Special calendaring roller for flour food products and manufacturing method thereof

A manufacturing method and technology of calendering rollers, which can be applied in the fields of dough sheeting machine/rolling machine/rolling pin, application, food science, etc., and can solve the problems of poor water addition in noodle making, wear of roller surface, food hygiene, etc. , to achieve the effects of weakening the adhesion effect, improving wear resistance, increasing the contact area and deformation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

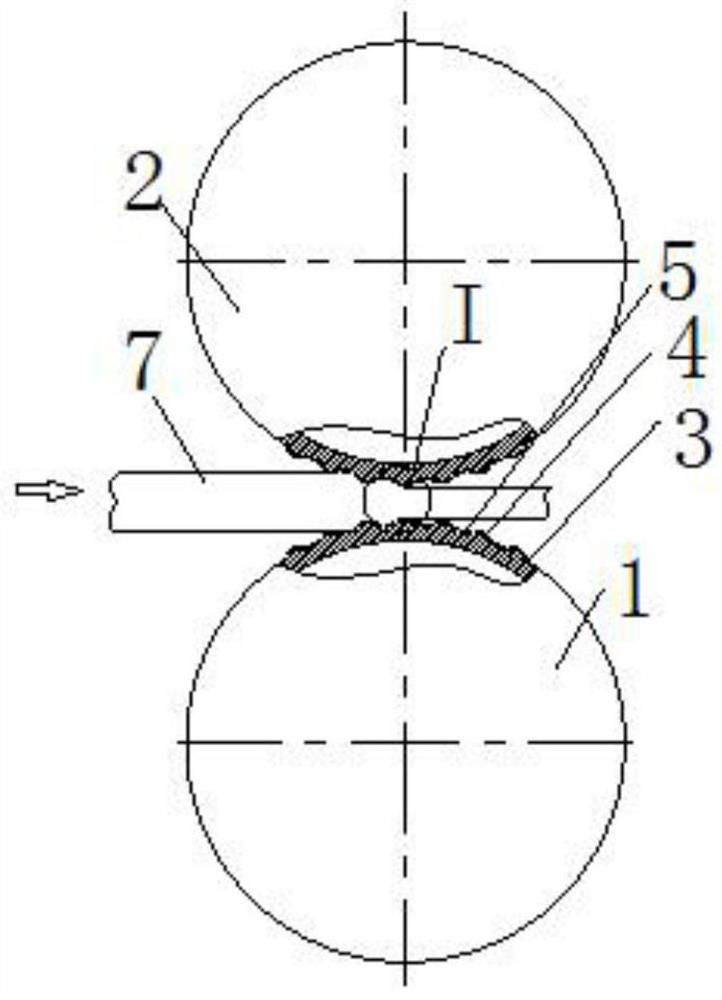

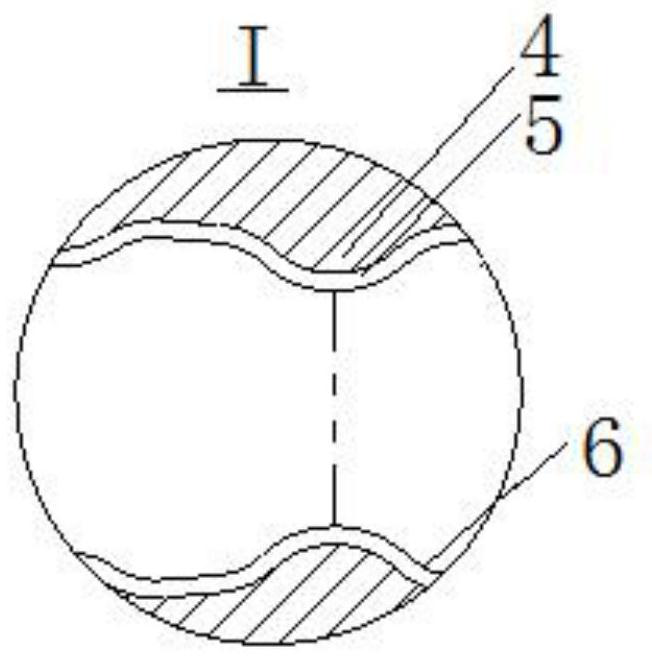

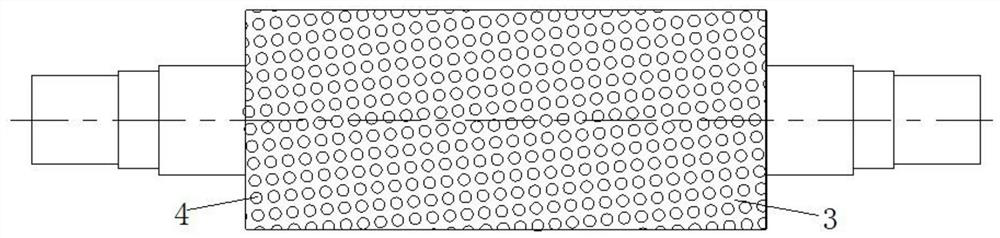

Embodiment 1

[0039] This embodiment provides a special calendering roll for pasta products and its manufacturing method. The stainless steel plate length×width×thickness=594.5×210×1.5 mm is selected, and the surface roughness Ra is 1 μm obtained by grinding. Protrusions with densely packed microspherical structures were prepared on the surface of the substrate by a stamping and stretching process, and the stretching force was 6700N. The protrusions have a diameter of 4.5 mm, a height of 1 mm, and a pitch of 6 mm. The base material with the raised portion was rolled into a cylinder having an outer diameter of 191 mm and a length of 210 mm. Using CO 2 The weld seam is laser welded and the weld seam is ground and polished; the welding parameters are current I=160A, pulse width T=6ms, frequency f=20Hz, and welding speed v=450mm / min. The secondary grinding and polishing treatment ensures the surface finish, Ra0.8μm. Prepare the fluorinated diamond-like carbon film (F-DLC) on the outer surfac...

Embodiment 2

[0041] This example provides a special calender roll for pasta products and its manufacturing method. The stainless steel plate is length×width×thickness=624.5×240×2.0 mm, and the surface roughness Ra is 1 μm obtained by grinding. A stamping and stretching process is used to prepare densely packed protrusions on the surface of the substrate, and the stretching force is 11000N. The protrusions have a diameter of 4.8 mm, a height of 1.3 mm, and a pitch of 7 mm. The base material with the raised portion was rolled into a cylinder with an outer diameter of 201 mm and a length of 240 mm. Electron beam welding (EBW) is used to weld the weld and the weld is ground and polished; the main welding parameters are high voltage 50kV, beam current 20mA, focusing current 1.82~1.83A, line speed v=500mm / min, vacuum degree 3.0×10 -2 Pa. The secondary grinding and polishing treatment ensures the surface finish, Ra 0.8μm. A fluorinated diamond-like carbon film (F-DLC) was prepared on the outer...

Embodiment 3

[0043] This embodiment provides a special calender roll for pasta products and its manufacturing method. The stainless steel plate is length×width×thickness=750.5×300×2.0 mm, and the surface finish is Ra 2 μm after grinding. A stamping and stretching process is used to prepare densely packed protrusions on the surface of the substrate, and the stretching force is 11500N. The protrusions have a diameter of 4.8 mm, a height of 1.5 mm, and a pitch of 7 mm. The base material with the protrusions was rolled into a cylinder with an outer diameter of 240 mm and a length of 300 mm. Welds with CO 2 Laser welding and grinding and polishing of the weld seam; welding parameters are current I=160A, pulse width T=5ms, frequency f=18Hz, welding speed v=450mm / min. The secondary grinding and polishing treatment ensures the surface finish, Ra 1.6μm. The fluorinated diamond-like carbon film (F-DLC) was prepared on the outer surface of the cylinder, the vacuum degree was 1.0Pa, the ratio of ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com