Coolant radiating device, air conditioner with coolant radiating device and temperature control method of coolant radiating device

A temperature control method and refrigerant heat dissipation technology, which are used in the temperature control of refrigerant radiators and in the field of refrigerant heat dissipation devices, which can solve the problems of inverter condensation, damage to inverters, and insignificant heat dissipation effect, so as to reduce energy loss and ensure work. Temperature, the effect of improving the ability to work at full load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

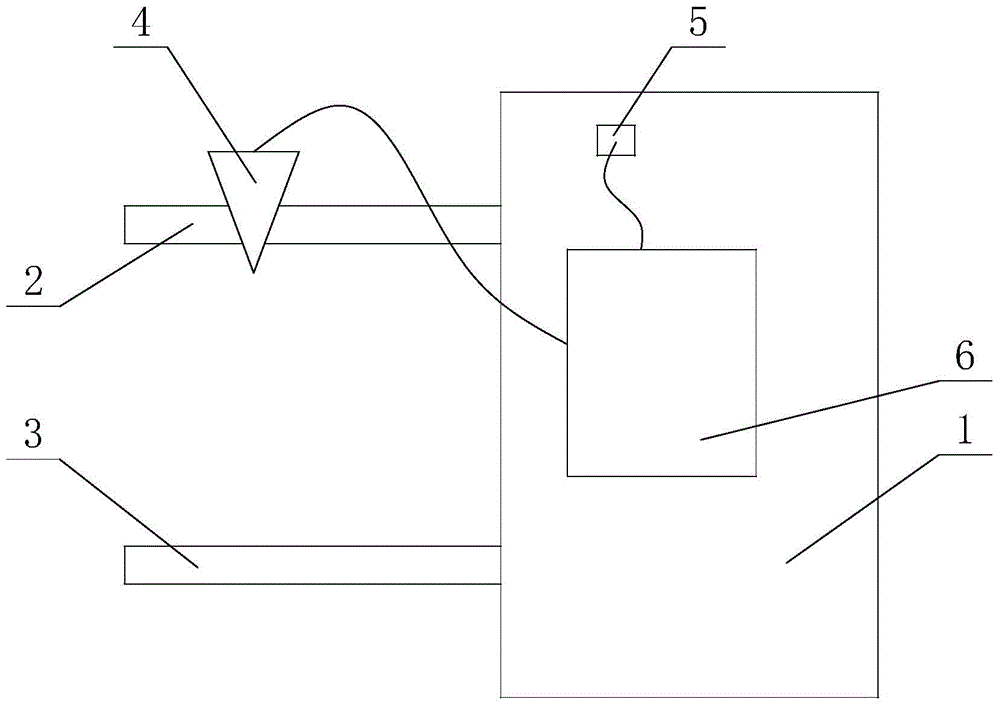

[0031] Such as figure 1 Shown is a structural diagram of the cooling medium cooling device provided in the first embodiment.

[0032] A refrigerant cooling device provided in this embodiment includes a controller, a radiator 1 , a refrigerant inlet pipe 2 , a refrigerant outlet pipe 3 , an expansion valve 4 and a temperature sensor 5 . Both the refrigerant inlet pipe 2 and the refrigerant outlet pipe 3 are connected to the radiator 1 , the expansion valve 4 is arranged on the pipeline of the refrigerant inlet pipe 2 , and the temperature sensor 5 is attached to the outer surface of the radiator 1 .

[0033] The expansion valve 4 and the temperature sensor 5 are connected to the controller, and the controller is used to receive the detection signal of the temperature sensor 5 to adjust the opening of the expansion valve 4 and realize the constant temperature control of the radiator 1 . If the radiator 1 is installed on the frequency converter, the constant temperature control ...

Embodiment 2

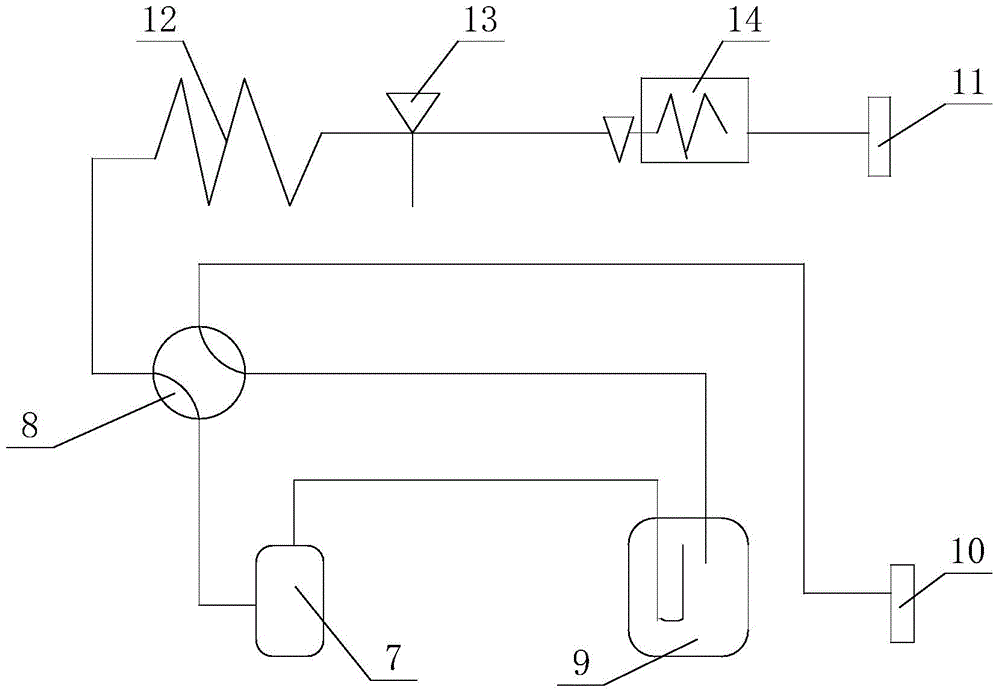

[0036] Such as figure 2 Shown is the structural diagram of the air conditioner provided in the second embodiment.

[0037] The air conditioner installed with the refrigerant heat exchange device in Embodiment 1 provided in this embodiment includes a frequency converter, a compressor 7, a four-way valve 8, a gas-liquid separator 9, a gas refrigerant pipe 10, a liquid refrigerant pipe 11, Outdoor heat exchanger 12, throttle valve 13, cooler 14 and other components.

[0038] The gaseous refrigerant pipe 10 is connected to the first valve port of the four-way valve 8 , and the liquid refrigerant pipe 11 is connected to the second valve port of the four-way valve 8 . The refrigerant inlet and refrigerant outlet of the compressor 7 are respectively connected to the third valve port of the four-way valve 8 and the gas-liquid separator 9 . The third valve port of the four-way valve is connected with the gas-liquid separator 9 .

[0039] Further, an outdoor heat exchanger 12 , a th...

Embodiment 3

[0042] A method for controlling the temperature of the refrigerant cooling device in Embodiment 1 is implemented according to the following steps:

[0043] Step S00: preset the target temperature value T in the internal memory of the controller m and the limit temperature value T a . Among them, the target temperature value T m It means to control the temperature of the inverter at a fixed value during actual operation to ensure that the inverter does not condense or overheat. It can also be considered that this value is the optimum operating temperature value of the inverter.

[0044] Limit temperature T a It means that when the environmental stability is lower than a certain value, there is no need to use a refrigerant cooling device at this time, and the inverter will not overheat.

[0045] Step S10: the temperature sensor 5 detects the temperature signal on the surface of the radiator 1, and transmits the temperature signal to the controller to obtain the detected tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com