Reciprocating friction-wear test apparatus and method

A friction and wear test, reciprocating technology, applied in the direction of testing wear resistance, etc., can solve the problems of poor reciprocating motion stability, multi-stage coupling piston, tripping, etc., to ensure the accuracy of stroke control and meet the quantitative evaluation requirements , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

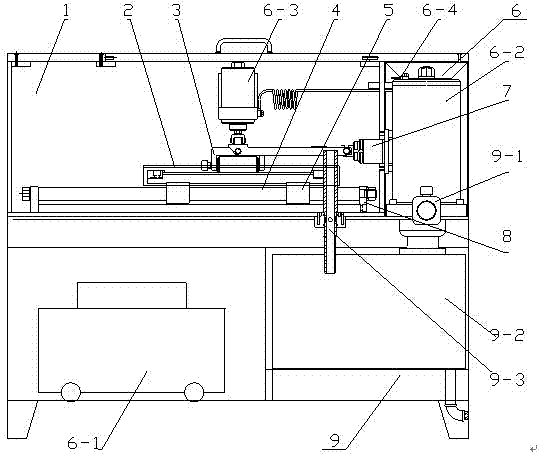

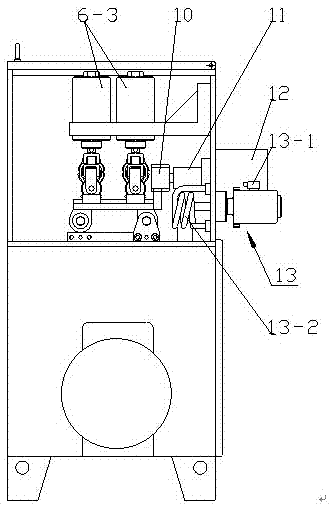

[0020] according to Figure 1-2 , a reciprocating friction and wear test device, including a test chamber 1, a tubing clamping part 2, a specimen clamping part 3, a tubing reciprocating sliding system, a loading system 6, a friction sensor 7, a medium circulation system 9, and a temperature control system 13. The oil pipe clamping part and the test piece clamping part are all arranged in the test chamber 1, and after the oil pipe clamping part and the test piece clamping part hold the oil pipe and the test piece respectively, press the test piece on the oil pipe The oil pipe clamping part and the oil pipe are connected together on the oil pipe reciprocating sliding system, a loading system 6 acts on the specimen clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com