Axial clearance adjusting mechanism of automatic noodle press

A technology of axial clearance and adjustment mechanism, which is applied in the direction of dough sheeting machine/rolling machine/rolling pin, etc., can solve the problems affecting food safety and sanitation, grinding black flour iron filings into the dough, etc., to achieve safe and secure use The effect of health and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

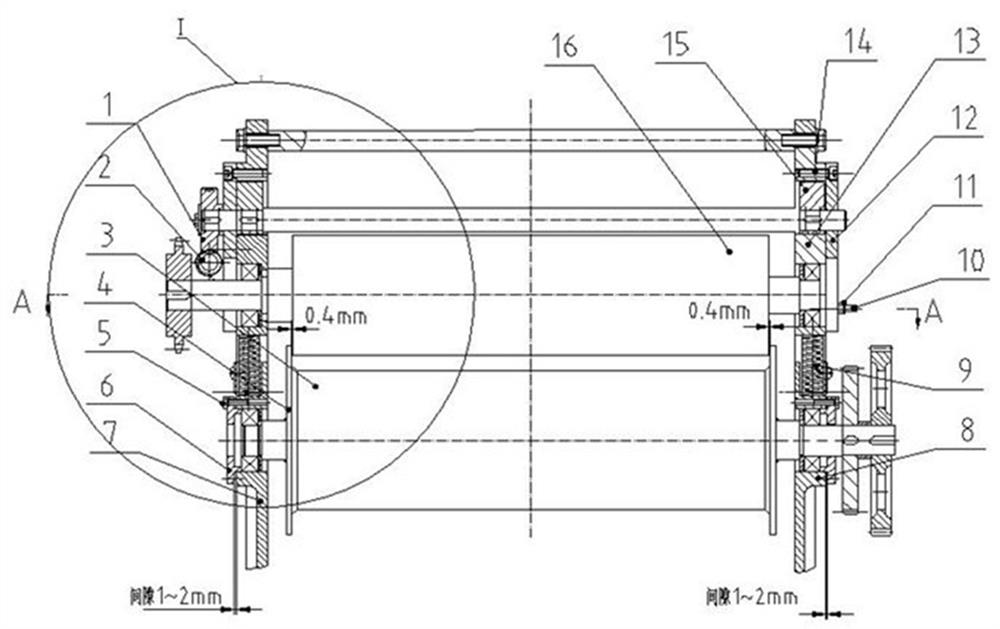

[0017] figure 1 Shown is the structural representation of the present invention.

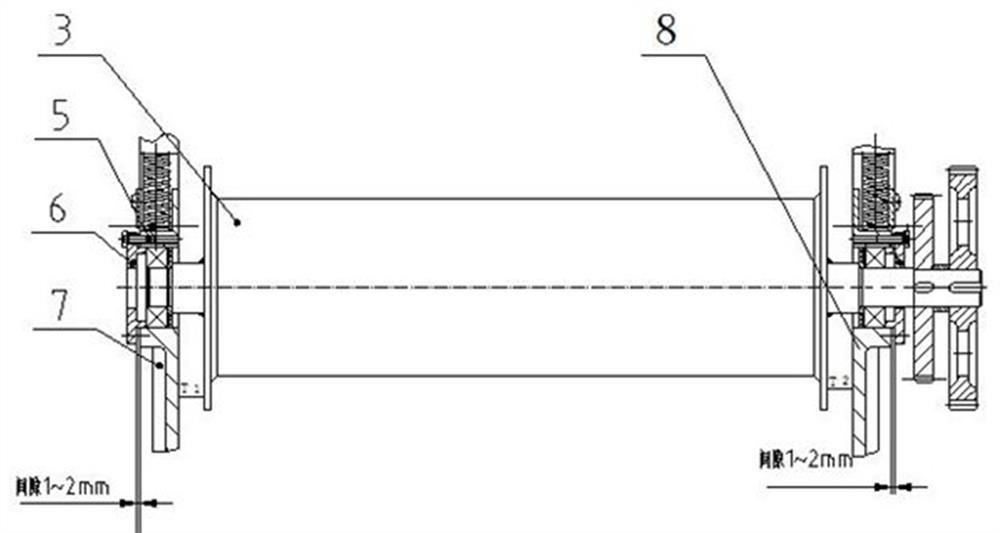

[0018] figure 2 Shown is a schematic diagram of the axial position adjustment of the upper roll of the present invention.

[0019] image 3 Shown is the invention figure 1 A-A cutaway view.

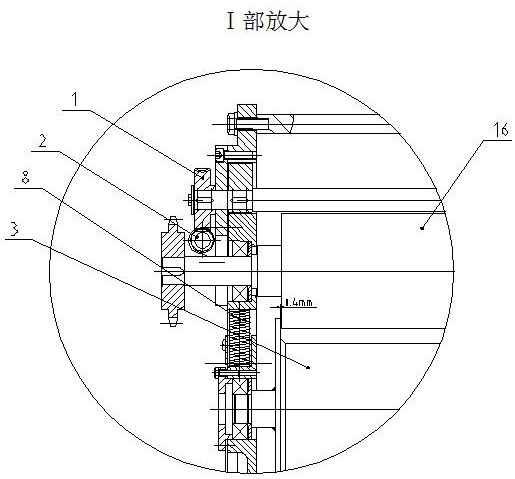

[0020] Figure 4 shown as the present invention figure 1 The enlarged schematic diagram of Part I.

[0021] The invention provides an axial gap adjustment mechanism of an automatic noodle press, which includes an upper roll 3, an upper roll retainer 4, a worm wheel 1, a worm 2, a left bracket 7 and a right bracket 8, a bearing cover 6, an adjustable roll 16. Fixed plate 12, set screw 10, backup nut 11, roll bearing seat 13, hexagon socket head screw 14, compression spring 9, eccentric wheel 15, the left bracket 7 and the right bracket 8 are symmetrical structures, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com