Solid rocket motor seal life prediction method based on seal life cycle

A solid rocket, life cycle technology, applied in computer-aided design, instrumentation, geometric CAD, etc., can solve problems such as limited reference value and analysis of the rebound phenomenon of rubber seals, to facilitate calculation and analysis, improve reliability and accuracy , the effect of simplifying the processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

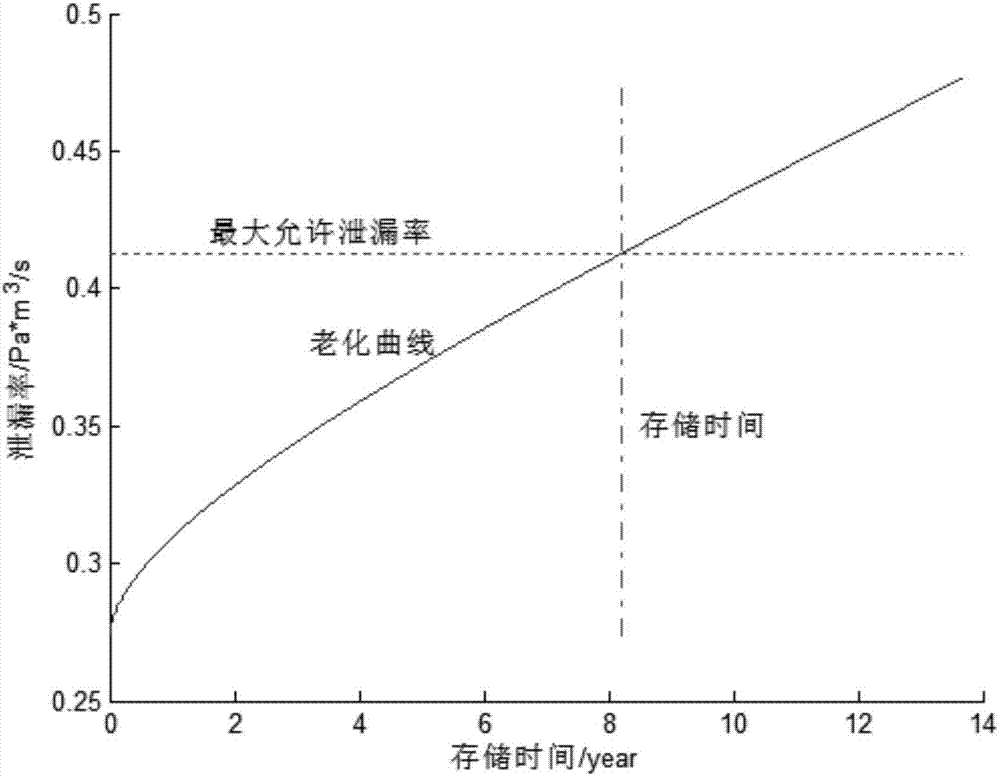

[0067] The implementation process of the present invention includes: 1) determining the aging model of the silicone rubber at room temperature; 2) determining the compression deformation rate of the silicone rubber sealing ring after aging; 3) determining the compression deformation rate of the silicone rubber sealing ring after aging and rebound; 4) Determine the engineering stress of the silicone rubber sealing ring when the solid rocket motor is working; 5) Determine the life prediction model of the solid rocket motor based on the life cycle of the seal; 6) Determine the aging storage time under the maximum allowable leakage rate.

[0068] (1): Determine the aging model of silicone rubber at room temperature

[0069] The expression of aging reaction rate and aging temperature of silicone rubber is:

[0070] K=7863.6exp(-4706.3 / T)

[0071] Then at room temperature, the aging model of silicone rubber is:

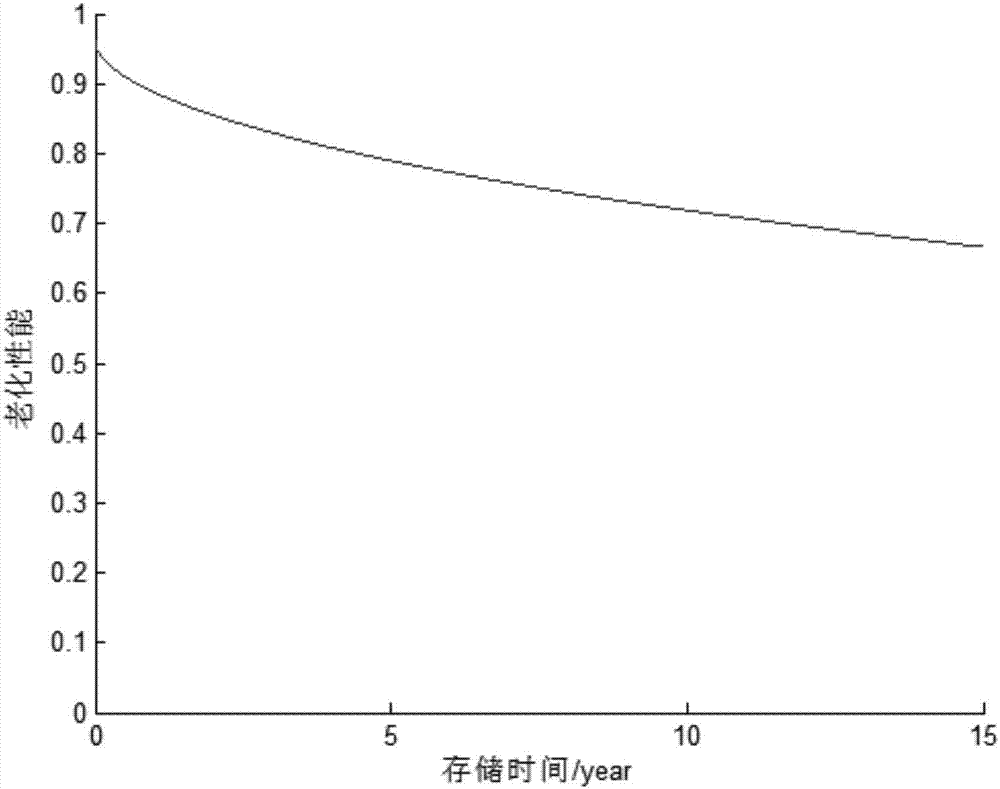

[0072] f(P)=0.9603exp(-0.0027t 0.57 )

[0073] (2): Determine the compression de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com