Piezoelectric drive type miniature thermoacoustic refrigerator

A thermoacoustic refrigerator and piezoelectric drive technology, which is applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of low reliability, loud noise, slow heat dissipation, etc., and achieve high reliability and extended service life Life and reliability improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

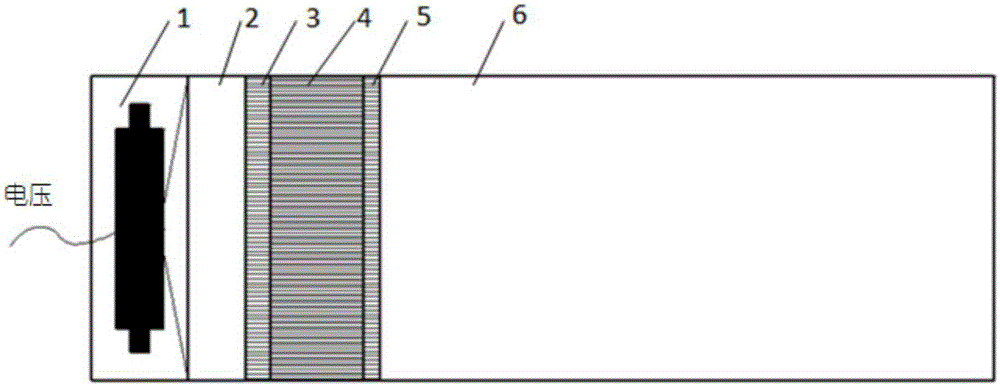

[0025] like figure 1 As shown, a piezoelectric-driven miniature thermoacoustic refrigerator is cylindrical, with a diameter of 30mm, a length of 40mm, and a working frequency of 5000HZ, including a piezoelectric buzzer 1, a hot-end resonant tube 2, a hot-end heat exchanger 3, Regenerator 4, cold end heat exchanger 5 and cold end resonant tube 6.

[0026] The piezoelectric buzzer 1 is connected to one end of the hot-end resonant tube 2, the other end of the hot-end resonant tube 2 is connected to one end of the hot-end heat exchanger 3, and the other end of the hot-end heat exchanger 3 It is connected to one end of the regenerator 4, one end of the regenerator 4 is connected to one end of the cold end heat exchanger 5, and the other end of the cold end heat exchanger 5 is connected to one end of the cold end resonant tube 6, so The other end of the resonant tube 6 at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com