Kneading type wheaten food processing device

A kind of processing equipment and pasta technology, which is applied in food science, dough mixer, horizontal installation tool mixing/kneading, etc. It can solve the problems of poor kneading effect, poor taste of pasta finished products, reduced processing efficiency, and low operating efficiency. The effect of splashing dough and equipment adhesion, improving dough mixing efficiency, and facilitating cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

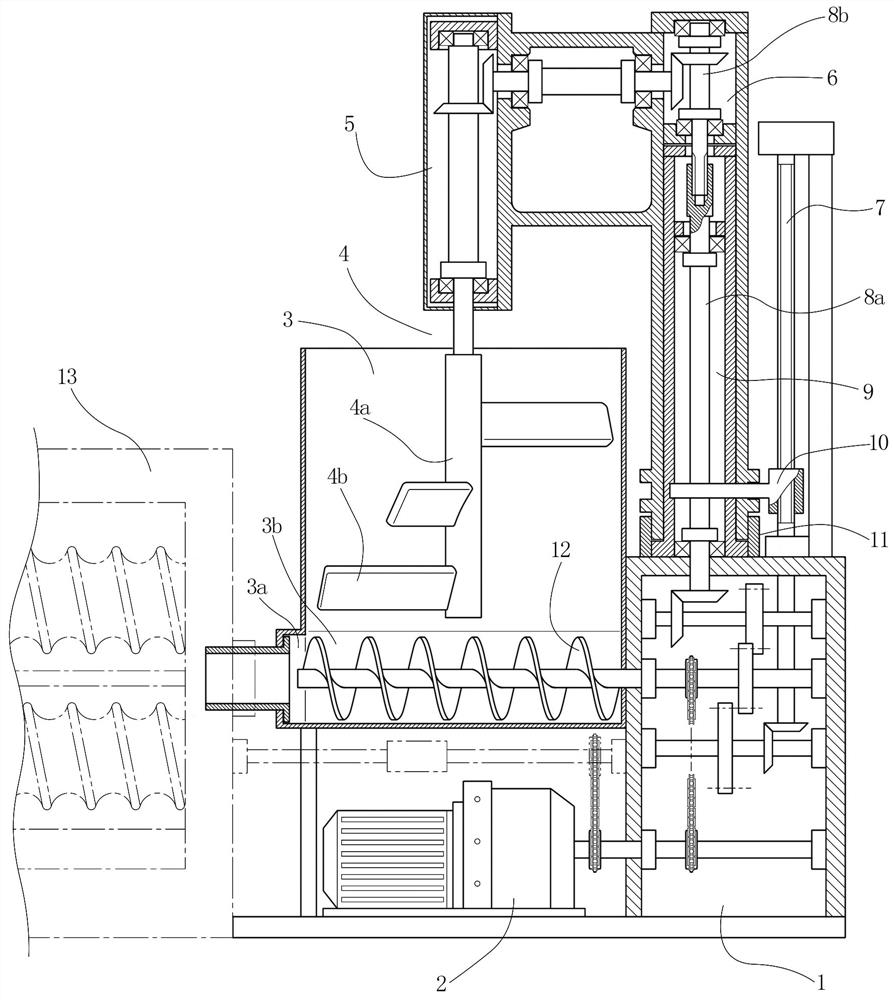

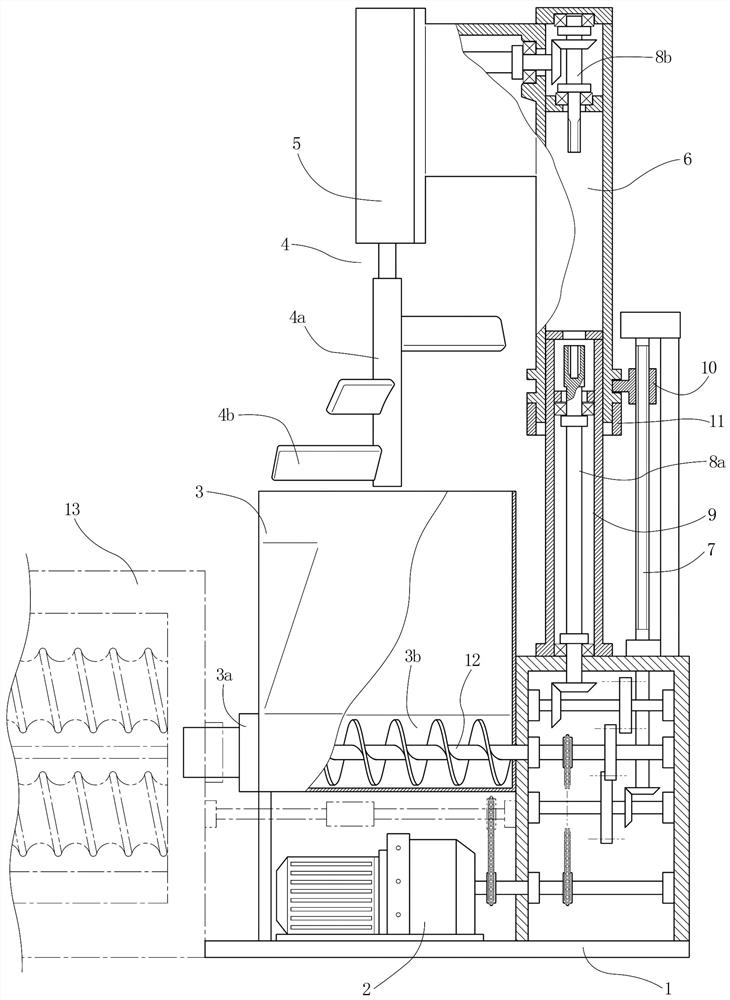

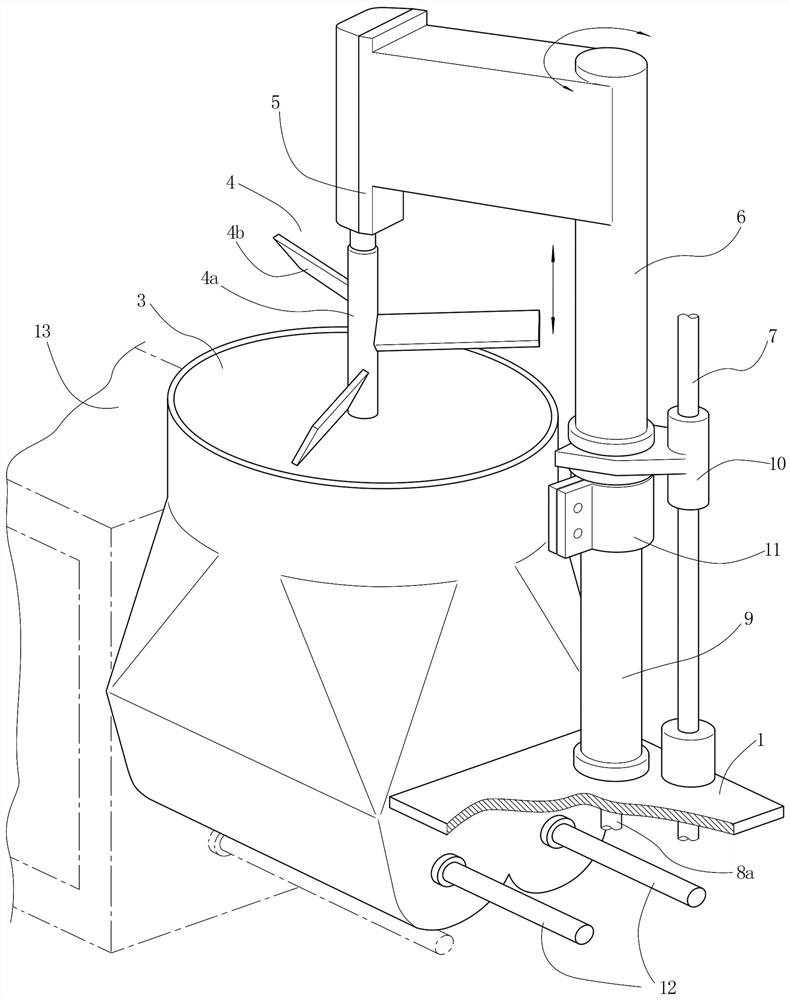

[0031] From Figure 1 ~ Figure 3 It can be seen that the technical solution of the present invention includes a main frame 1, a power unit 2 installed on the main frame, a control system connected to the power unit, a transmission mechanism, a dough mixing bucket 3, a screw push rod 12, an agitator 4, an agitator support, lifter;

[0032] The kneading bucket 3 is fixedly connected to the main frame 1, and the top opening of the kneading bucket 3 is a feed inlet, and the lower side wall of the kneading bucket is provided with a discharge port 3a;

[0033] Described screw push rod 12 is horizontally installed in the lower part in the kneading barrel 3, and one end of the screw push rod 12 corresponds to the position of the outlet 3a of the kneading bucket, for ease of description, the position corresponding to the outlet 3a The end is called the end, that is, the end of the screw push rod 12 points to the discharge port 3a of the kneading bucket;

[0034] The support of the ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com