Dough making and kneading device for food processing

A food processing and noodle box technology, applied in the direction of mixing/kneading with vertical installation tools, application, food science, etc., can solve the problems of lack of dough kneading operation, low production efficiency, low degree of automation, etc., to reduce work Burden, improve production efficiency, improve the effect of mixing surface efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

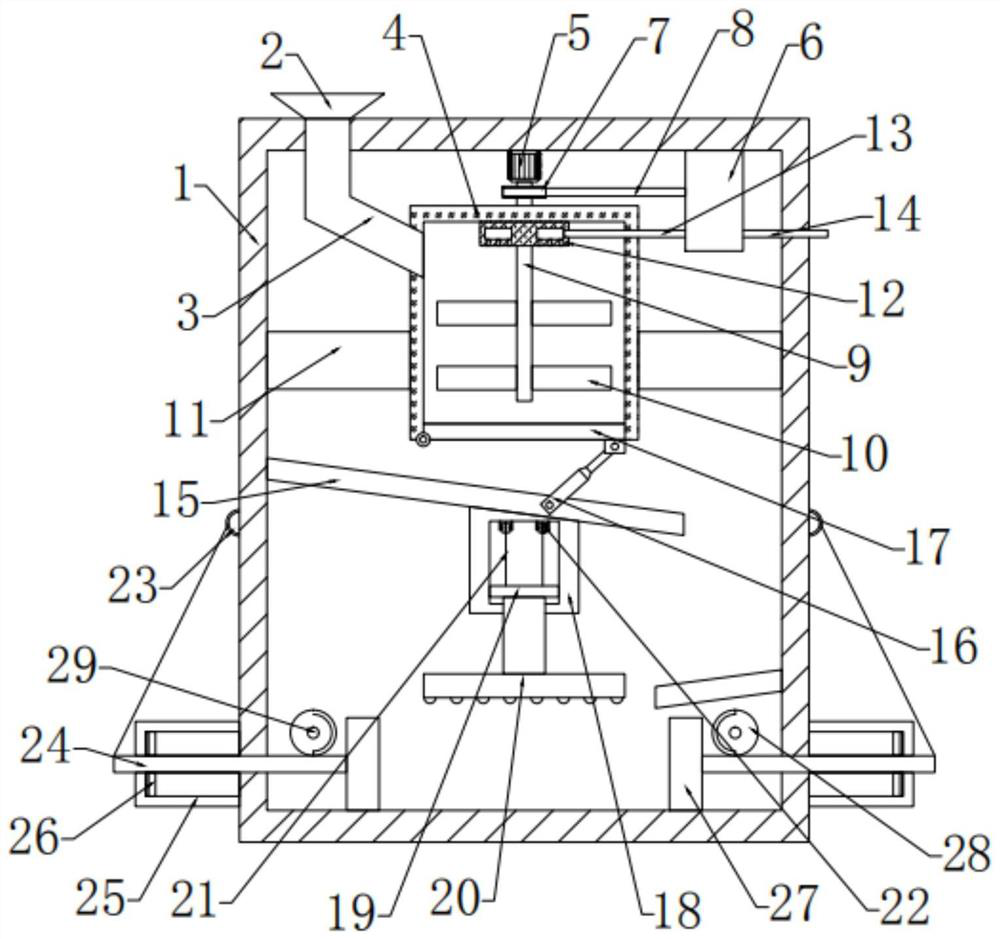

[0025] see Figure 1-4 , in an embodiment of the present invention, a food processing and dough kneading device includes a housing 1, the top of the housing 1 is provided with a feeding hopper 2, and the bottom end of the feeding hopper 2 is connected to the The kneading mechanism arranged inside the housing 1 is connected, and a kneading mechanism is arranged on the underside of the kneading mechanism, and several guide plates 15 fixedly connected with the housing 1 are arranged between the kneading mechanism and the kneading mechanism.

Embodiment 2

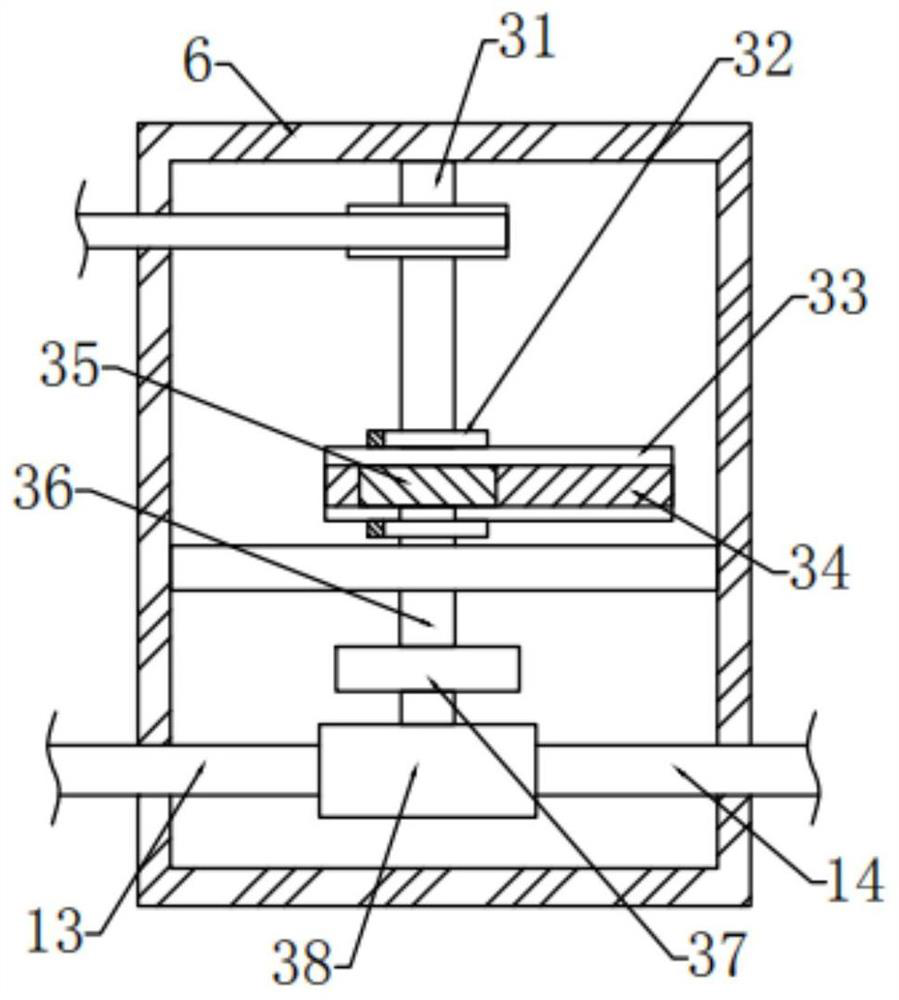

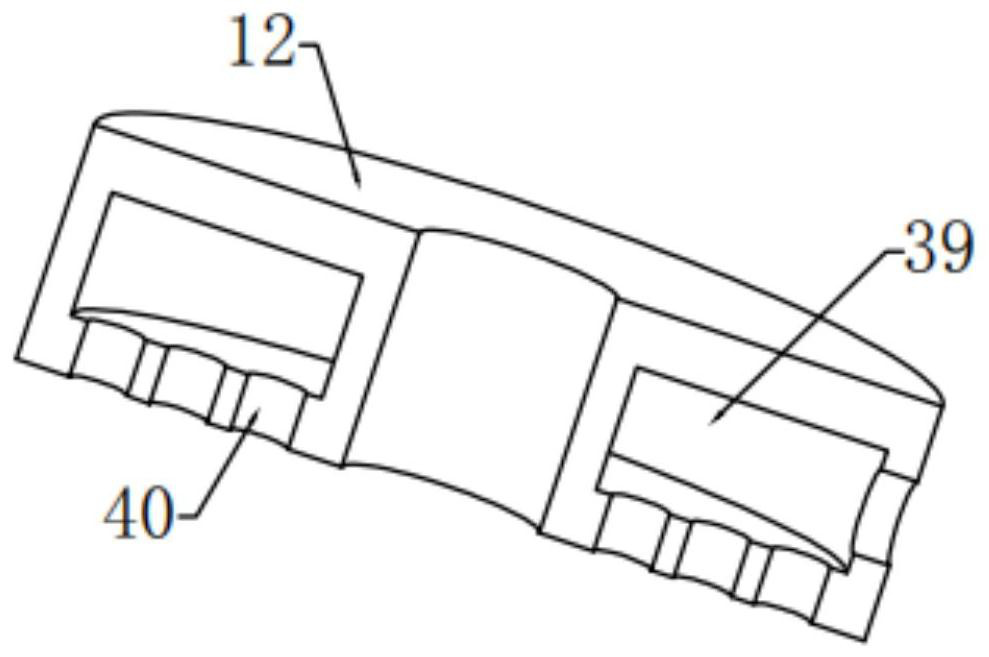

[0027] In this embodiment, the dough kneading mechanism includes a kneading box 4, and support rods 11 are fixedly connected between the left and right ends of the kneading box 4 and the housing 1, and the upper side of the kneading box 4 is provided with a The first motor 5 connected by bolts to the shell 1, the output end of the first motor 5 is connected to the rotating rod 9, and the rotating rod 9 is fixedly connected to the outer side of the inner part of the noodle box 4 and provided with several stirring rods 10. The outside of the rod 9 is provided with a water injection mechanism, the outside of the water injection mechanism is provided with an adjustment mechanism, the bottom of the kneading box 4 is hingedly provided with a bottom plate 17, and a telescopic rod 16 is hinged between the bottom end of the bottom plate 17 and the guide plate 15. The kneading mechanism is set up to realize automatic mixing of noodles with water, which not only improves the efficiency of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com