Pump motor cooling noise reduction device based on pulsating heat pipe

A pulsating heat pipe and motor cooling technology, applied in the direction of cooling/ventilation devices, electromechanical devices, electrical components, etc., to achieve the effect of detachable structure, convenient maintenance, and efficient cooling treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

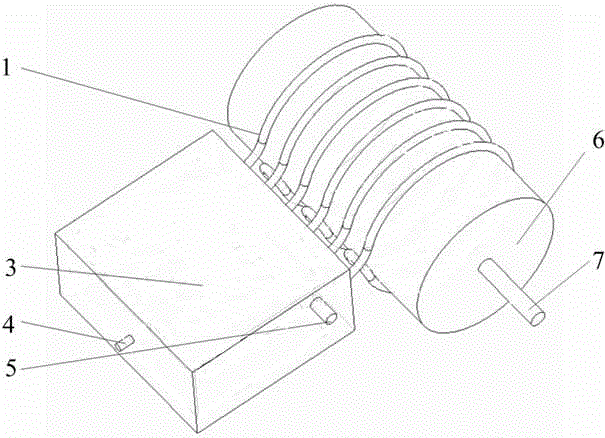

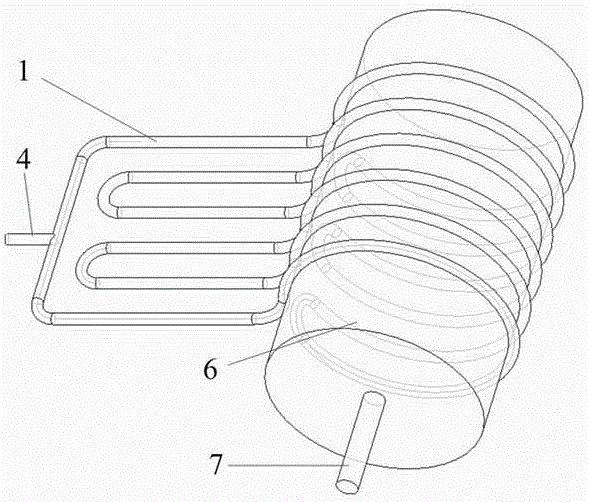

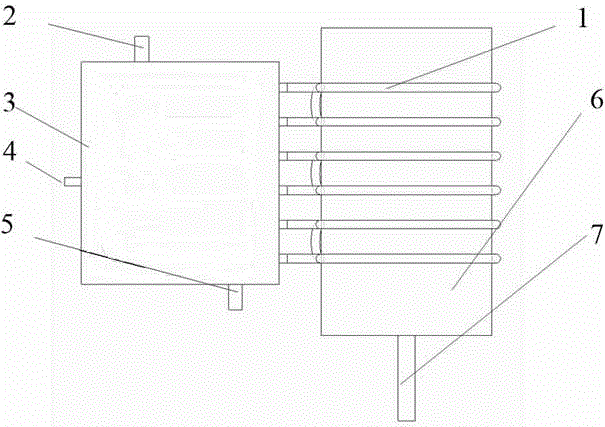

[0017] The technical solution of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0018] The main structure of this embodiment lies in the pulsating heat pipe cooling device arranged in the outer shell of the motor. The pulsating heat pipe mainly includes a space-distorted closed channel with multiple elbows. Cooling treatment is respectively implemented at one end of the channel, and the water tank of the pulsating heat pipe device is immersed Among them, the water tank is arranged with an inlet and outlet to realize the circulation and constant temperature of the water in the water tank. The other end is attached to the surface of the motor casing. In addition, the cross section of the closed passage can be designed as a circular cross section. The function of the invention is that the motor can be efficiently cooled, thereby replacing the existing motor with fan cooling structure and realizing low-noise operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com