Modified starch stirring making machine for cooked wheaten food processing

A technology of modified starch and stirring mechanism, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, sustainable manufacturing/processing, etc., which can solve the problems of low work efficiency, labor-consuming, and manual fatigue, etc., to save manpower, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

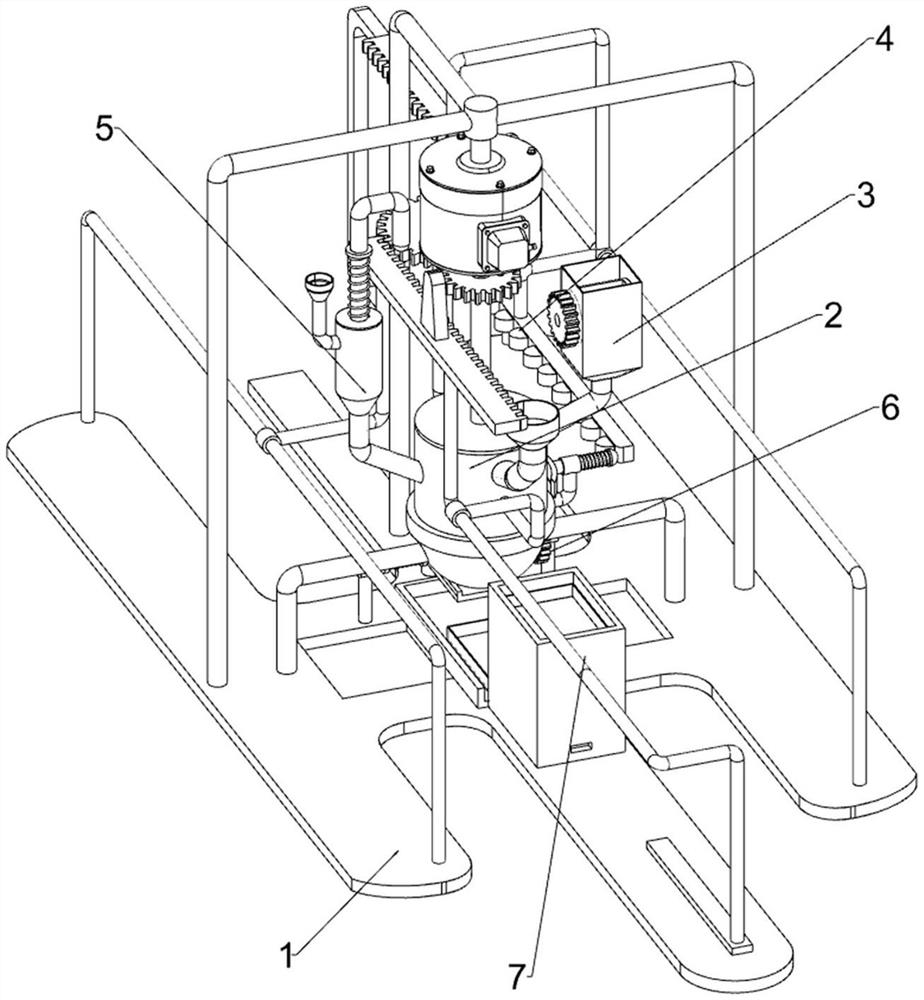

[0024] A kind of pasta processing machine with modified starch stirring and making machine, such as Figure 1-7 As shown, it includes a bottom plate 1, a stirring mechanism 2 and a feeding mechanism 3. The bottom plate 1 is provided with a stirring mechanism 2 for stirring by rotating, and the bottom plate 1 is provided with a feeding mechanism 3 for feeding by rotating.

[0025] When using the device, the worker puts the starch into the feeding mechanism 3, then the starch flows into the stirring mechanism 2 for stirring, and after the stirring is completed, the worker collects it.

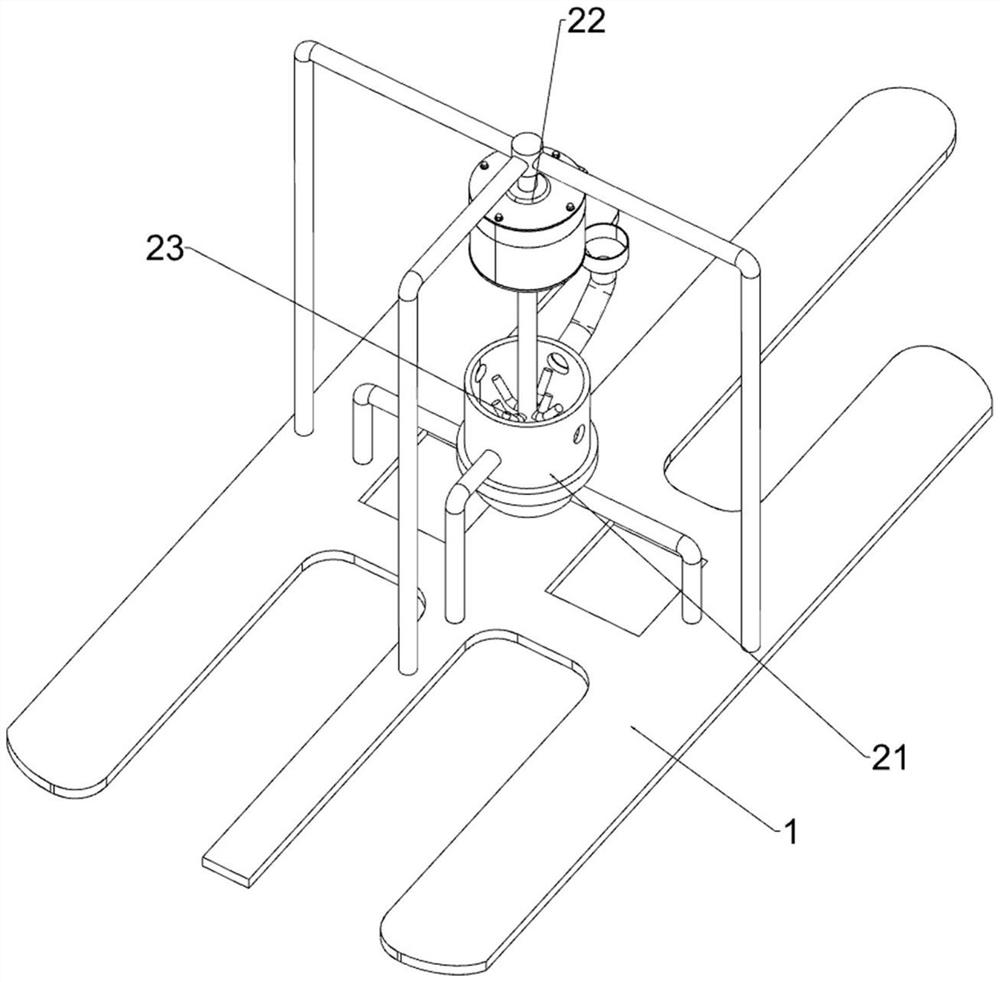

[0026] Such as figure 1 , figure 2 and Figure 5 As shown, the stirring mechanism 2 includes a material holding frame 21, a motor 22 and a stirring rod 23, the bottom plate 1 is fixedly connected with the material holding frame 21 by bolts, the upper middle part of the bottom plate 1 is fixedly connected with a motor 22 by bolts, and the output shaft of the motor 22 A stirring rod 23 is arran...

Embodiment 2

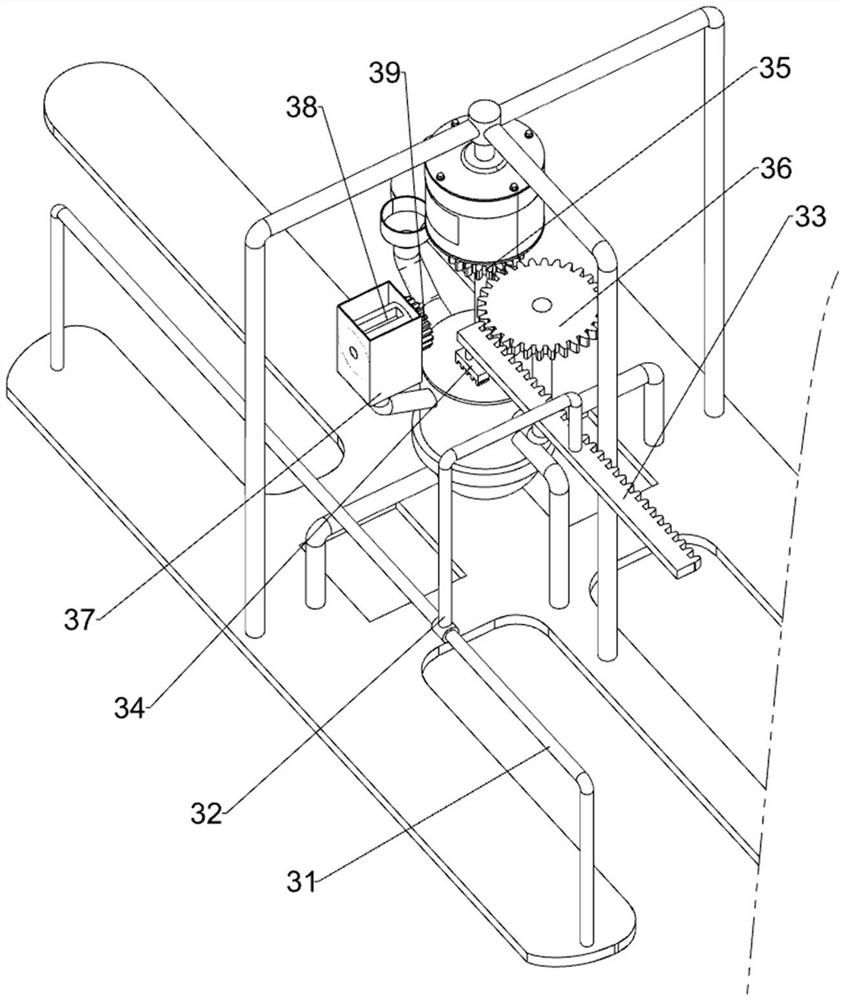

[0031] On the basis of Example 1, such as figure 1 and Figure 4 As shown, it also includes a vibrating and beating mechanism 4. The vibrating and beating mechanism 4 includes a wave vibrating bar 41, a second fixed sliding sleeve 42, a hitting sliding rod 43 and a first spring 44. The left side of the first fixed sliding sleeve 32 is provided with a wave The vibrating bar 41 is provided with a second fixed sliding sleeve 42 on the right side of the material holding frame 21, and the sliding type inside the second fixed sliding sleeve 42 is provided with a striking sliding rod 43, and the striking sliding rod 43 is connected with the second fixed sliding sleeve 42 There is a first spring 44, and the striking slide bar 43 contacts and cooperates with the wave vibrating bar 41.

[0032] When the starch is stirred, the first fixed sliding sleeve 32 slides forward to drive the wave vibrating bar 41 to move forward, and when the wave vibrating bar 41 moves forward to contact with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com