Automatic steaming production line

An automatic production line and steaming technology, which is used in baking, food preparation, dough fermenters, etc., can solve the problems of low output and work efficiency, high labor intensity, poor working conditions, etc., to improve output and work efficiency, and reduce labor intensity. , the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

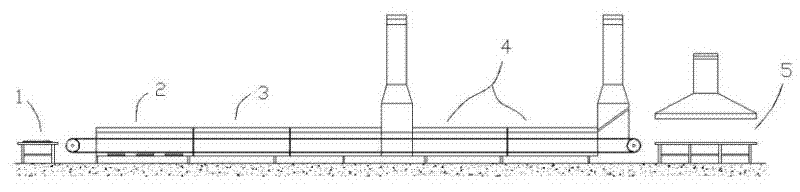

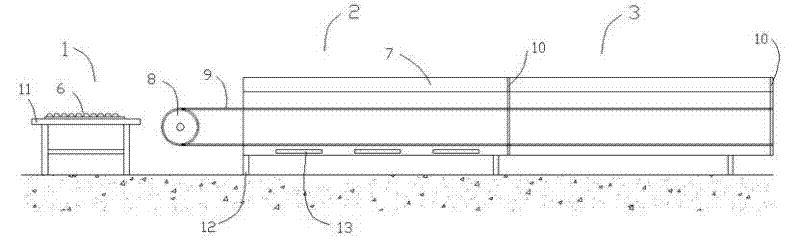

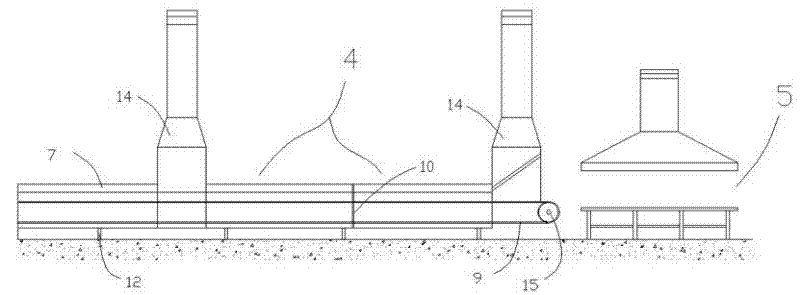

[0022] The essential spirit of the present invention is that the tray of steamed buns is transported by a closed chain conveyor through a proofing section, a steaming section and a cooling section to obtain finished steamed buns, so that the steamed buns can be produced in large quantities and continuously in a mechanized manner. The essence and spirit of the present invention will be described in detail below in conjunction with the embodiments and the corresponding drawings.

[0023] figure 1 A schematic diagram of the overall structure of the present invention is shown, figure 2 and image 3 yes figure 1 Schematic diagram of the corresponding part of the structure to make up for figure 1 A defect in which the fine structure is unclear. As can be seen from the figure, the wake-up and steaming automatic production line includes a closed chain conveyor mainly composed of a driving sprocket 8, a driven sprocket 15, a chain 9, a closed transport channel 7 and a frame 12....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com