Condensing gas water heater and flue gas flowing mode

A gas water heater, condensing technology, applied to water heaters, fluid heaters, lighting and heating equipment, etc., to achieve the effect of flame stability control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

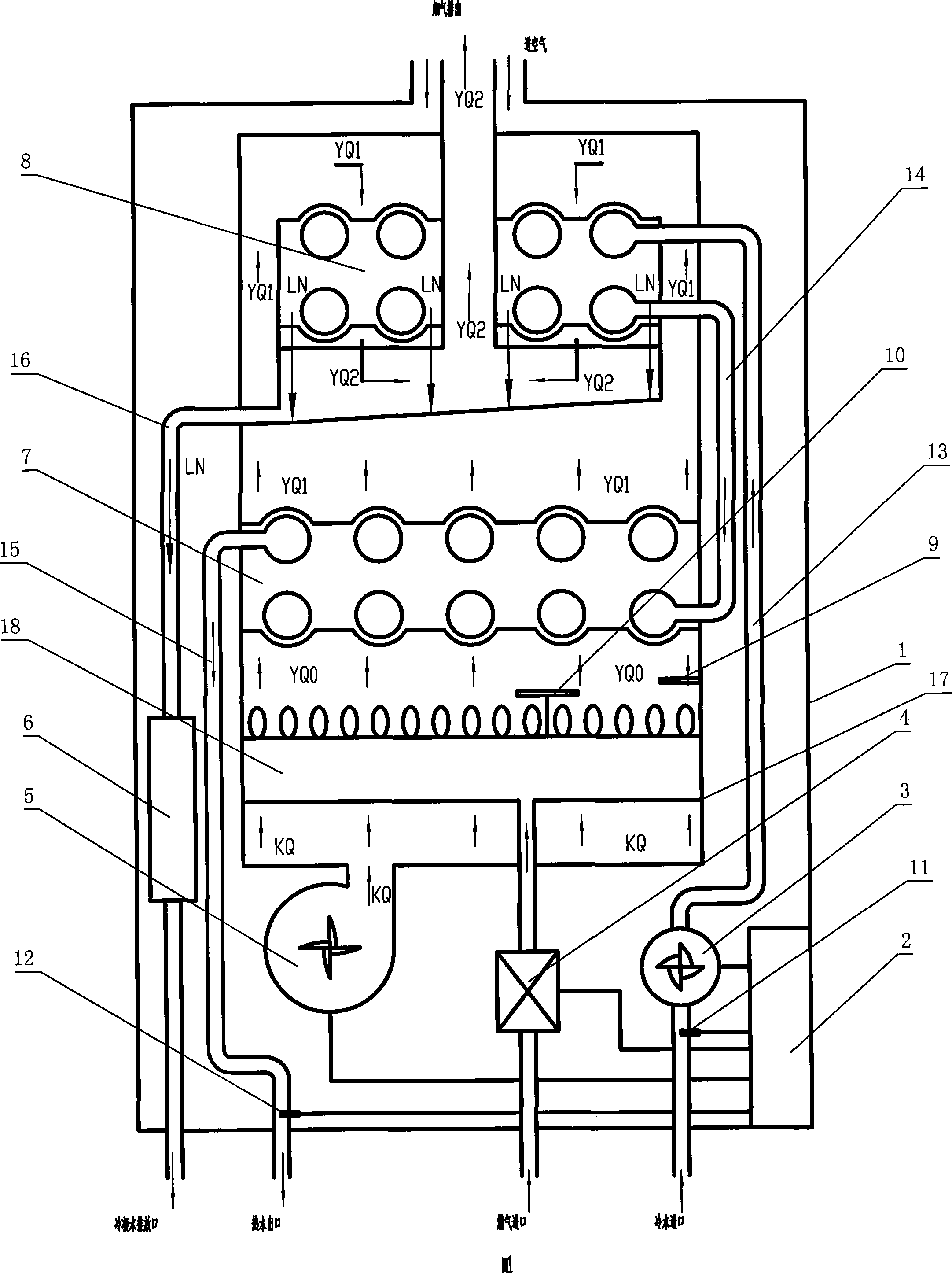

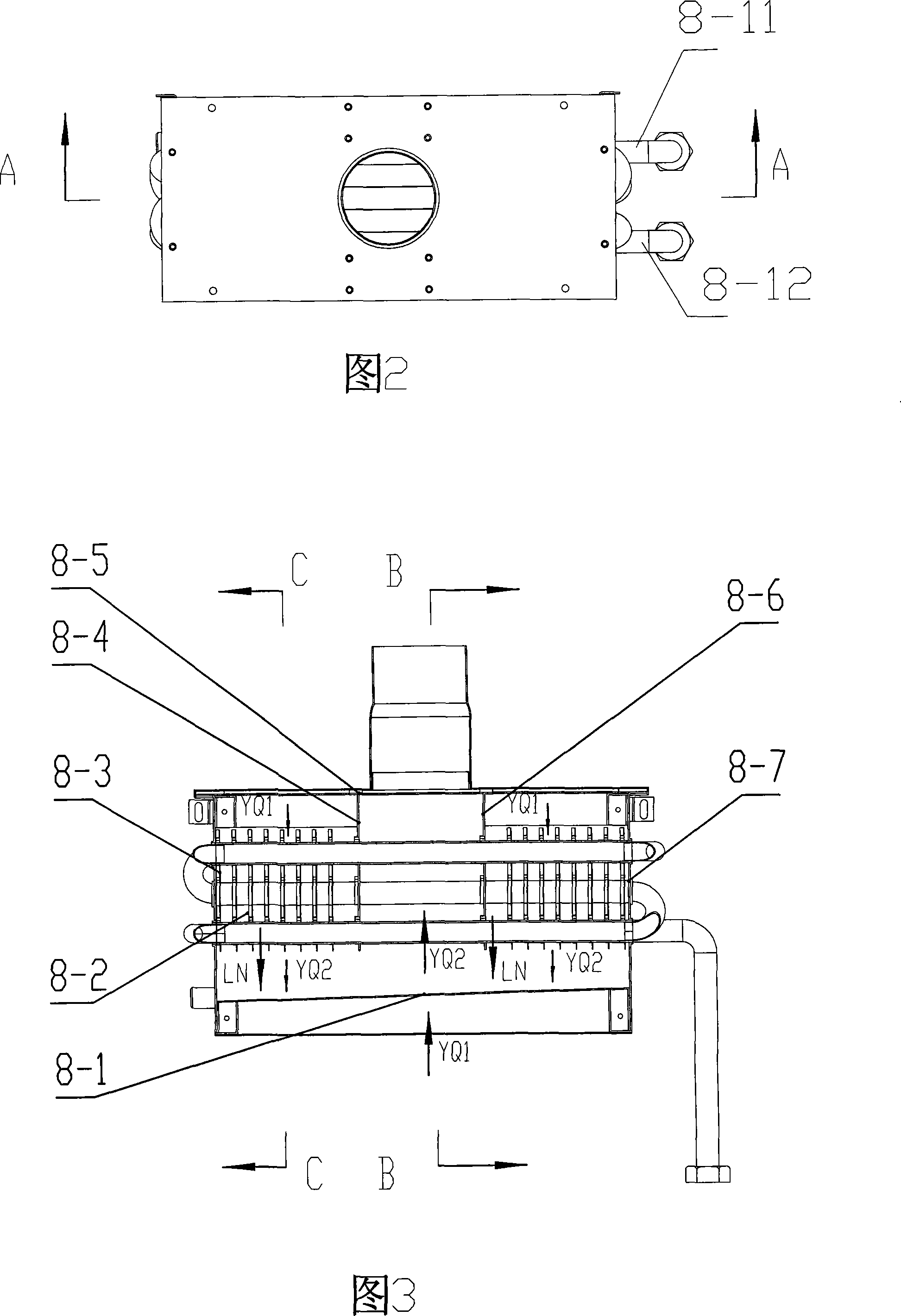

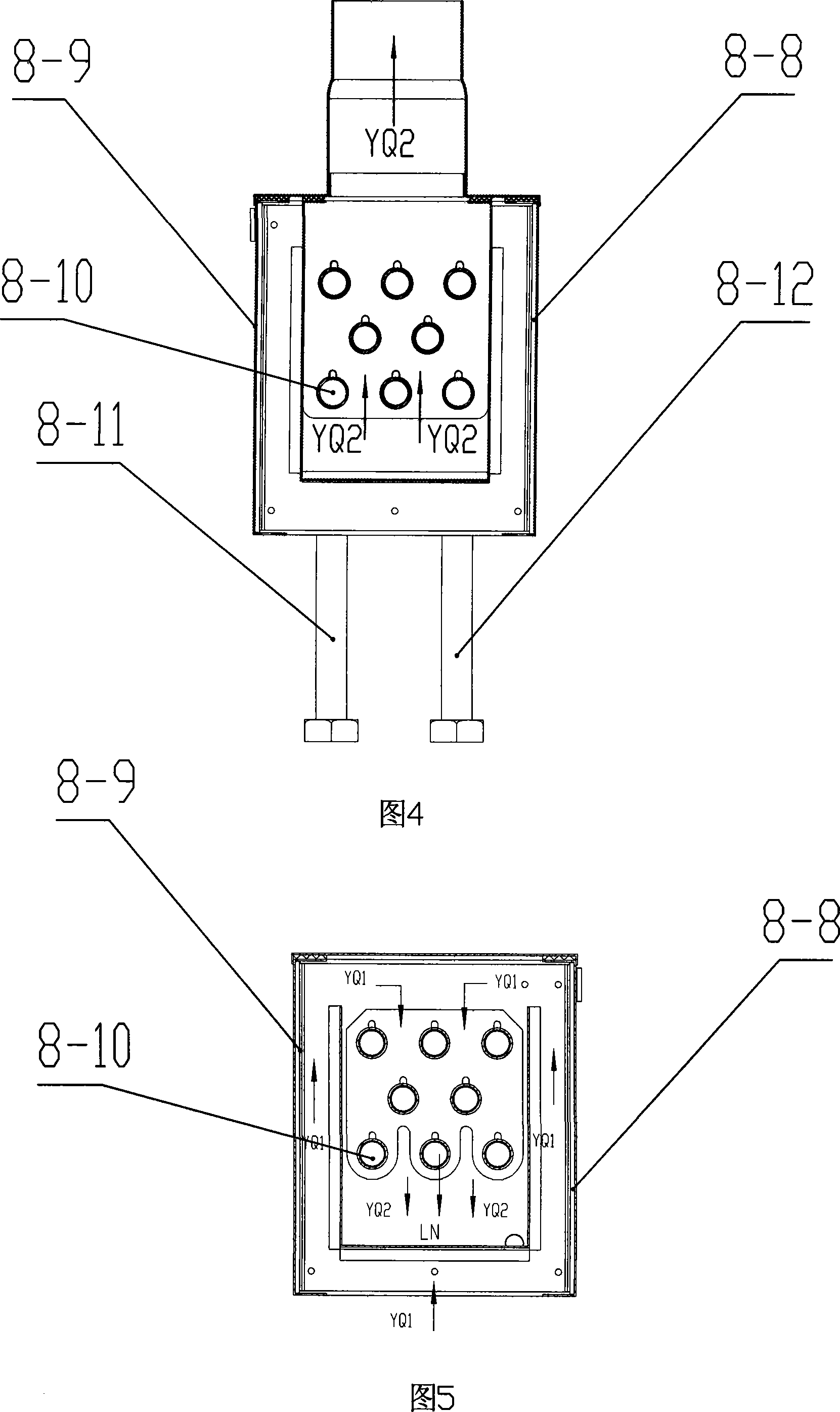

[0042] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5 and Fig. 6, a condensing gas instant water heater includes a casing 1, a controller 2 installed in the casing 1, a water flow sensor 3, a gas Road control valve 4, fan 5, condensed water neutralization device 6, main heat exchanger 7, secondary heat exchanger 8, ignition device 9, sensing device 10, water inlet temperature sensor 11, water outlet temperature sensor 12, water inlet pipe 13, main Secondary heat exchanger connection pipe 14, water outlet pipe 15, condensed water discharge pipe 16 combustion chamber 17, burner 18. The combustion chamber 17, the main heat exchanger 7 and the secondary heat exchanger 8 in the water heater are arranged sequentially from bottom to top. A water collecting cavity 8-1 is integrally formed, a smoke hood is covered outside the secondary heat exchanger 8, and a smoke exhaust tube is arranged in the middle of the secondary heat exchanger 8, and the lower end of the smoke exhaust tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com