Steamed bun leavening, steaming and airing all-in-one machine

An all-in-one machine and steamed bun technology, which is applied in baking, cooking utensils, household utensils, etc., can solve the problems of increased risk of food hygiene, inconsistent size and quality of steamed buns, and achieve unique taste, stable quality of steamed buns, and extended shelf life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

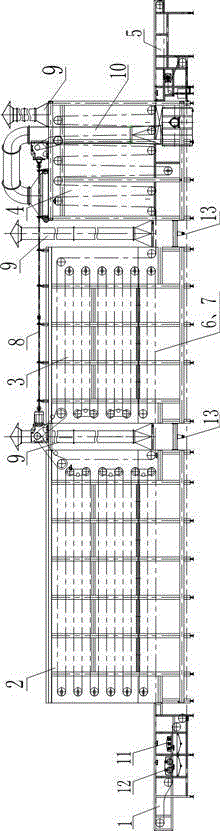

[0027] refer to figure 1 As shown, the equipment is an all-in-one machine for waking up, steaming, and drying steamed buns. From left to right in the figure, it includes an integrated entrance 1, waking area 2, steaming area 3, airing area 4, and outlet 5. A number of hanging basket assemblies 6 for carrying steamed buns are installed throughout the above-mentioned five parts of the area. The hanging basket assemblies 6 are driven by the conveying chain 7 to run continuously in the above-mentioned areas in sequence, and the main power system 8 is installed on the upper part of the steaming area 3. The main power system 8 drives the conveyor chain 7 to move.

[0028] Wherein, both sides of the steaming area 3 and the airing area 4 are provided with moisture discharge pipes 9 . In this embodiment, the conveying chains 7 in the noodle resting area 2 and the steaming area 3 are arranged to reciprocate horizontally, and the conveying chains 7 in the drying area 4 are arranged to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com