Combined cycle energy supply system

A combined cycle and energy supply technology, applied in the direction of fluid circulation arrangement, irreversible cycle compressors, heating and refrigeration combination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0089] The first thing to explain is that in the expression of the structure and process, it will not be repeated if it is not necessary; the obvious process will not be expressed. The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

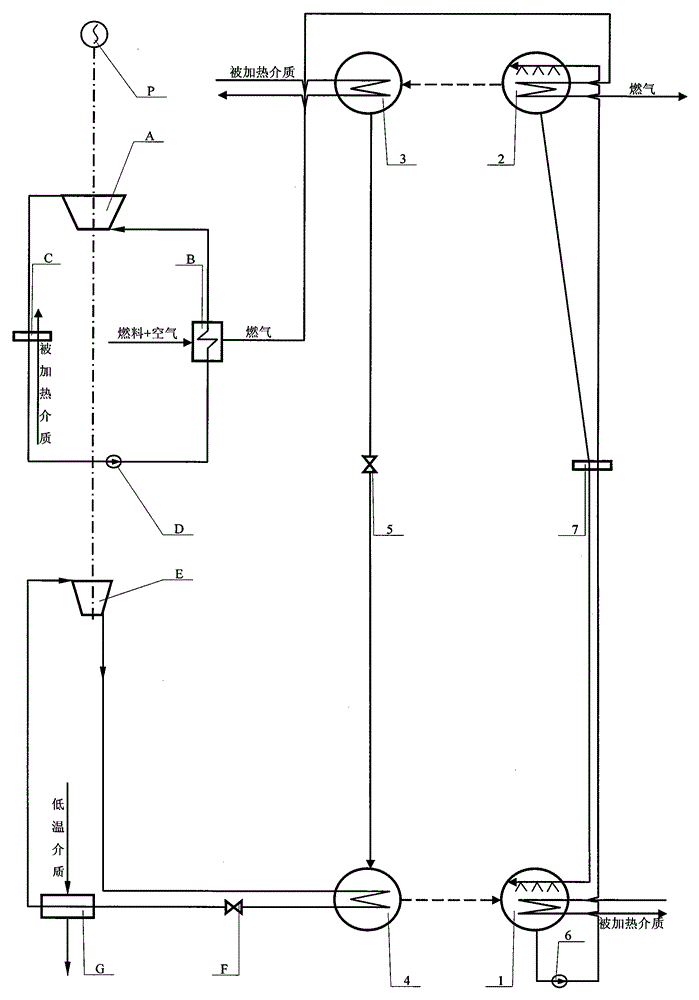

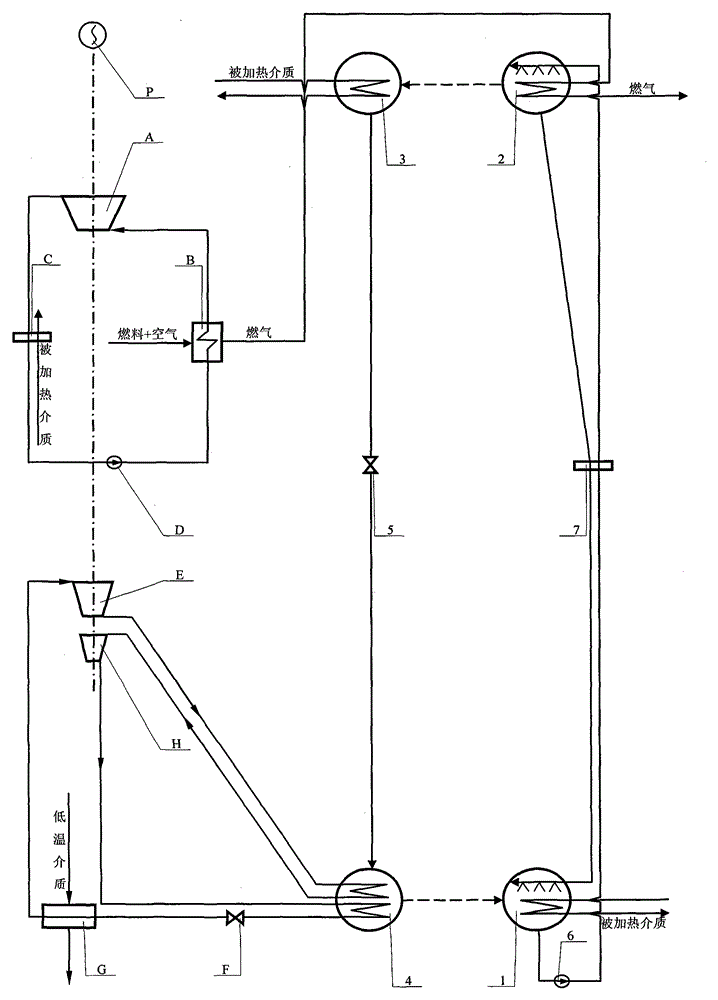

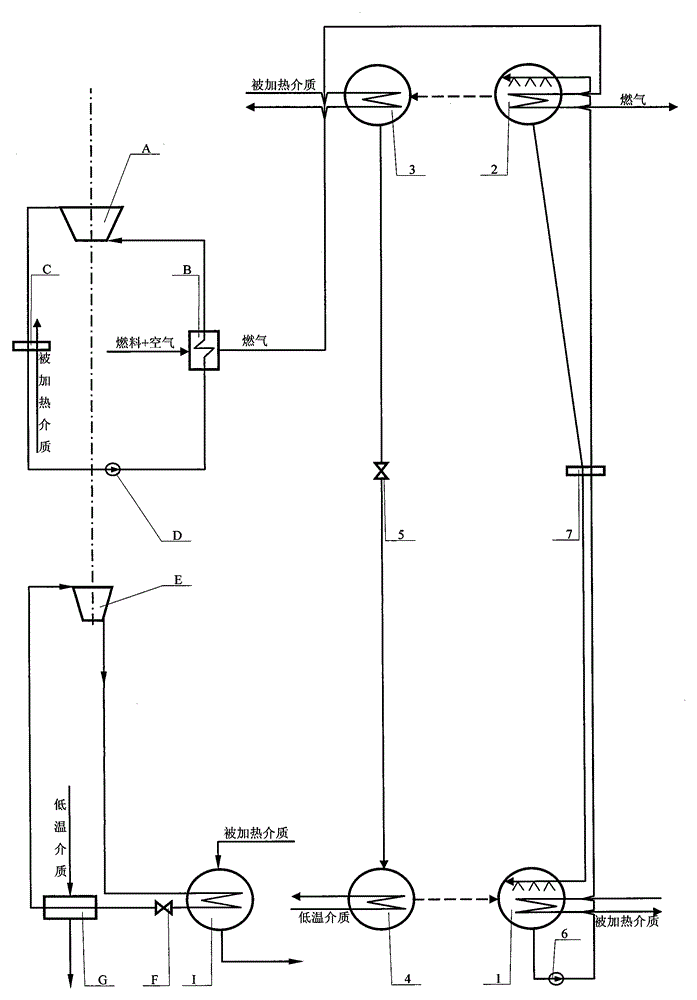

[0090] figure 1 The combined cycle energy supply system shown is realized as follows:

[0091] (1) Structurally, it mainly consists of turbine, boiler, condenser, circulation pump, compressor, low temperature throttle valve, low temperature heat exchanger, evaporator, absorber, generator, condenser, throttle valve, solution pump , solution heat exchanger and working machine; the turbine A has a low-pressure steam channel connected to the condenser C, and the condenser C also has a condensate pipeline connected to the boiler B through the circulating pump D, and the boiler B has a high-pressure steam channel connected to the turbine A is connected, boiler B has fuel and air channels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com