Unattended automatic noodle cooking machine

A cooking machine and noodle technology, which is applied in the field of unmanned automatic noodle cooking machines, can solve the problems of not being able to obtain noodles immediately, affecting the progress of noodle processing, and not being able to reflect fast food culture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

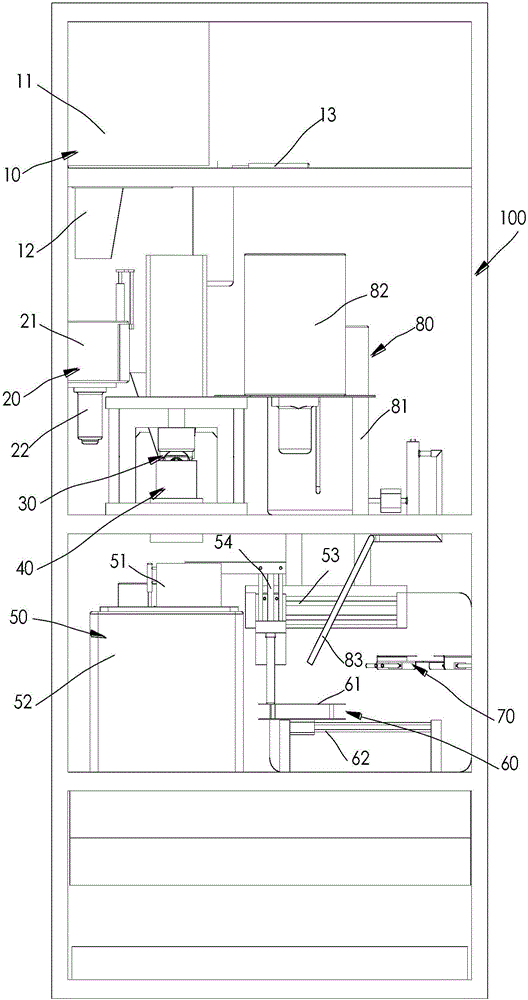

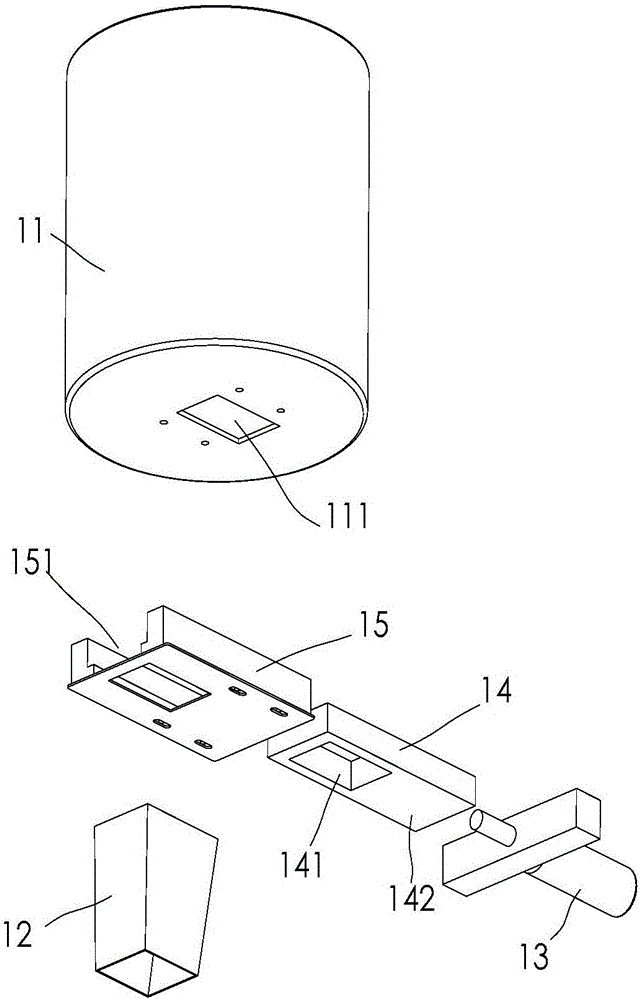

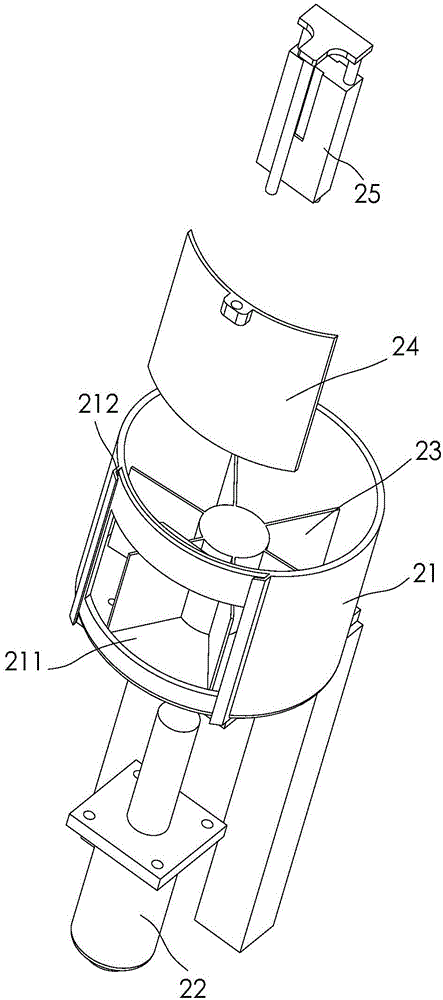

[0032] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0033] Such as Figure 1-9 A kind of unmanned automatic noodle cooking machine shown, comprise frame 100 and all be installed on frame 100 and noodle mechanism 20, noodle forming mechanism, cooking mechanism 50 and bowl mechanism 60; And set on frame 100 There is a noodle mouth (not shown), and the noodle mouth is connected to the bowl holding mechanism 60 places. Concrete noodle forming mechanism comprises forming barrel 41 and stamping part 42, offers a plurality of forming holes 411 at the bottom of forming barrel 41; Stamping part 42 is installed in forming barrel 41 and can be along the height direction of forming barrel 41 In addition, the noodle cooking mechanism 50 includes a noodle cooking bucket 51 and a noodle cooking furnace 52, the noodle cooking bucket 51 is used to receive the fabric extruded from the forming hole 411; and the noodle coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com