Efficient fully-automatic semi-finished stewed noodle production line

A fully automatic, production line technology, applied in the direction of dough processing, dough forming machinery or equipment, horizontal installation tools for mixing/kneading, etc., it can solve the problem of inability to automatically cycle kneading dough and braised dough, low efficiency of kneading machines, and inability to Fully automatic production and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

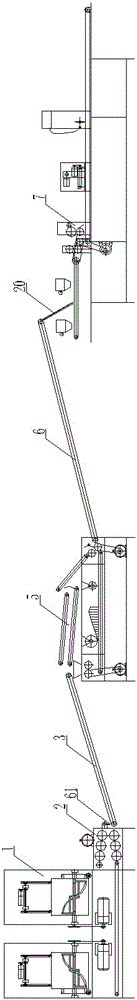

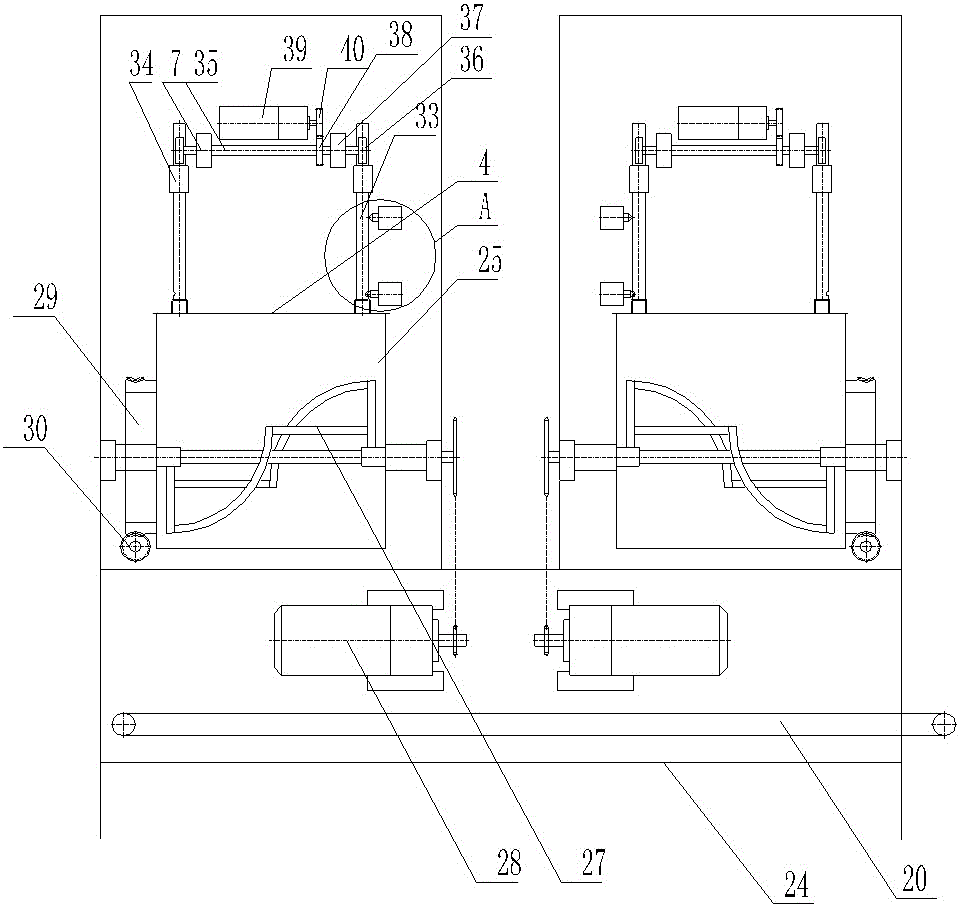

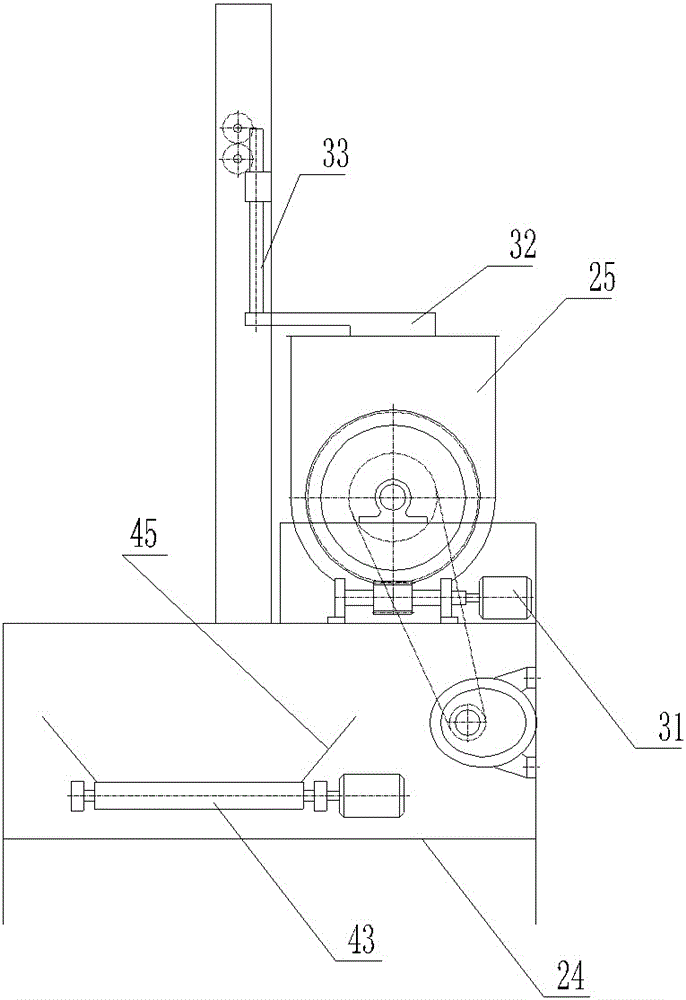

[0025] An embodiment of a high-efficiency full-automatic braised noodle base production line, in Figure 1 to Figure 11 Among them, the outlet of the noodle device 1 is connected with a rough rolling device 2, the front end of the rough rolling conveyor belt 3 to be transferred is provided with a noodle belt cutting mechanism 61, and the outlet of the rough rolling device 2 is connected with a rough rolling waiting device. Transfer conveyor belt 3, the front end of the rough pressing and waiting transfer conveyor belt 3 is provided with a noodle block cutting machine 4, and the rear of the rough rolling and waiting transfer conveyor belt 3 is connected with a double-head automatic circulation kneading device 5. The rear of head full-automatic circulation kneading dough device 4 is provided with kneading and rolling and waits to turn conveyor belt 6, and kneads and rolls and waits to turn the rear of conveyor belt 6 and connects and is provided with stewed noodle blank forming d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com