3D printer for foods

A 3D printer, printer technology, applied in bakery, food science, dough forming machinery or equipment, etc., can solve problems such as unsanitary, waste of time, etc., to extend service life, avoid mutual contamination, and improve product success rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

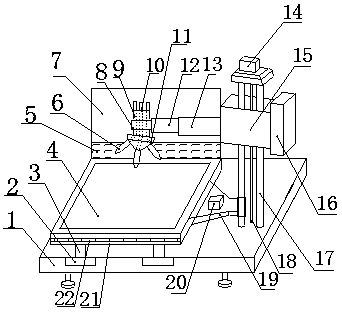

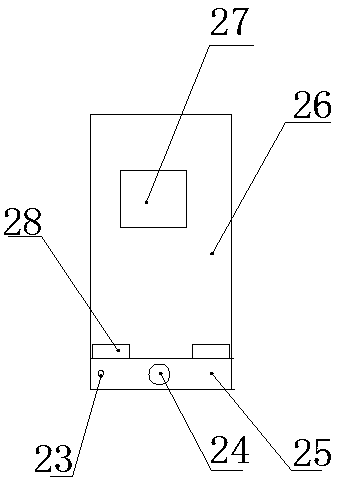

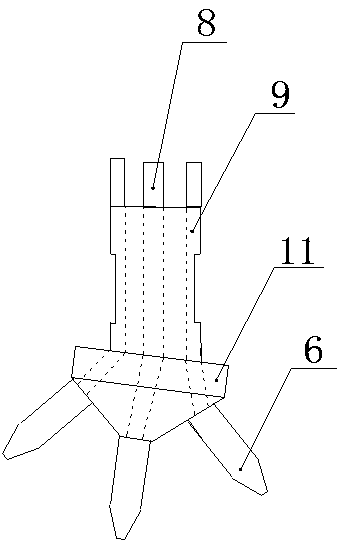

Embodiment 1

[0021] Such as Figure 1-3 As shown, a food 3D printer includes a printer base 1, a workbench 21, a nozzle holder 15 and a thermostat 26. A workbench 21 is provided above the printer base 1, and the printer base 1 is internally arranged There is a hydraulic cylinder 2, a hydraulic column 3 is arranged between the printer base 1 and the worktable 21, an electric heating system 22 is arranged inside the worktable 21, and a substrate 4 is arranged above the worktable 21 An air compressor 7 is provided behind the printer base 1, an air outlet 5 is provided below the air compressor 7, and a Z axis guide rail 17 and a Z axis are provided on the right side of the printer base 1 Screw 18, a rocker arm 19 is sleeved under the Z-axis screw 18, the rocker arm 19 is connected to the worktable 21, and the rocker arm driving motor 20 is arranged above the rocker arm 19, the A nozzle holder 15 is sleeved above the Z-axis guide rail 17 and the Z-axis screw 18, the right side of the nozzle hol...

Embodiment 2

[0024] A food 3D printer, which includes a printer base 1, a worktable 21, a nozzle support 15 and a thermostat 26. A worktable 21 is arranged above the printer base 1, and a hydraulic cylinder is arranged inside the printer base 1. 2. A hydraulic column 3 is arranged between the printer base 1 and the worktable 21, an electric heating system 22 is arranged inside the worktable 21, and a substrate 4 is arranged above the worktable 21. An air compressor 7 is provided at the rear of the printer base 1, an air outlet 5 is provided below the air compressor 7, and a Z-axis guide rail 17 and a Z-axis screw 18 are provided on the right side of the printer base 1. A rocker arm 19 is sleeved under the Z-axis screw 18, and the rocker arm 19 is connected to a worktable 21. A rocker drive motor 20 is provided above the rocker arm 19, and the Z-axis guide rail 17 and the Z-axis screw 18 are sleeved with a nozzle holder 15, the right side of the nozzle holder 15 is provided with a telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com