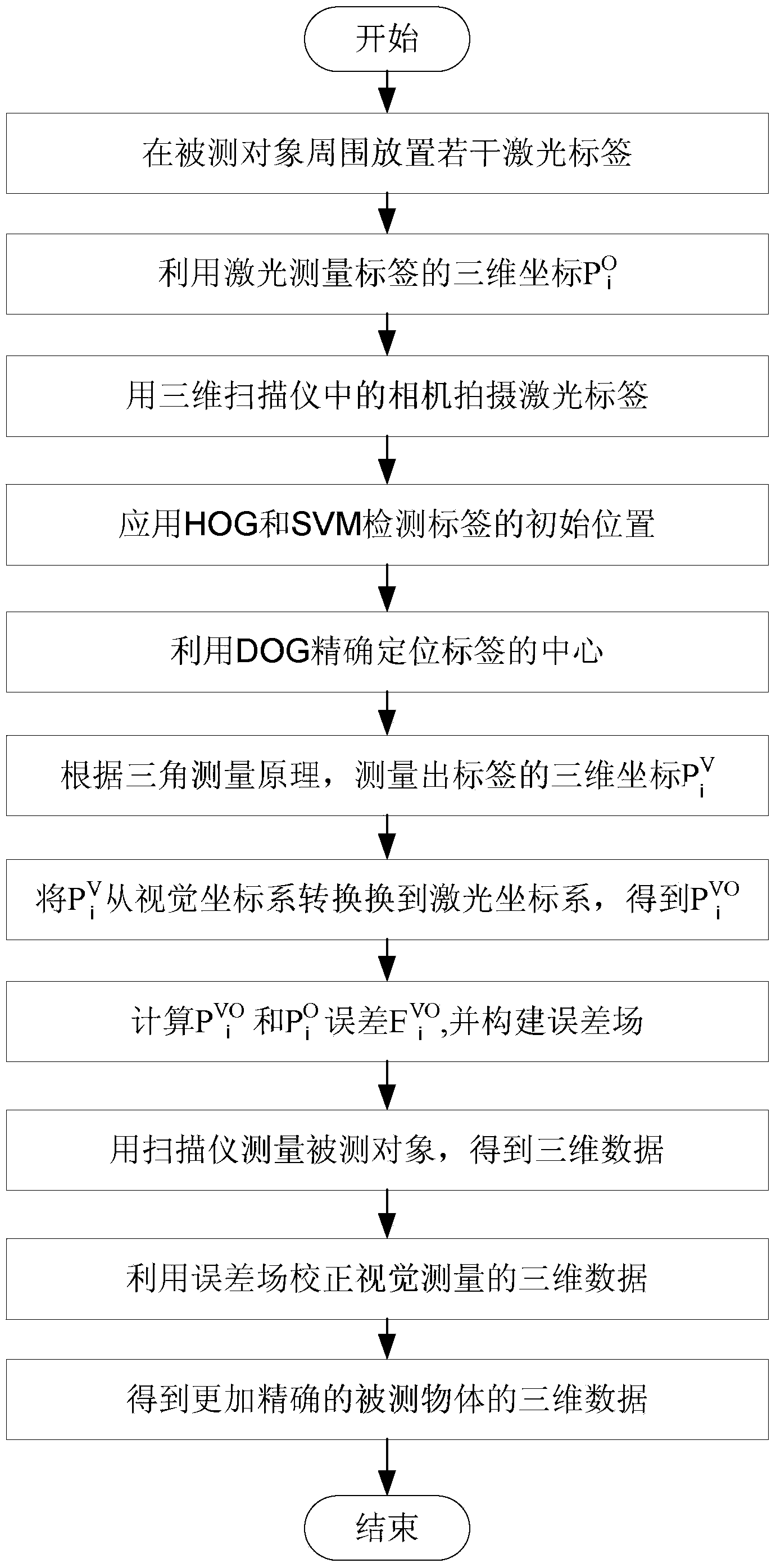

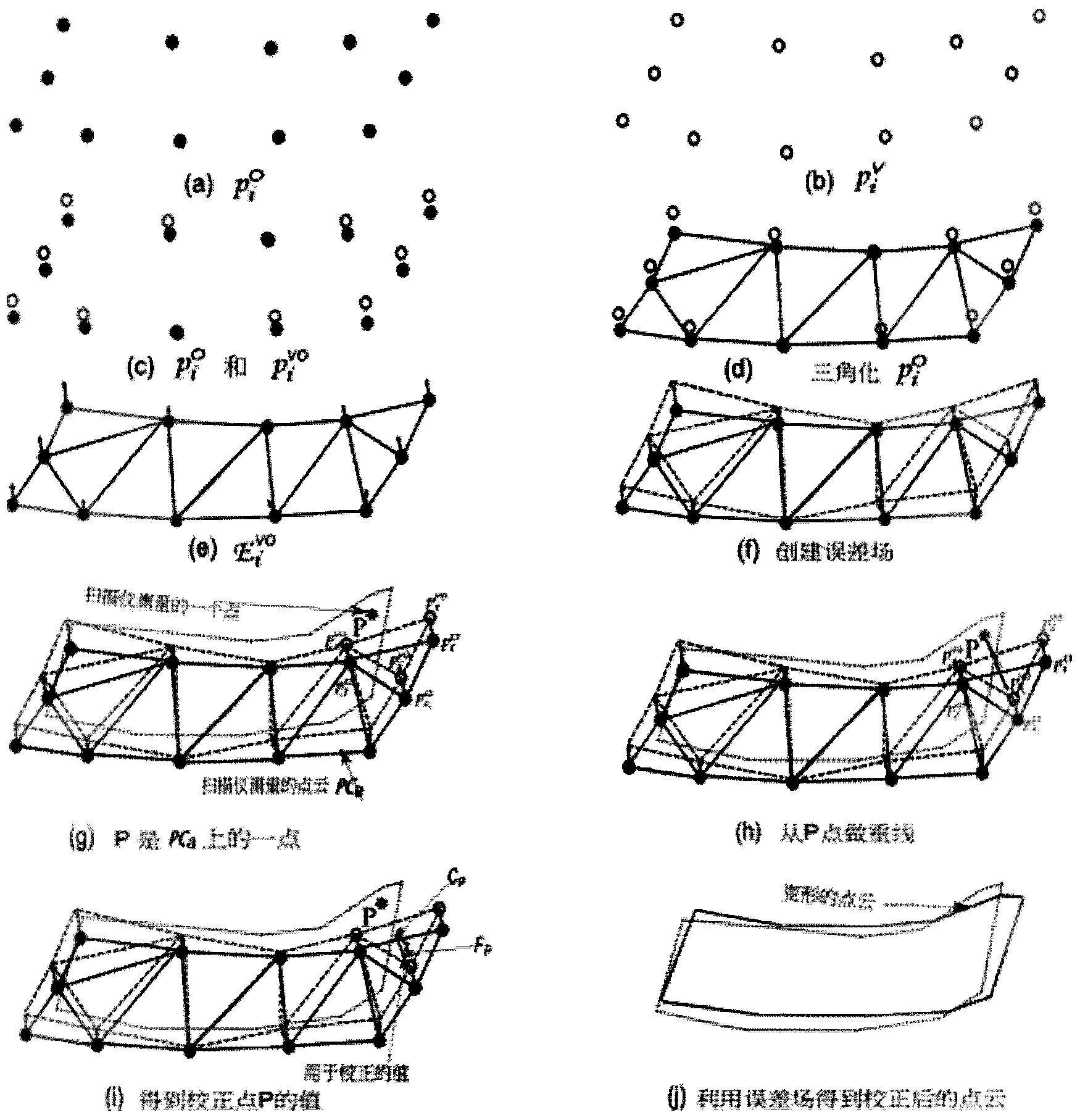

[0021] Such as figure 1 As shown, the system consists of a 3D scanner, two background projectors, a total station and a high-performance GPU server. Among them, the 3D scanner includes a high-brightness projector and two synchronous high-resolution industrial cameras with a resolution of 1440*1080 or higher and a frame rate of 10fps. All cameras in the system are connected to the server through 1394 lines and 1394 cards; all projectors are connected to the server through usb interfaces; total sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com