Patents

Literature

93results about "Dough heat treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High fiber and high protein baked goods production

InactiveUS20100303991A1Pleasant tastePotential healthDough/pre-mixesConfectioneryStarch gelatinizationHigh protein food

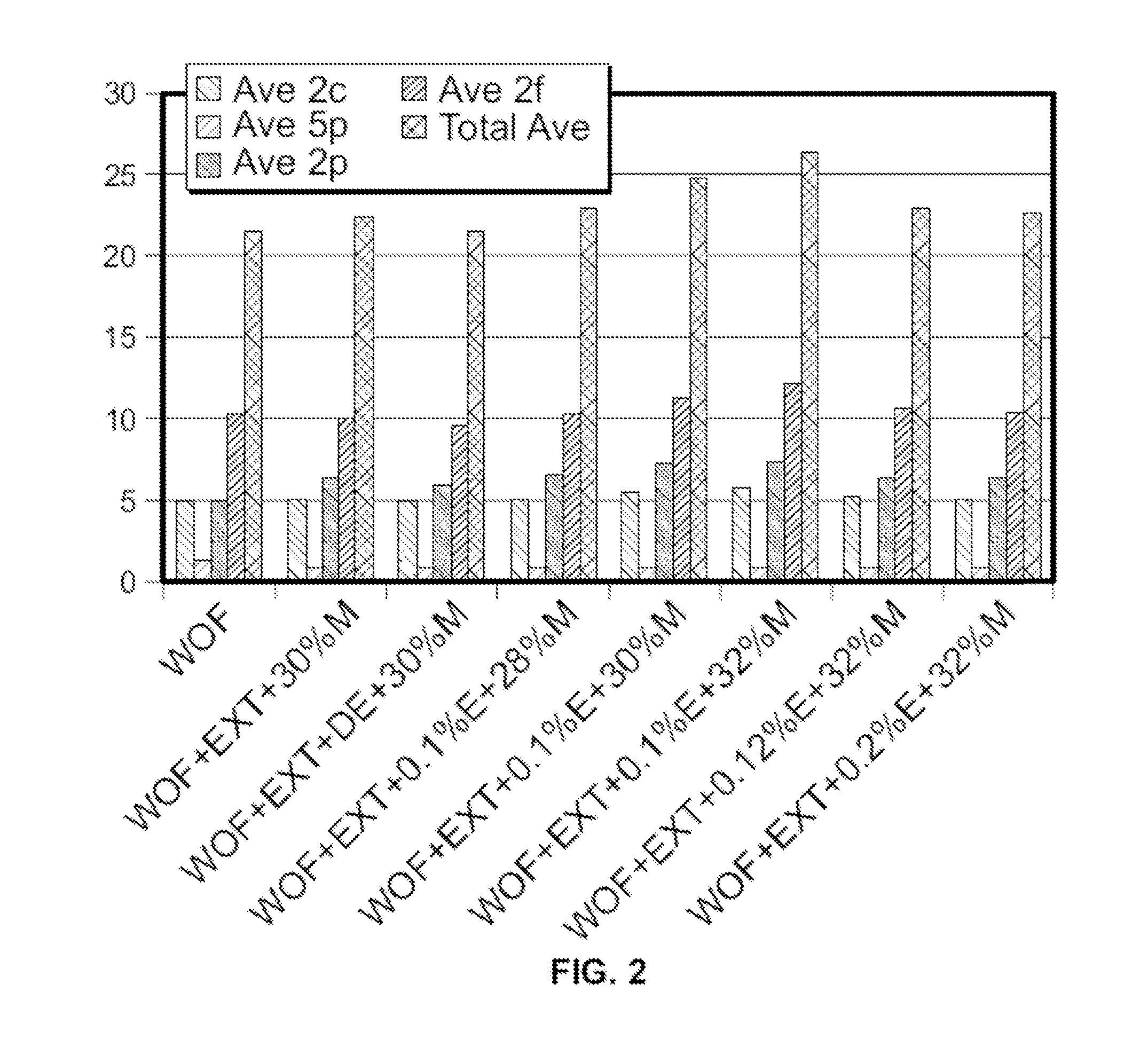

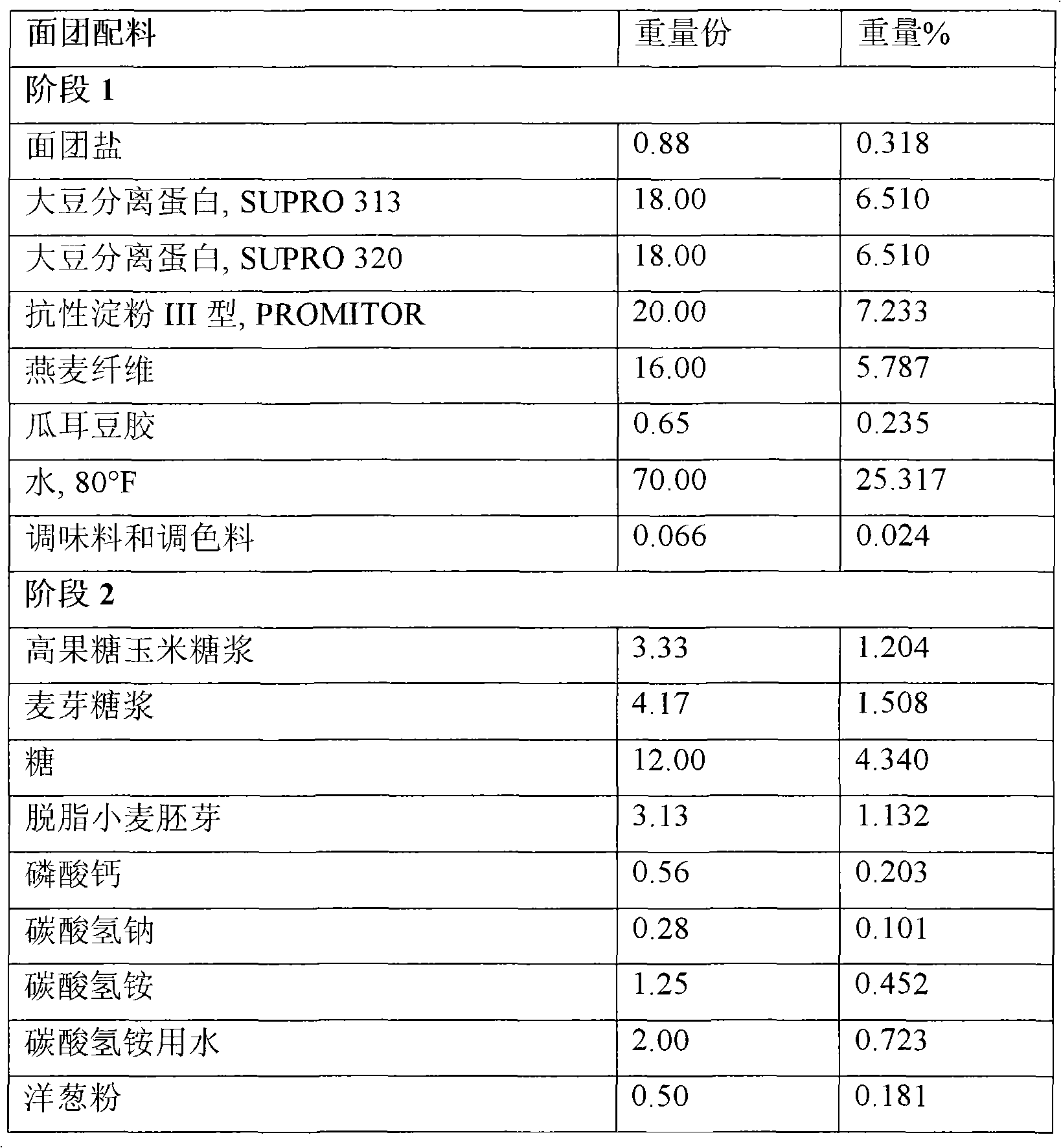

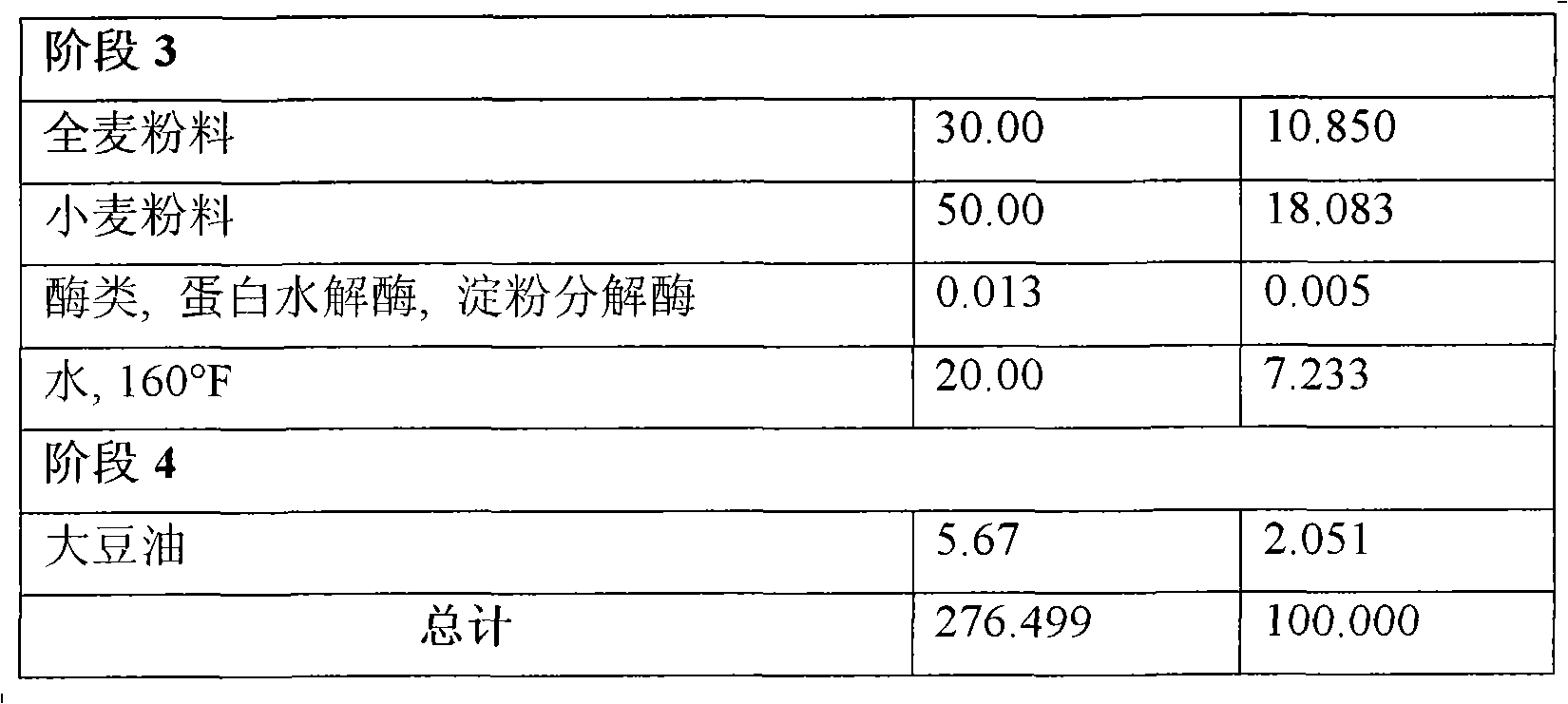

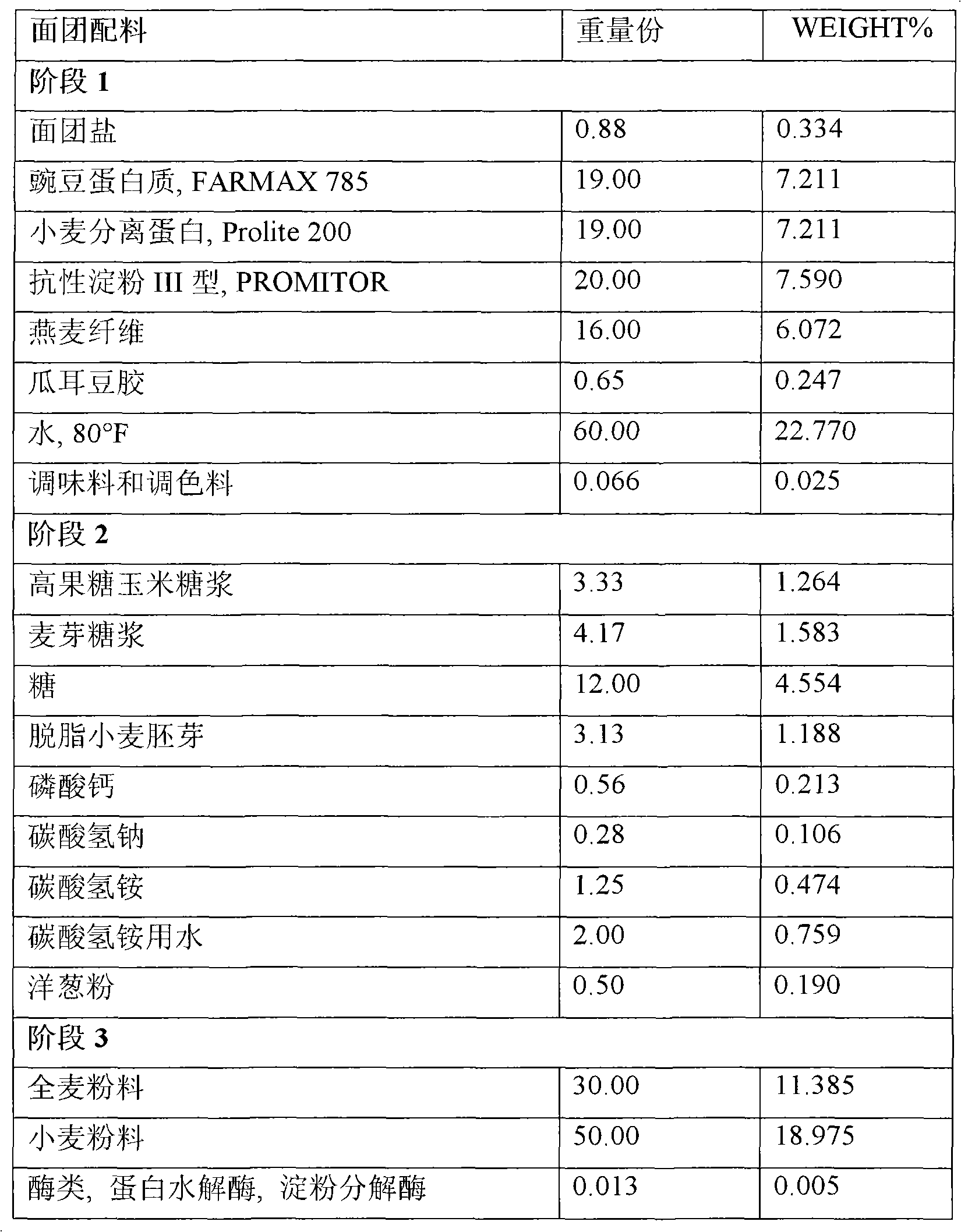

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

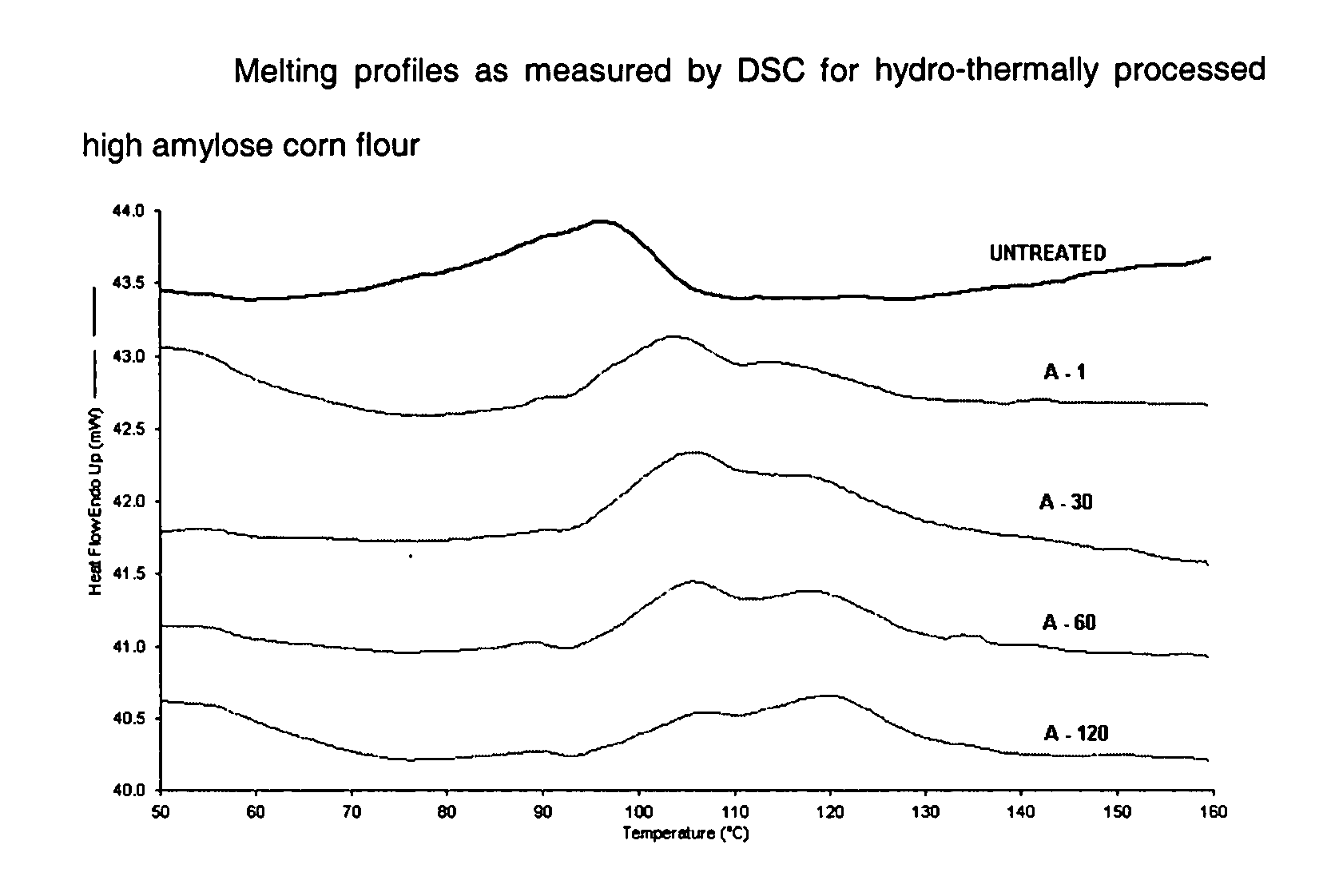

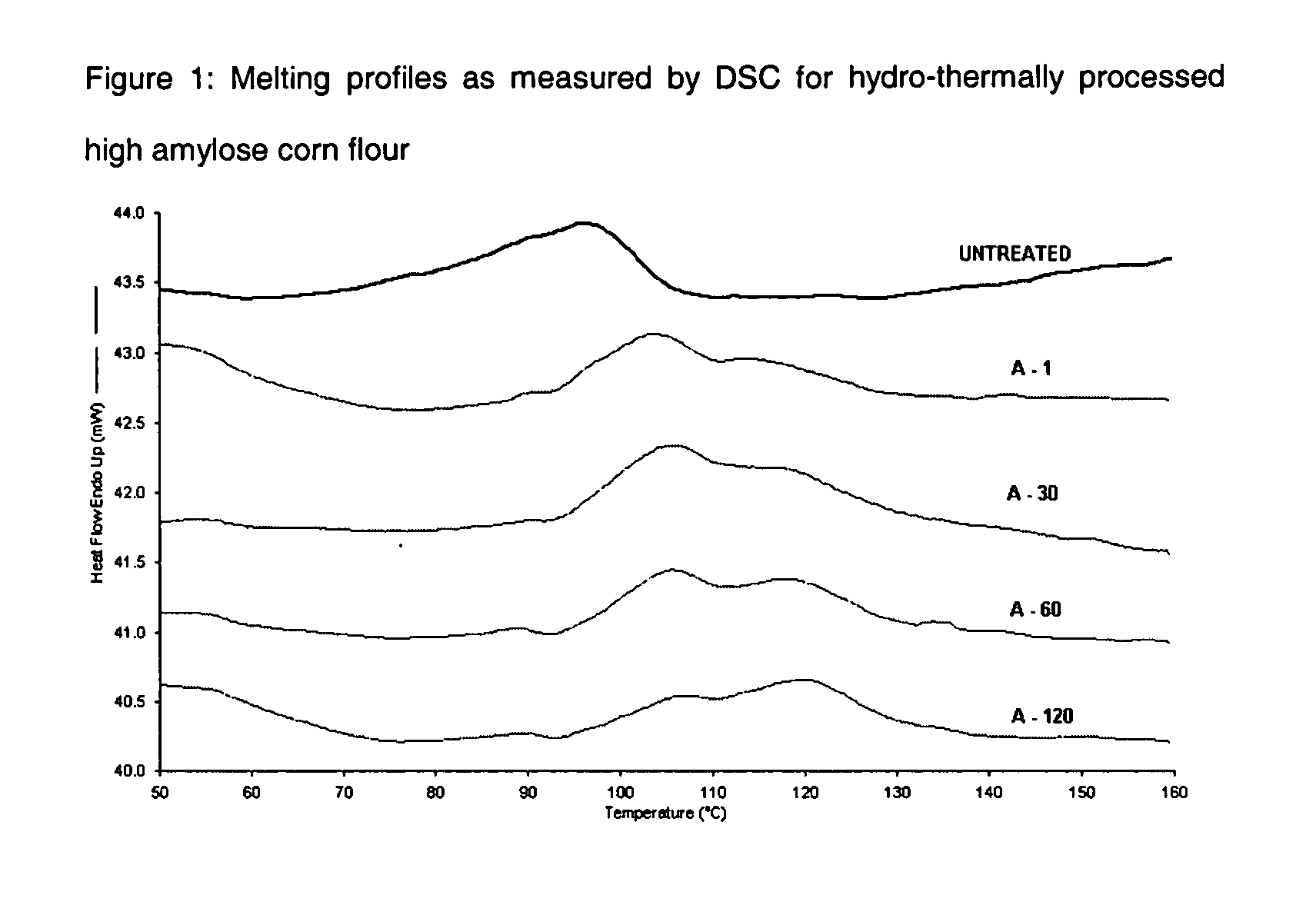

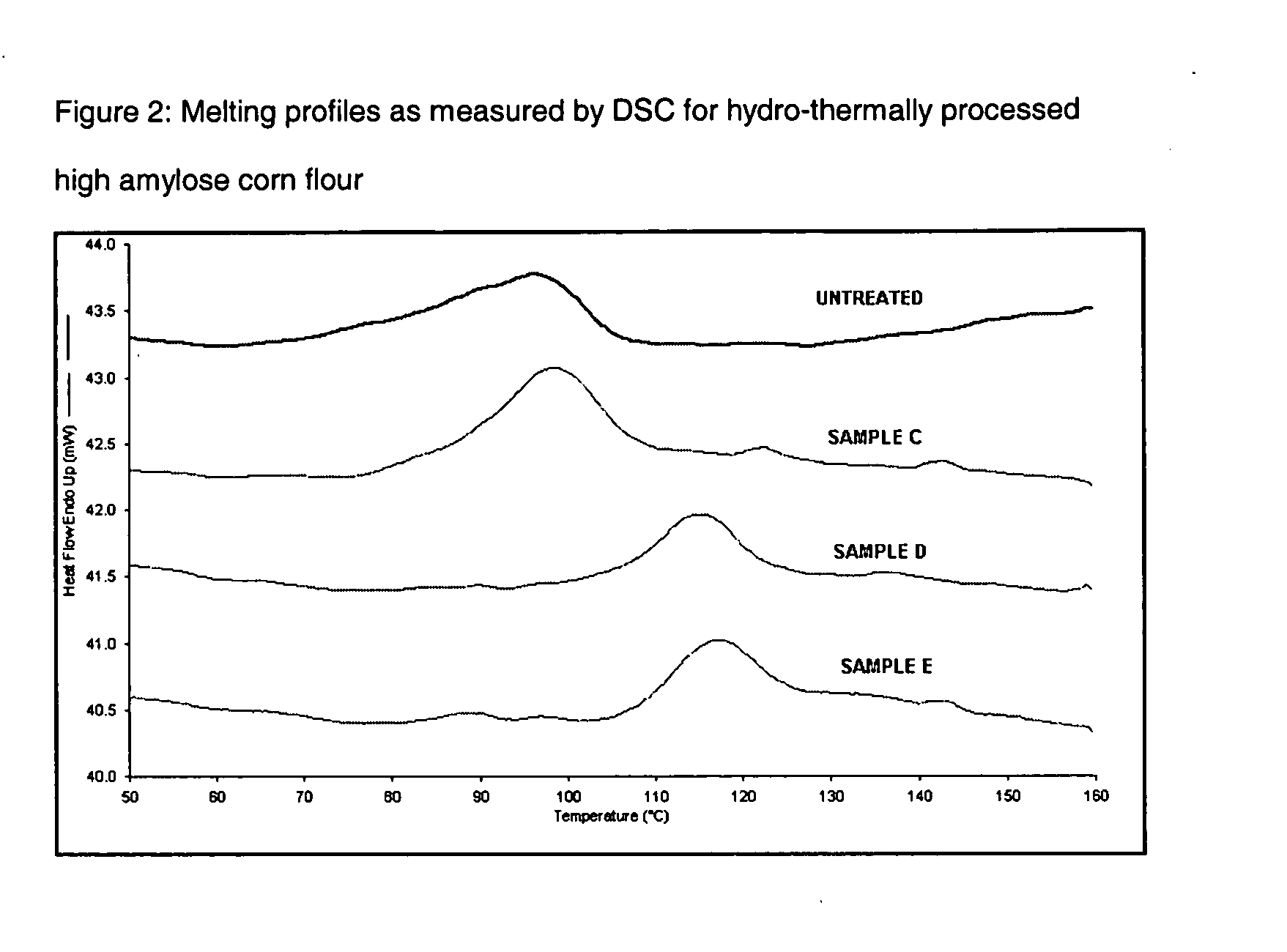

Flour composition with increased total dietary fiber, process of making, and uses thereof

High amylose flour may be processed by a short hydrothermal treatment to increase its total dietary fiber (TDF) content. These flours may be prepared by heating a high amylose flour at a total water content of from about 10 to 50% by weight at a temperature of from about 80 to 160° C., for about 0.5 to 15 minutes at target temperature. This invention further relates to products which contain the high TDF flour, including food products.

Owner:CORN PROD DEV INC

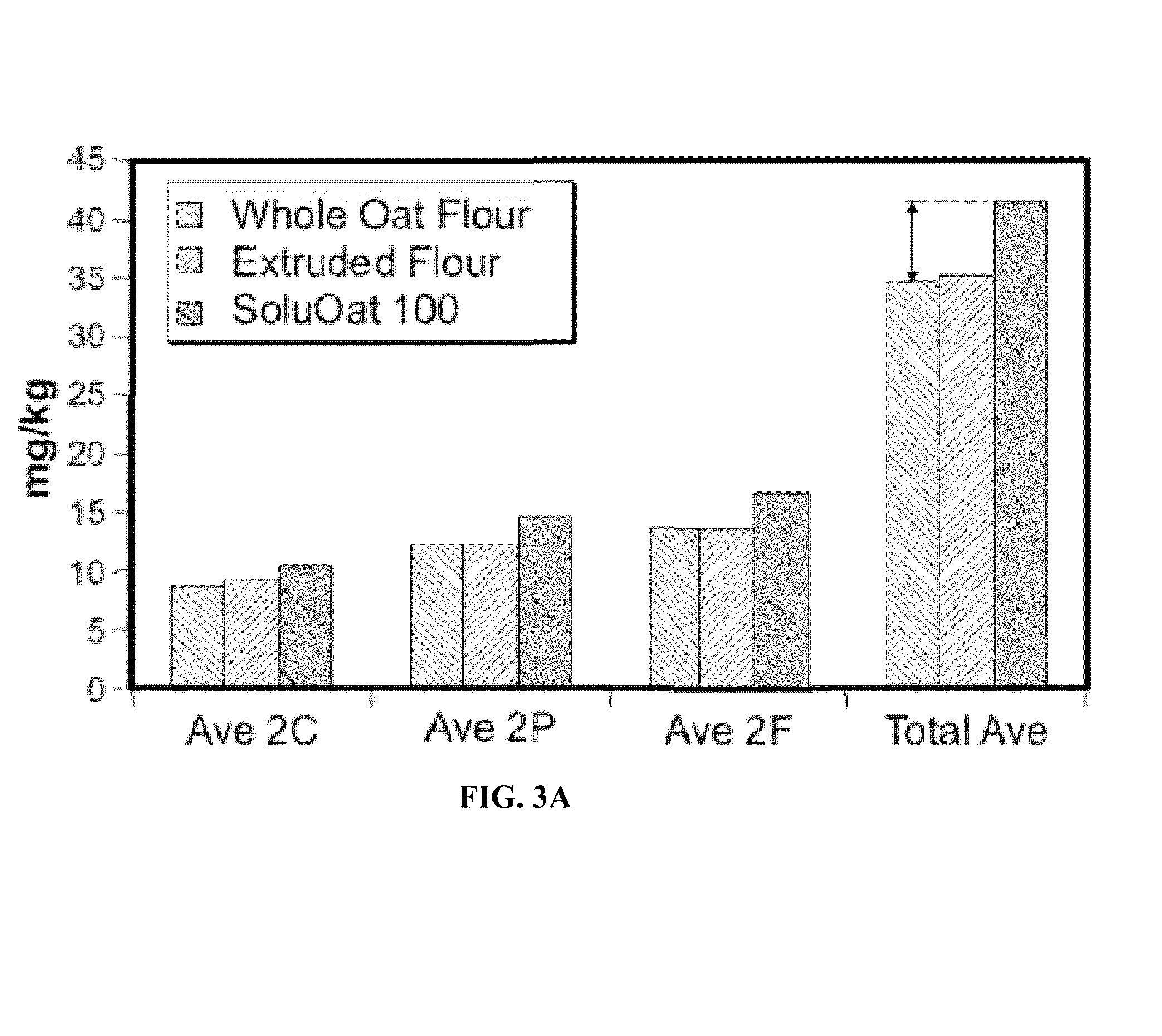

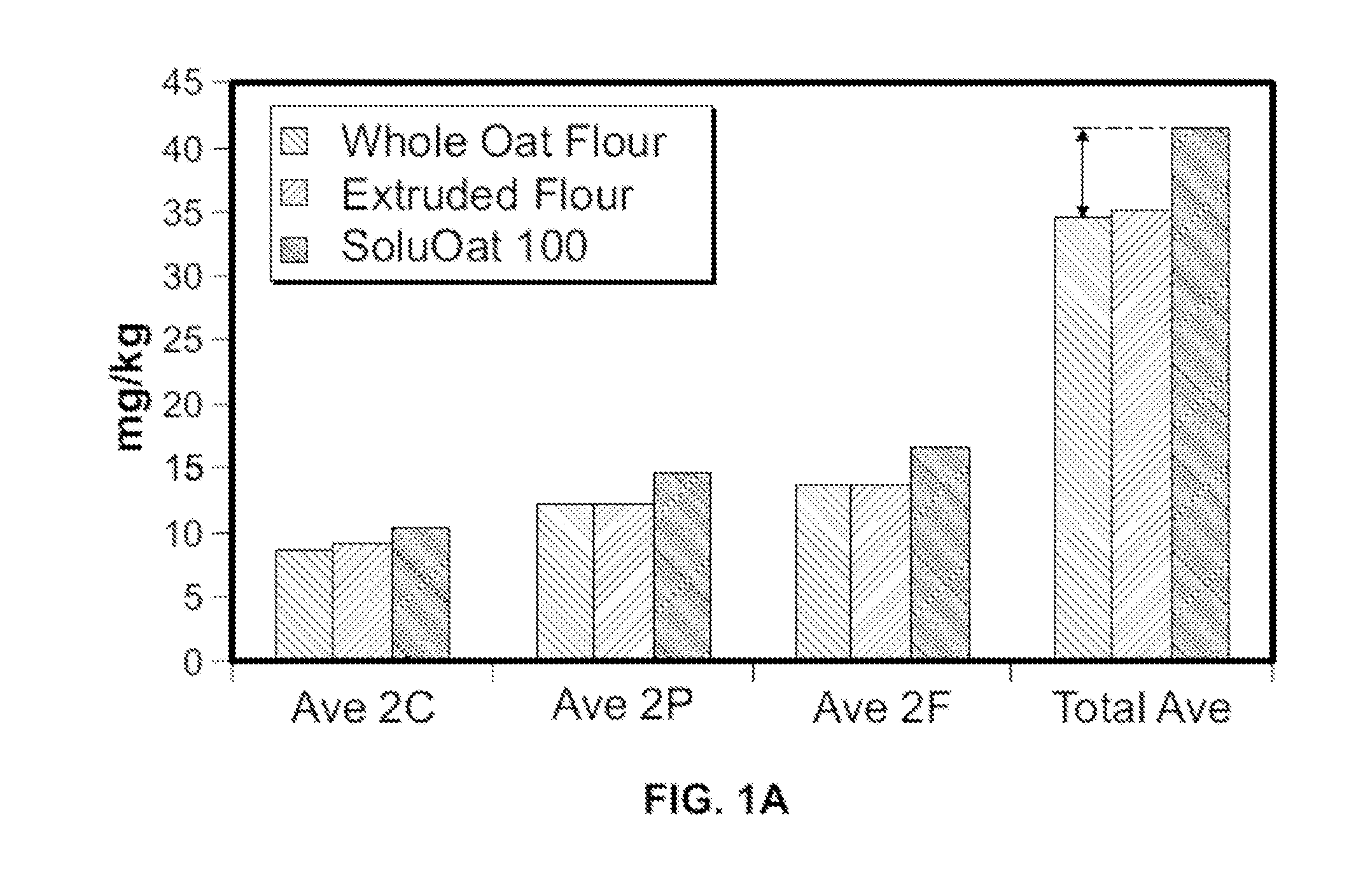

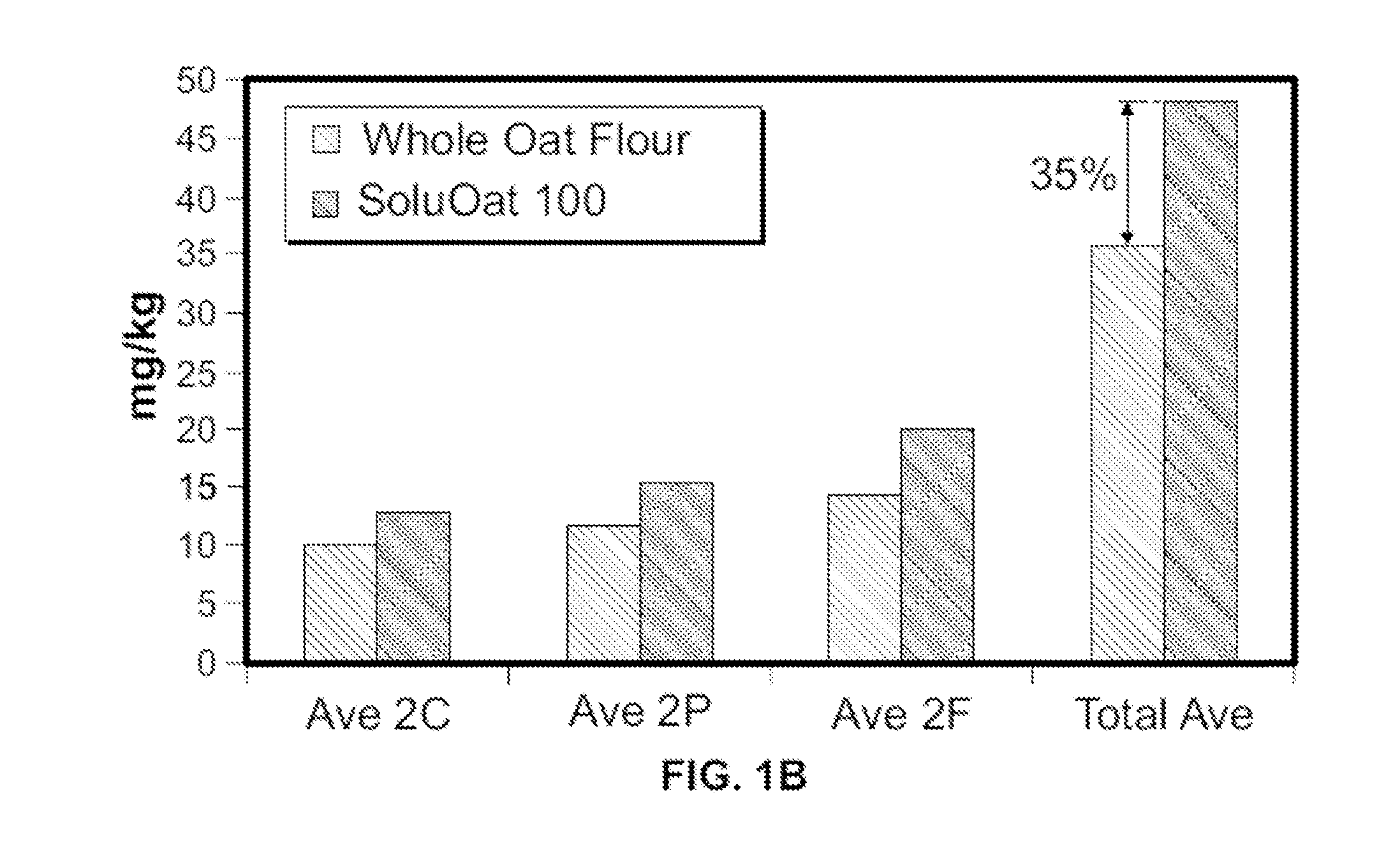

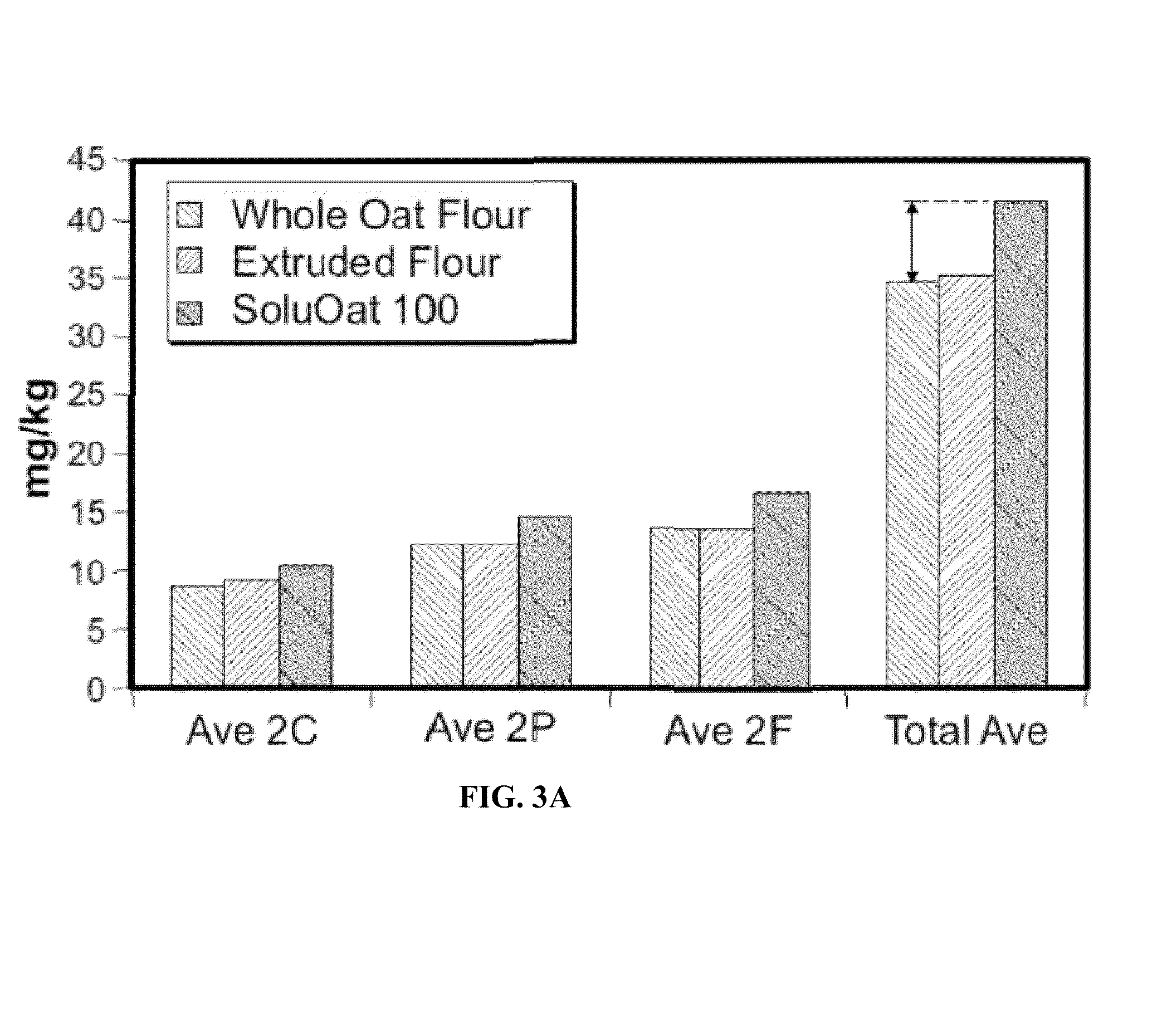

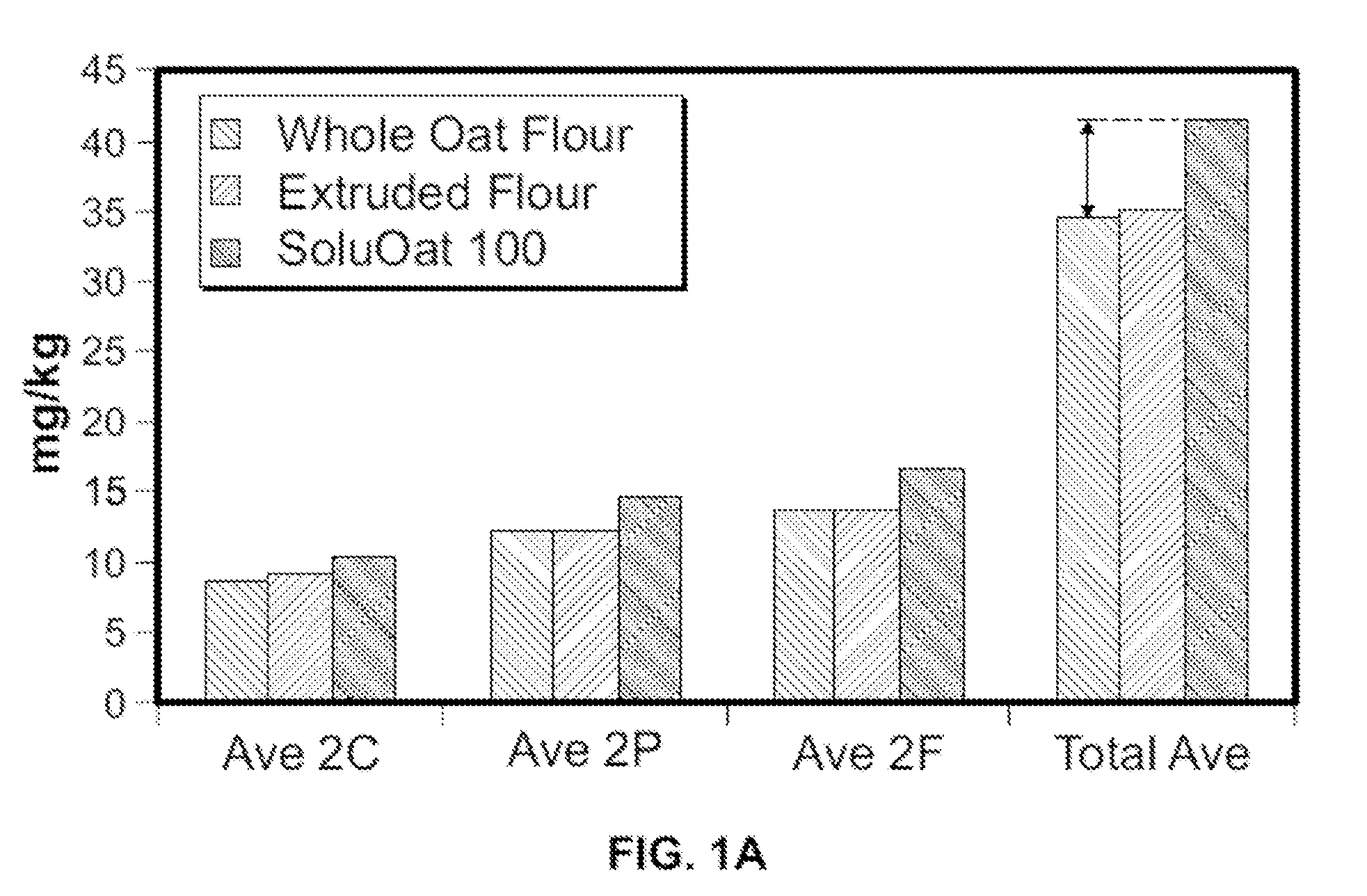

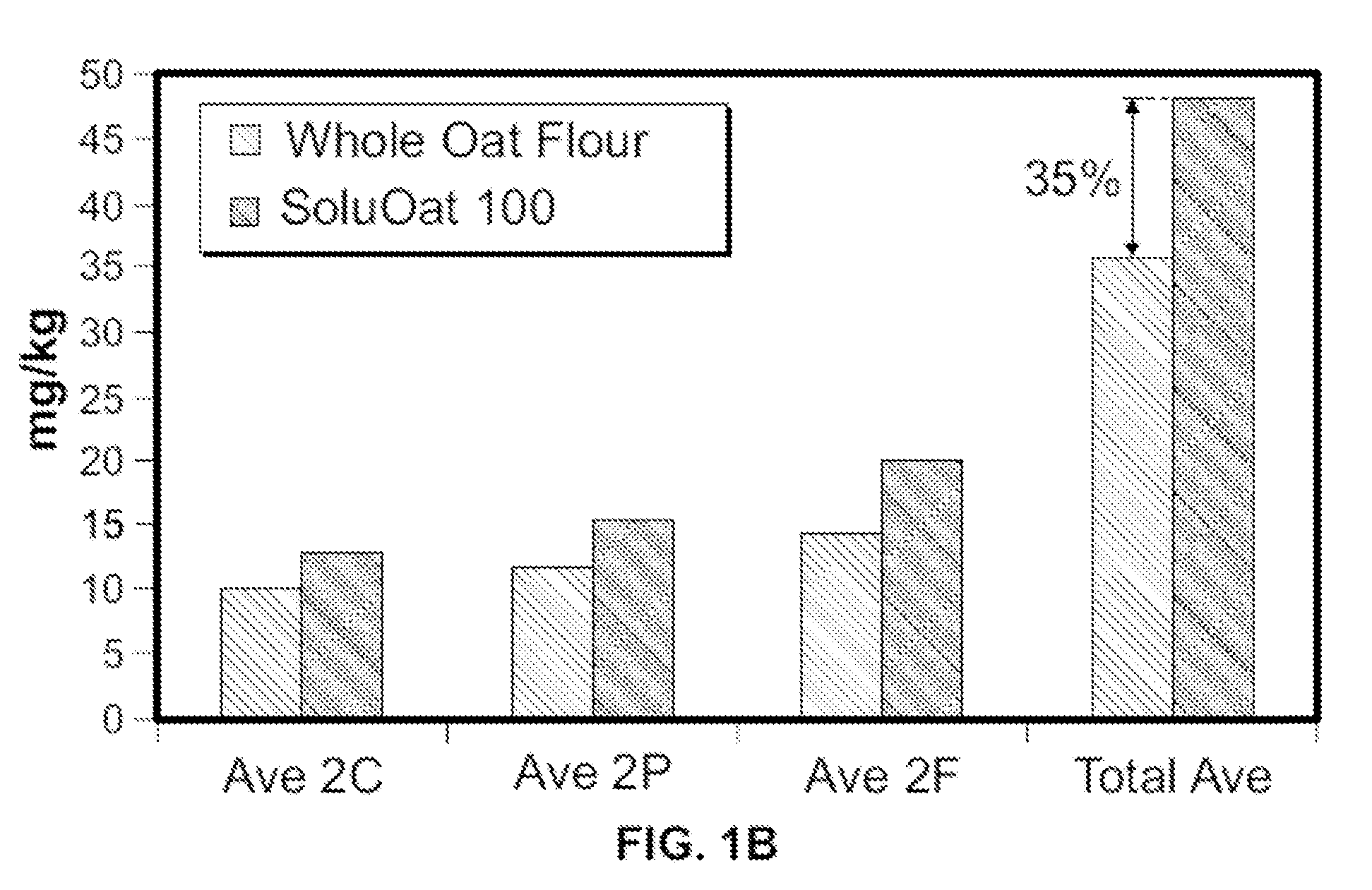

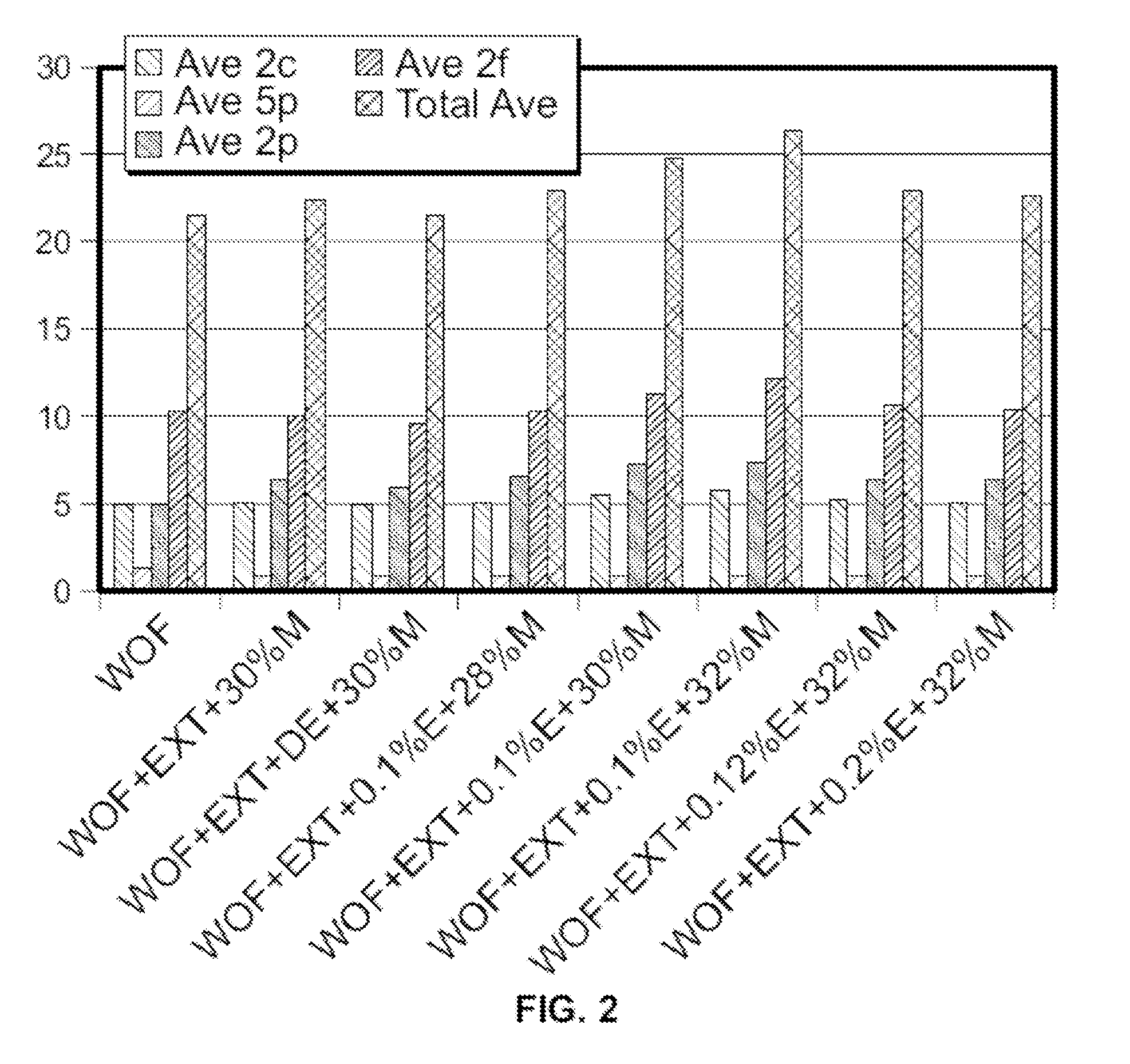

Method of Preparing Highly Dispersible Whole Grain Flour with an Increased Avenanthramide Content

ActiveUS20130209610A1Increased avenanthramide contentMaintain integrityWort preparationMetabolism disorderWhole grainsAvenanthramide

A method of preparing a highly dispersible whole grain oat flour by hydrolyzing, milling and agglomerating grain flour to arrive at a whole grain oat flour having an increased avenanthramide content compared to native oat flour.

Owner:THE QUAKER OATS CO

Method of Processing Oats to Achieve Oats with an Increased Avenanthramide Content

Producing soluble oat flour with an increased level of avenanthramides by using enzymes to precondition whole oat flour prior to extrusion.

Owner:THE QUAKER OATS CO

High fiber and high protein baked goods production

ActiveCN101897353APleasant tasteNo smellDough/pre-mixesConfectioneryHigh protein foodAdditive ingredient

Substantially uniform hydration and dispersion of high amounts of protein and fiber are achieved while avoiding lump formation, hard textures, and off-tastes in the continuous, mass production of high protein and high fiber content sheetable doughs, and baked goods such as crackers, snacks, and cookies made from the sheeted doughs, by hydrating the protein and fiber with water at a temperature below the denaturization temperature of the proteins, and steaming the hydrated mixture without substantial gelatinization of starch during dough production. The steamed, hydrated mass may be admixed with ingredients comprising at least one flour comprising starch to obtain a dough while avoiding substantial gelatinization of starch of the at least one flour during mixing. The baked goods may have a protein content of at least about 4 g, a fiber content of at least about 4 g, and a whole grain flour content of at least about 4 g per 30 g serving.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Heat-Treated Flour

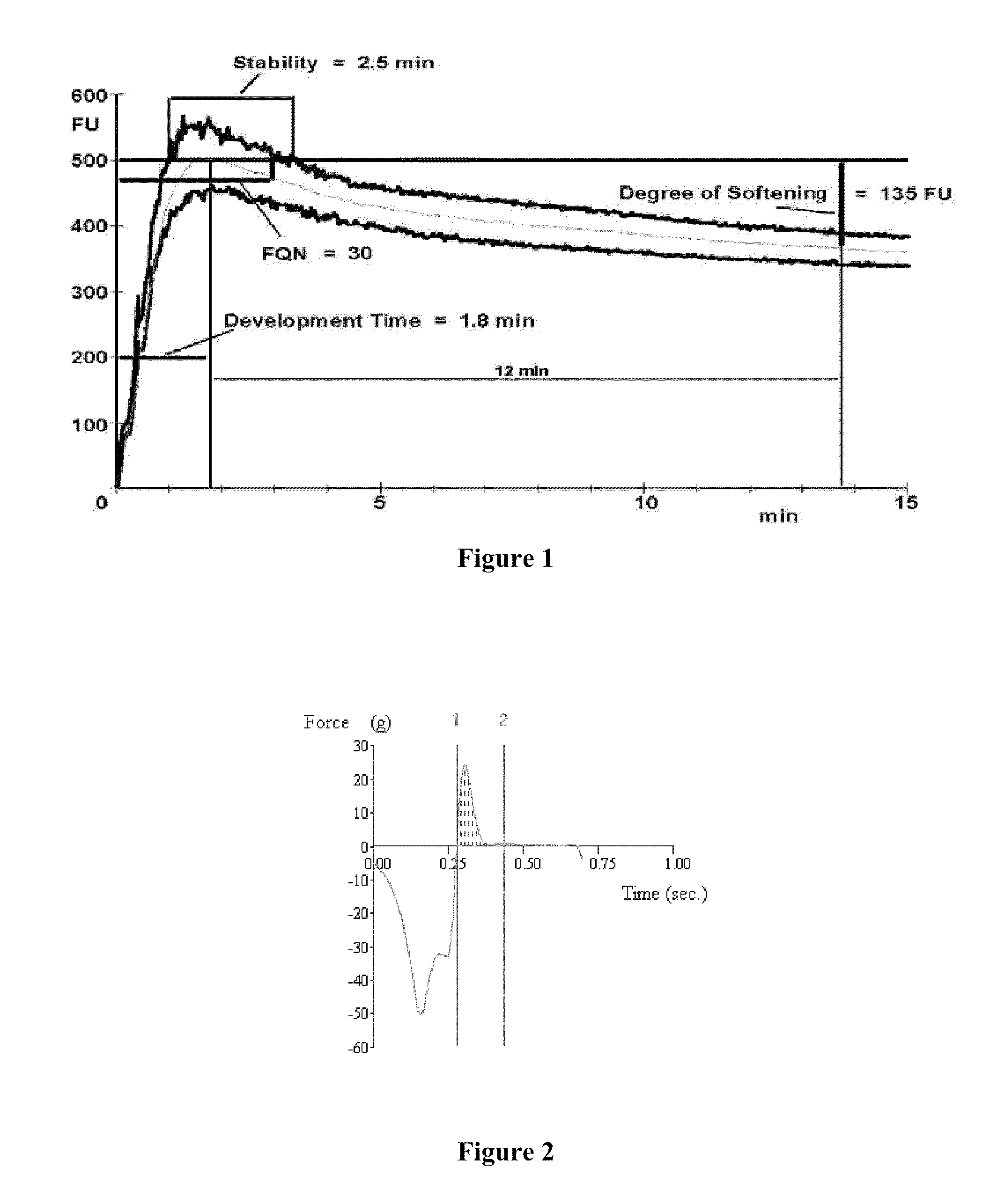

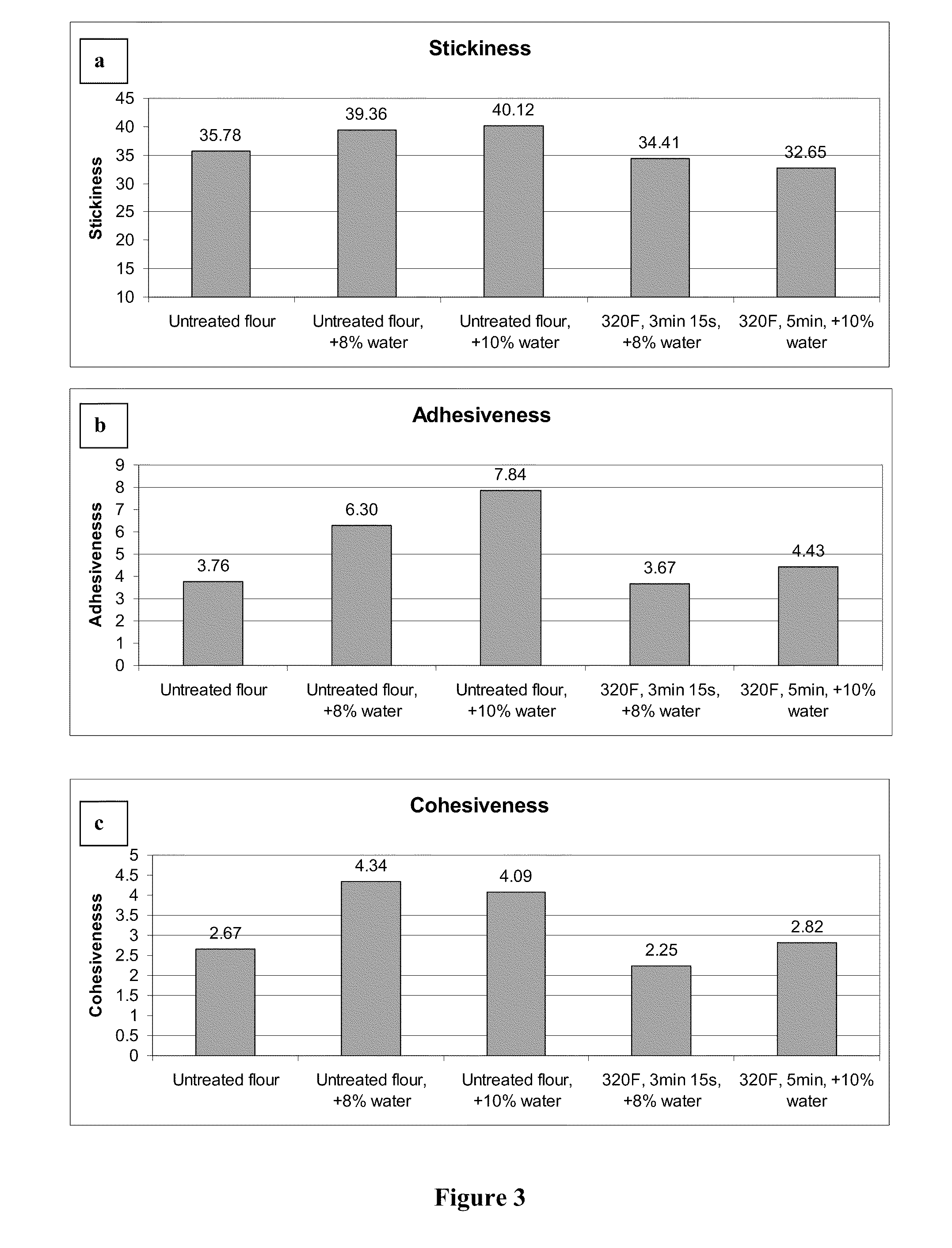

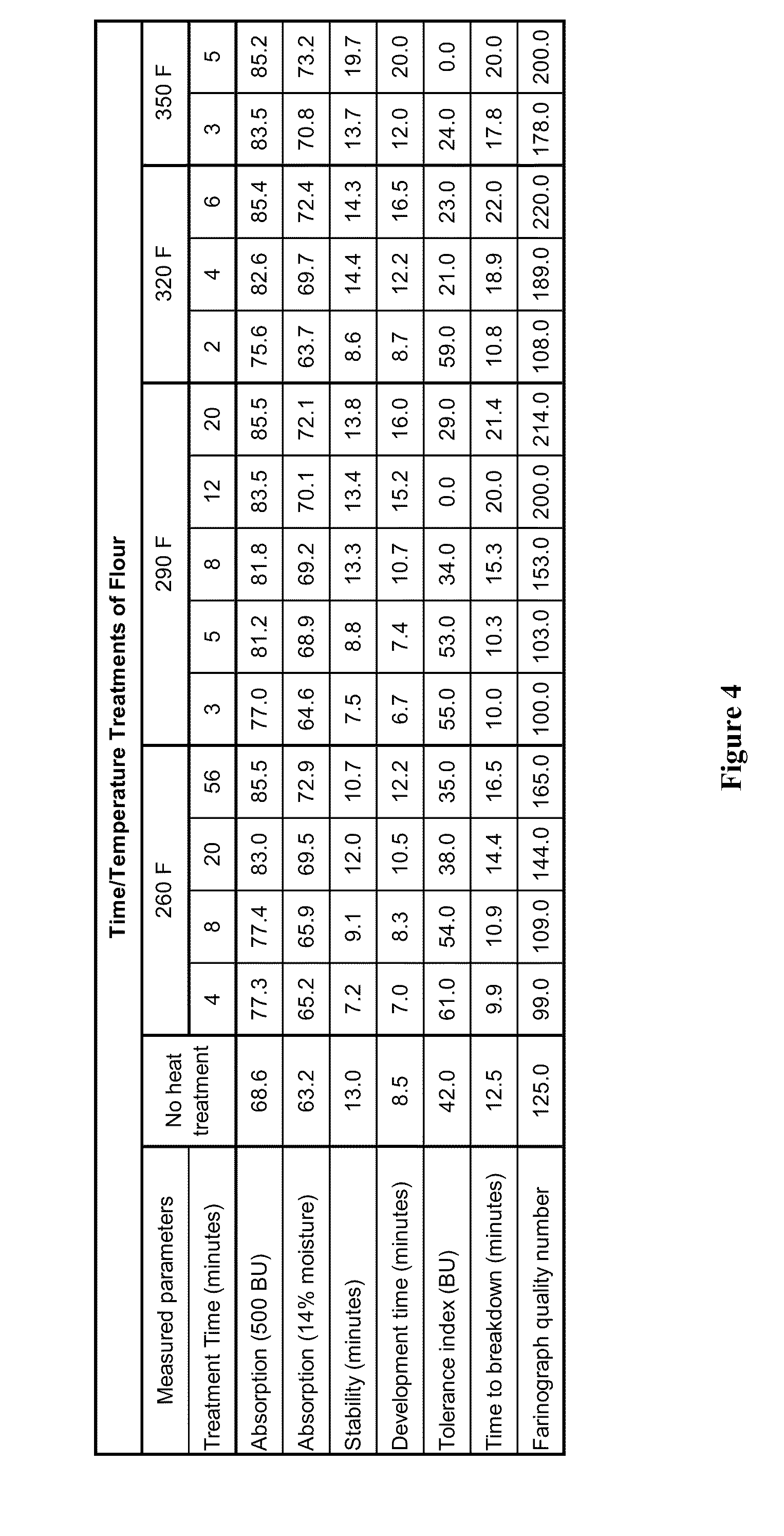

InactiveUS20100092639A1Improve performanceReduce viscosityBaking mixturesBakery productsBaked goodsMoisture absorption

A method for heat-treating flour comprising the steps of dehydrating the flour to minimize or avoid gelatinization, and heat treating the dehydrated flour. The resulting flour has increased moisture absorption. Dough made from the heat-treated flour has improved performance and baked goods made from the heat-treated flour have improved properties relative to dough and baked goods made from untreated flour.

Owner:RICH PRODUCTS

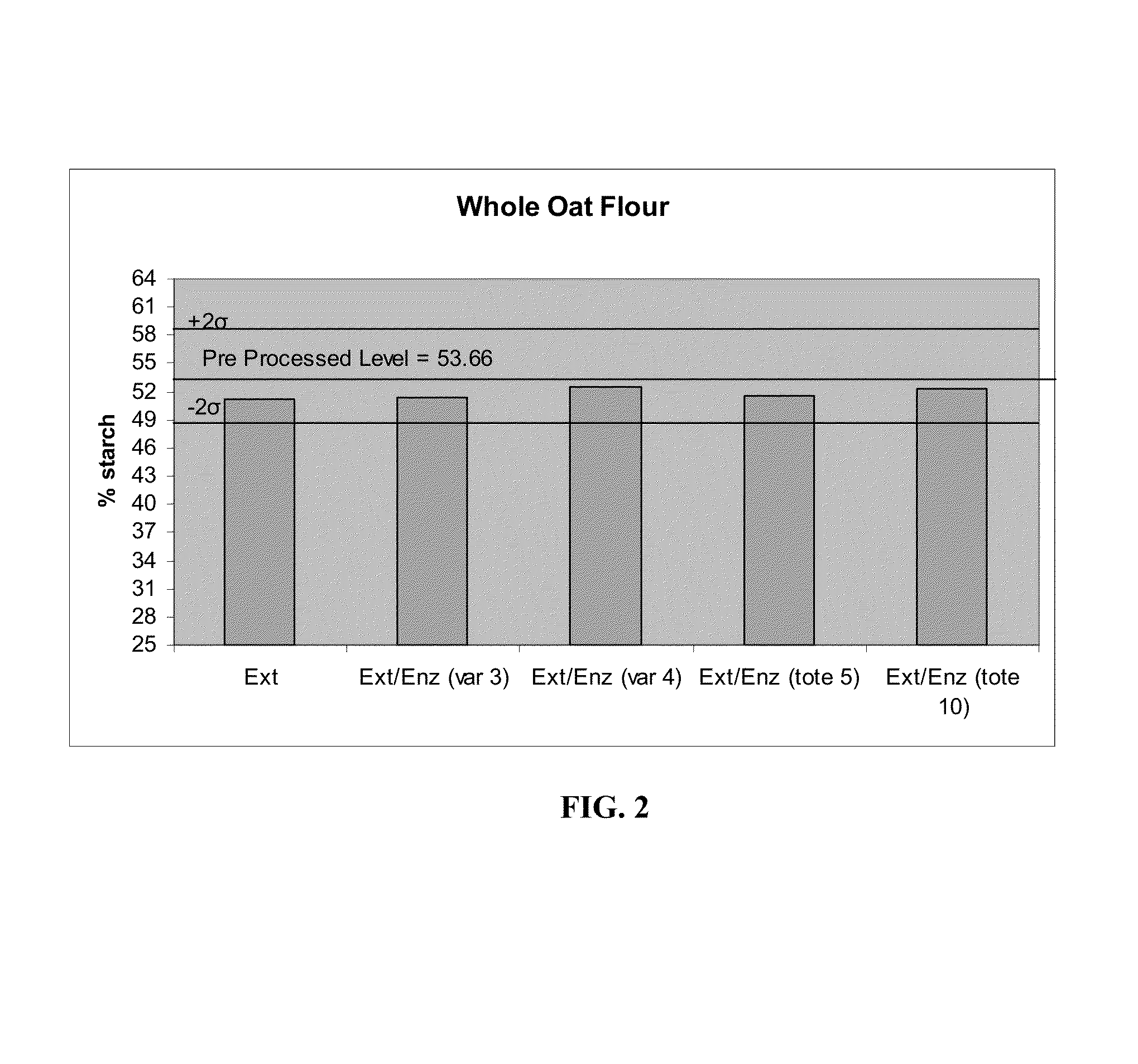

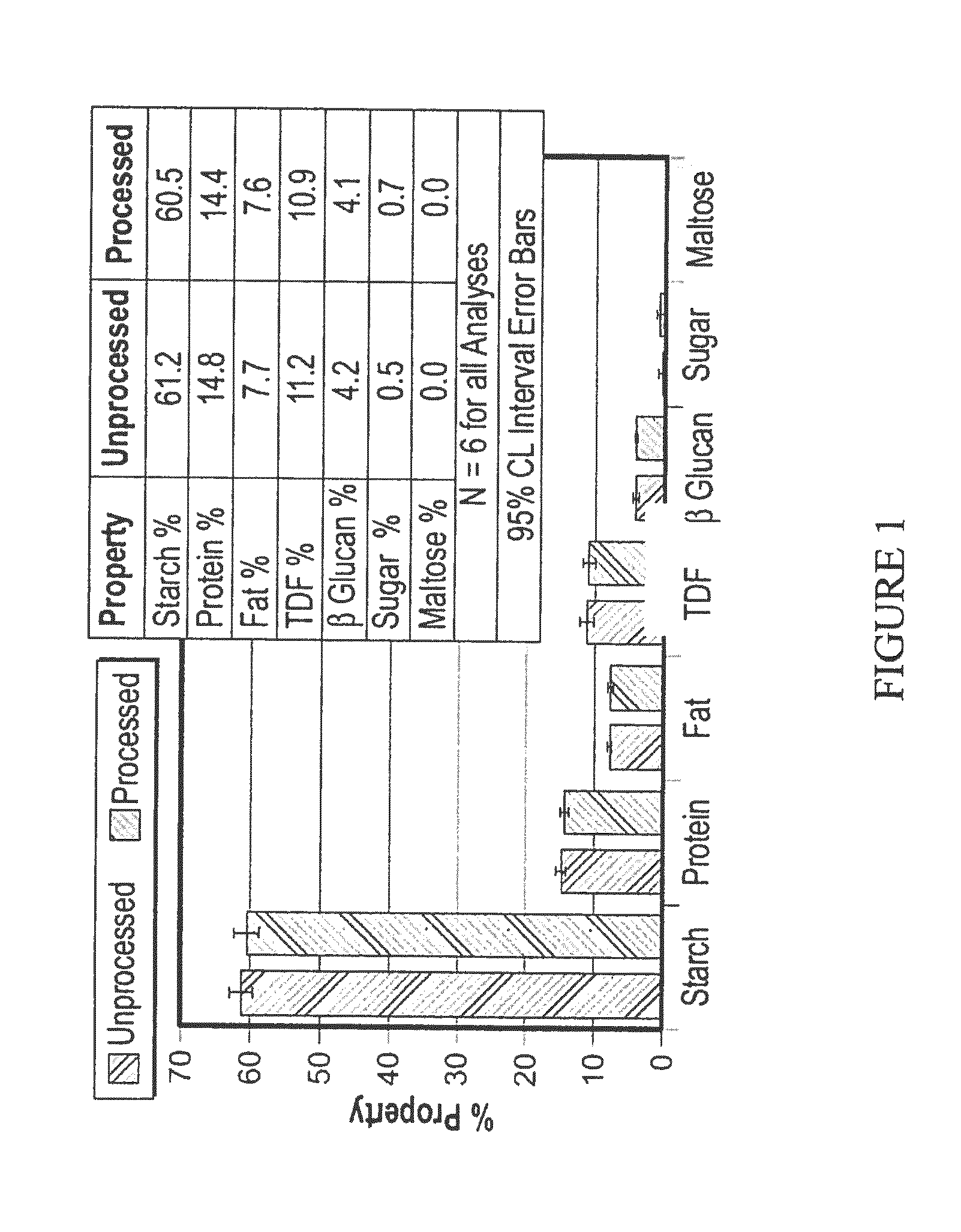

Whole Grain Composition Comprising Hydrolyzed Starch

A composition comprising a whole grain with hydrolyzed starch. Although the starch can shift from relatively higher molecular weight moieties to relatively lower molecular weight moieties during hydrolysis, the relative proportions of the principal anatomical components of the caryopses of the grain—the starchy endosperm, germ and bran—remain approximately the same as evinced, for example, by the weight percentages and relative mass ratios of starch, fat, protein, dietary fiber, beta-glucan, and sugar in the composition. Additionally, the whole grain composition can be a powder, for example, a flour, and the whole grain composition can be granulated to a desired size to provide a powder that is highly dispersible in liquid. When gelatinized, hydrated and dispersed in a liquid, the whole grain with hydrolyzed starch can have a lower viscosity, grittiness, and graininess compared to the same variety of whole grain with unhydrolyzed starch.

Owner:THE QUAKER OATS CO

Process for Neutralizing Enzymes in Corn

A method of making an enhanced corn masa by roasting corn kernels to neutralize the corn seed prior to cooking and soaking the corn in lime. Roasting of the corn kernels provides numerous benefits including the ability to dial in a roasted flavor with the use of blends of roasted and unroasted kernels, a higher conversion of the corn kernel into a finished product, a reduced acrylamide content in finished product, and fewer off-flavors in baked products.

Owner:FRITO LAY NORTH AMERICA INC

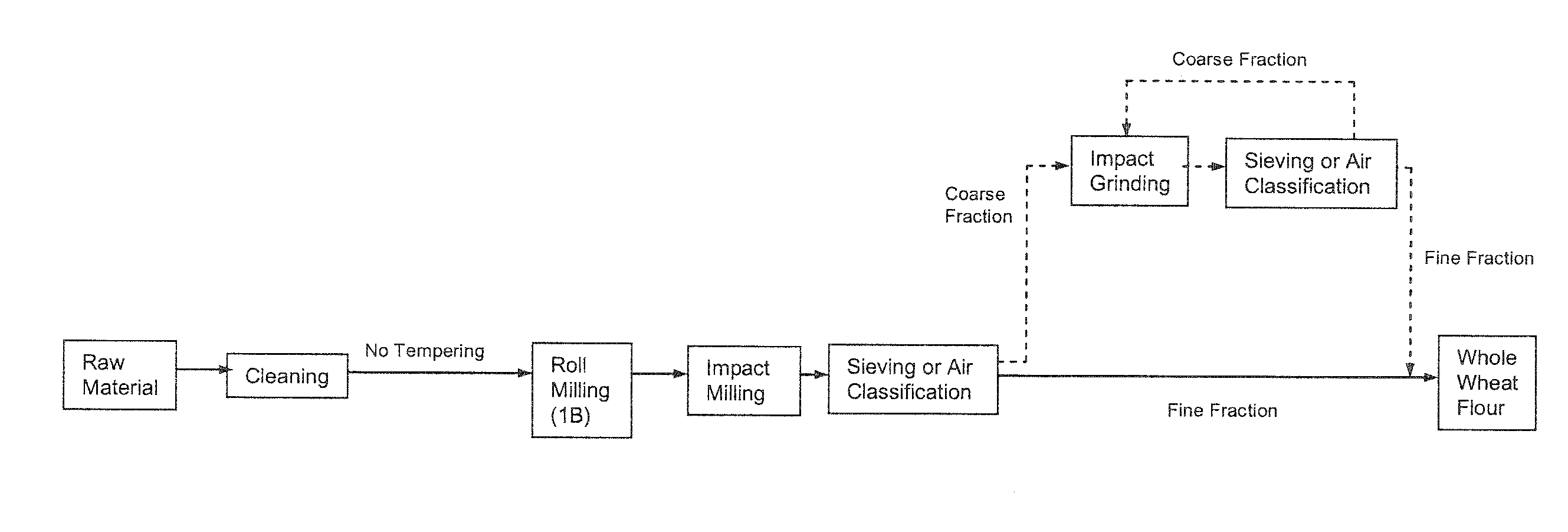

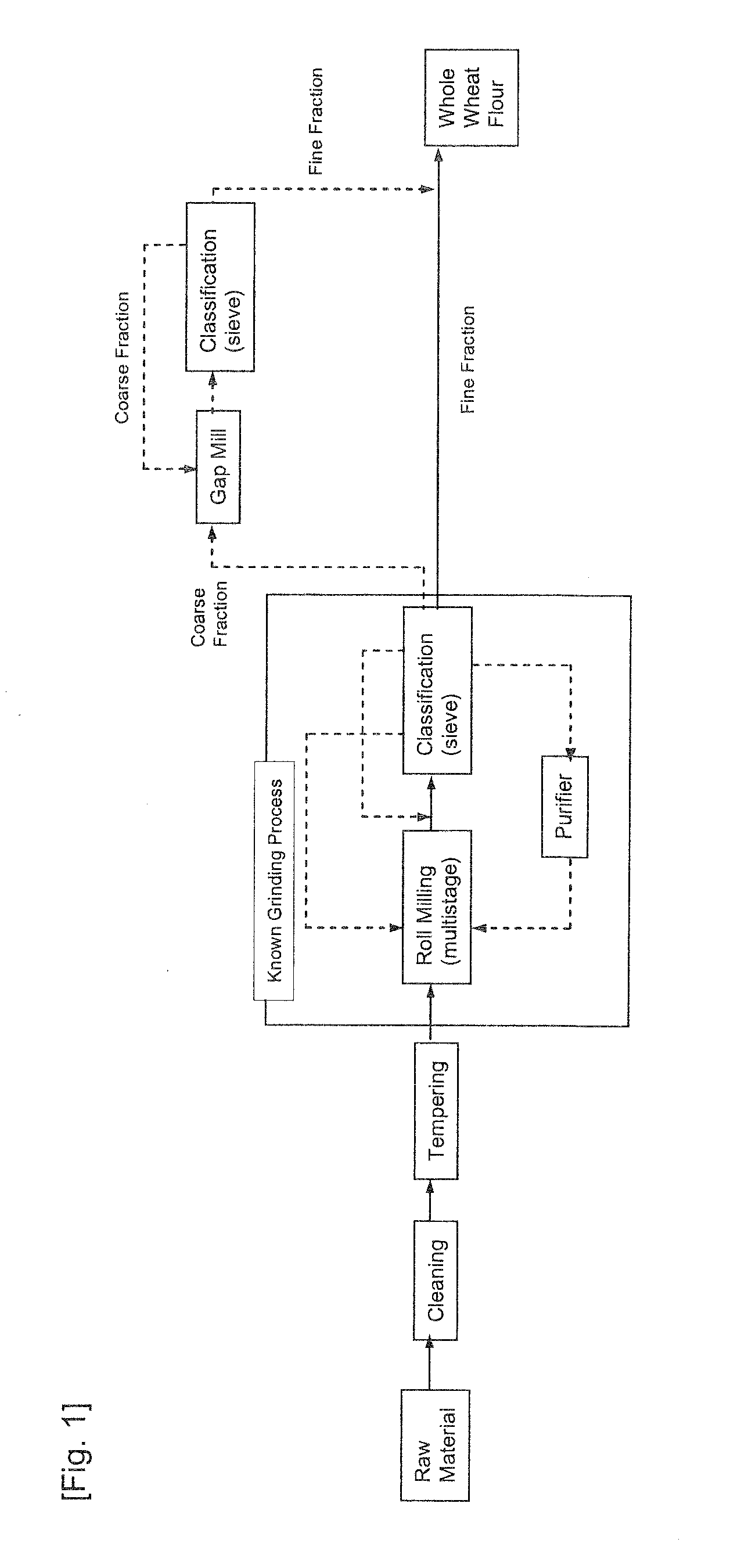

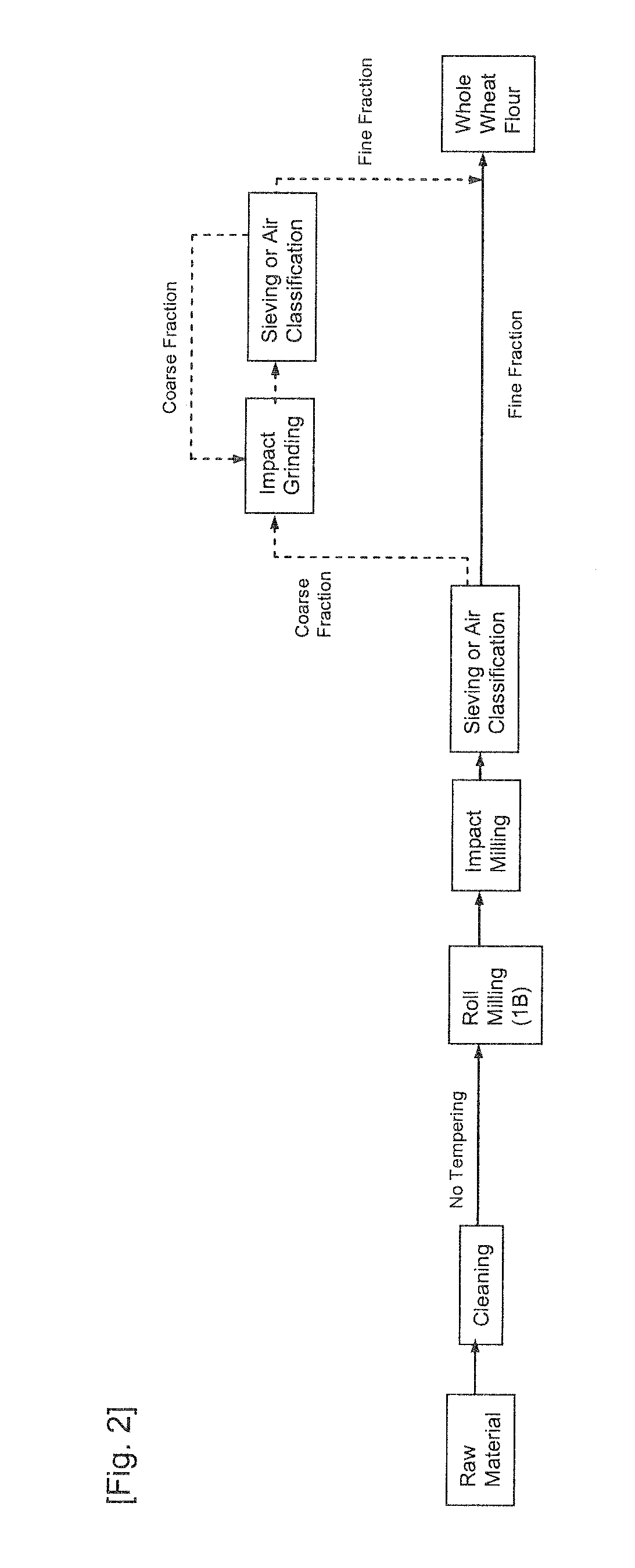

Process of producing whole wheat flour

InactiveUS20090169707A1Efficient productionDamage to starchBakery productsFood shapingMoistureWholemeal flour

A process of producing whole wheat flour including the steps of (1) coarsely grinding wheat kernels, (2) separating the resulting ground product into a fine fraction with an average particle size less than a size ranging from 150 to 200 μm and a coarse fraction with an average particle size more than that of the fine fraction and at or above a size ranging from 150 to 200 μm, (3) pulverizing the coarse fraction by impact grinding, (4) fractionating the resulting ground product obtained in step (3) to collect a fine fraction with an average particle size less than a size ranging from 150 to 200 μm, and (5) combining the fine fraction from step (2) and the fine fraction obtained in step (4). Preferably, the coarse fraction obtained in step (2) is subjected to a heat-moisture treatment, and the heat-moisturized fraction is pulverized by impact grinding in step (3).

Owner:NISSHIN FLOUR MILLING CO LTD +1

Pasteurized uncooked batters and refrigerated ready-to-bake batters, and the methods of manufacturing

Described are uncooked batters that have been effectively pasteurized and have no gelatinized starch. These batters are characterized as having low viscosity, a water activity of greater than 0.90, the absence of an active leavening agent, and a total plate count of less than 1000 per gram. There are two methods of manufacturing these pasteurized uncooked batters. One method uses irradiated flour and sterile aqueous liquid to make a pasteurized flour slurry; the other method uses a process of treating the whole grain at temperature and time conditions such that the exterior of grain is pasteurized followed by wet milling of the whole grain in a sterile aqueous liquid such that the slurry passes through a 20 mesh screen. In both methods, the farinaceous material remains uncooked and the starch has not been gelatinized. The pasteurized aqueous flour slurries, are then added to the pasteurized remaining ingredients of the batter in a sterile environment. Refrigerated Ready-to-Bake batters can be made by the addition of gas upon dispensing the batter from a container having the batter and a compressed gas such as carbon dioxide, nitrous oxide, or nitrogen.

Owner:MITCHELL CHERYL R +1

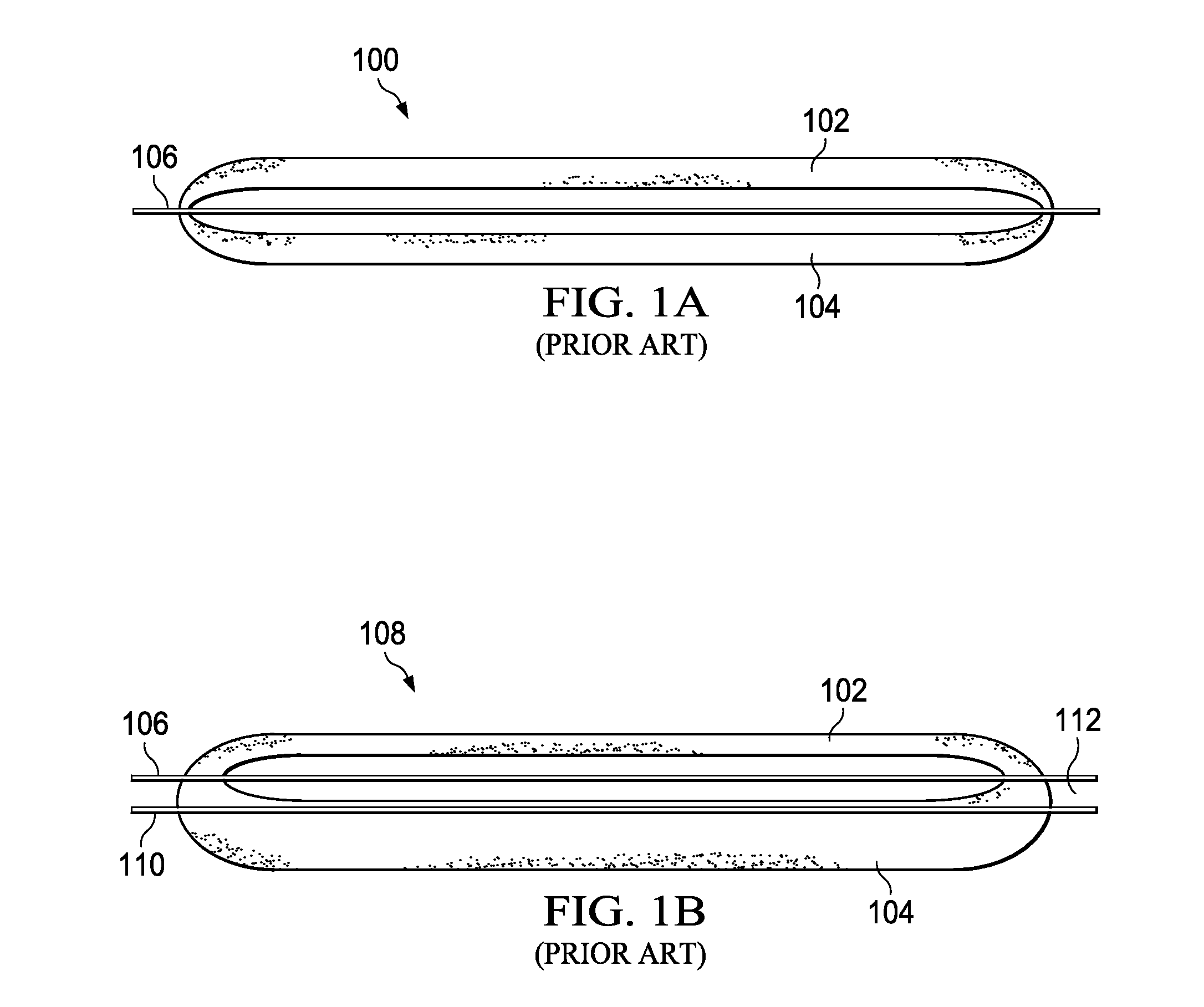

Wheat Materials and Related Methods

InactiveUS20080152781A1Reduce and minimize damageAvoid damageDough heat treatmentFood preparationActive enzymeAdditive ingredient

Described are methods of treating wheat materials, including reducing the amount of active enzymes in a wheat material by treating with steam; as well as wheat flour, dough, and other compositions and food ingredients prepared from the treated wheat material.

Owner:DREESE PATRICK C

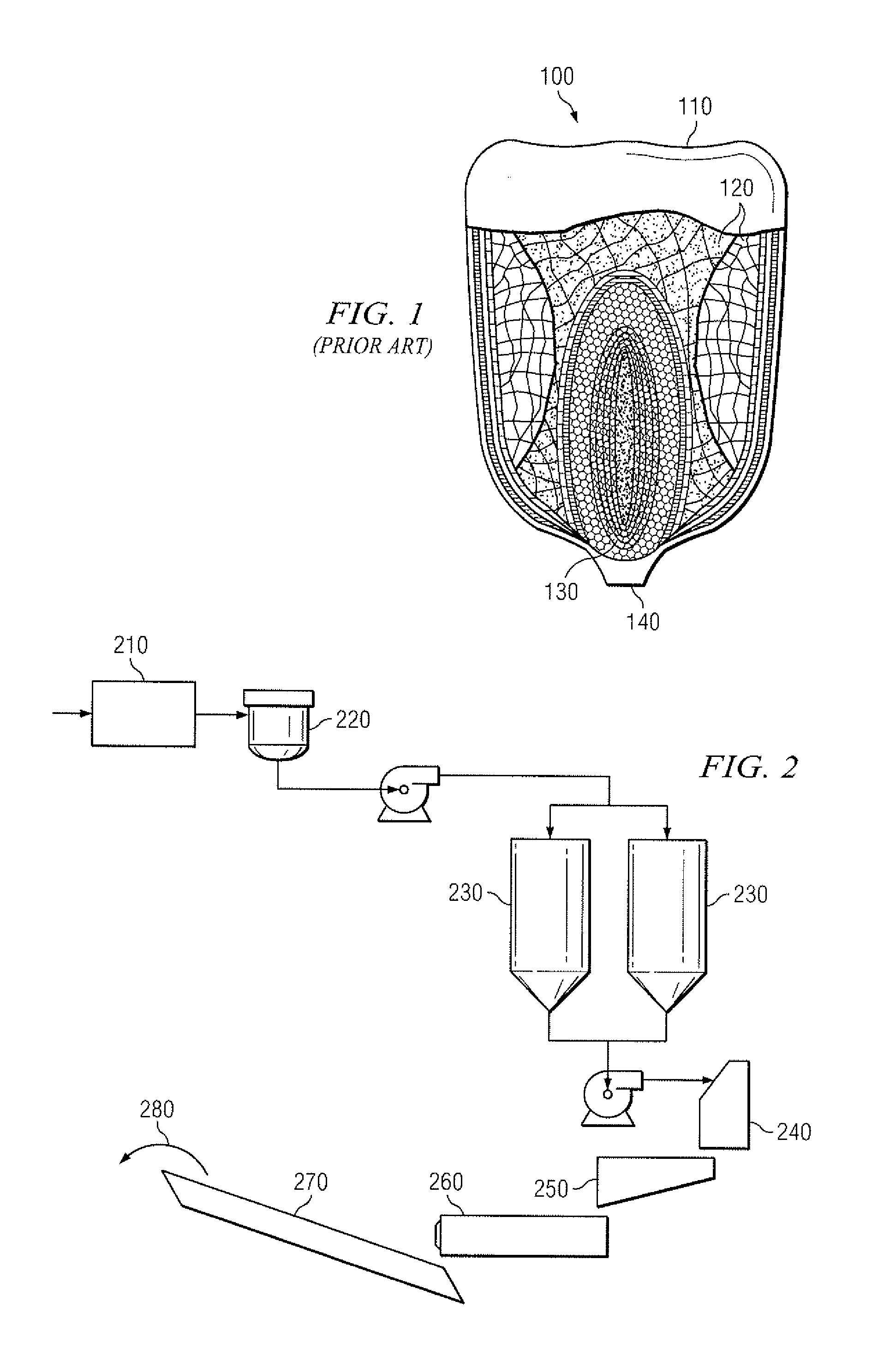

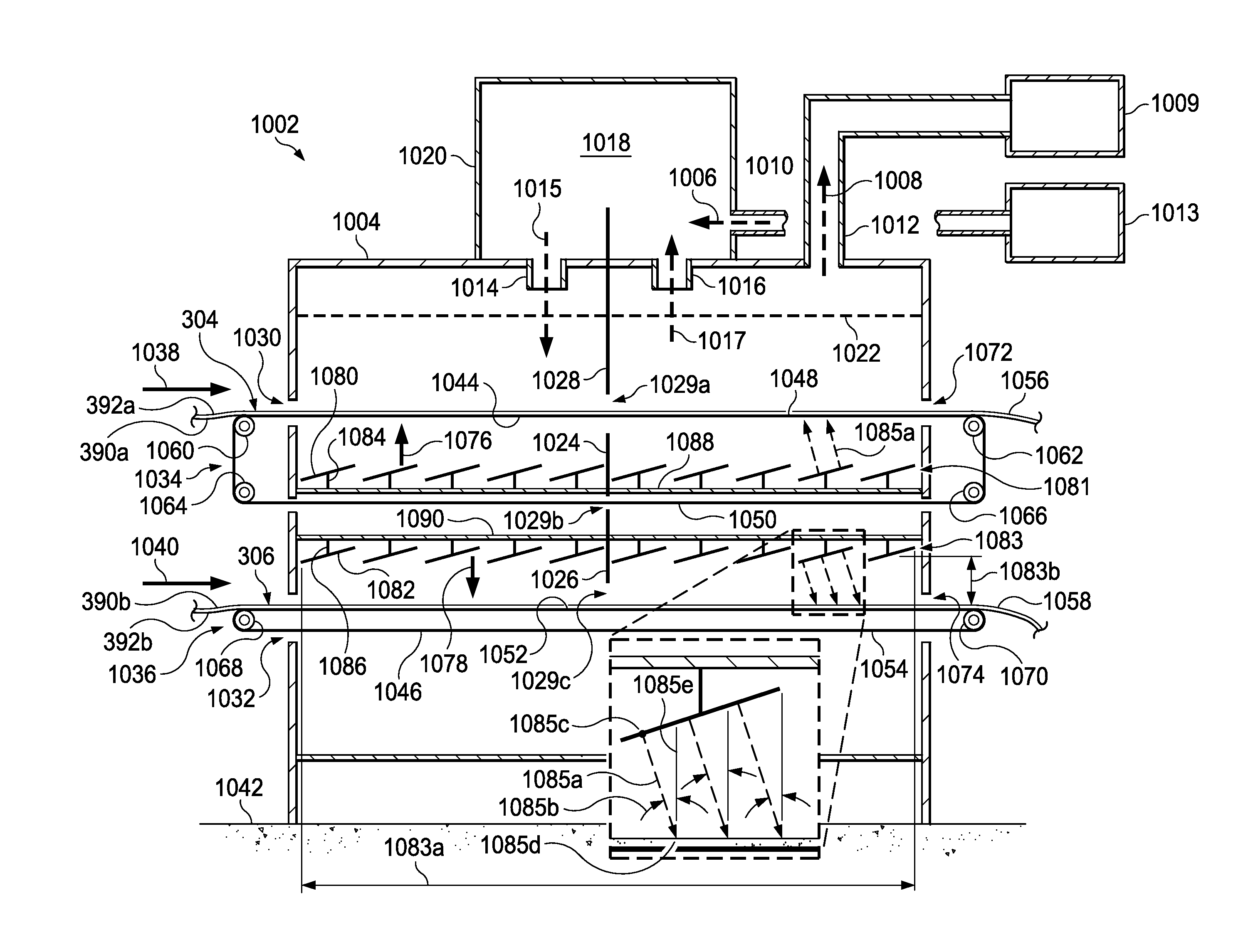

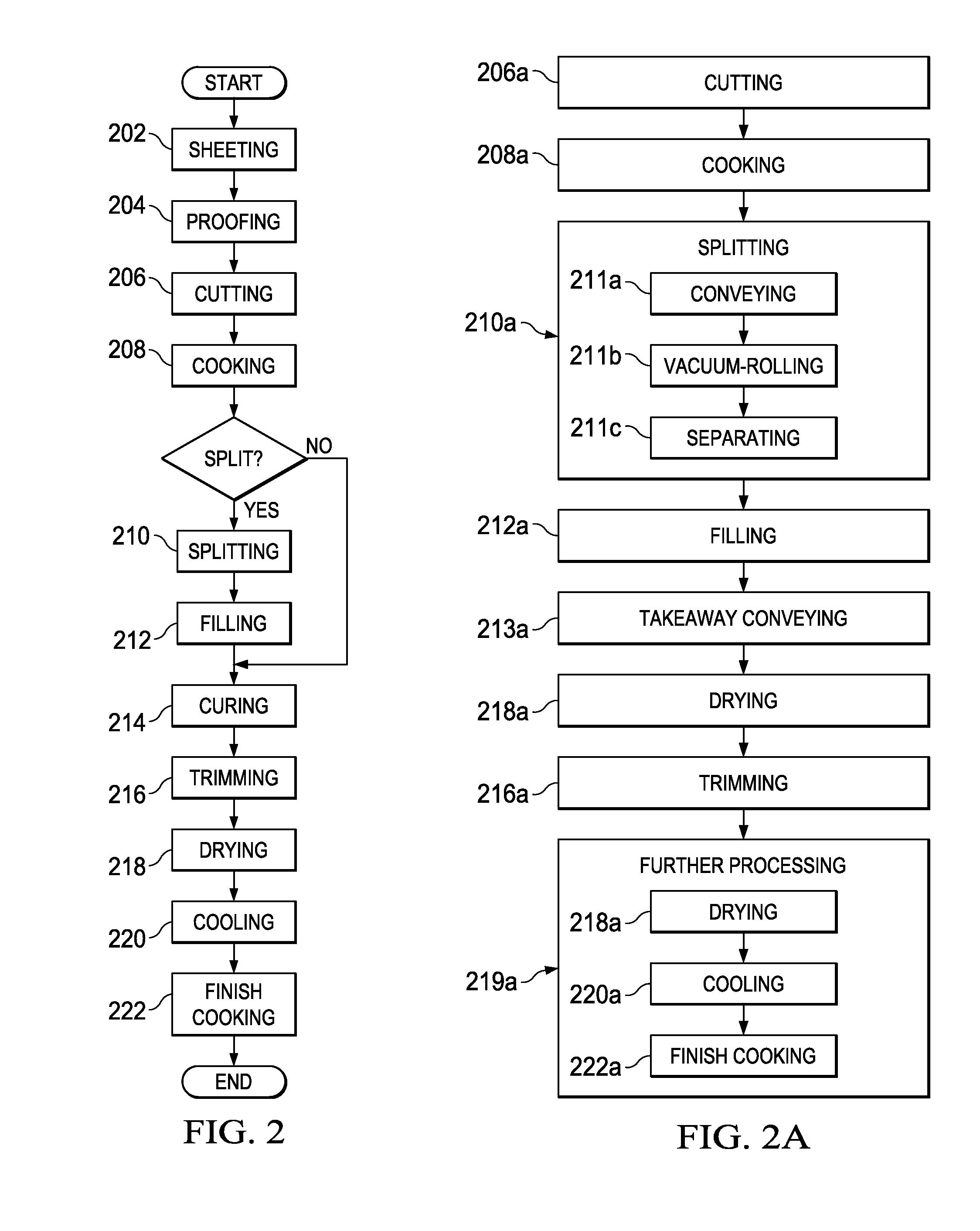

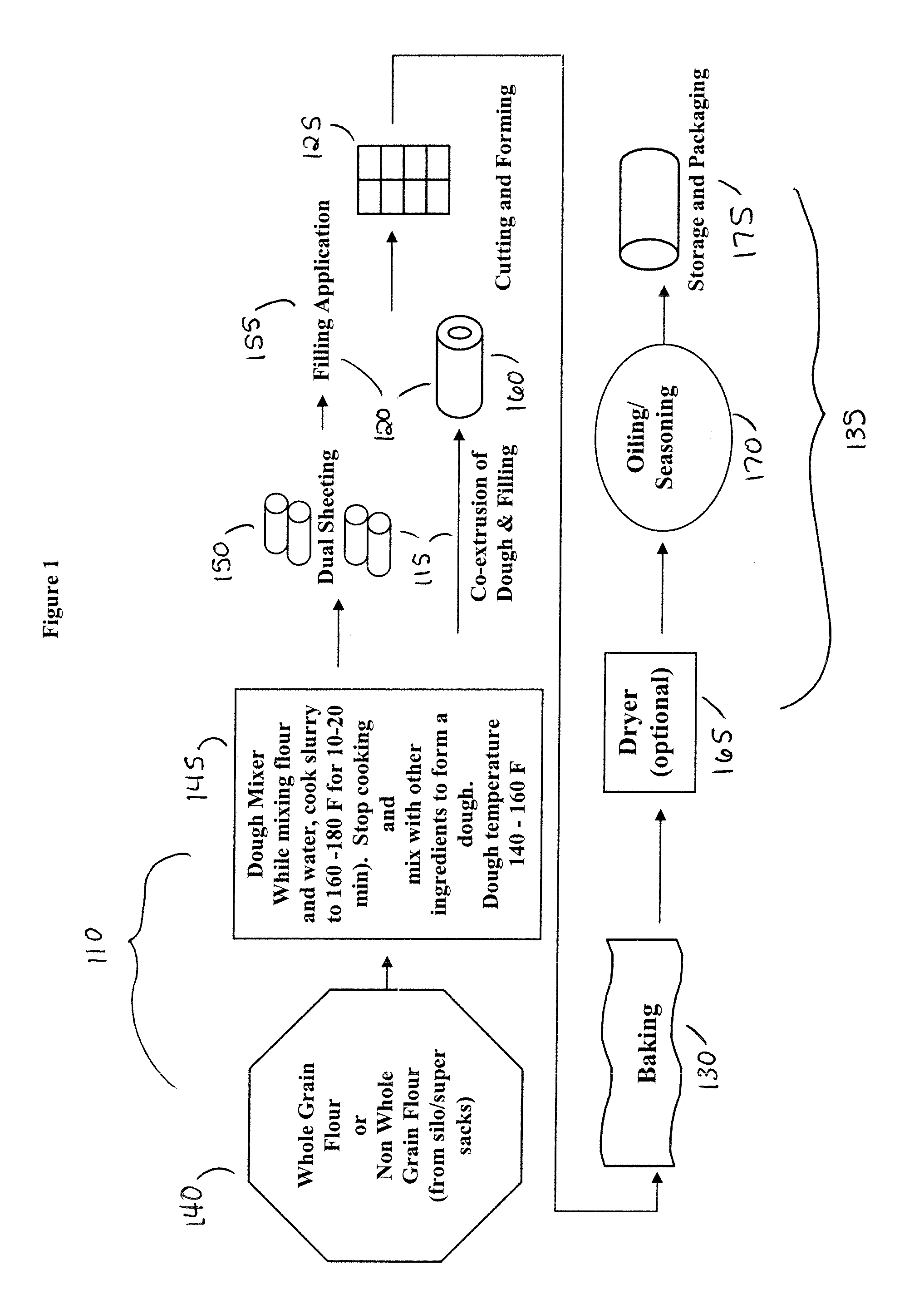

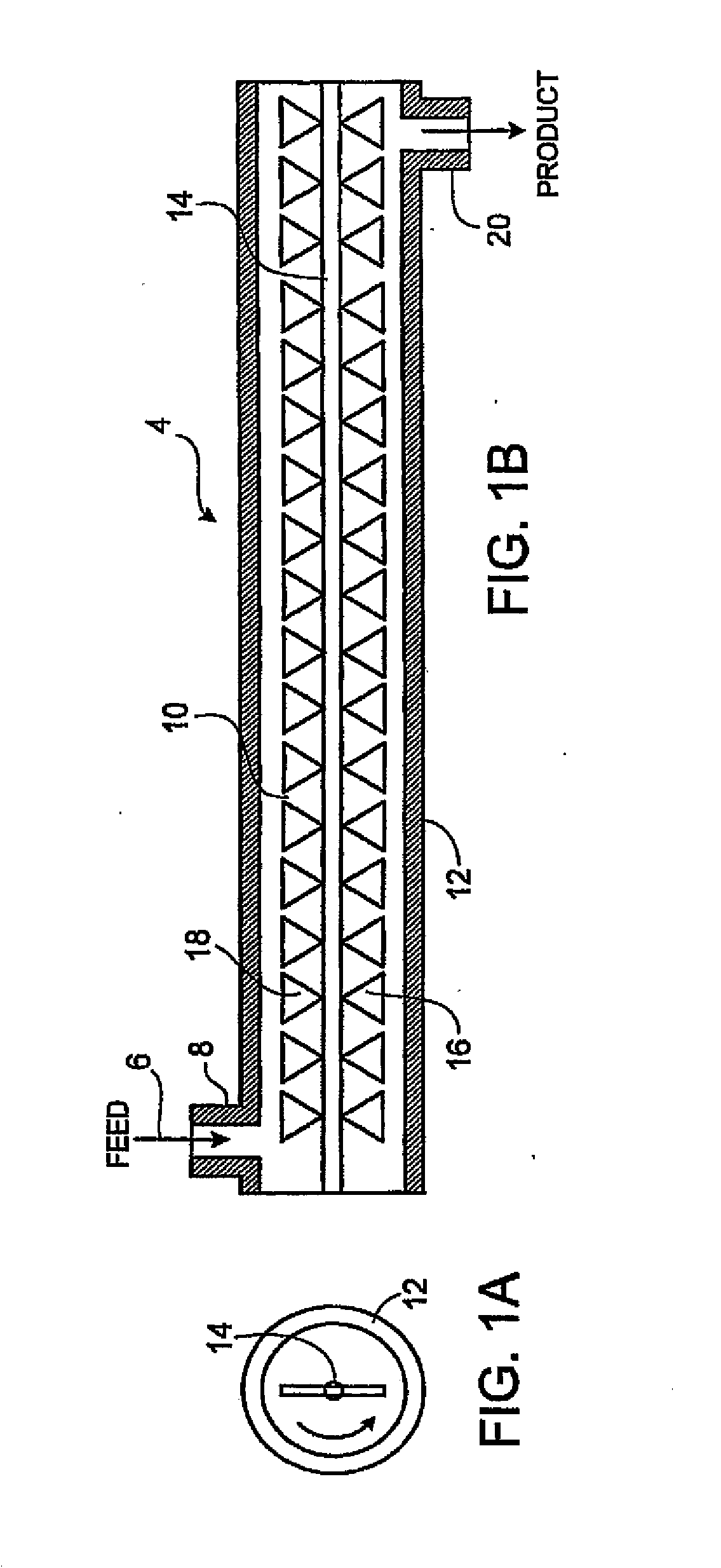

Continuous process and apparatus for making a pita chip

InactiveUS20150150270A1Eliminates and reduces disadvantageDrying solid materials with heatBaked article fillingEngineeringMechanical engineering

A method and apparatus for processing dough, for example, curing dough to make a pita chip. In a first aspect, the method comprises providing a first portion of dough on a first conveyor, conveying the first portion into an oven, directing a heating medium at the first portion using a first discharge array, and conveying the first portion out of the oven. In a second aspect, the apparatus comprises an oven, a first conveyor for conveying a first portion of dough, and a first discharge array. The oven comprises an oven housing, a first entrance of the oven housing for the first portion of dough, and a first exit of the oven housing for the first portion of dough. The first discharge array is positioned and oriented to direct a heating medium at the first portion of dough when the first portion of dough is positioned for conveyance by the first conveyor.

Owner:FRITO LAY NORTH AMERICA INC

Food product comprising masa flavored flour

InactiveUS6277421B1Reduced and limited nixtamalizationReduced and limited and masa flavor formationBaking mixturesConfectioneryFood flavorClosed system

A nixtamalized farinaceous component having pronounced masa flavor alone or together with other food components wherein the nixtamalized farinaceous component is produced by heating a superficially dry composition comprising farinaceous component, alkaline compound in a concentration of at least 0.2 parts by weight per 100 parts by weight farinaceous component (d.s.b.) and water in a closed system to develop a pronounced masa flavor without pasting the starch component of the farinaceous component while maintaining the water content of the composition in the closed system at 2% to 20% by weight of the composition.

Owner:BUNGE MILLING

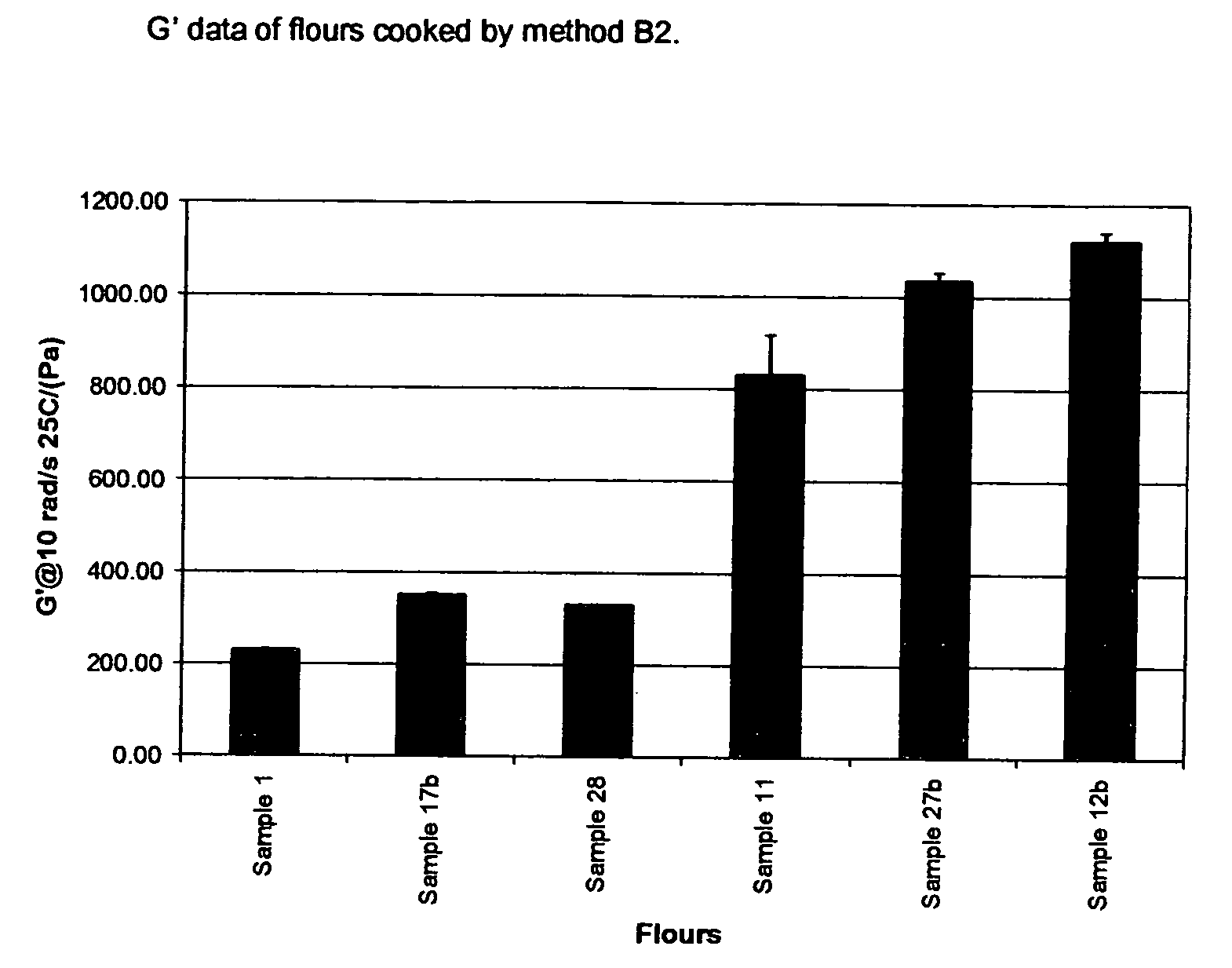

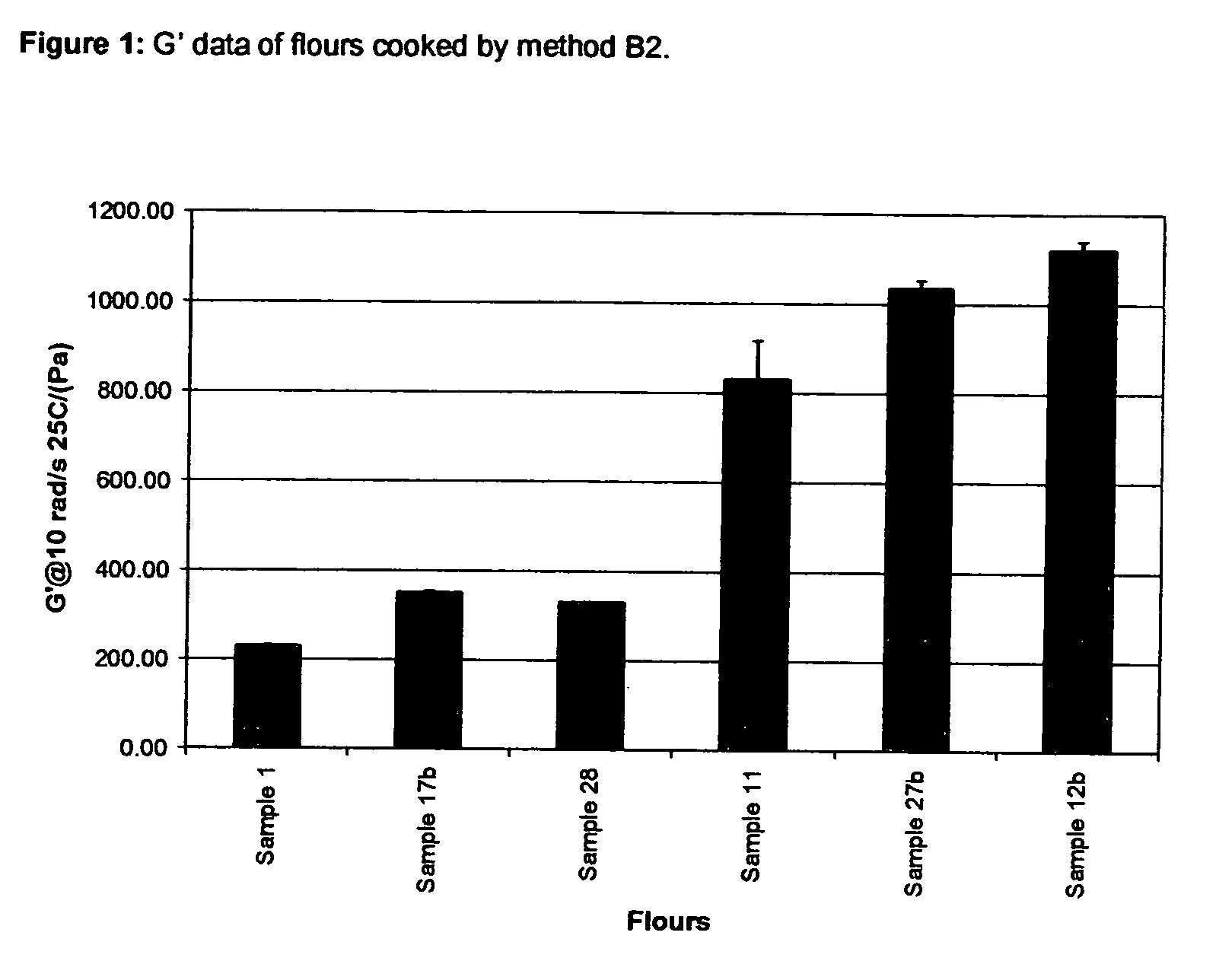

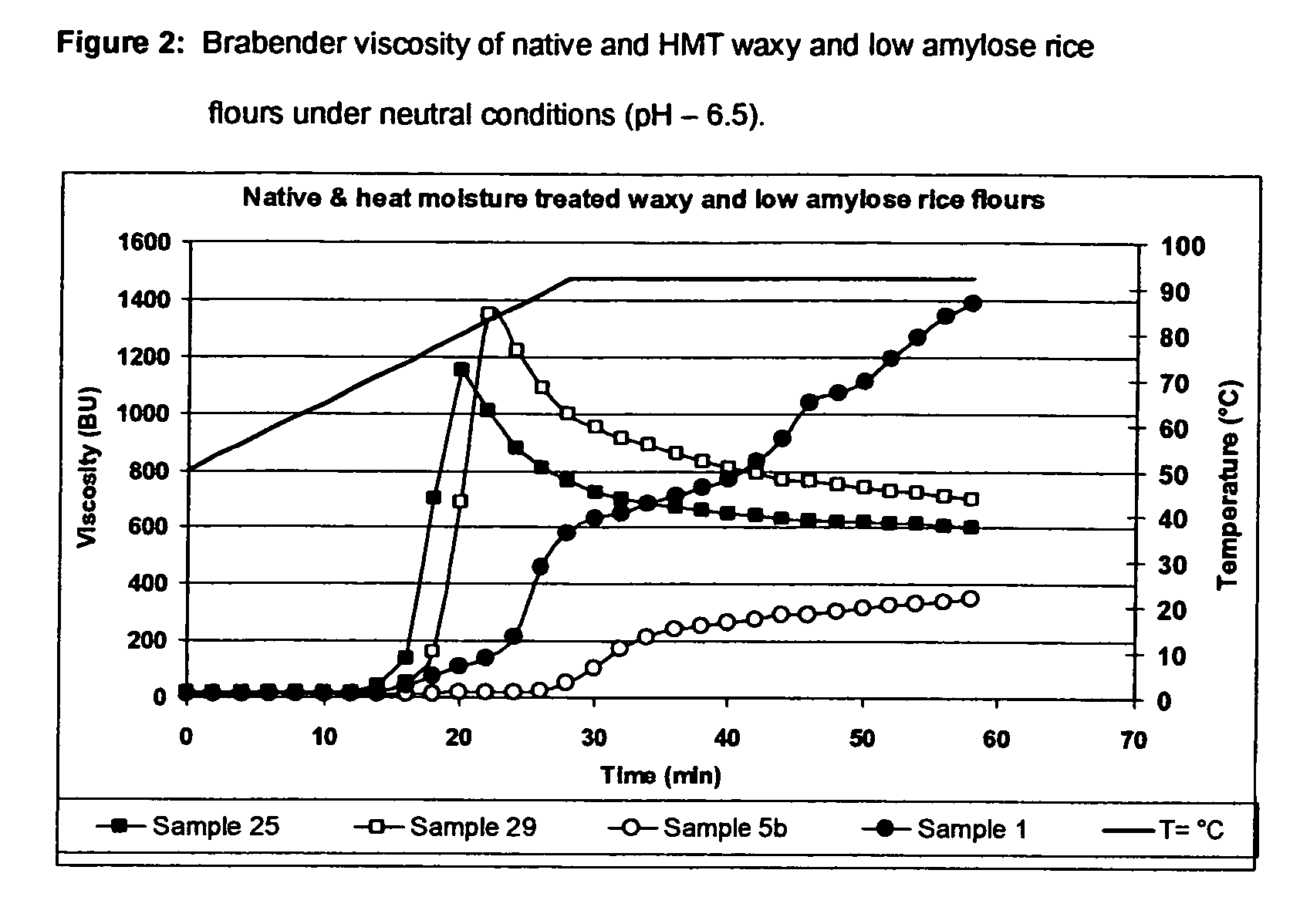

Rice flour composition with enhanced process tolerance and solution stability

InactiveUS20060251792A1Improve stabilityImprove toleranceDough heat treatmentFood preparationMoistureIngested food

The present invention relates to a rice flour composition with enhanced process tolerance and solution stability, the method of making such flour, and uses thereof. The flour is prepared by heat-moisture treatment of a low amylose rice flour. The resultant flour is useful in a variety of industrial applications, particularly in foods.

Owner:CORN PROD DEV INC

Hard crust ham moon cake and preparation method thereof

The invention relates to the field of food processing and discloses a hard crust ham moon cake and a preparation method thereof. The hard crust ham moon cake is characterized by comprising a wrapper and a filling, wherein the wrapper is prepared from flour, lard oil, water, honey, sugar powder and ammonia powder; the filling is prepared from a cooked Xuanwei ham, white sugar, honey and cooked flour; the weight ratio of the wrapper to the filling of the hard crust ham moon cake is 9:7. The preparation method comprises the steps of preparing the wrapper, preparing the filling and baking. The grease content, the sugar content and the salt content of the hard crust ham moon cake prepared through a specific preparation mode and adaptive parameter control are obviously less than those in the prior art, and the problem that the body burden of a user is increased when the user enjoys the delicious moon cake because the existing hard crust ham moon cake has high grease content, high sugar content and high salt content is solved.

Owner:昆明饭店有限公司

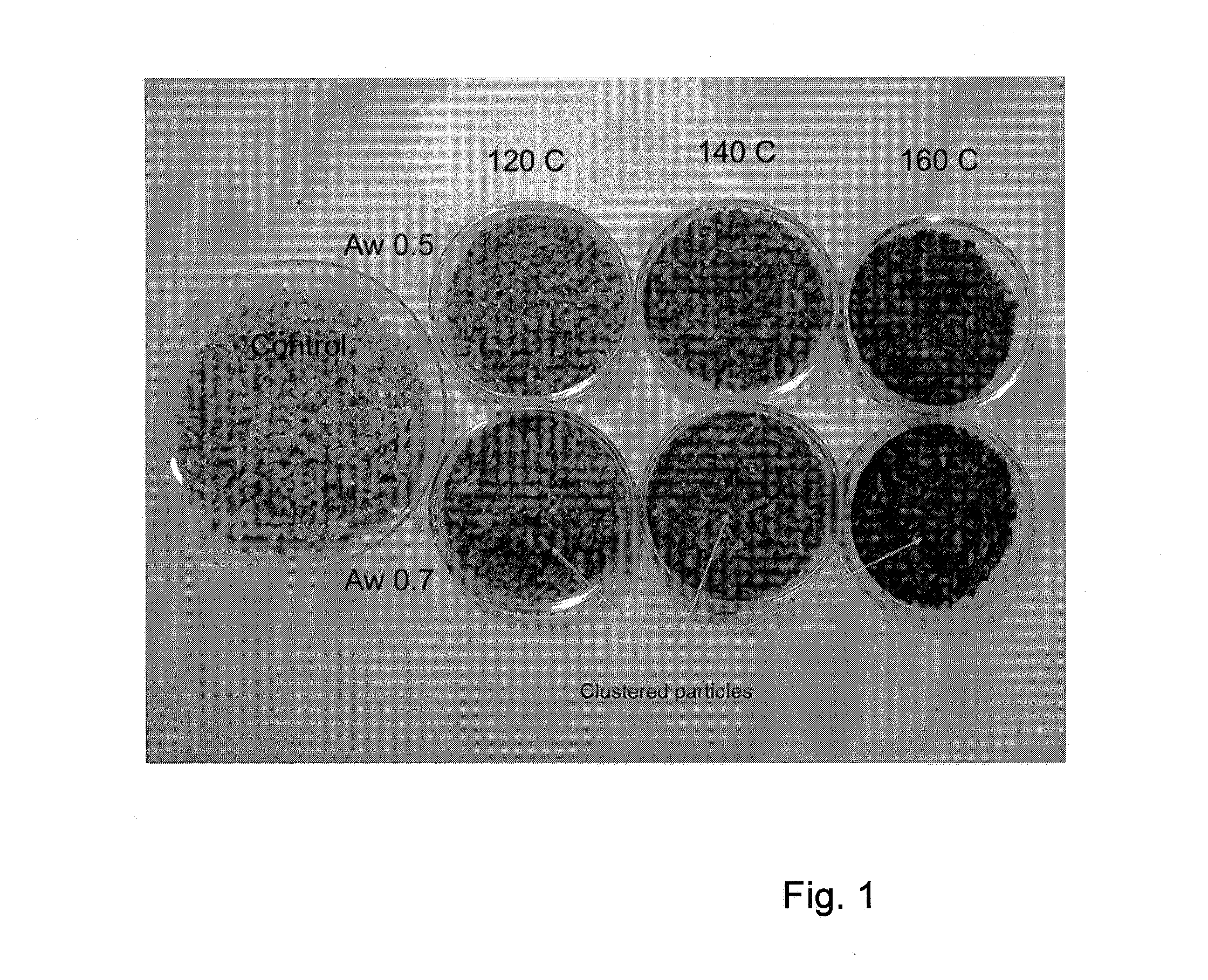

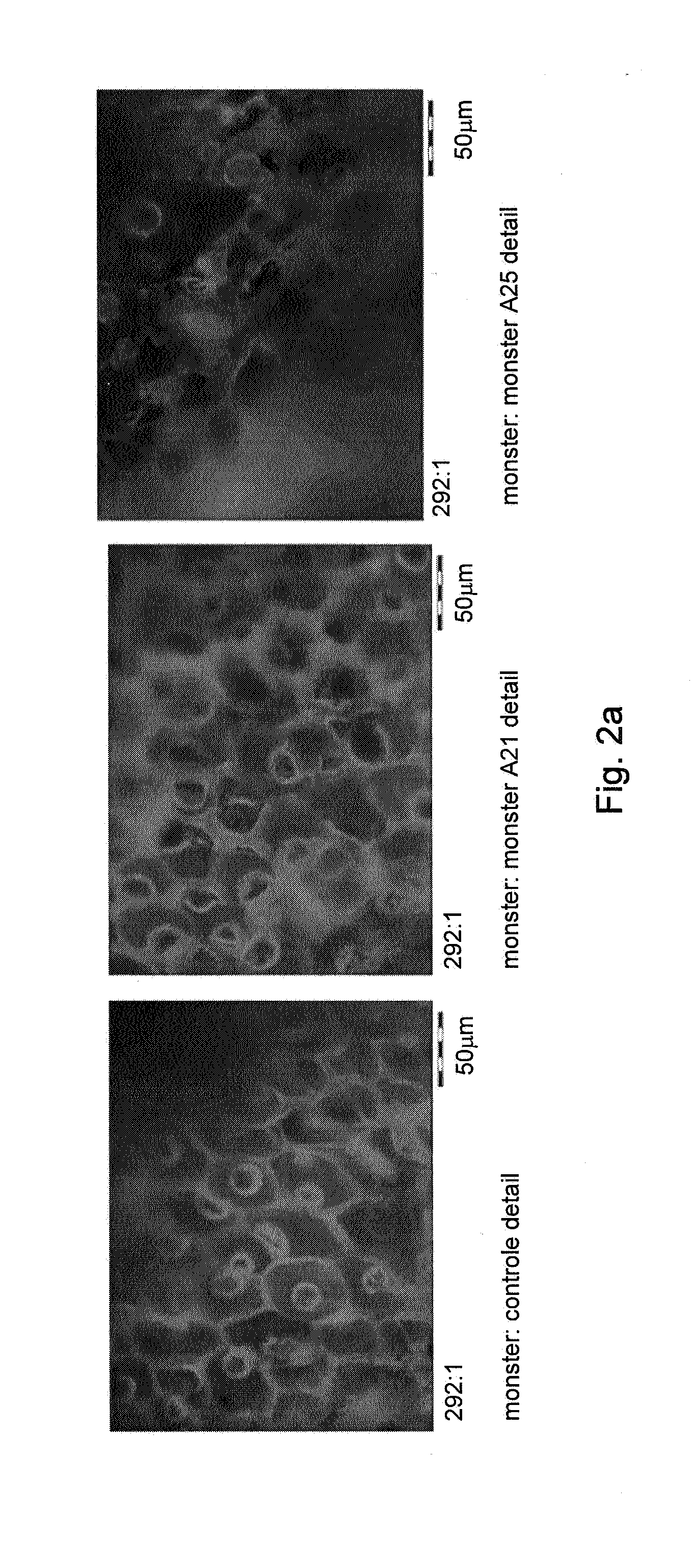

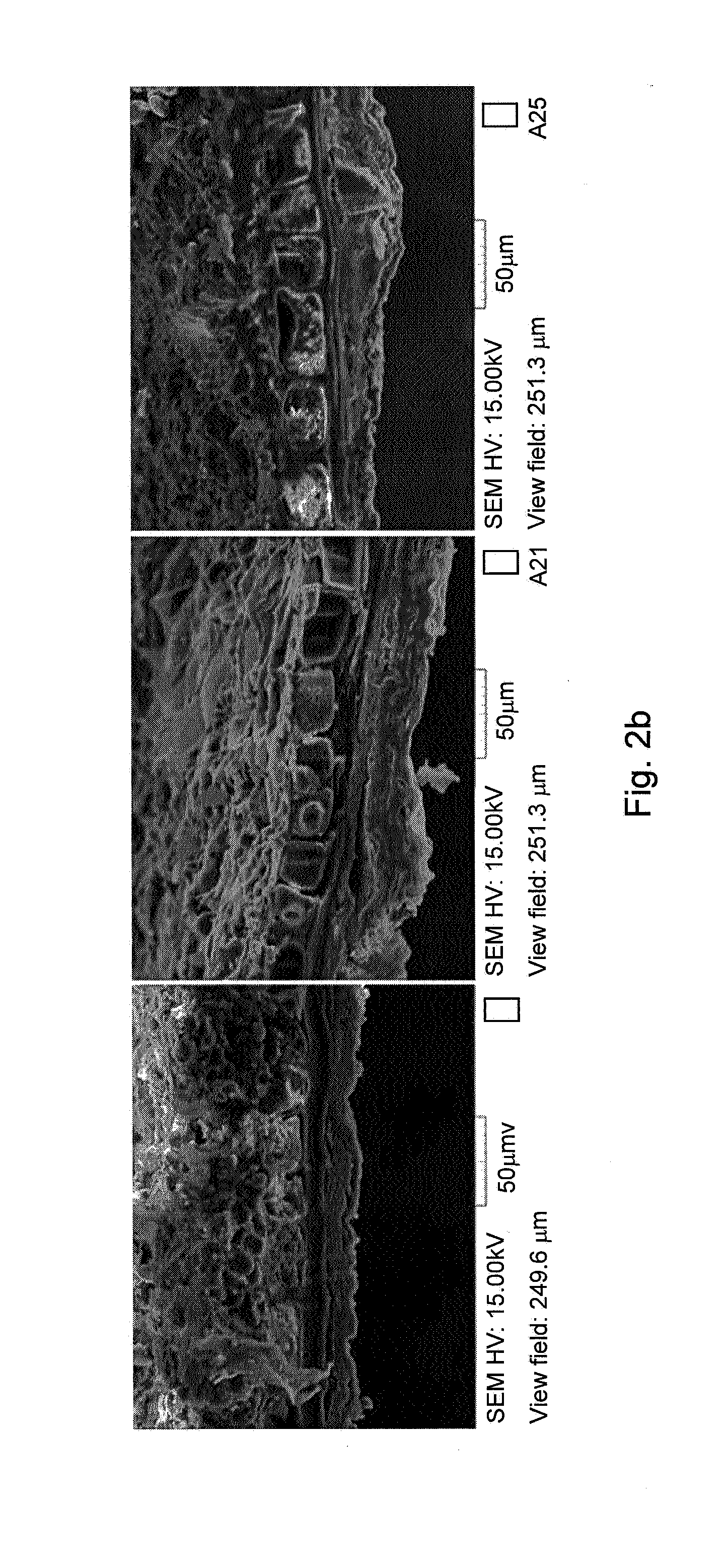

New foods with modified cereal bran and methods for producing these

InactiveUS20150250212A1Improve food valueMeat/fish preservation by heatingPre-baking dough treatmentPre treatmentBran

A food is modified by adding bran that has been treated with super-heated steam (SHS) to the food, or replacing the bran that already was present in the food by a cereal bran that has been treated with SHS. The SHS-treated cereal bran may or may not have undergone a pre-treatment with acid, base or water. The SHS-treated cereal bran and food products including such SHS-treated cereal bran have enhanced nutritional value.

Owner:STICHTING WAGENINGEN RES

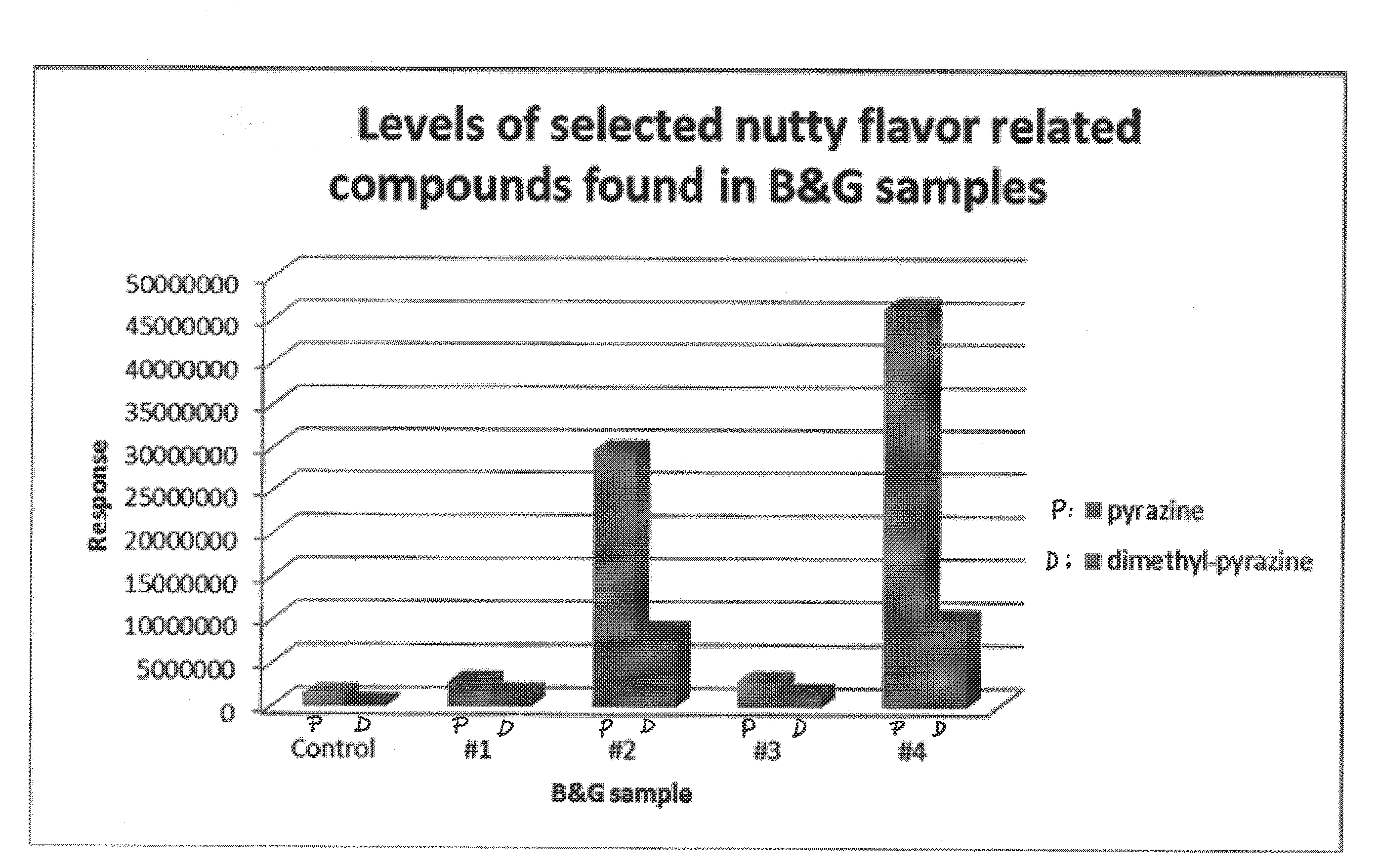

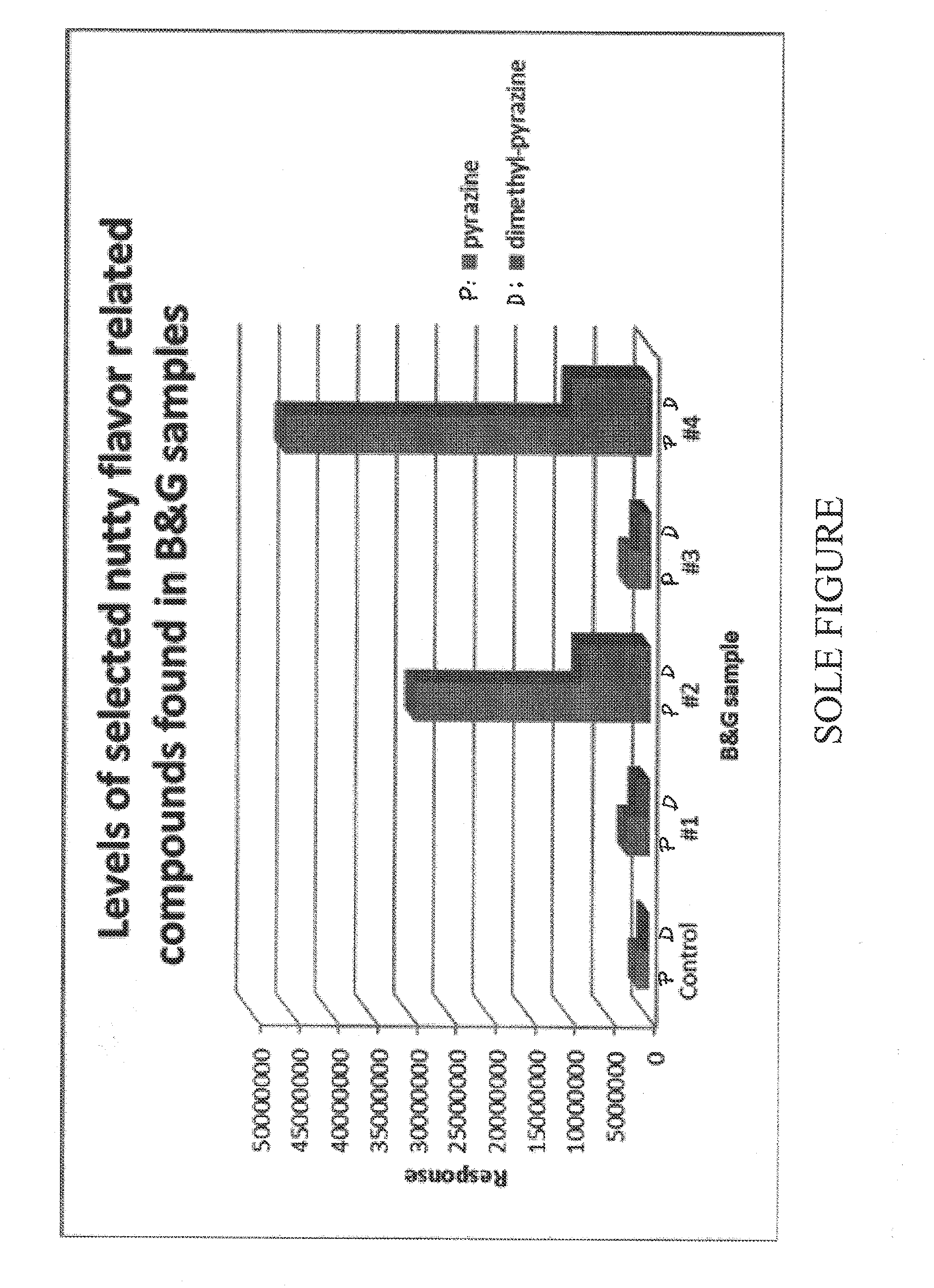

Bran And Germ Flavor And Texture Improvement

ActiveUS20160021899A1Reduce moisture contentFlavor often developBaking mixturesBakery productsAdditive ingredientFood flavor

The flavor and texture of a ground bran and germ component or fraction is improved by subjecting the ground bran and germ component to heating while conveying and mixing the ground bran and germ component in a conveying and mixing device. The heating may be conducted to heat the bran and germ component or fraction to a temperature of from about 285° F. to about 410° F. to volatilize volatile wheaty flavor components and moisture in the ground bran and germ component and to develop a buttery, nutty, caramelized flavor in the bran component. The wheaty flavor components and moisture are removed from the mixing and conveying device during the heat treatment. The use of substantial moisture reduction with high temperature heating at a low moisture content provides flavor development while reducing wheatiness, graininess, or rawness, and also achieves lipase inhibition and stabilization against rancidity from free-fatty acid production.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

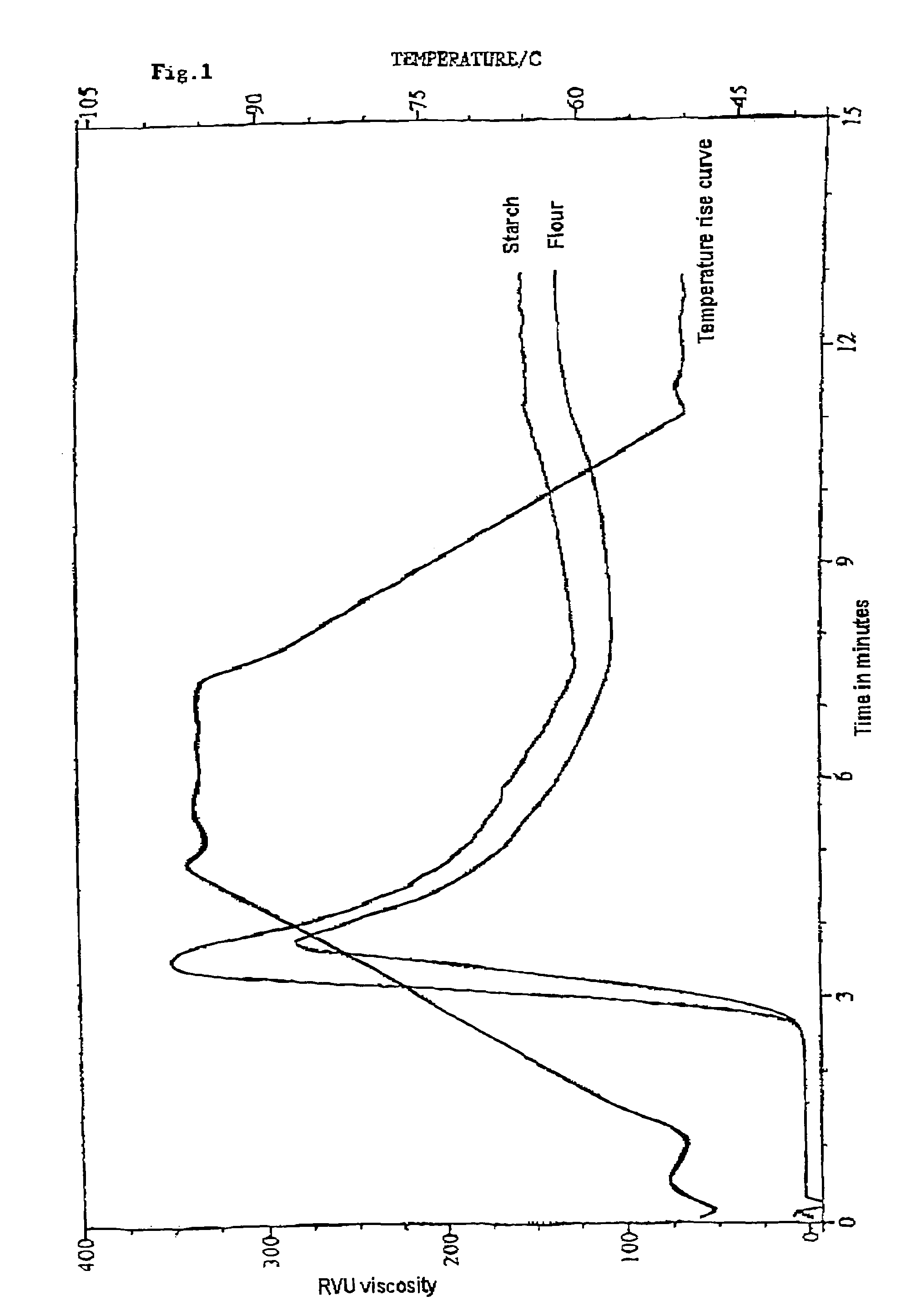

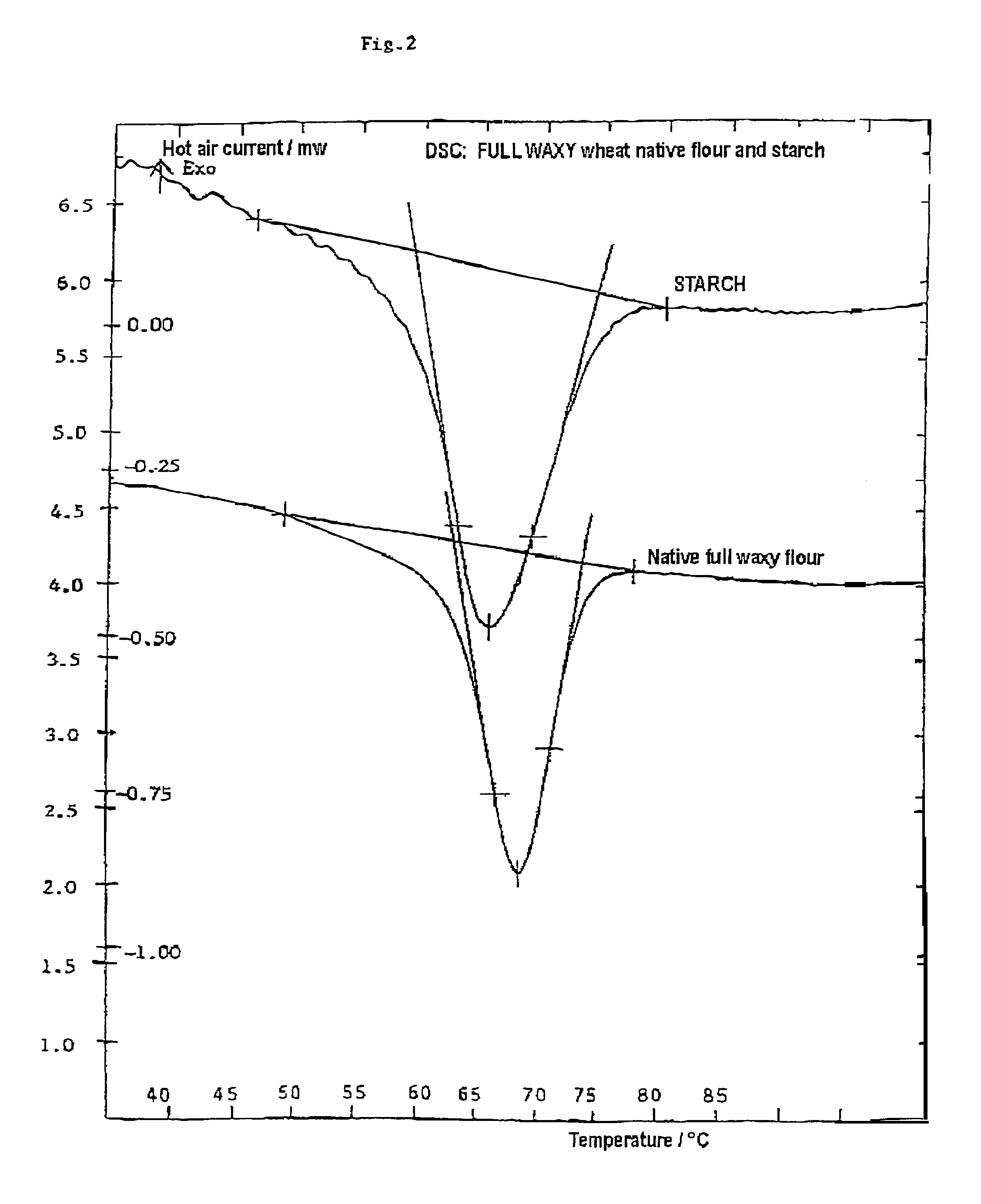

Flours and starch with a very high amylopectin content and methods for the production and uses thereof

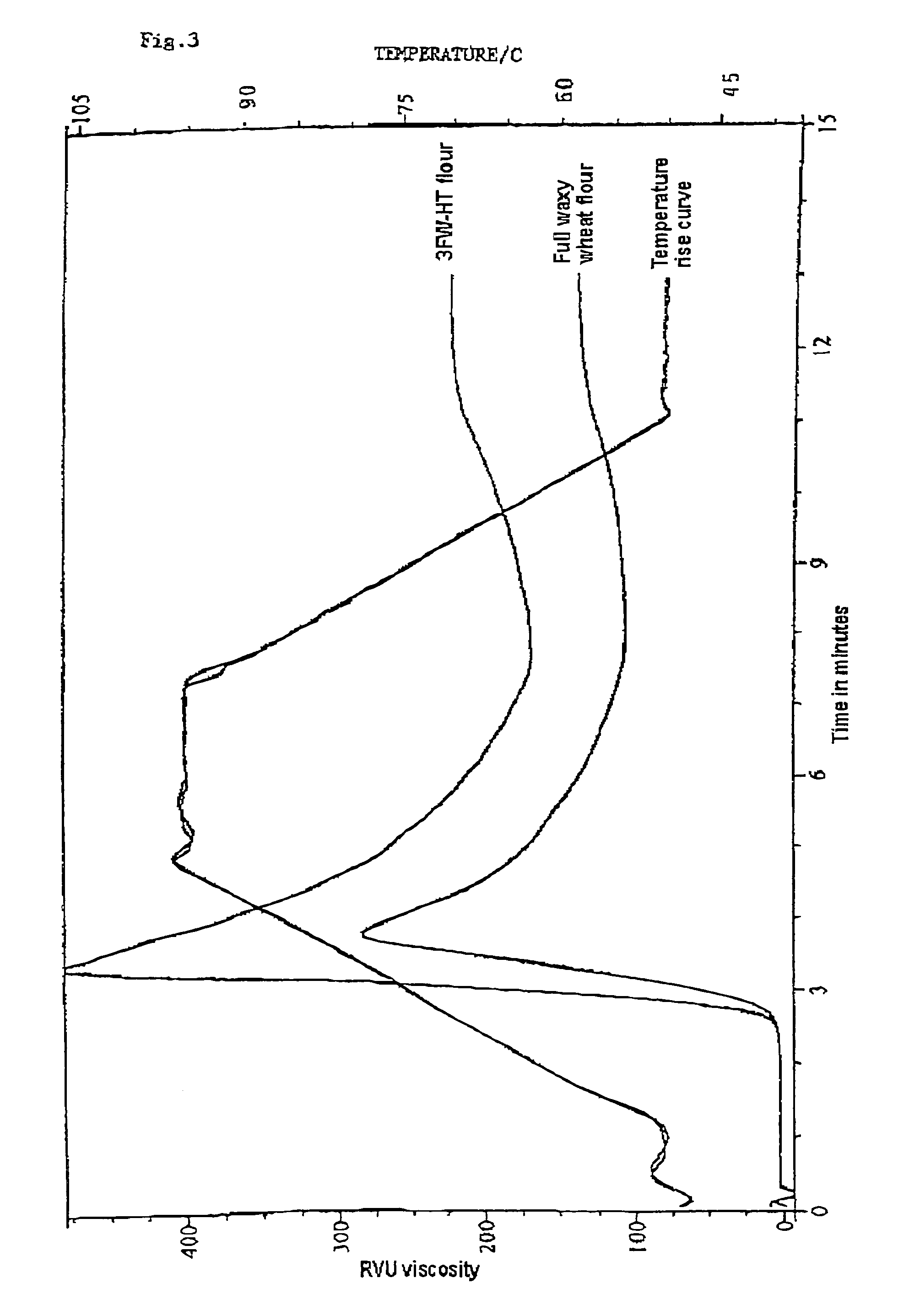

InactiveUS7348036B2Many applicationsNeutral tasteBaking mixturesAnimal feeding stuffWheat grainHeat energy

A full waxy wheat flour or starch characterized in that its amylose content is about 0%±about 1%, and a process for preparing a functional full waxy wheat flour including preparing an initial flour with a defined size grading starting from full waxy wheat grains, and subjecting the flour to a heat-moisture treatment including adding water or steam and heat energy to achieve a degree of gelatinization of starch between about 15 and about 99% for less than about 5 minutes.

Owner:LIMAGRAIN CEREALES INGREDIENTS

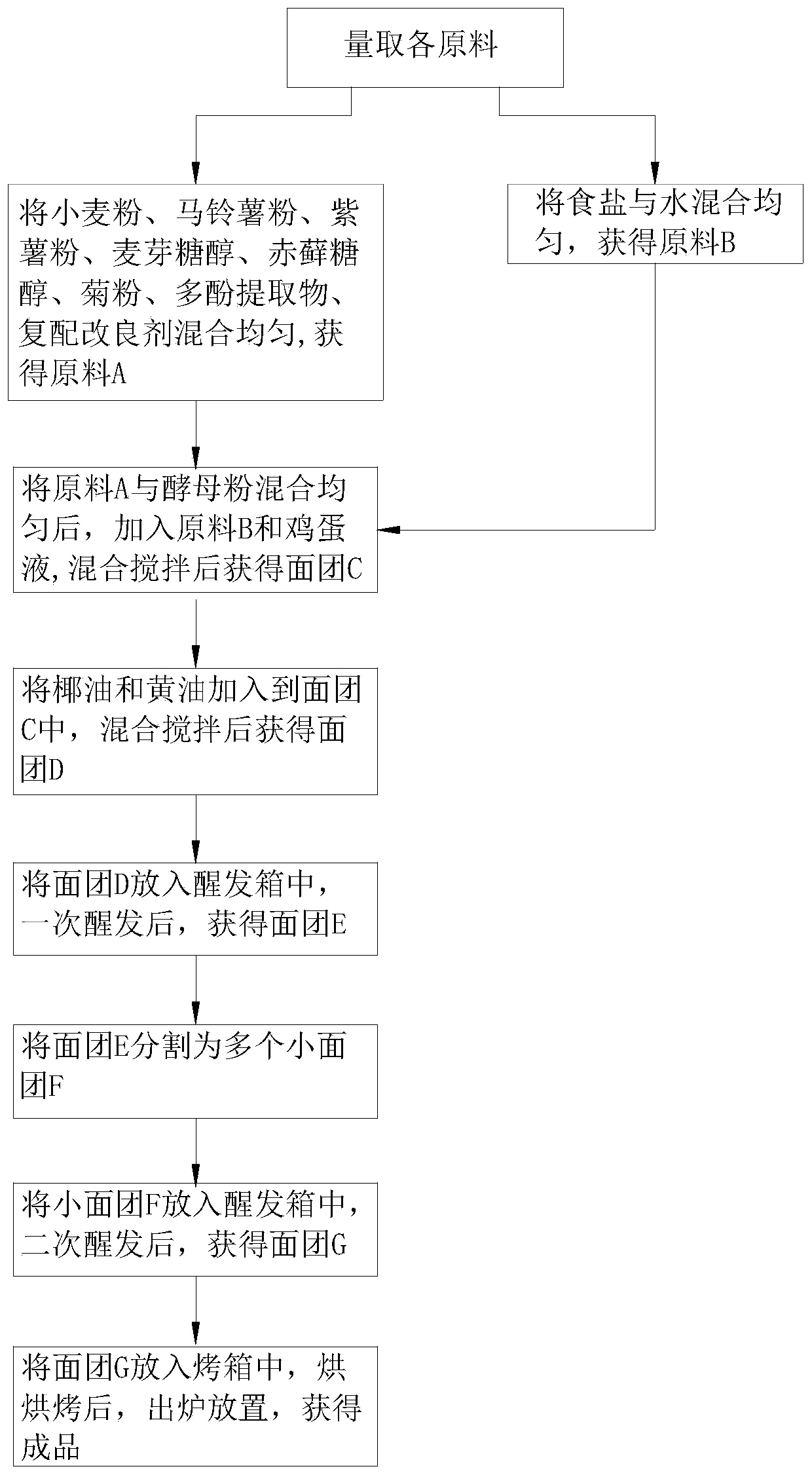

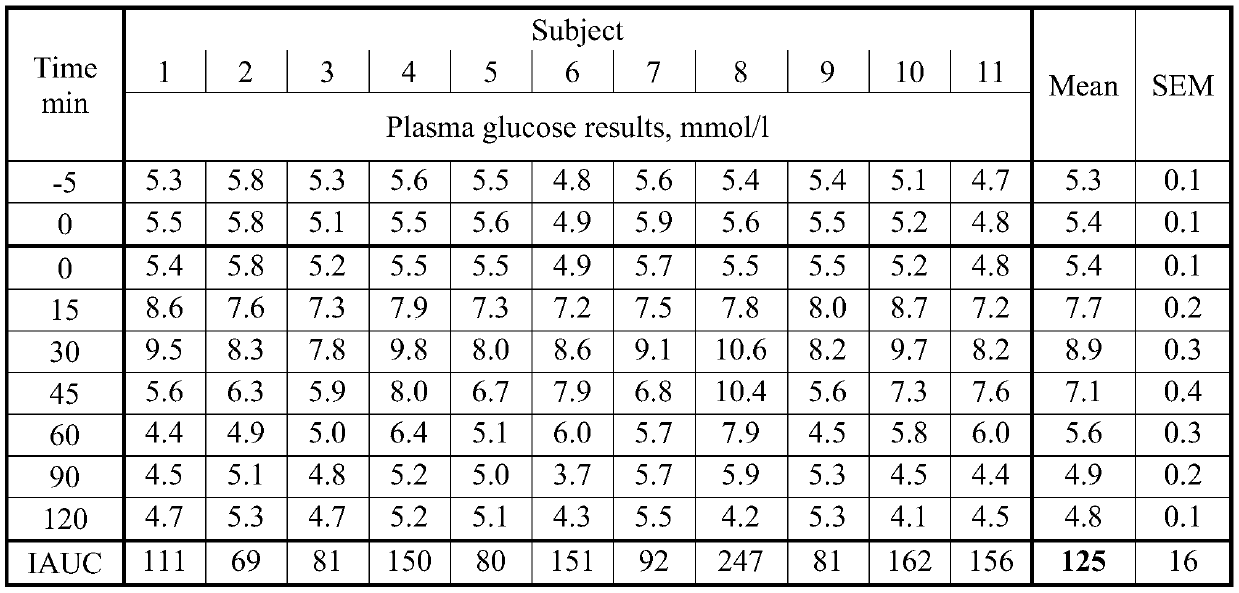

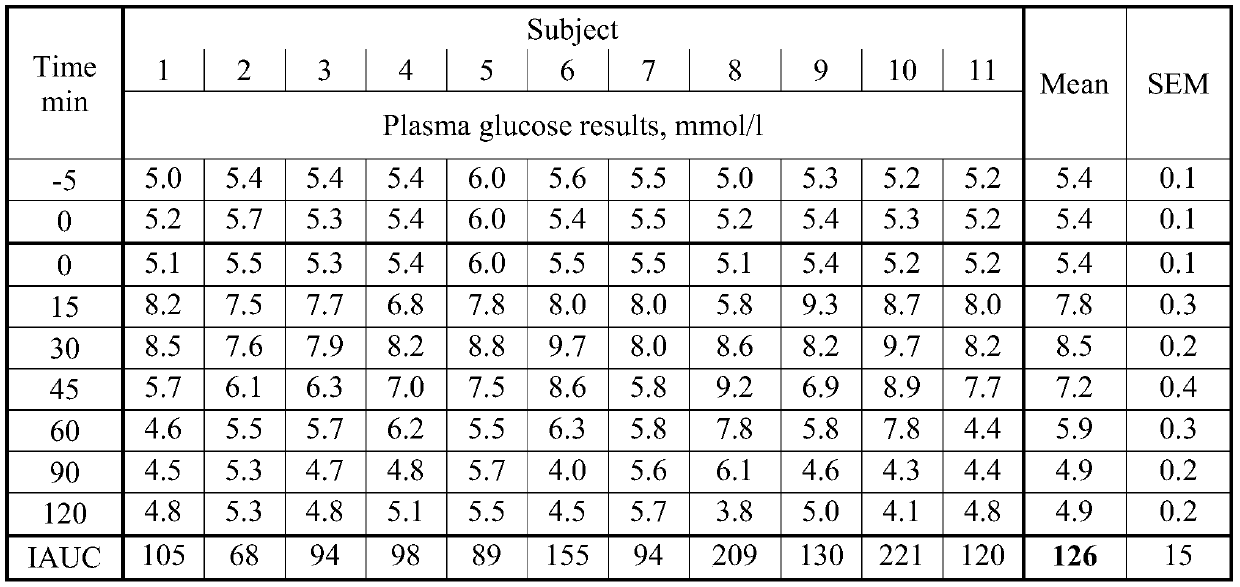

Composition of low GI potato bread and preparation method of composition

InactiveCN110839674AReduce intakeIncrease peristalsisDough irradiationDough heat treatmentBiotechnologyNutritive values

The invention is suitable for the technical field of nutritious food, and provides a composition of low GI potato bread. The composition comprises the following components: wheat flour, potato flour,purple potato flour, maltitol, erythritol, inulin, a polyphenol extract, yeast powder, salt, butter, coconut oil, an egg liquid, a compound modifier and water. Aiming at the defect of high GI value ofcommon wheat flour bread, the low GI potato bread is researched and developed through adjustment of the composition; by adopting potato powder, purple potato powder, sugar alcohol and particularly adding inulin dietary fiber, the low GI potato bread not only has a good supplement effect in the aspects of minerals, vitamins, essential amino acids, dietary fiber and the like, but also a low GI bread product is obtained through reasonable compatibility of raw material components; and the bread does not cause rapid fluctuation of blood sugar after being ate, so that the bread not only can meet the nutritional requirements of common diets of eaters, but also has obvious improvement in the aspects of bread calories, flavor and nutritional value.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

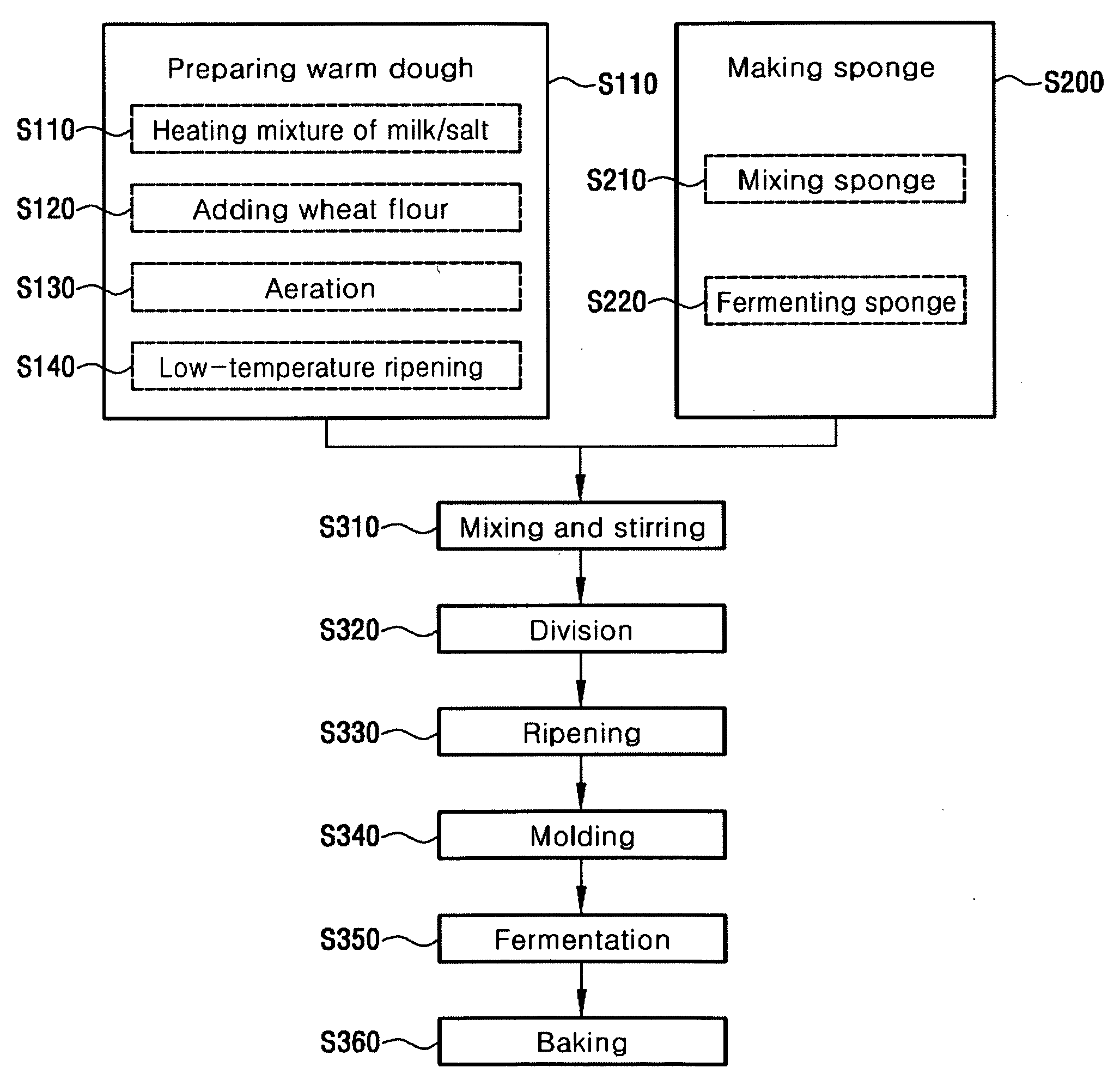

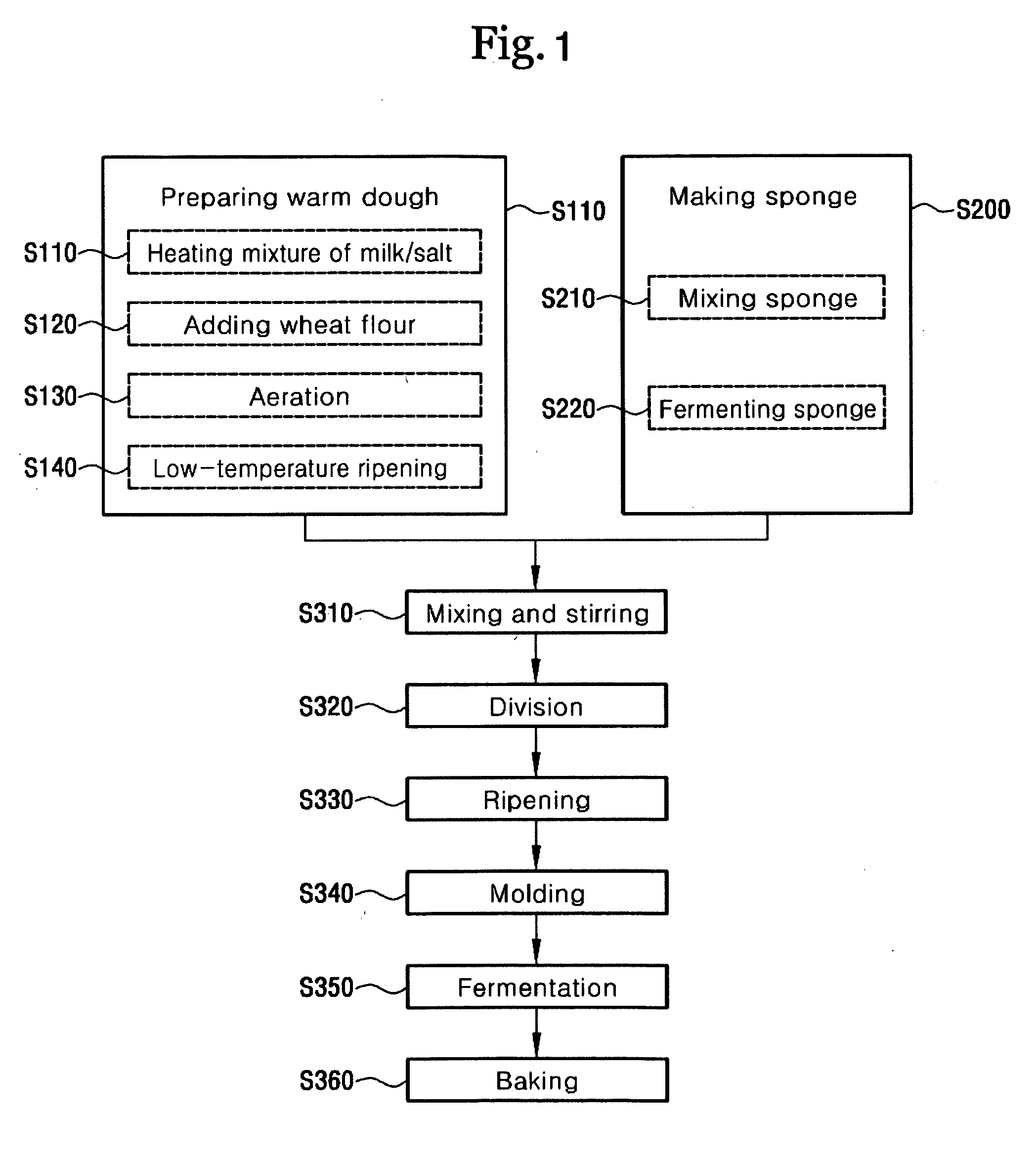

Method of making bread

ActiveUS20100255149A1High activityIncrease powerMilk preparationPre-baking dough treatmentSugarHeated milk

A method of making bread is provided. The method includes a warm dough making process in which a warm dough is formed by heating a mixture of milk and salt, adding wheat flour to the heated mixture, aerating the resulting mixture, and ripening the resulting mixture at low-temperature, a sponge making process in which a sponge is formed by mixing wheat flour, dried yeast, yeast food, bread improver, salt, and water and fermenting the mixture, a dough mixing process in which a dough is formed by mixing the warm dough and the sponge with wheat flour, salt, butter, dried yeast, dried milk, sugar, egg, and water and stirring the mixture, a division process in which the dough is divided into equal-sized pieces, a ripening process in which the divided dough is rolled out and ripened for a predetermined period of time, a molding process in which the resulting dough is molded to fit a bread pan, a fermentation process in which the molded dough is placed in the bread pan to be fermented, and a baking process in which the fermented dough is heated.

Owner:PARIS CROISSANT

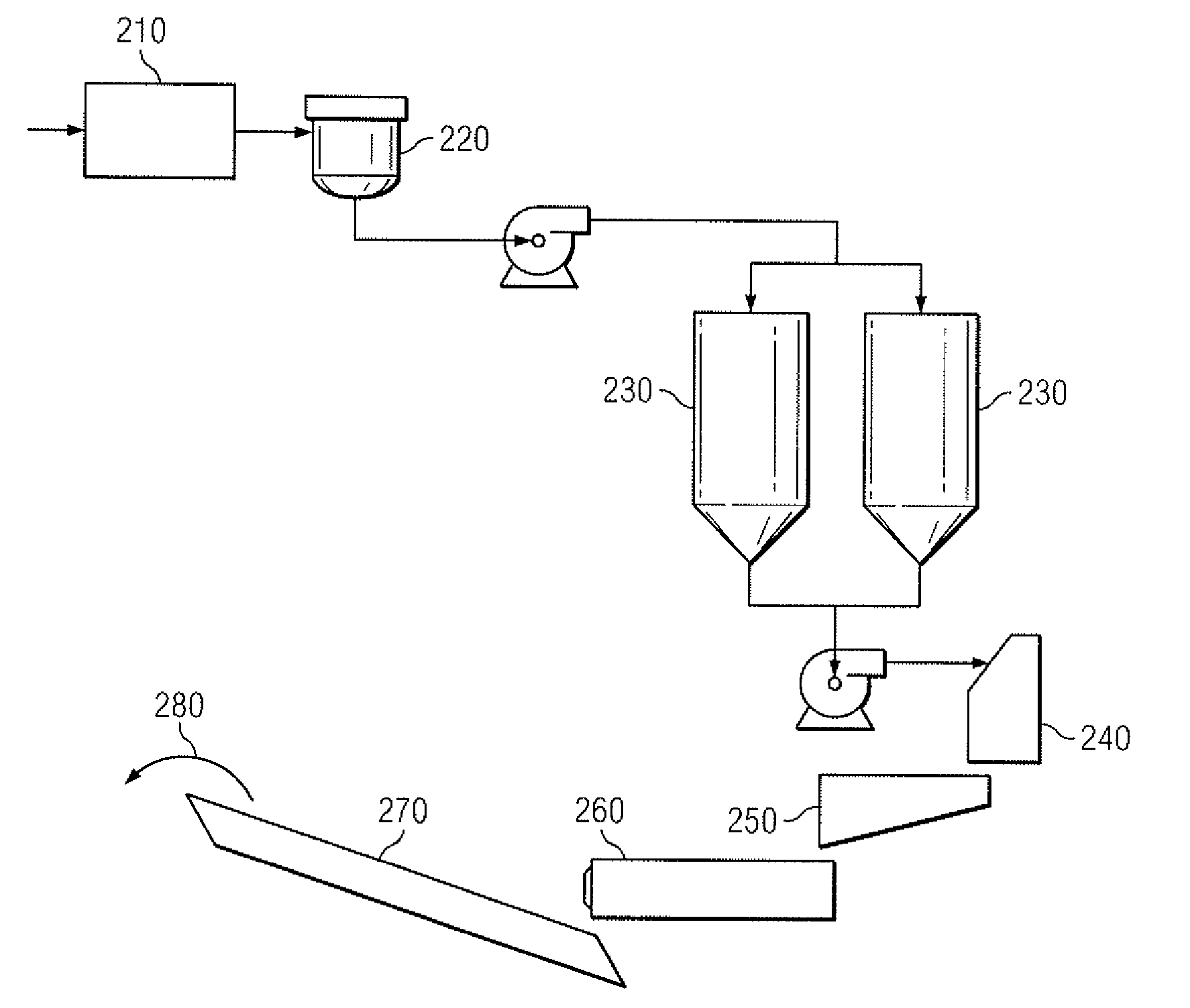

Flour heat treatment processing process

InactiveCN105815364AAchieve sex changeAchieve gelatinizationDough heat treatmentFood gradeProcess engineering

The invention relates to a flour heat treatment processing process. Traditional wheat-processed flour is conveyed into a heat treatment unit by a pre-set flow; the heat treatment unit comprises at least one grade of a spiral conveyor with a jacket layer, which is sequentially connected in series; the flour enters from a feeding hole of the first-grade spiral conveyor and is output from a discharging hole of the last-grade spiral conveyor; in a flour conveying process, steam is introduced into the jacket layer of each grade of the spiral conveyor, and food-grade steam is introduced into a conveying chamber of the first-grade spiral conveyor at least to be mixed with the steam, and a spiral blade propels and stirs; the flour subjected to the heat treatment is output through a conveying pipeline; in the flour conveying process, the flour is sufficiently scattered through a high-speed online crusher; the scattered flour is rapidly cooled and the moisture content is rapidly reduced in drying equipment; and finally, the flour is unloaded and stored. According to the flour heat treatment processing process, modification and gelatinization of starch and proteins in the flour are realized through steps of online continuous steam humidification and heating and the like, so that the performance of the flour is greatly improved.

Owner:WUXI DADONG GRAIN ENG TECH CO LTD

Churros and method for making same

InactiveUS20050112261A1Less oilPre-baking dough treatmentPreservation by coolingMarkedly elevated IgEAdditive ingredient

Owner:1010684 ONTARIO

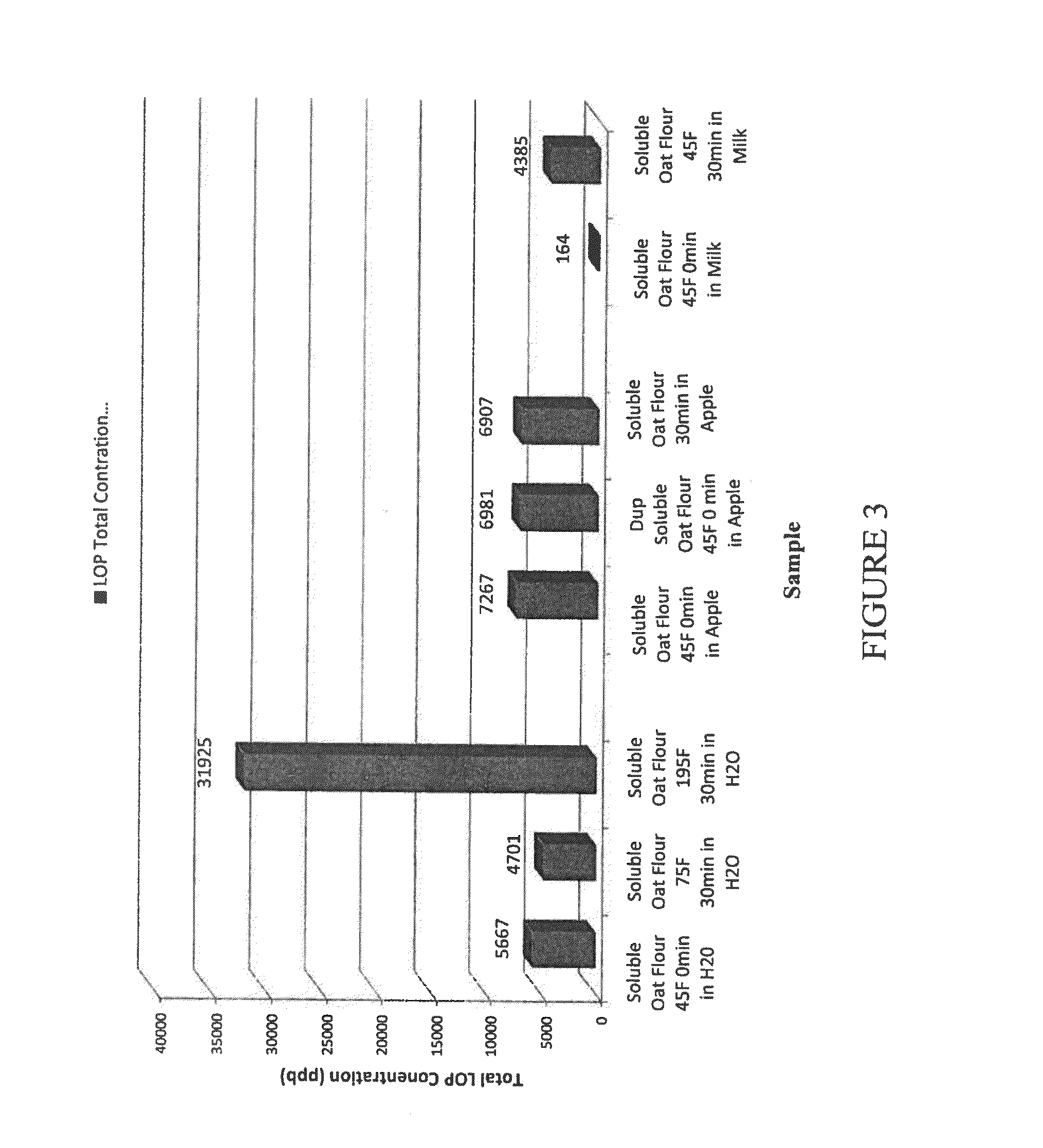

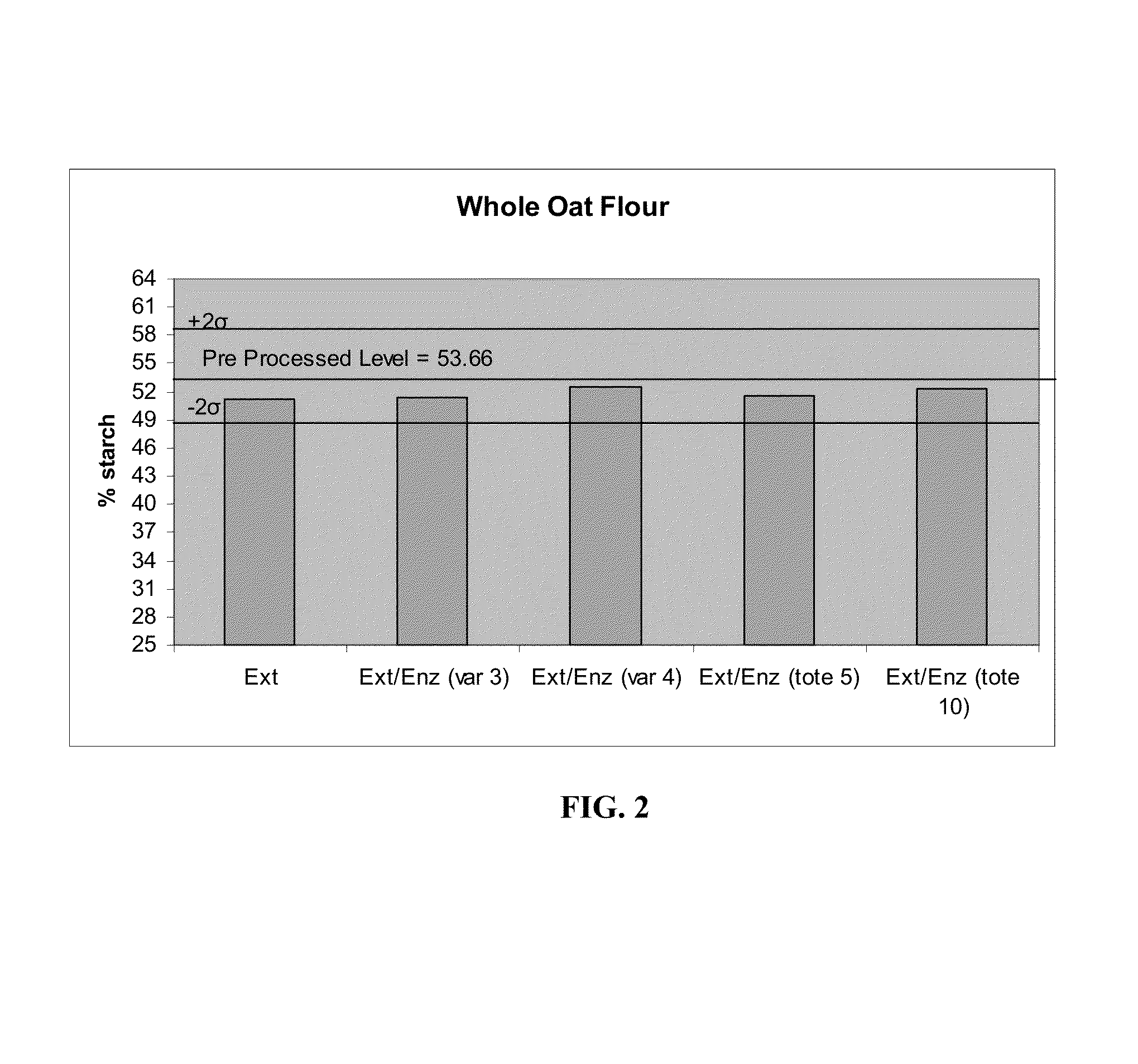

Method of preparing highly dispersible whole grain flour with an increased avenanthramide content

A method of preparing a highly dispersible whole grain oat flour by hydrolyzing, milling and agglomerating grain flour to arrive at a whole grain oat flour having an increased avenanthramide content compared to native oat flour.

Owner:THE QUAKER OATS CO

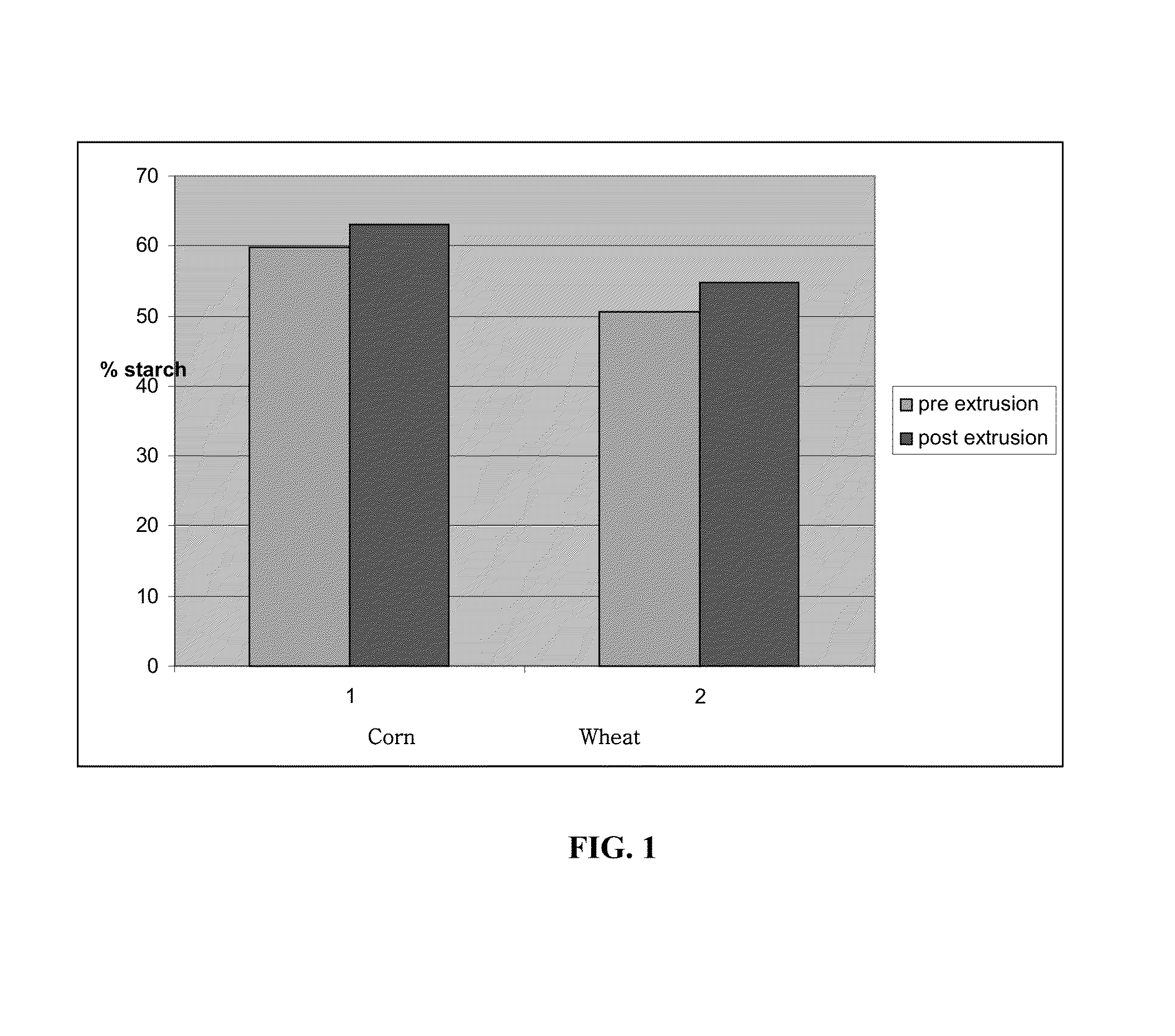

Method of processing oats to achieve oats with an increased avenanthramide content

Producing soluble oat flour with an increased level of avenanthramides by using enzymes to precondition whole oat flour prior to extrusion.

Owner:THE QUAKER OATS CO

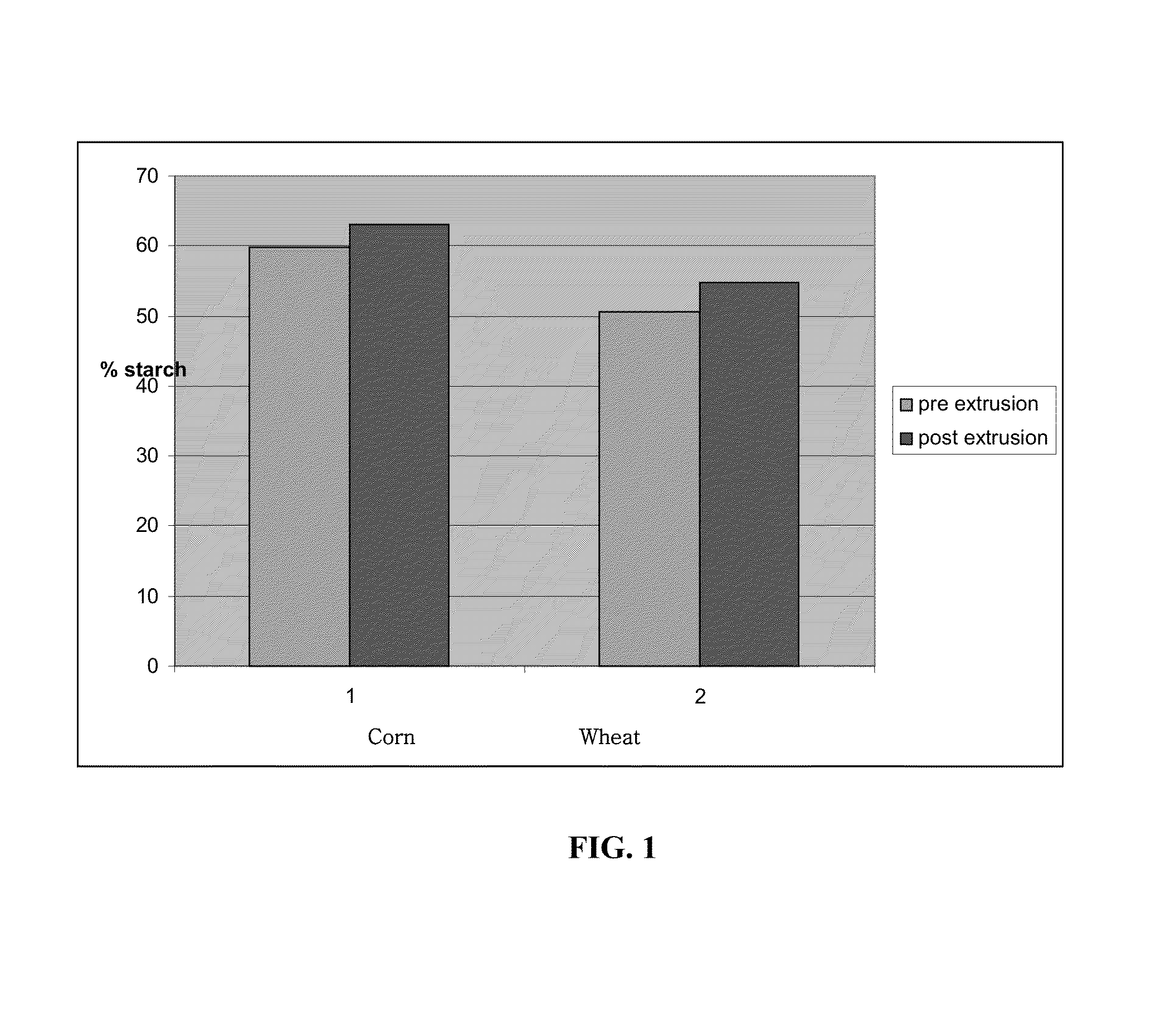

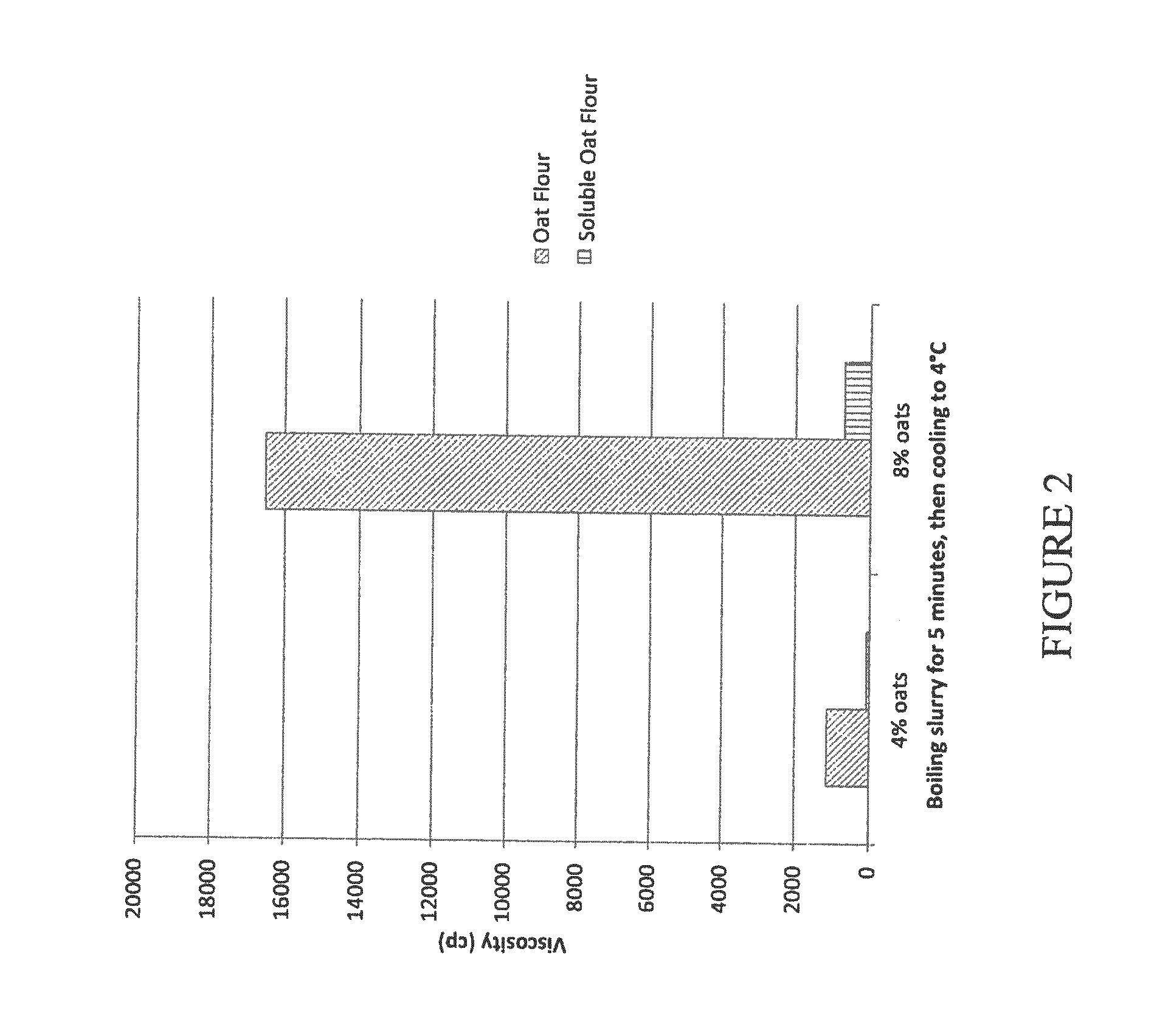

Soluble Oat or Barley Flour and Method of Making Utilizing a Continuous Cooker

Preparing soluble oat or barley flour in one-step using an extrusion (continuous cooking) process to dextrinize and gelatinize cook the oat or barley flour.

Owner:THE QUAKER OATS CO

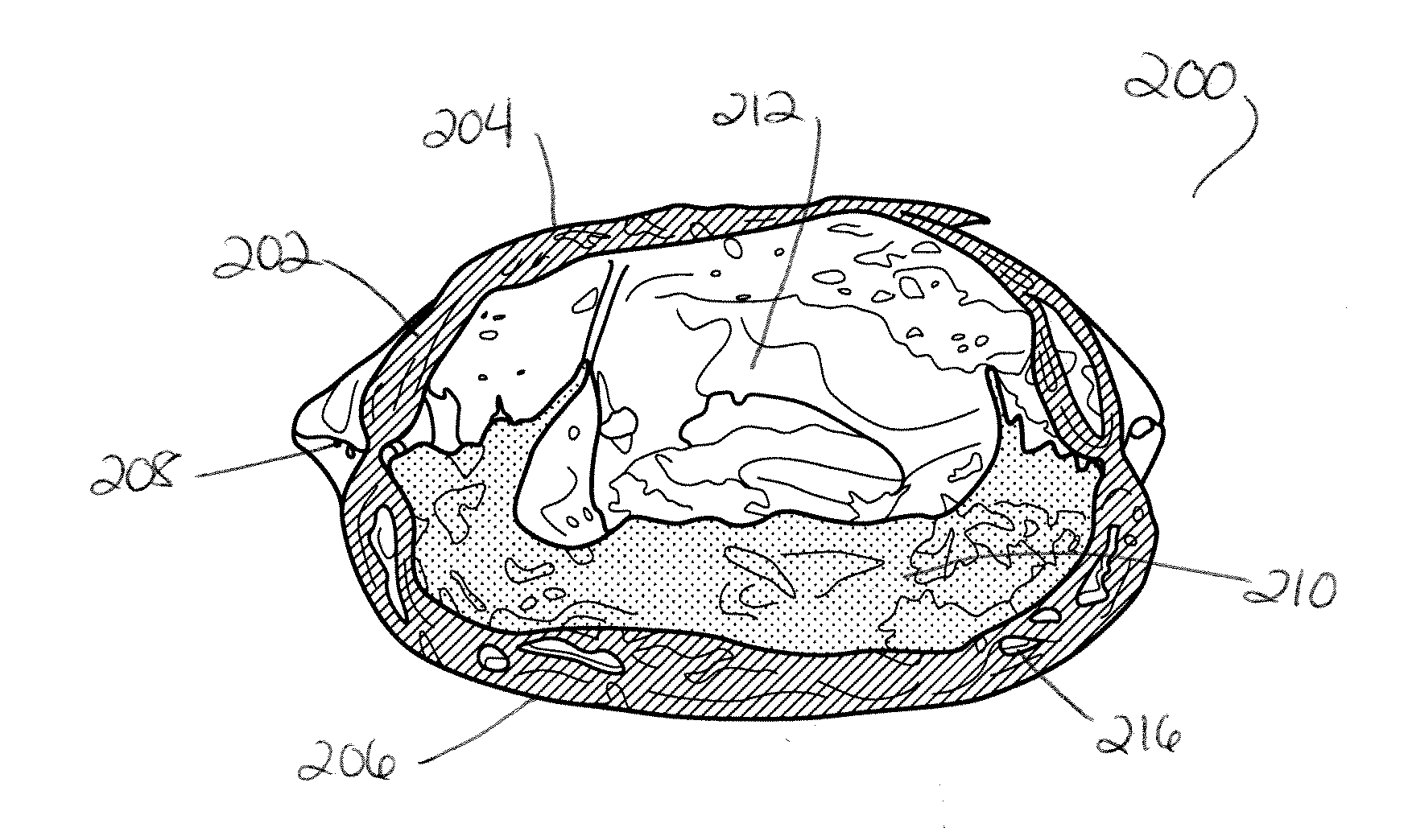

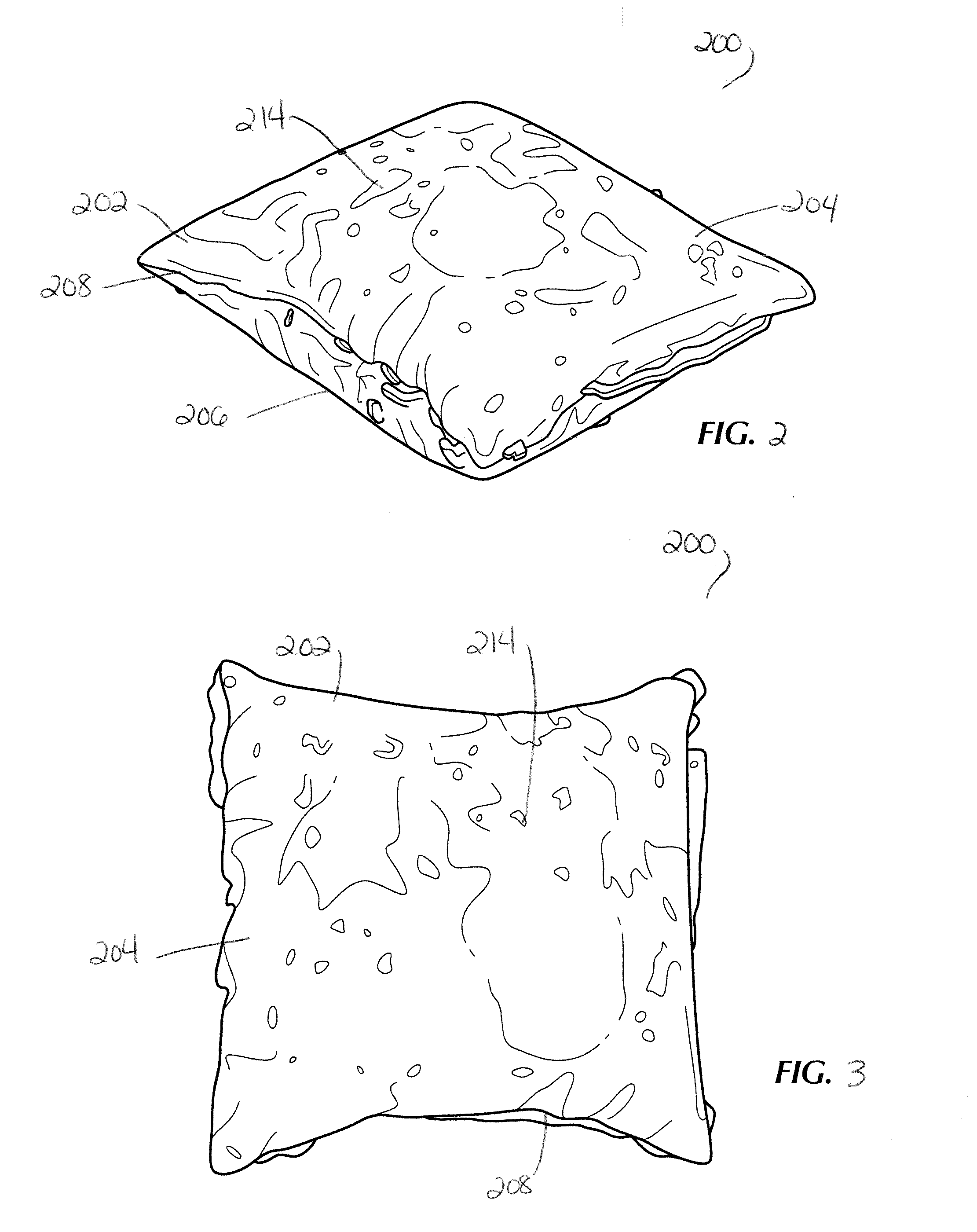

Crispy foodstuff with soft portion

Compositions and methods related to a baked dough-based component based on a pre-baked heat-treated flour, the baked dough-based component having a first fat concentration and a crispy texture; and a baked fat-based component in direct contact with the baked dough-based component, having a second fat concentration that is higher than the first fat concentration, the baked fat-based component having a soft texture; wherein the foodstuff exhibits a dual texture comprising a crispy texture of the dough-based component and a soft texture of the fat-based component, and wherein the dual texture is maintained throughout the shelf life of the foodstuff.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

Stabilized whole grain flour

InactiveUS20120189756A1Modified flavorModified functionalityBakery productsDough heat treatmentFlavorCorn flour

Stabilized whole grain corn flour having extended storage stability and modified functional properties, such as improved processing tolerance, improved dough properties and enhanced corn flavors, is described, as are methods of making such stabilized whole grain corn flour.

Owner:CARGILL INC

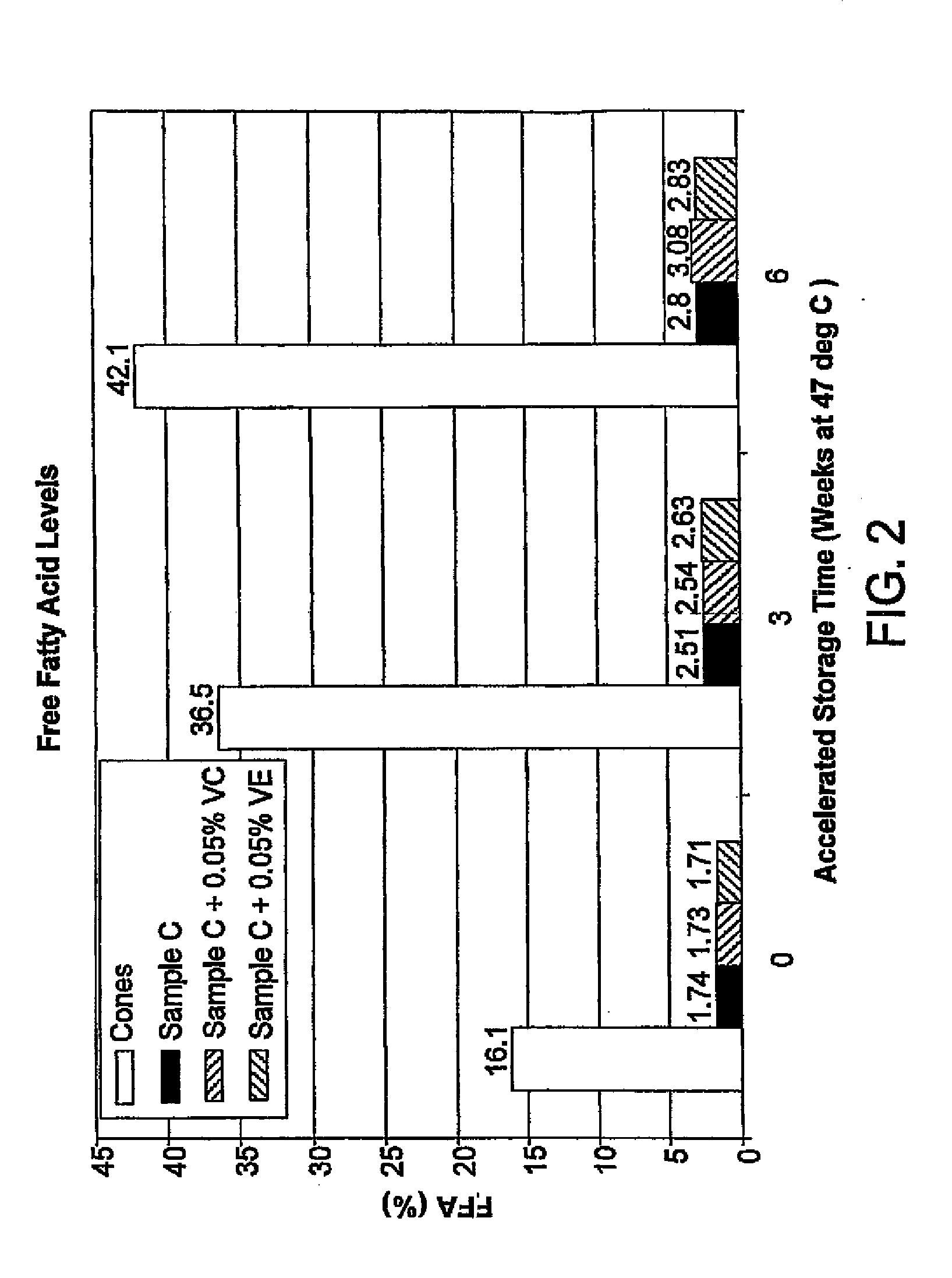

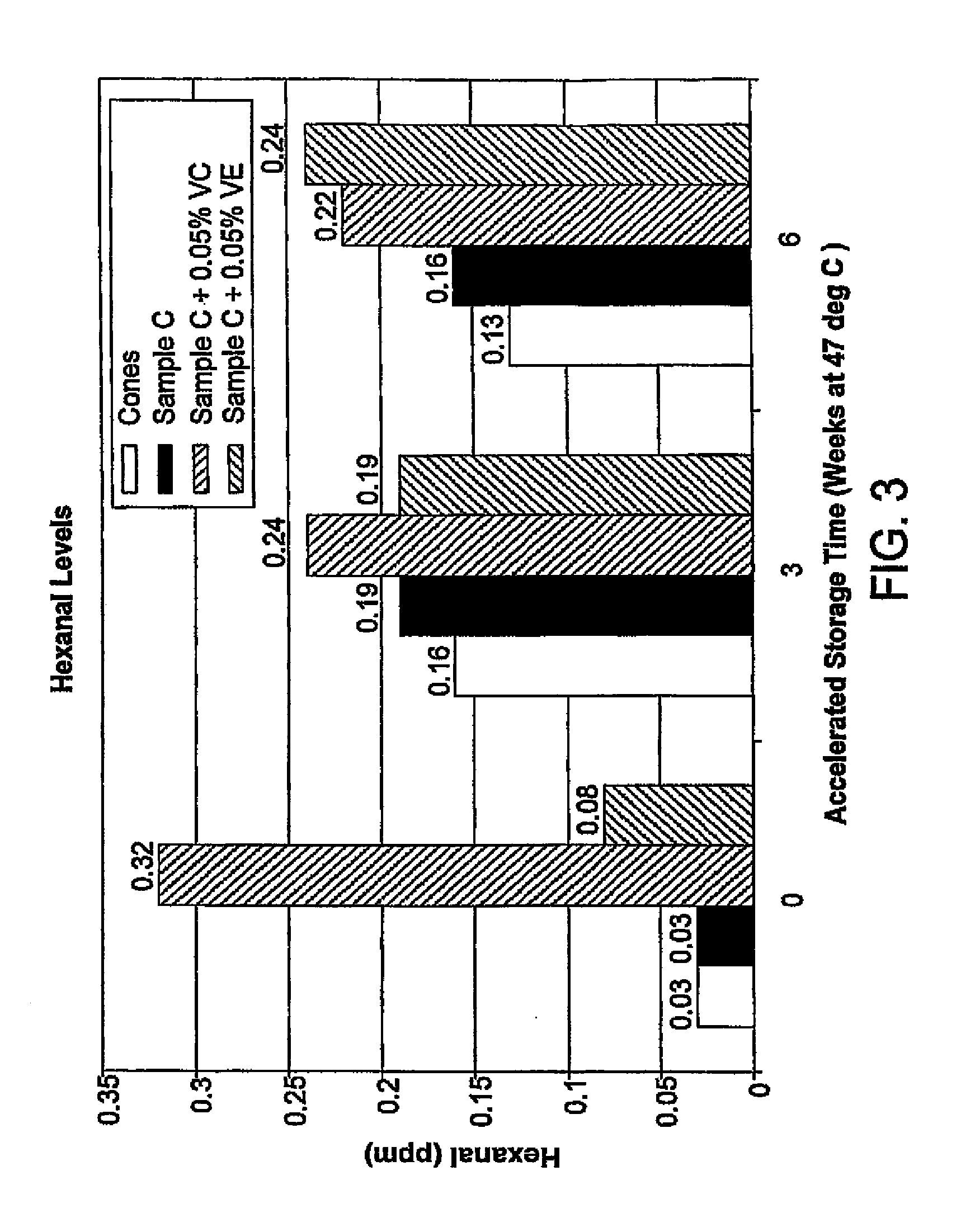

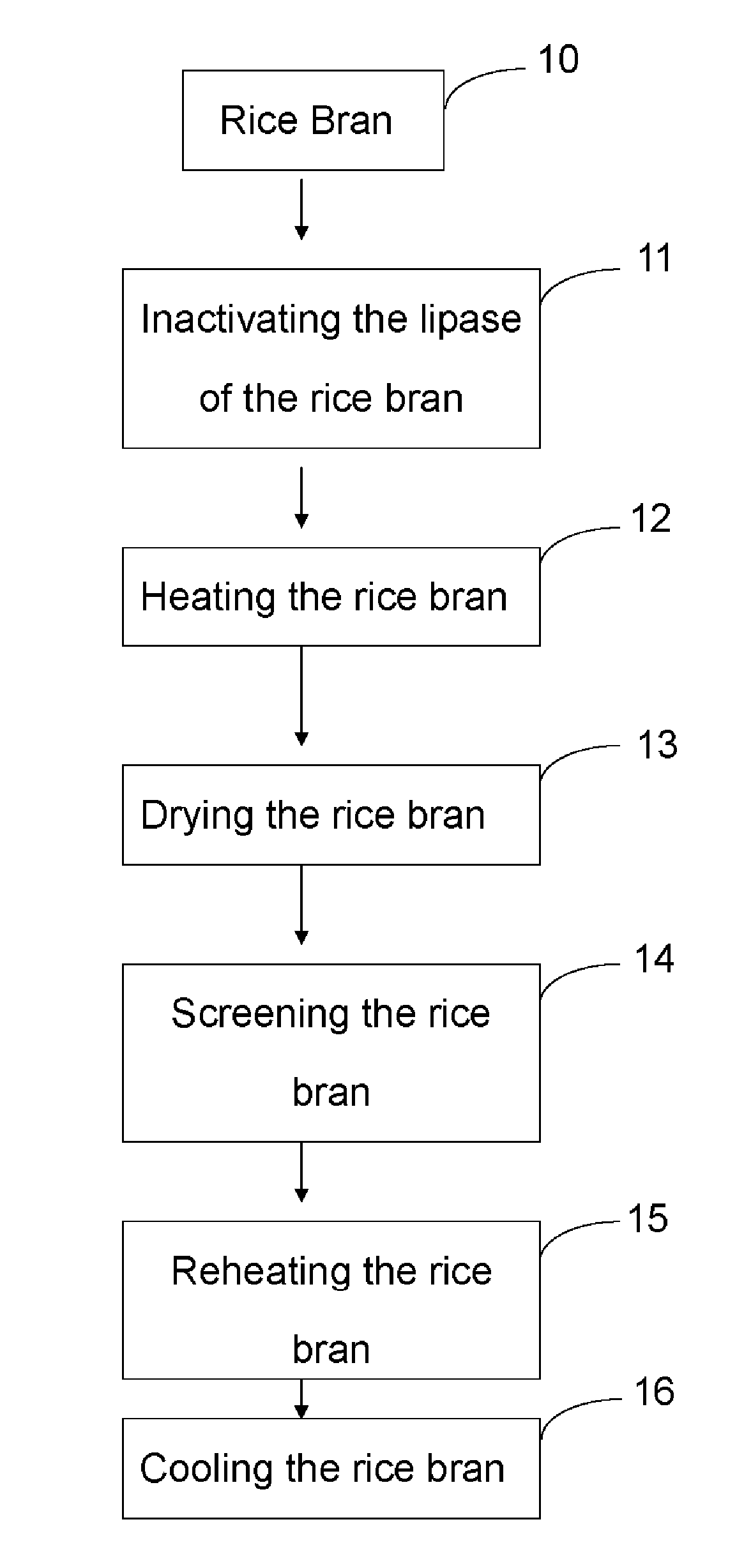

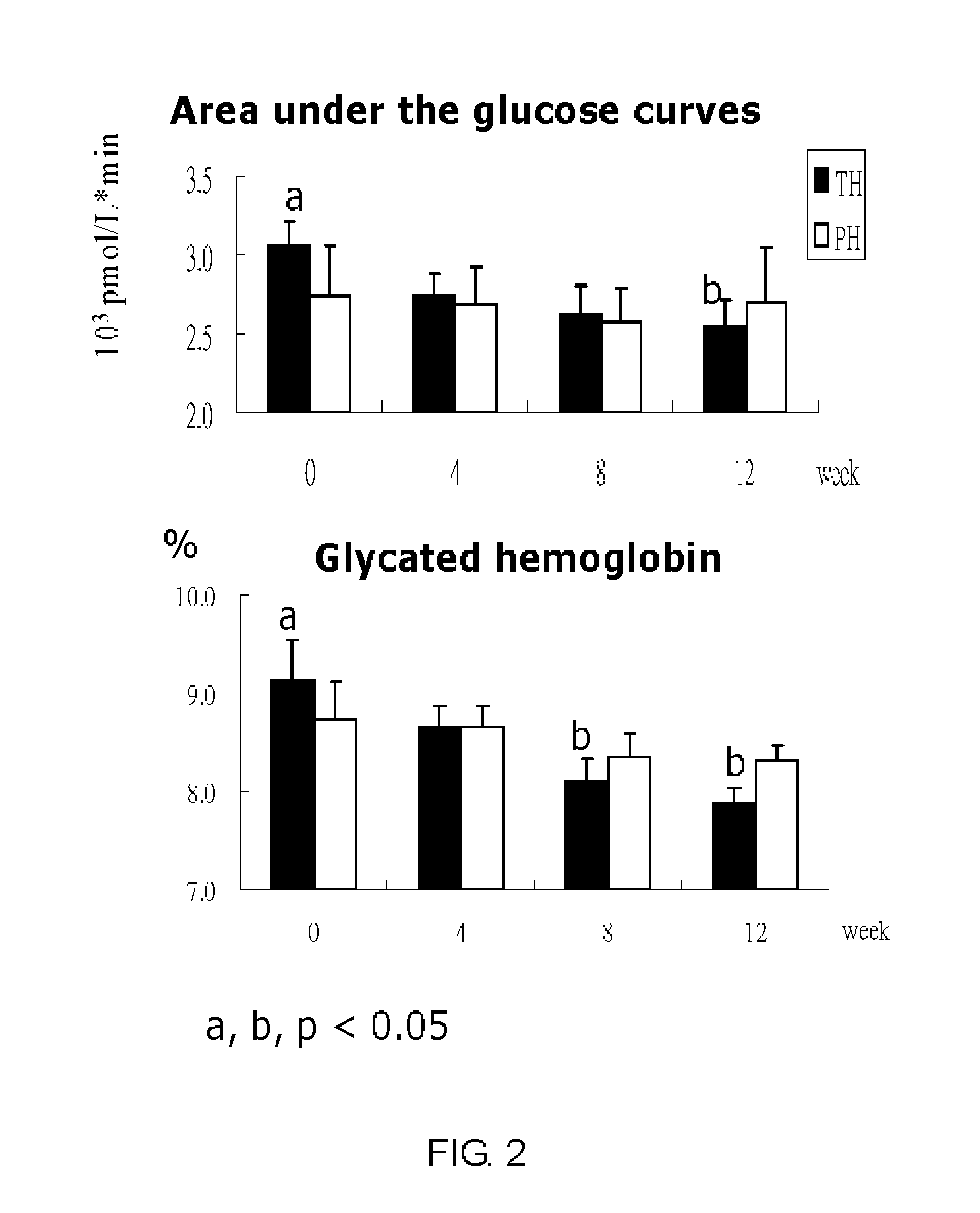

Rice bran flour and method of making thereof

InactiveUS20070087097A1Reduce pollutionEasy to useFood shapingDough heat treatmentHigh pressureDiabetic patient

This invention discloses a method for making rice bran flour by treating rice bran under high pressure and high temperature for a long period of time in two separate steps, the method comprising: husking and grinding the rice, then collecting the rice bran; inactivating the lipase of the rice bran; treating the rice bran under high pressure and high temperature; drying and screening the rice bran; treating the rice bran flour so obtatined under high pressure and high temperature again; and cooling the rice bran. Said rice bran flour made from said method is effective in lowering glycosylated hemoglobin and increasing insulin of diabetes mellitus patients.

Owner:TAIPEI MEDICAL UNIV

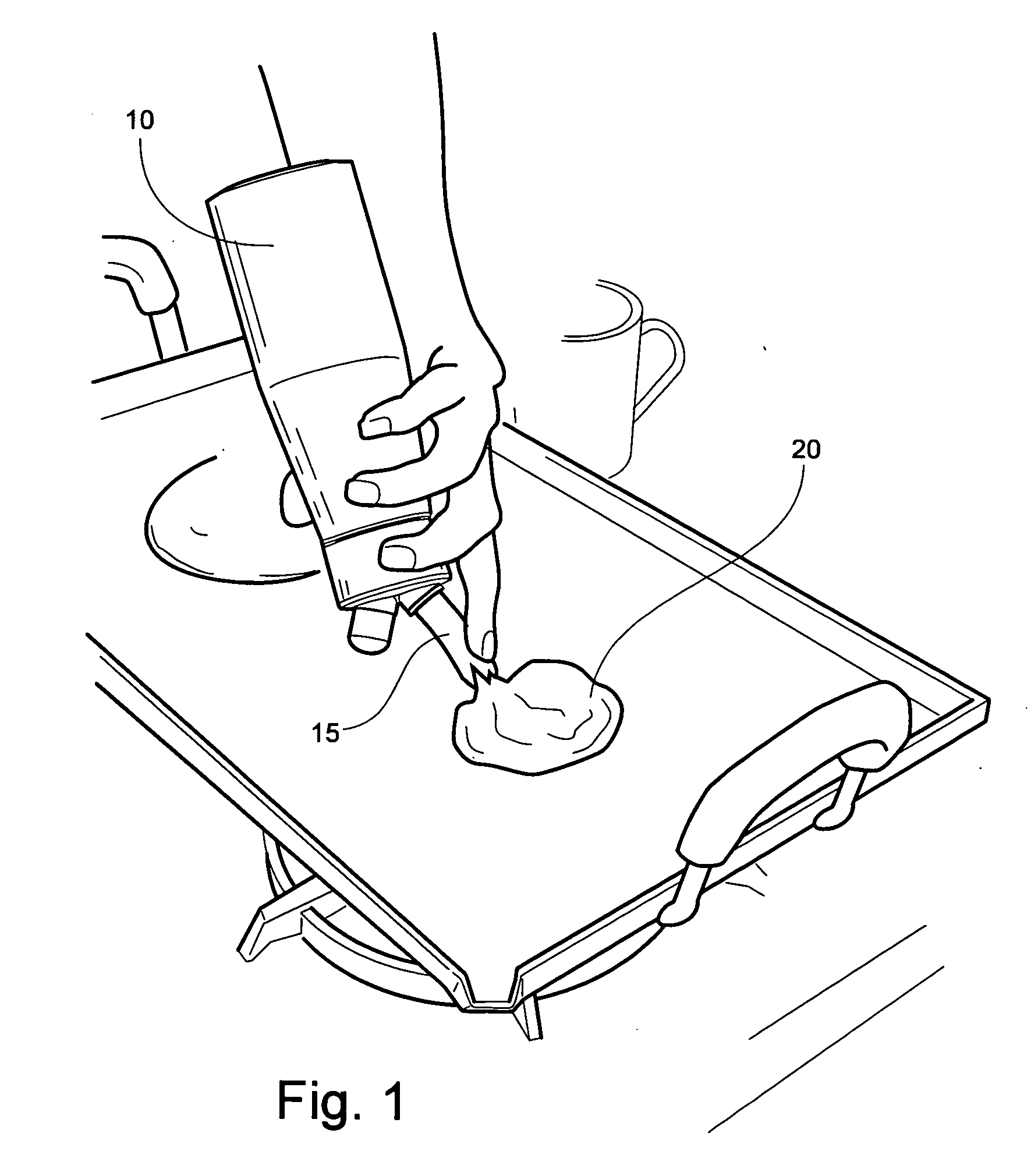

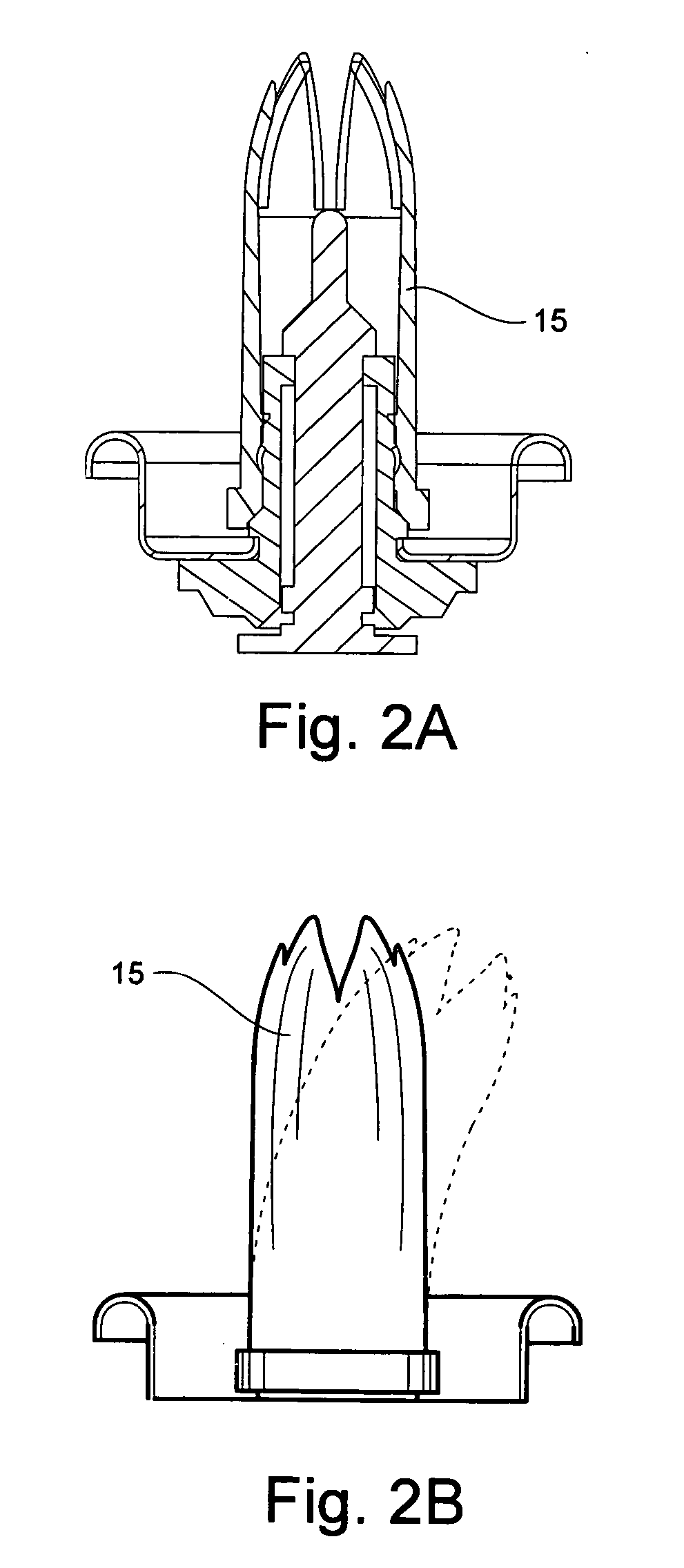

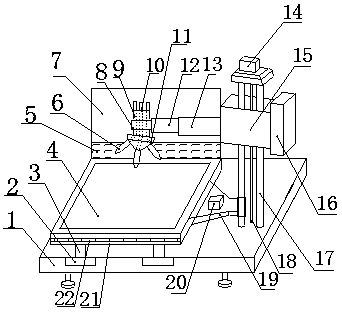

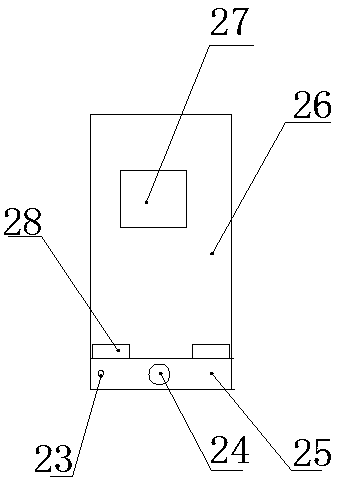

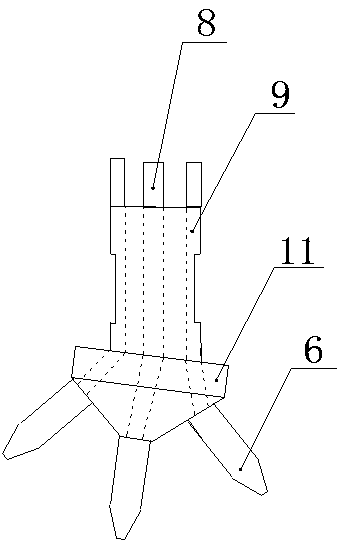

3D printer for foods

InactiveCN107821516AAvoid mutual contaminationImprove work efficiencyDough shapingBakery productsEngineeringHead holder

The invention relates to a food 3D printer, which includes a printer base, a workbench, a nozzle bracket and a constant temperature box. A workbench is arranged above the printer base, an electric heating system is arranged inside the workbench, and a substrate is arranged above the workbench. There is an air compressor behind the printer base, a Z-axis guide rail and a Z-axis screw are installed on the right side above the printer base, and a rocker arm is sleeved under the Z-axis screw rod, and the rocker arm is connected to the worktable, Z-axis guide rail and Z-axis screw. The top of the screw rod is sleeved with a nozzle bracket, the left side of the nozzle bracket is provided with an outer rod, the outer rod is sleeved with an inner rod, the front end of the inner rod is provided with a collar, and the inner sleeve of the collar is connected to the feed column, and the feed column The lower end is provided with a rotating head, the lower part of the rotating head is provided with a spray head, the upper end of the feeding column is connected with a consumable pipe, and the consumable pipe is connected with a constant temperature box; the present invention has the advantages of simple structure, automatic positioning, high working efficiency, high molding rate and multiple functions. , The advantage of prolonging the service life of the equipment.

Owner:HENAN LONGJING TECH

Health bread based on non-grain flour

Owner:KAUFMAN NATHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com