Bionic metal ultra-wetting trans-scale structure design method and preparation method

A structural design, cross-scale technology, applied in metal processing equipment, welding equipment, laser welding equipment and other directions, can solve the problems of difficult geometric modeling, disconnection between structural design and preparation results, etc., to achieve simple preparation process, simple and fast process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

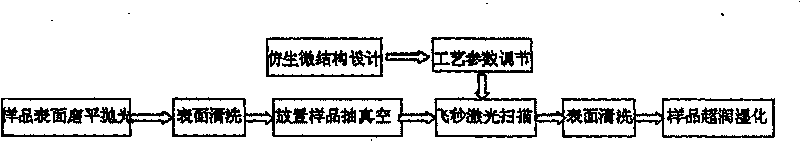

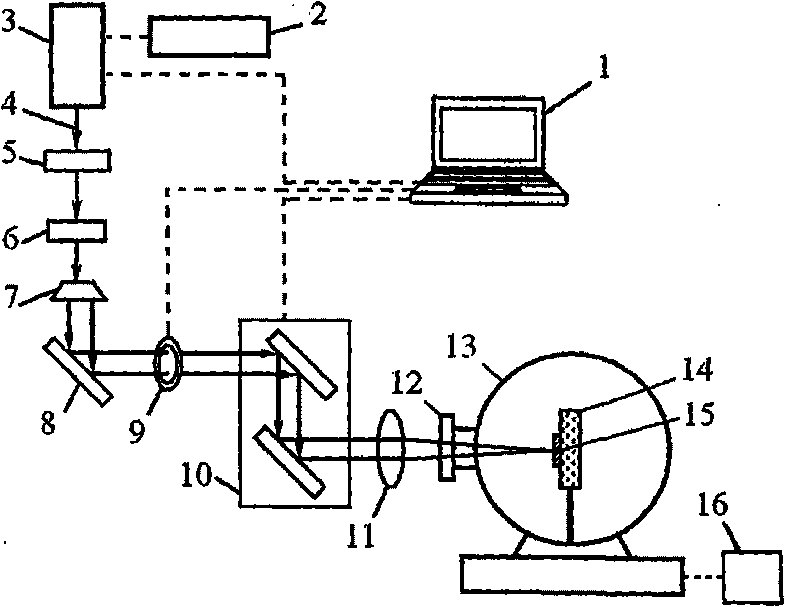

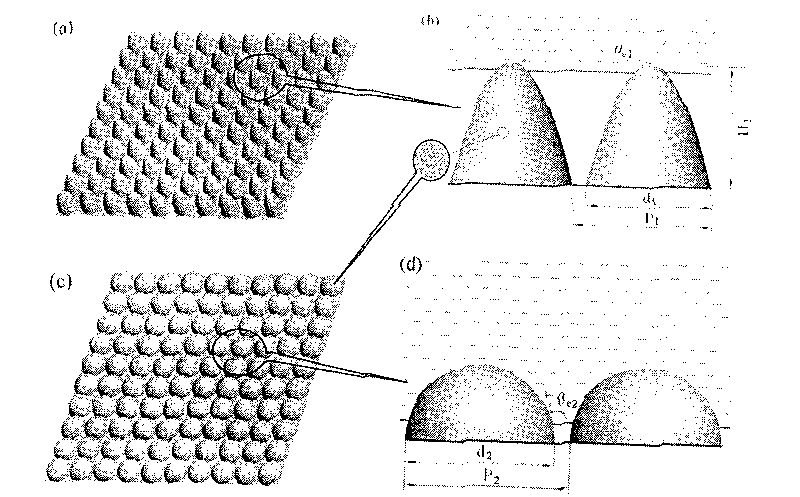

[0023] figure 1 It is a schematic flow chart of the design and preparation method of the biomimetic metal superhydrophobic microstructure surface. Firstly, the bionic microstructure topography is designed, and the biosurface topography is geometrically modeled, simplified into a structure that is easy to prepare by laser, and optimized geometric parameters are designed; corresponding laser parameters are designed according to the optimized structural parameters. The surface of the sample is ground and polished; the polished surface is ultrasonically cleaned with deionized water and acetone for 30 minutes, and dried with a cold blower; the sample is placed on the sample holder in the vacuum target chamber, and the target chamber is evacuated into a high vacuum ; Use the designed laser parameters to control the laser, and perform femtosecond laser micromachining. First, scan the plane with high-energy laser, then rotate the sample by 90°, and then perform a plane scan with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com