Automatic lifting rice frying machine

A technology of automatic lifting and frying rice machine, which is applied to heating devices, cooking utensils, household appliances, etc., can solve the problems of inconsistent taste of fried rice, poor customer service experience, time-consuming and labor-consuming, etc., and achieves beautiful appearance and good heat dissipation. Effects, effects with a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

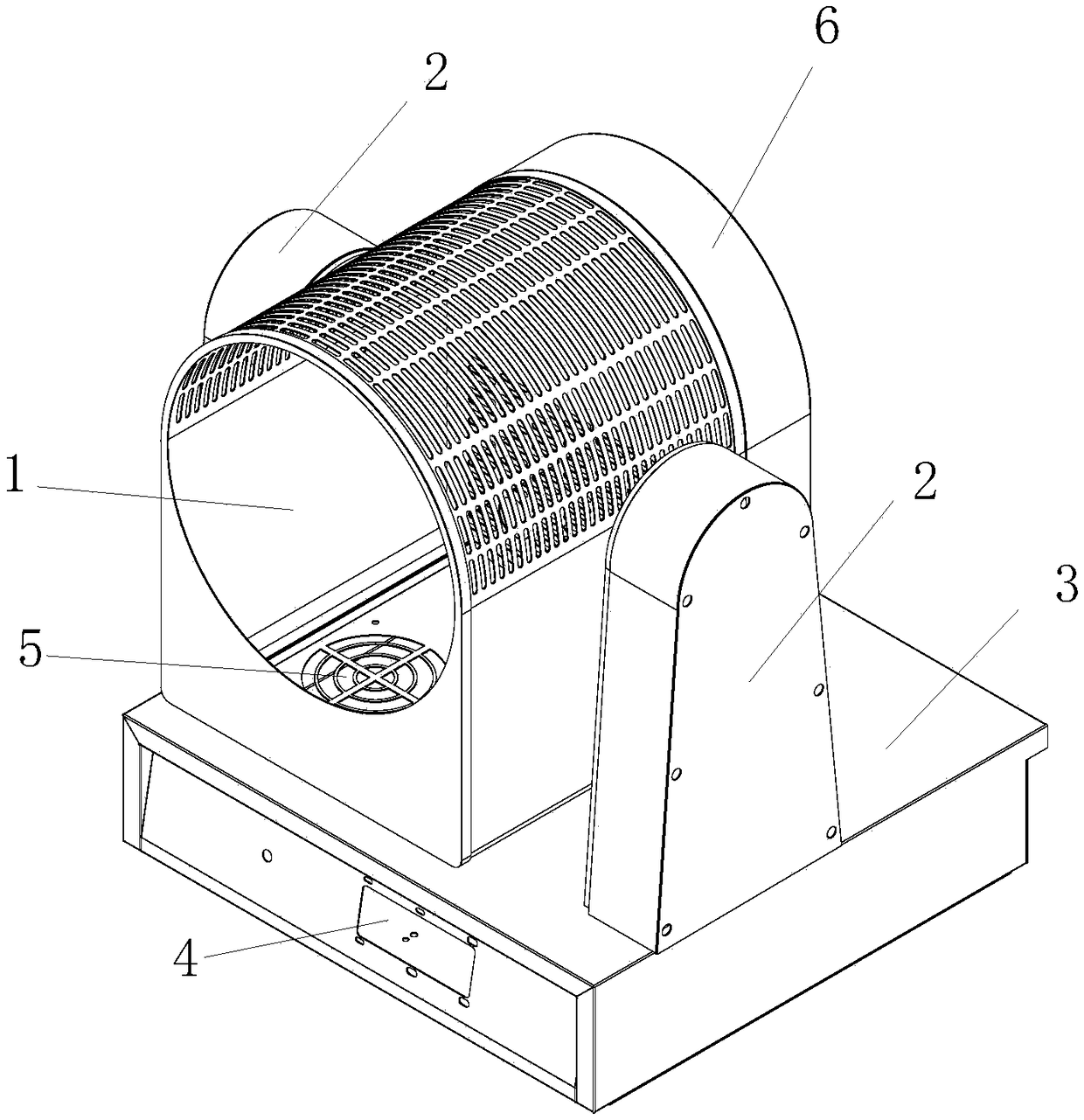

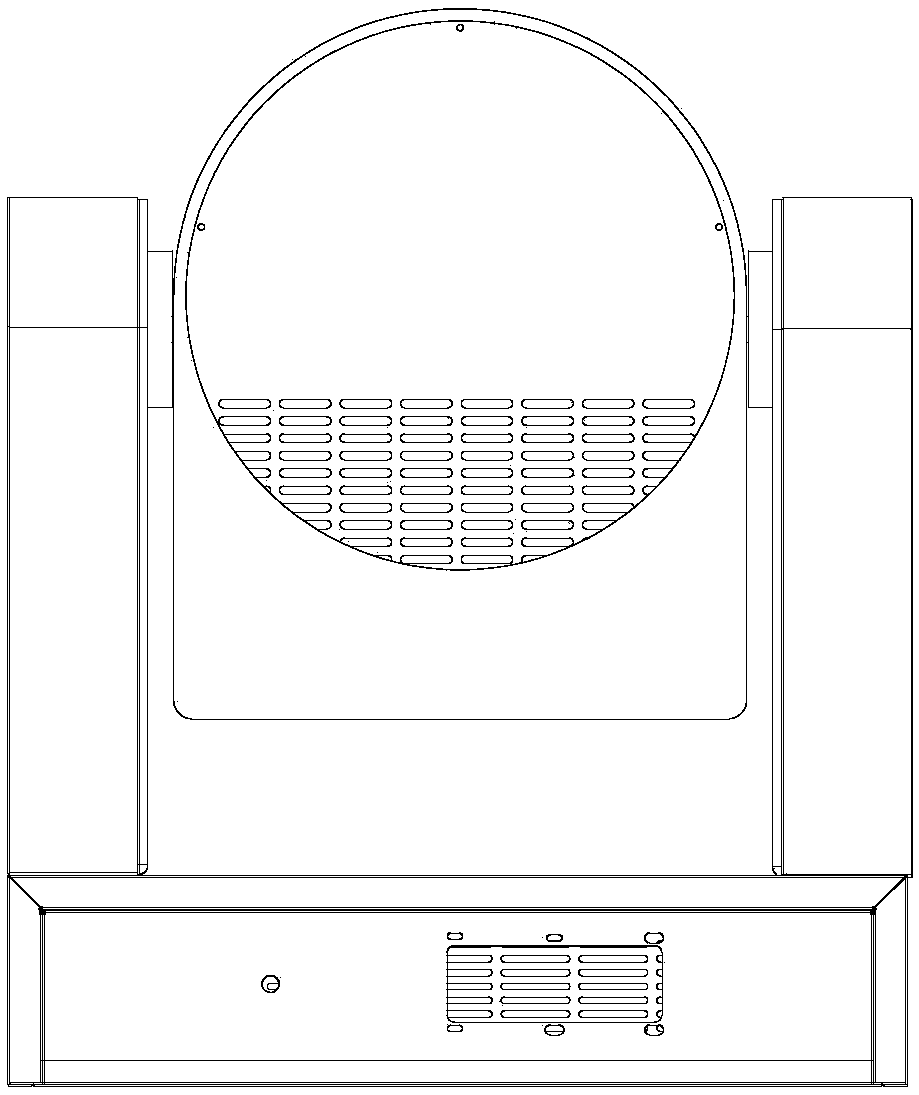

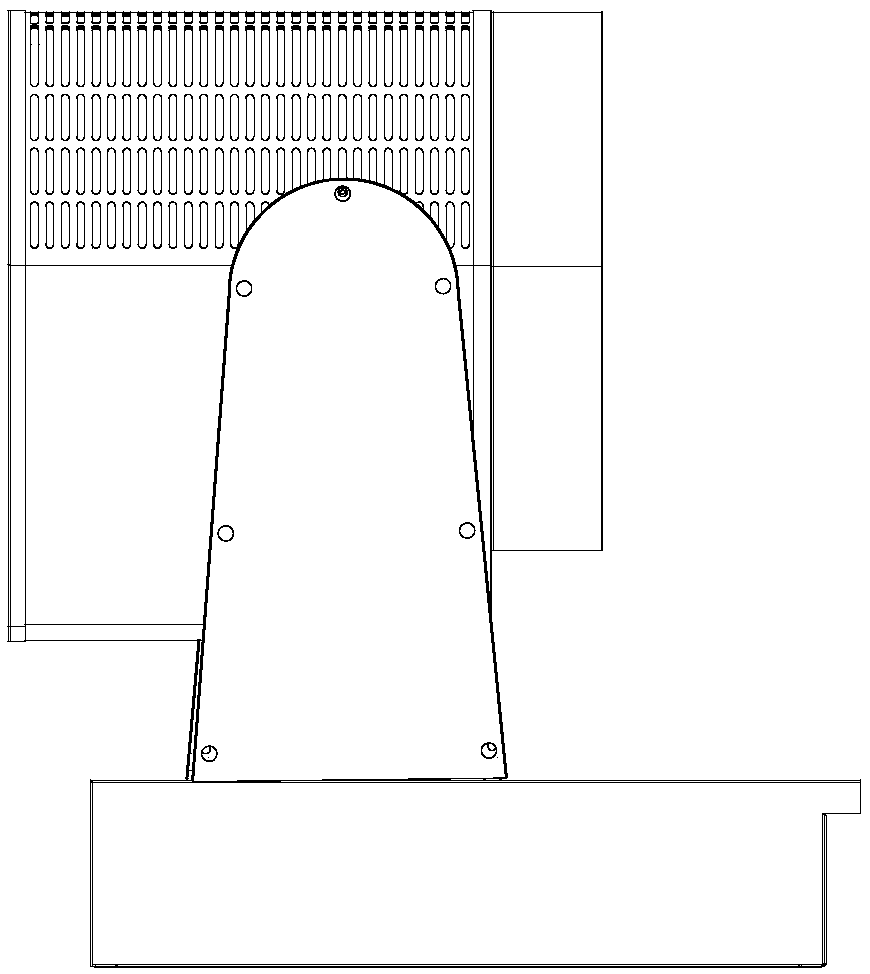

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention discloses an automatic lifting fried rice machine, which mainly includes a stirring bar for stir-frying food, a drum for flipping food, a pot body 1 for driving the drum to stir-fry and rotate, a supporting pot body 1 and realizing An automatic lifting support base 2, and a base 3 for controlling the movement of the support base 2 and the pot body 1. The base 3 is set as a stable cuboid structure, and a control panel for controlling the stir-frying process is provided inside. The front of the base 3 is provided with a control panel 4 that is convenient for user operation, and the control panel 4 is electrically connected to the control panel. There are two supporting bases 2, both of which are fixedly installed on the base 3. The pot body 1 is located between two support bases 2 and is connected with the support base 2 in transmission. The drum is installed in the pot body 1 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com