Method for synthesizing polyether glycol in microstructure reactor

A microstructure reactor and polyether polyol technology, applied in the field of polyether polyol preparation, can solve the problems of limited heat and mass transfer effect, reduced molecular weight of polyether polyol, and high requirements for process condition control, and can avoid large problems. The molecular weight of polyether polyol is generated, the polymerization reaction rate is increased, and the effect of overcoming the excessive polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The catalyst solution produced by the reaction of propylene oxide, 1,3-propanediol and potassium hydroxide is fed at a molar ratio of propylene oxide to 1,3-propanediol of 16:1, and pumped into the micro-mixer and extended residence time respectively. In the microstructure reactor composed of tubes, the content of potassium hydroxide is 3000ppm, the inner diameter of the channel of the micromixer is 45um, and the outlet of the micromixer is connected to a 25m residence time extension tube with an inner diameter of 0.5mm and a material of 316L. Control the reaction time to be 120s, the reaction temperature to be 190°C, and the reaction pressure to be 10MPa. The collected products go through the steps of neutralization, adsorption, degassing, and filtration in sequence to obtain a refined polyether polyol, which is designated as sample A1. The obtained product has a hydroxyl value of 162 mgKOH / g and a relative molecular mass of 1034 g / mol.

Embodiment 2

[0018] The mixture of propylene oxide and ethylene oxide (mass fraction of ethylene oxide is 15%), glycerin and potassium hydroxide react the catalyst liquid that generates with the mixture of propylene oxide and ethylene oxide and glycerine Alcohol is fed at a molar ratio of 35:1 and pumped into a microstructure reactor composed of a micromixer and a residence time extension tube, wherein the content of potassium hydroxide is 3000ppm, and the channel size of the micromixer has an inner diameter of 45um , the outlet of the micro-mixer was connected to a 50m residence time extension tube with an inner diameter of 0.5mm and a material of 316L, the reaction time was controlled to be 240s, the reaction temperature was 190°C, and the reaction pressure was 10MPa. The collected product goes through the steps of neutralization, adsorption, degassing, and filtration in sequence to obtain refined polyether polyol, which is designated as sample A2. The hydroxyl value of the obtained prod...

Embodiment 3

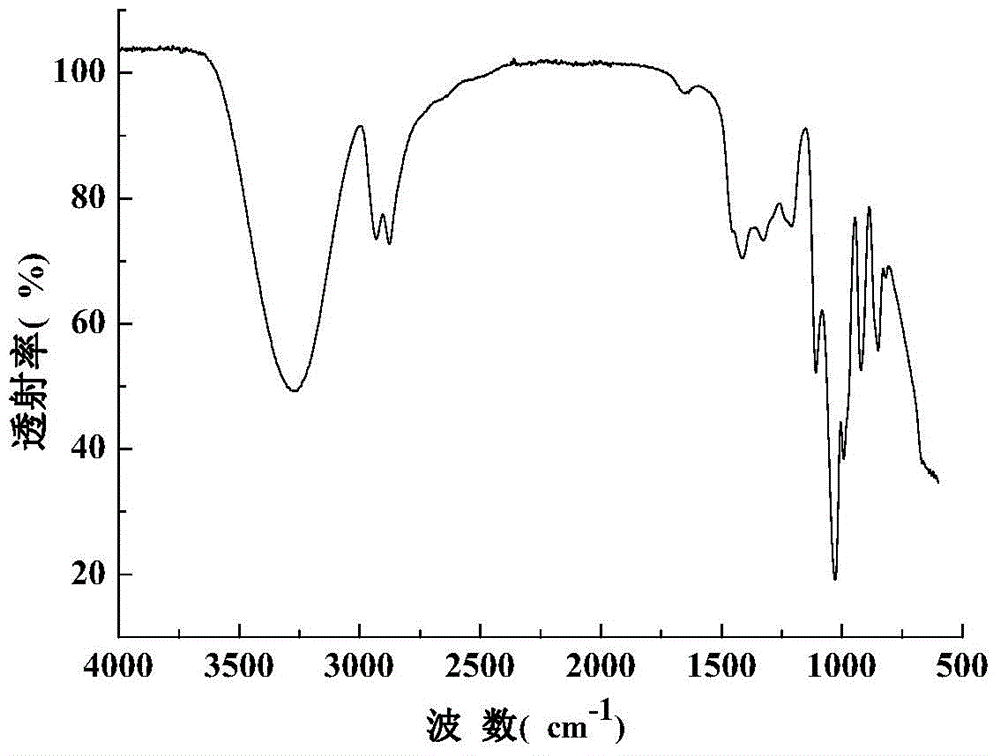

[0020] The catalyst solution generated by the reaction of propylene oxide, glycerol and potassium hydroxide is pumped into the microstructure reactor composed of micro-mixer and residence time extension tube respectively (wherein the molar ratio of propylene oxide and glycerin is 4:1 is fed, and the content of potassium hydroxide is 3000ppm), and the inner diameter of the channel size of micro-mixer is 25um, and the micro-mixer outlet connection 6m inner diameter is 0.5mm, the residence time extension tube of titanium tube material, and the control reaction time is 30s, the reaction temperature is 175°C, and the reaction pressure is 3MPa. The collected product goes through the steps of neutralization, adsorption, degassing, and filtration in sequence to obtain refined polyether polyol, which is designated as sample A3. The hydroxyl value of the obtained product is 519 mgKOH / g, and the relative molecular mass is 324 g / mol. The infrared spectrum of sample A3 is as follows figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com