Automatic stuffing filling type stuffed noodle maker

A noodle machine and automatic technology, which is applied in the directions of cutting noodles, processing dough, dough forming and cutting equipment, etc., can solve the problems of non-formed noodles, uneven filling, clogging of filling pipes, etc. The effect of processing quality and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

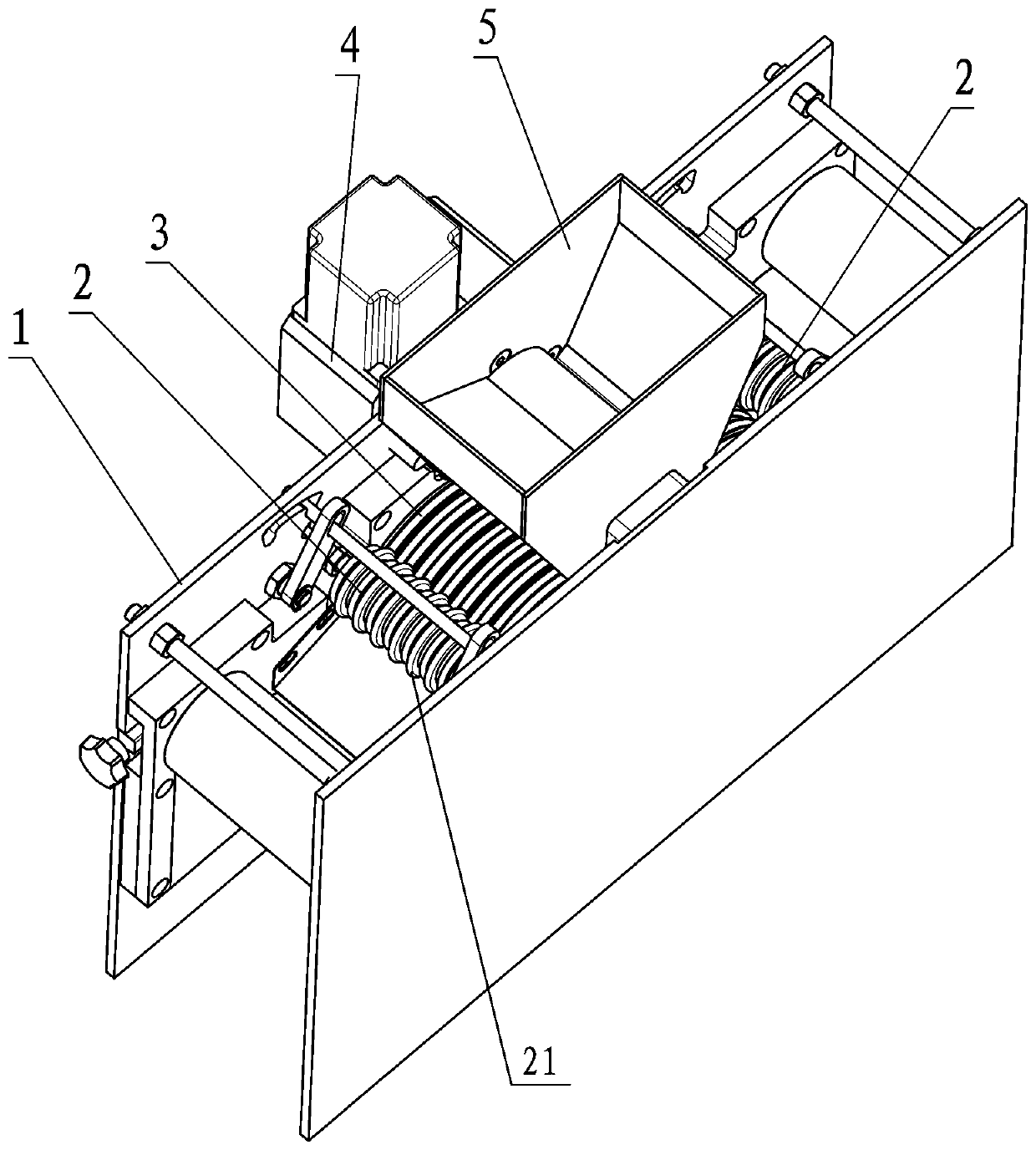

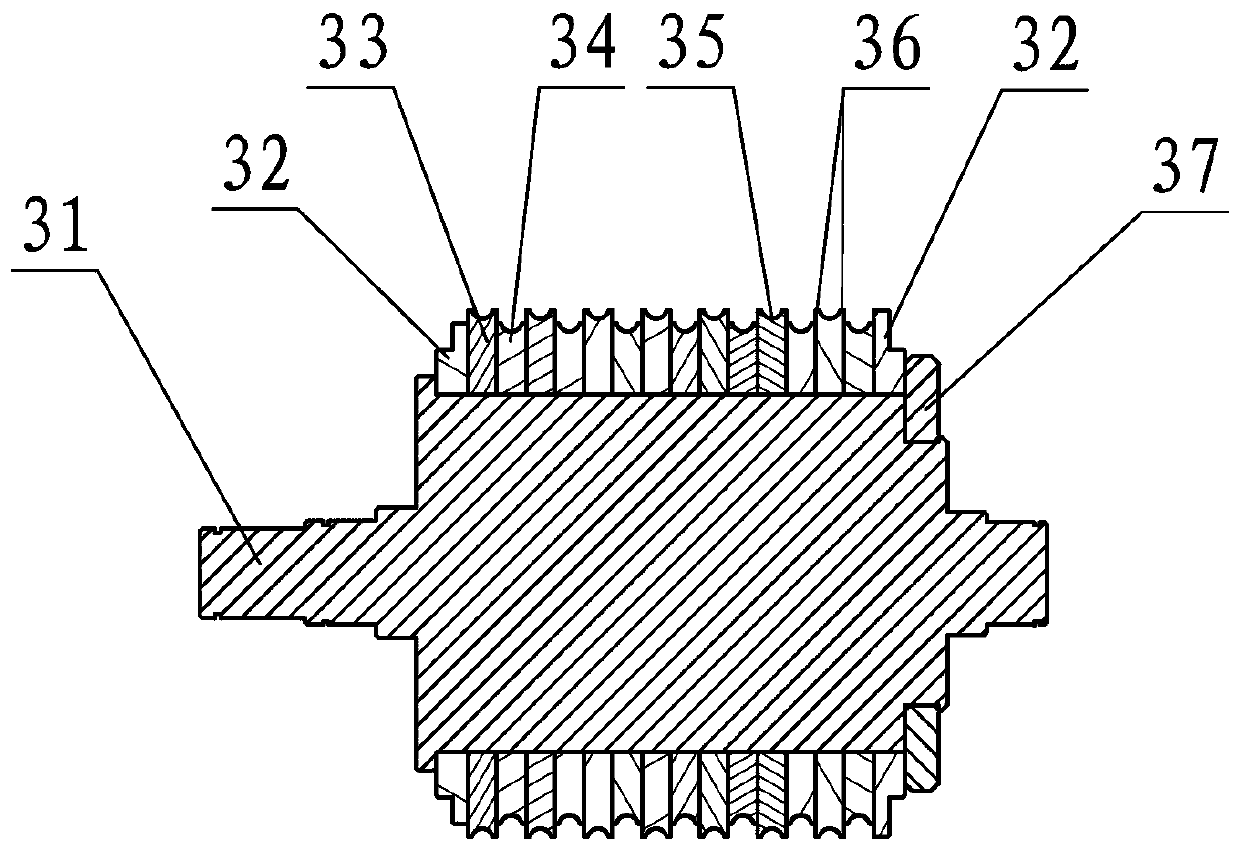

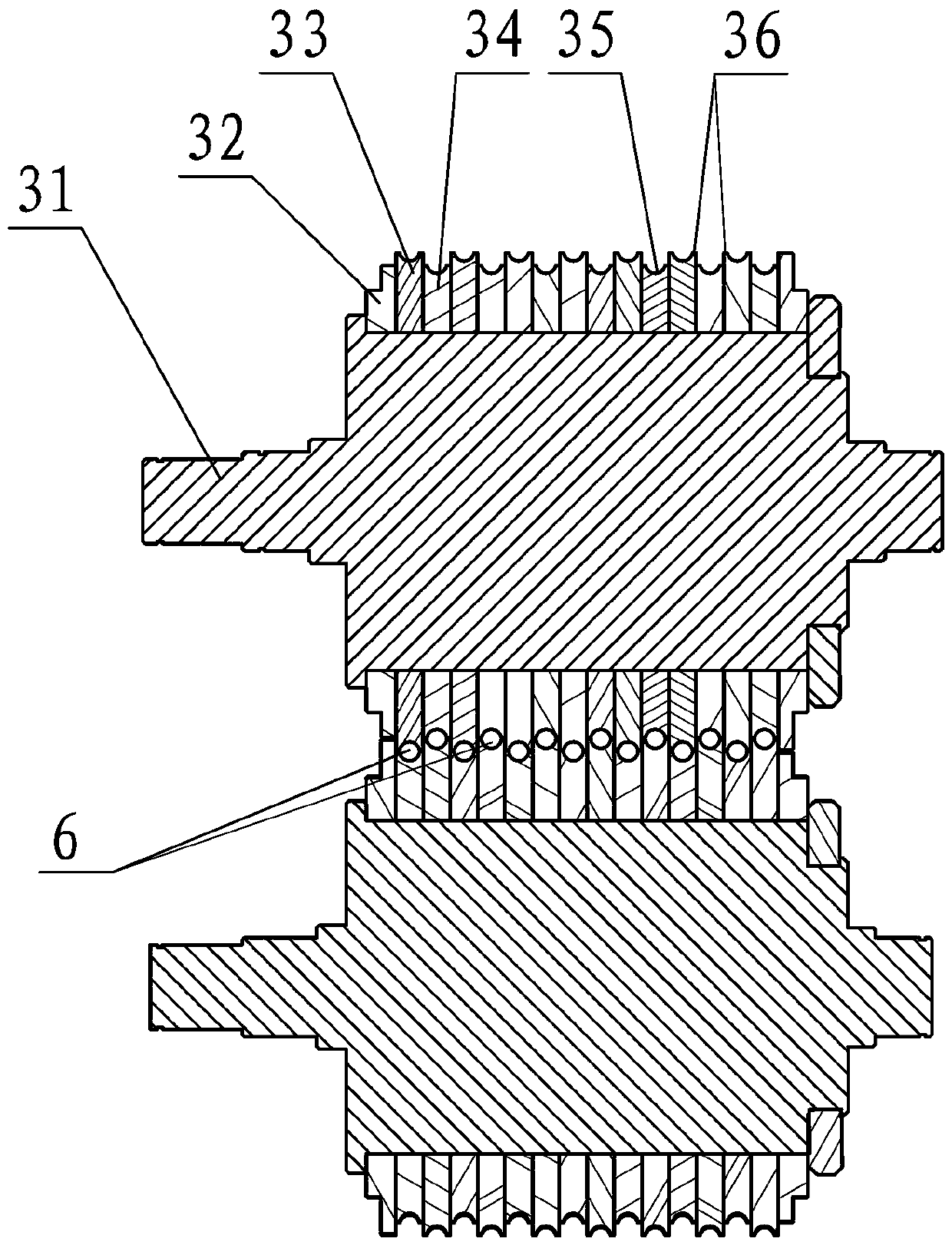

[0016] according to Figure 1~6 Describe the concrete structure of the present invention in detail, embodiment is for example figure 1 Shown, a kind of automatic stuffing type stuffing noodle machine comprises shell 1, a pair of forming roller 3, two squeeze rollers 2, driving device 4 and stuffing device 5. The shell adopts the structure of two side guard plates, the squeeze roller 2 and the forming roll 3 are arranged horizontally between the two side guard plates through the rotating shaft or the bearing, a pair of forming rolls are on the inner side, and the two pressing rolls are respectively provided with the front and rear of the forming rolls both sides, such as figure 2 and 3 As shown, the forming roller is provided with a plurality of annular grooves 35 along the circumferential surface, and the grooves of one forming roller are engaged with the grooves of the other forming roller to form a plurality of noodle forming passages 6 for pressing noodles. Annular cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com