Constant-temperature and constant-humidity fermenting box

A constant temperature and humidity, proofing box technology, applied in the direction of dough fermenter, baking, dough processing, etc., can solve the problem of the inability to monitor and adjust the temperature and humidity in real time, the water content and temperature of the noodles, and the environmental impact of proofing and curing. and other problems to achieve the effect of reducing pollution opportunities, prolonging shelf life and achieving bacteria reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

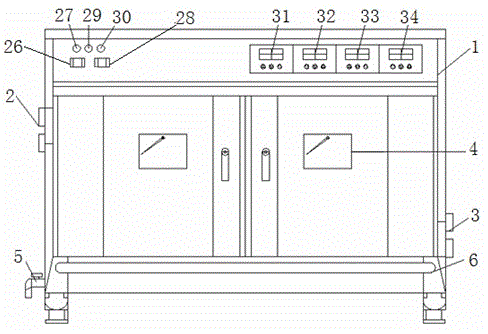

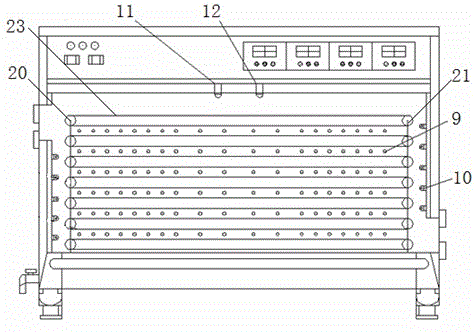

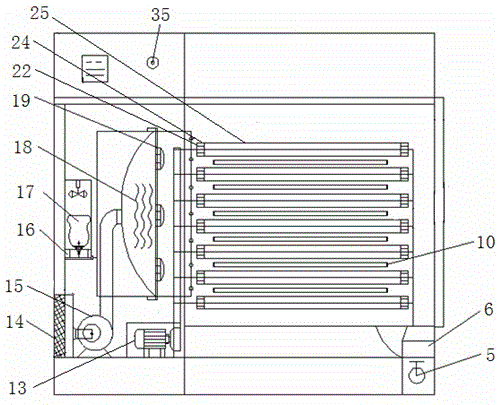

[0026] With reference to the accompanying drawings, this embodiment includes a box body 1, a transmission device, a sterilizing device, a heating device, a humidifying device, and a control center;

[0027] The upper left side of the box body 1 is provided with a first sliding window 2, the lower right side of the box body 1 is provided with a second sliding window 3, and the front side of the box body 1 is provided with a box door. The door is provided with an observation window 4, the observation window 4 is provided with a manual wiper, the bottom of the box 1 is provided with a drain valve 5 and an exhaust hole 6, and the drain valve 5 communicates with the exhaust hole 6;

[0028] The transmission device is installed inside the box body, including a motor 13, a transmission gear set connected to the motor, and a series of transmission gears and tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com