Electromagnetic heating constant temperature transfusion tube

An infusion tube and electromagnetic technology, which is used in pipeline heating/cooling, protection of pipelines through thermal insulation, heat preservation, etc., can solve the problem of inability to automatically control the temperature of the infusion tube at constant temperature, and achieve the effect of improving thermal efficiency and increasing heat transfer speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

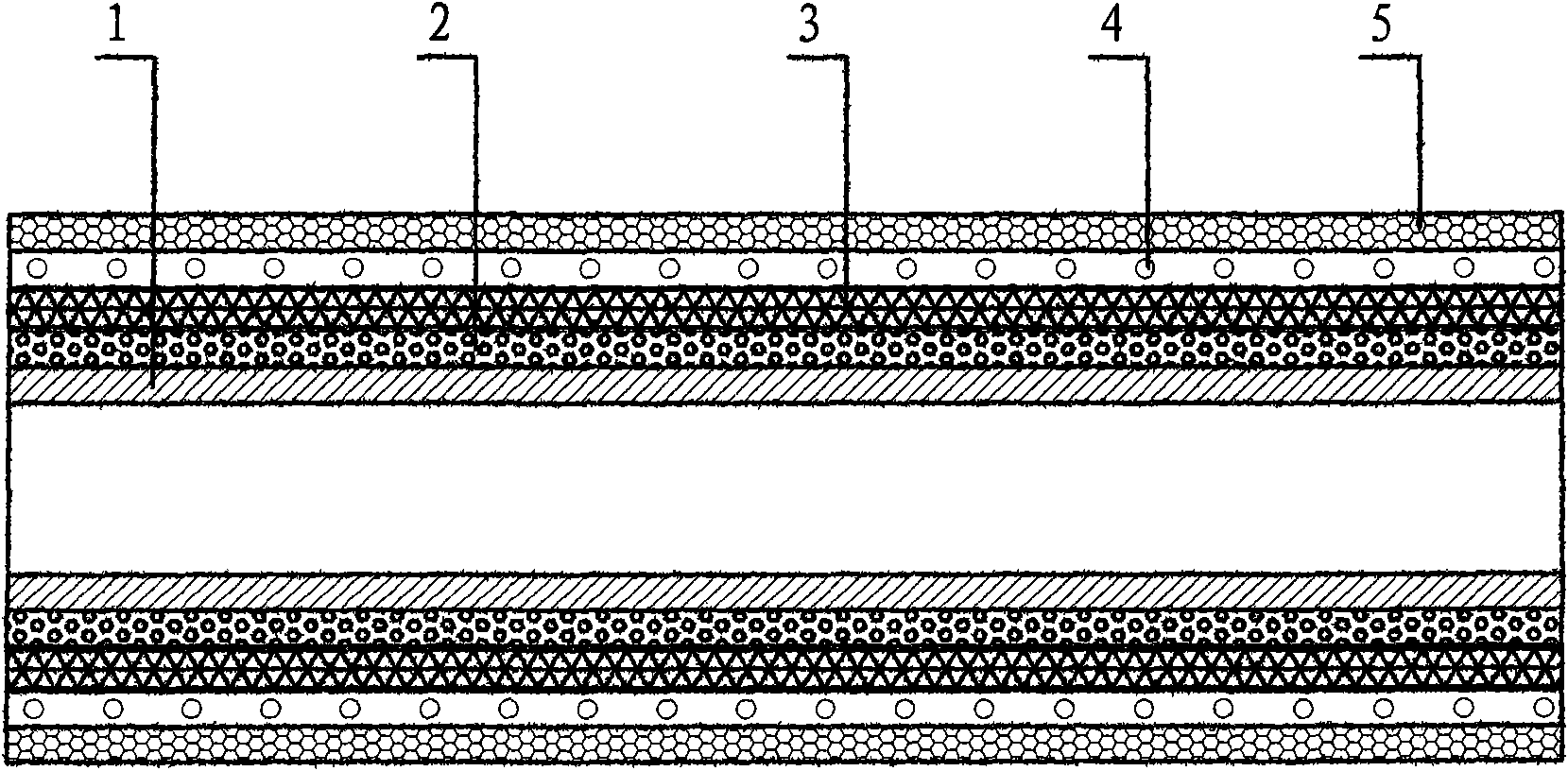

[0027] Electromagnetic heating constant temperature infusion tube section structure diagram figure 1 As shown, wherein: 1 is an aluminum oil pipeline, 2 is a magnetic material with a Curie point temperature of 105 degrees, 3 is an insulation material, 4 is a high-frequency electromagnetic induction coil, and 5 is a polyurethane heat preservation material. When the alternating current passes through the high-frequency electromagnetic induction coil 4, the coil 4 generates an alternating magnetic field. When the magnetic field lines in the alternating magnetic field pass through the magnetic material 2, countless small eddy currents are generated on the surface of the magnetic material 2, and the magnetic material 2 itself generates heat at high speed. When the temperature of the magnetic material 2 is higher than the Curie point temperature of 105 degrees, the magnetic material 2 loses its magnetism, and the heating stops. When the temperature of the magnetic material 2 is lower...

Embodiment 2

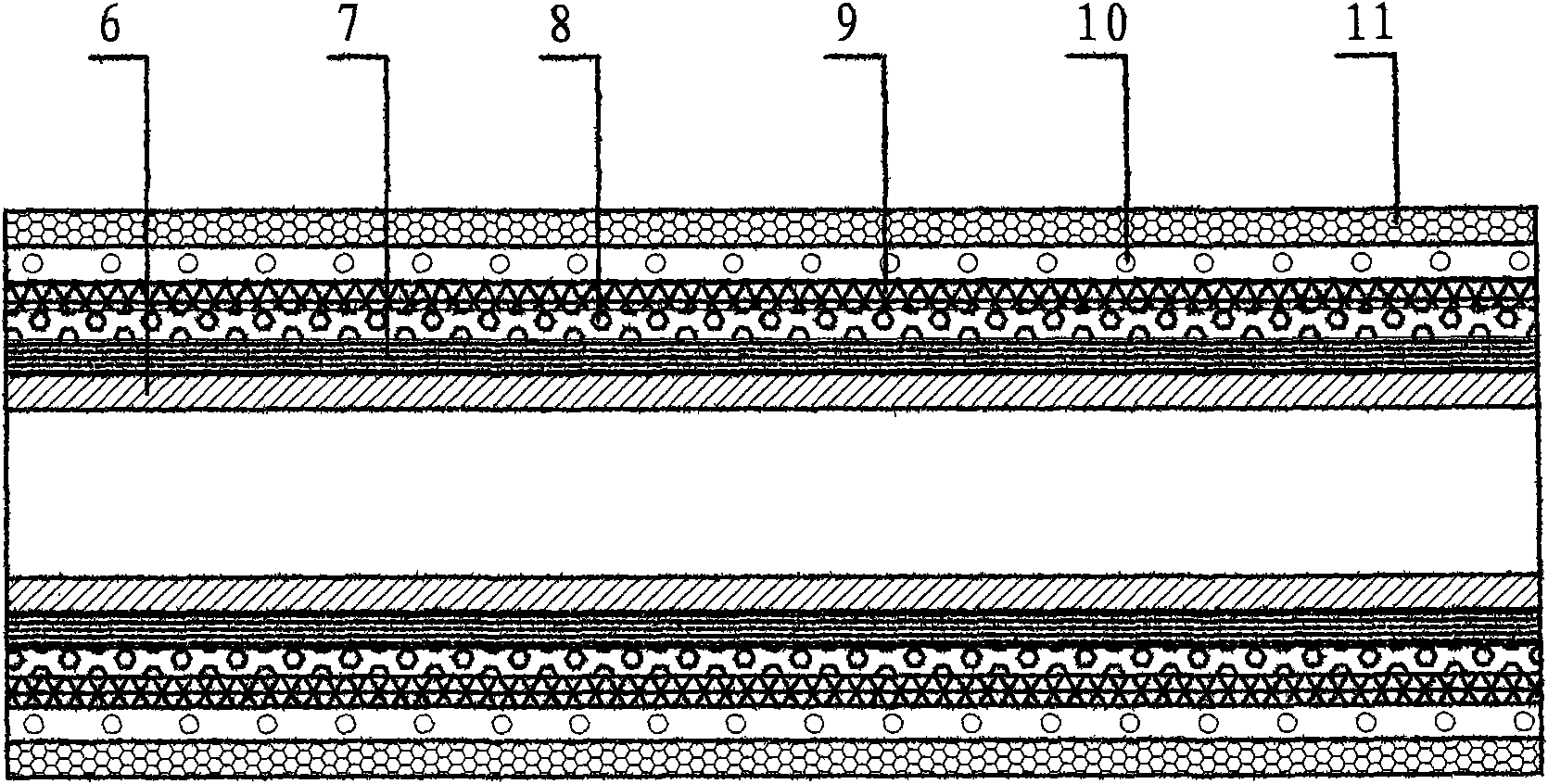

[0030] The cross-sectional structure diagram of the electromagnetic heating constant temperature infusion tube with phase change heat transfer material is as follows figure 2 As shown, among them: 6 is an aluminum oil pipeline, 7 is a low-melting polyester with a phase transition point of 100 degrees, 8 is a magnetic material with a Curie point temperature of 105 degrees, 9 is an insulating material, and 10 is a high-frequency electromagnetic induction coil, 11, polyurethane thermal insulation material. When the alternating current passes through the high-frequency electromagnetic induction coil 10, the coil 10 generates an alternating magnetic field. When the magnetic field lines in the alternating magnetic field pass through the magnetic material 8, countless small eddy currents are generated on the surface of the magnetic material 8, and the magnetic material 8 itself generates heat at high speed. Heating the low-melting-point polyester 7, the low-melting-point polyester 7...

Embodiment 3

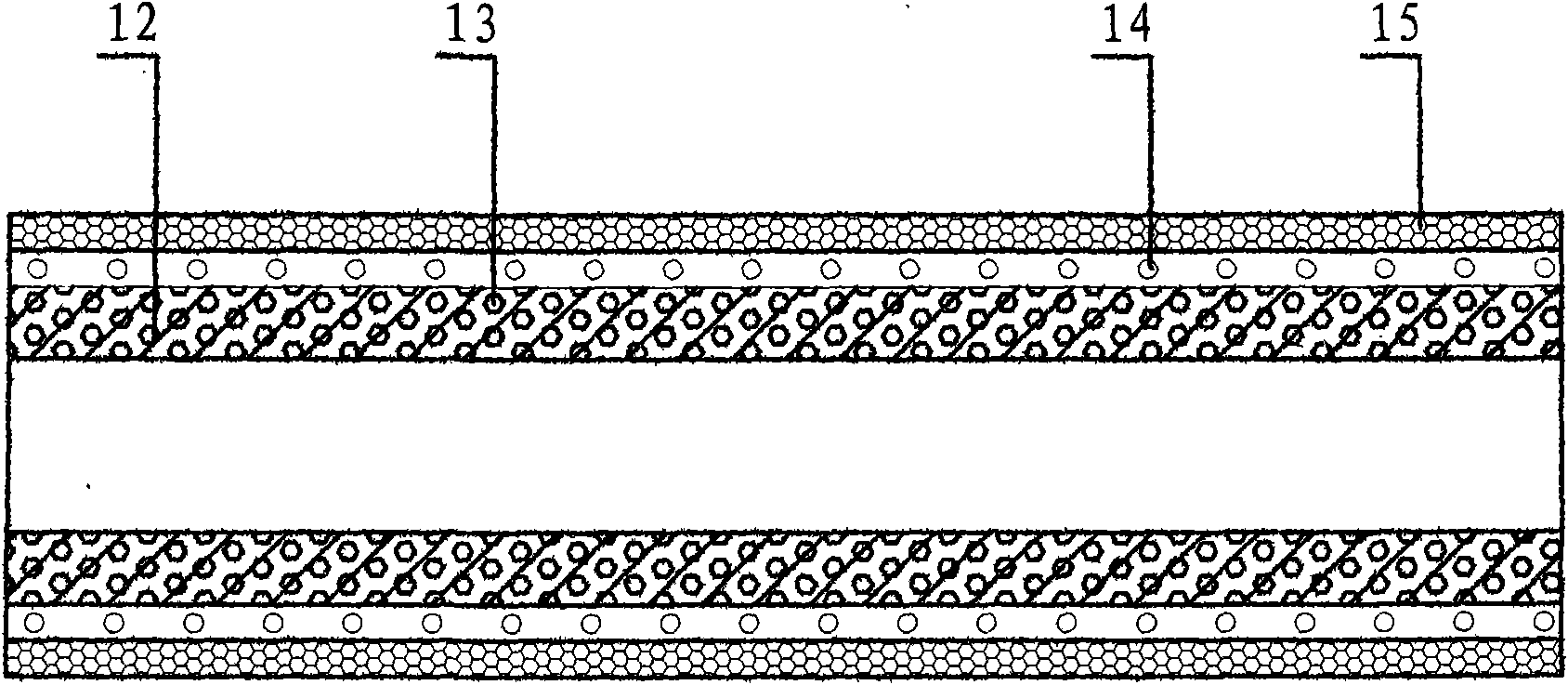

[0032] The cross-sectional structure diagram of simple electromagnetic heating constant temperature infusion tube is as follows image 3 As shown, wherein: 12 is an organic resin oil delivery pipe, 13 is a magnetic material with a Curie point temperature of 105 degrees, the magnetic material 13 is blended into the material of the organic resin oil delivery pipe 12, 14 is a high-frequency electromagnetic induction coil, and 15 is polyurethane Insulation Materials. When the alternating current passes through the high-frequency electromagnetic induction coil 14, the coil 14 generates an alternating magnetic field. When the magnetic field lines in the alternating magnetic field pass through the magnetic material 13, countless small eddy currents are generated on the surface of the magnetic material 13, and the magnetic material 13 itself generates heat at high speed. The liquid in the pipe is heated by the organic resin oil delivery pipe 12, and when the temperature of the magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com