Automatic dough mixing machine

A kneading machine, automatic technology, applied in the structural parts of mixing/kneading machinery, mixing/kneading of horizontal installation tools, etc., can solve the problems of poor operation, difficult to meet the needs of pasta, and uneven kneading effect. , to achieve the effect of simple and reliable opening and closing operation, simple and reliable transmission mechanism, and sufficient and uniform surface mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

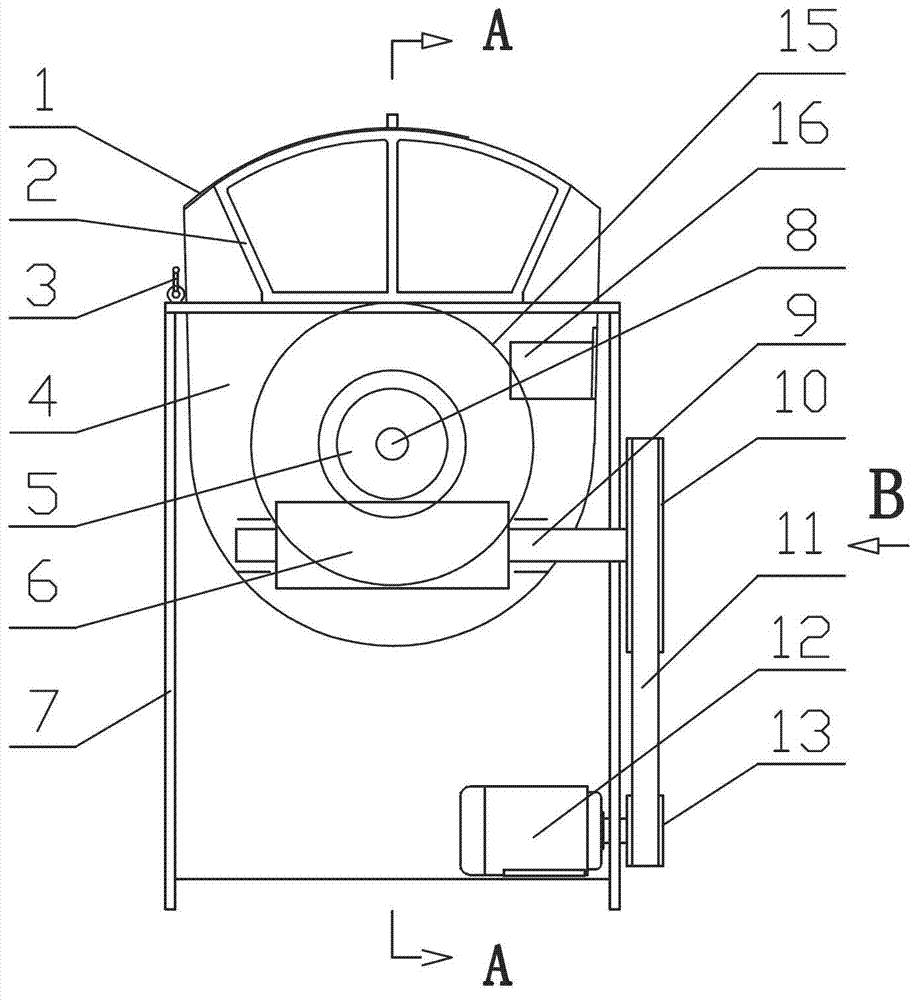

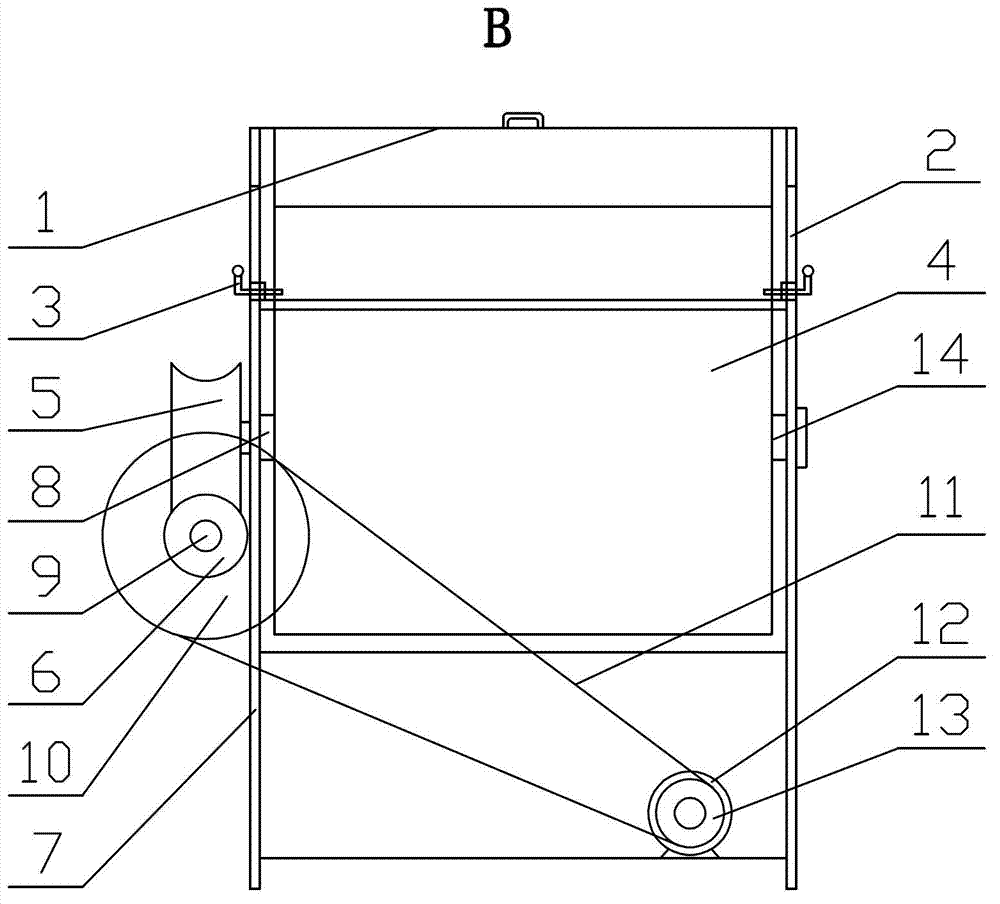

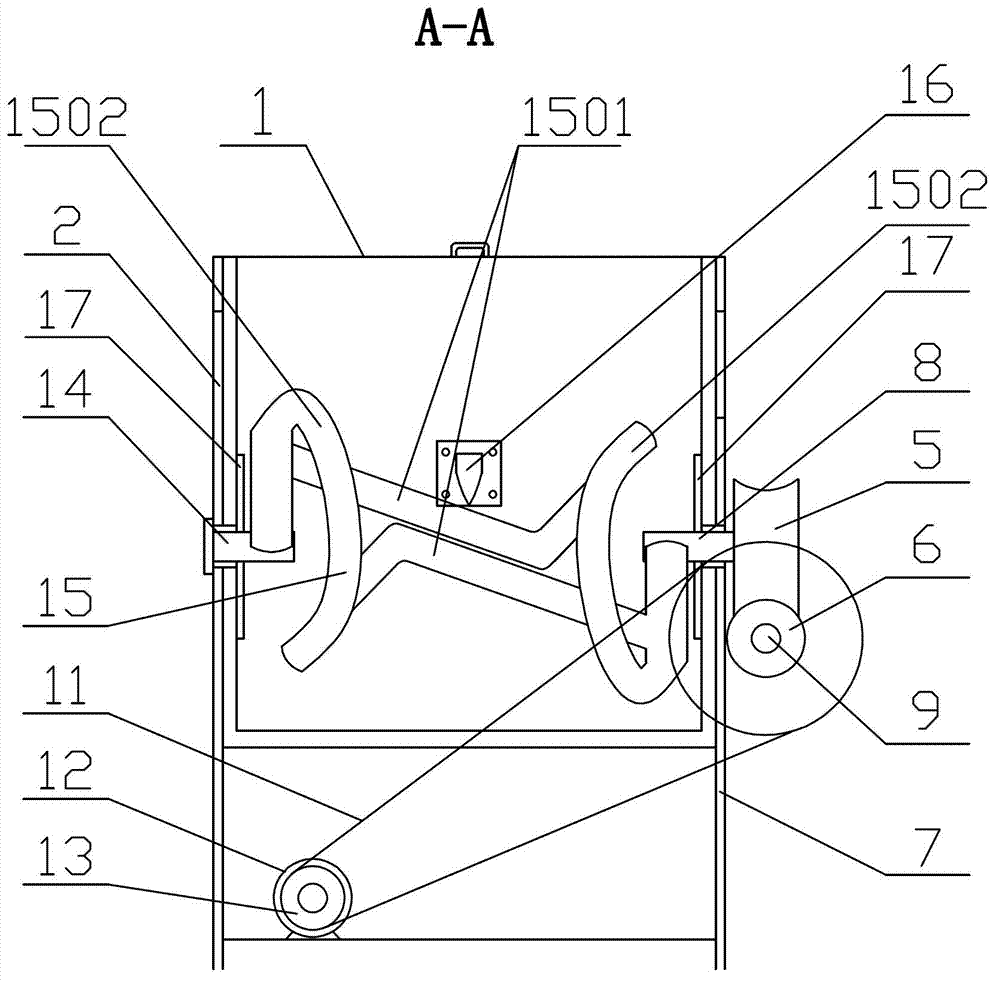

[0023] as attached figure 1 As shown, an automatic dough mixer mainly includes a frame 7, a dough box 4, an agitator 15, a motor 12 and a transmission device.

[0024] Its agitator 15 can be installed in the kneading box 4 around a horizontal axis.

[0025] The dough box 4 is arranged on the frame 7 . The top of the kneading box 4 is provided with an opening for putting and taking the noodles. The inner bottom surface of the kneading box 4 is made as an arc surface adapted to the direction of rotation of the agitator 15 . The two sides of the opening at the top of the kneading box 4 are upwardly arched arc edges, and the opening of the kneading box 4 is matched with an arc-shaped cover plate 1, and the two sides of the kneading box 4 are provided with an arc-shaped cover plate 1. An arc-shaped track 2 that slides in an arc direction, and the arc-shaped track 2 is fixedly supported on a frame 7.

[0026] The motor 12 and the transmission device are located outside the dough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com