Dried manyflower solomonseal rhizome and production method thereof

A Polygonatum chinensis, steaming and drying technology, applied in the field of food processing, to achieve the effect of prolonging the storage period, saving processing time and having a good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Dry Polygonatum preparation process: material selection→cleaning→cutting into pieces→repeated steaming and drying→anti-mildew treatment→vacuum packaging. Specific requirements are as follows:

[0019] A: Raw material selection: Eliminate pollution, insects, and deteriorated rhizomes and fibrous roots;

[0020] B: Cleaning of raw materials: Put sealwort into drinking water and scrub, clean the sediment and pick it up quickly, the cleaning time does not exceed 5 minutes, and dry the surface;

[0021] C: cut into pieces: cut the rhizome of Rhizoma Polygonatum into 3-4 cm long segments;

[0022] D: Repeated steaming and drying: Put the cut polygonatum into a pressure cooker (working pressure 80kpa) for heating and steaming for 15-30 minutes, take it out, and bake it in an environment of 50°C-60°C for 30-40 minutes (you can also use Dry in the sun, just dry the surface moisture at this time), this is "one steaming and one drying", and the number of steaming and ...

Embodiment 2

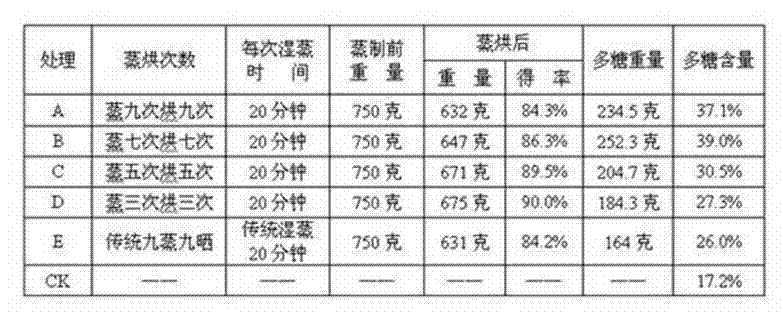

[0026] Example 2: Effect test of different steaming and drying parameters on Polygonatum polysaccharide content: After washing and cutting Polygonatum polysaccharides (same as Example 1), set different steaming and drying parameters, steam seven times and dry seven times, then determine the yield of Polygonatum polysaccharides . Then each treatment of Rhizoma Polygonatum was dried to constant weight, and the polysaccharide content was determined, see Table 1.

[0027] Table 1 Polygonatum Polysaccharide Content Determination Results

[0028]

[0029] The test results show that the polysaccharide content is high and the effect is better when the wet steaming time is 15-30 minutes, the drying time is 30-40 minutes each time, and the drying temperature is 50-60°C.

Embodiment 3

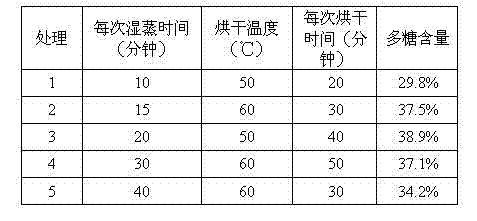

[0030] Example 3: This example is an experiment of the drying method of Rhizoma Polygonatum, aiming to obtain the steaming method with the highest polysaccharide content through experiments. The experiment was divided into four treatments A, B, C, and D. Each treatment was steamed for 20 minutes each time, and each time it was baked at 50-60°C for 35 minutes. The weight of sealwort before steaming was 750 grams, purchased in Anhui The same batch of Rhizoma Polygonatum (Polygonatum medicinal material) from Qingyang County, the province. Before the determination of Polygonatum Polysaccharides, each treatment of Polygonatum Polysaccharides was dried to constant weight, and then the content of Polygonatum Polysaccharides was determined by the method specified in the Pharmacopoeia, so as to screen out the best drying method. The test results are shown in the table below.

[0031] Table 2 Comparison of the effects of different drying methods of Rhizoma Polygonatum

[0032]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com