Object three-dimensional measurement system and measurement method based on structured light

A technology of three-dimensional measurement and measurement system, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of oblique trigonometry, such as complex implementation, limited application scenarios, and inability to meet different application scenarios, and achieve simple structure and equipment Effect of simple maintenance and simplified refraction compensation model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

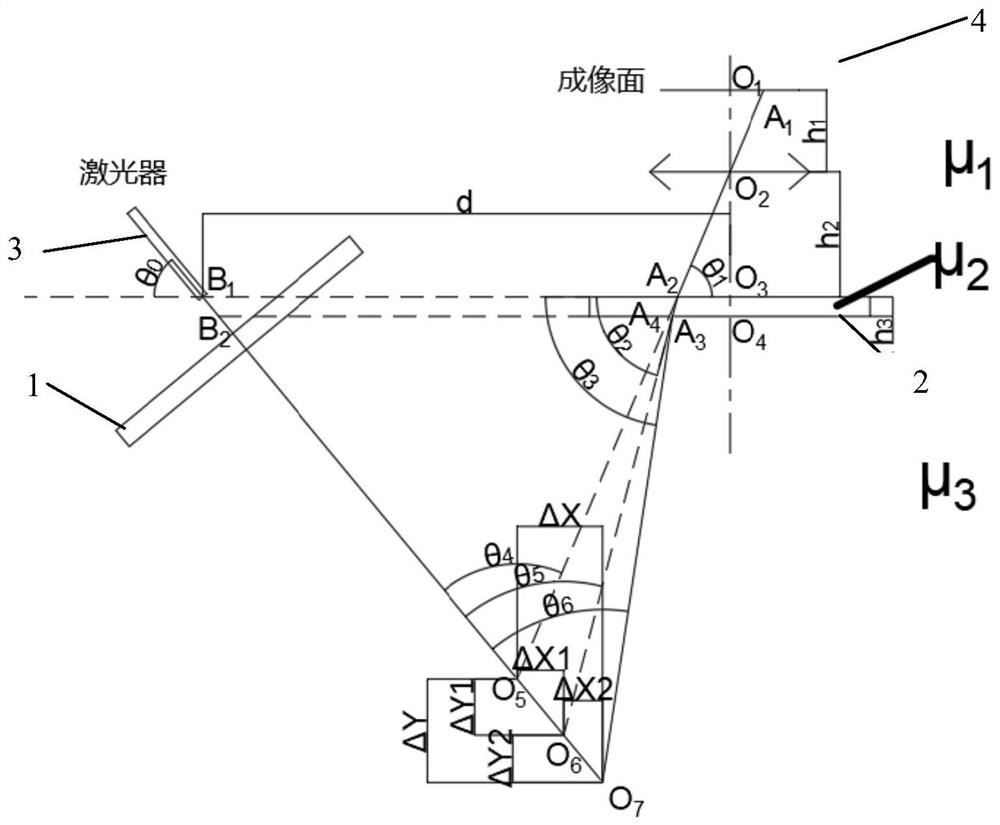

[0058] Such as image 3 As shown, the object three-dimensional measurement system based on structured light in this embodiment includes a first parallel plate 1, a second parallel plate 2, and a laser emitting unit 3 for emitting a laser beam based on structured light to the object to be measured. An image acquisition unit 4 for measuring objects for image wiping, the first parallel plate 1 is arranged according to a specified inclination angle and is perpendicular to the direction in which the laser emitting unit 3 emits a laser beam, so that the laser beam emitted by the laser emitting unit 3 is perpendicular to the first parallel plate 1 is emitted, the second parallel plate 2 is placed horizontally and on the same level as the laser emitting unit 3 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com