Mud for sanitary ceramics and mud preparation process

A technology for sanitary ceramics and mud, applied in the field of sanitary ceramics, can solve the problems of high sintering temperature and large energy consumption, and achieve the effects of low sintering temperature, less harmful impurities and low high temperature viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

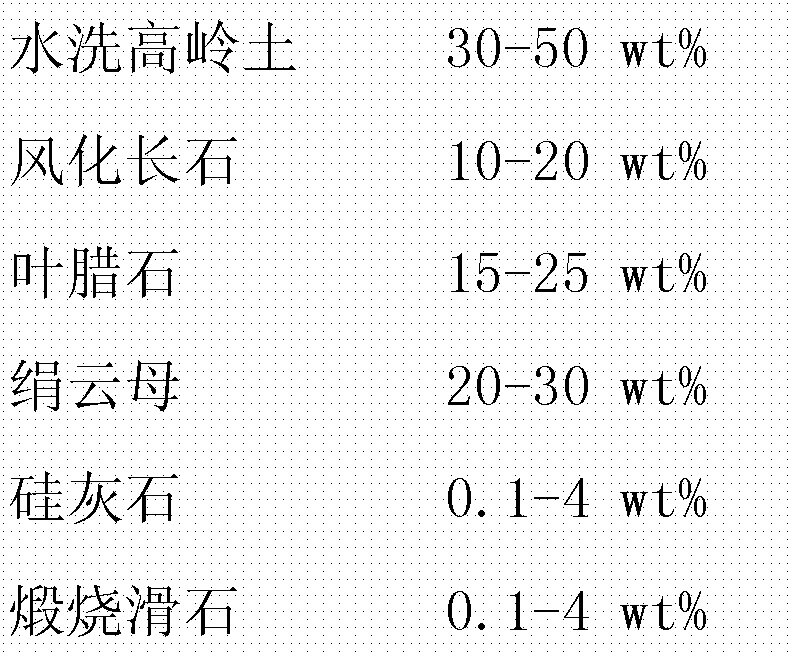

[0021] The mud that sanitary ceramics of the present invention is used mainly forms through ball milling by following each raw material and water mixing:

[0022]

[0023] Wherein, the consumption of water is 40-45wt% of the total amount of the above-mentioned raw materials. In the slurry obtained after ball milling, those with particle size less than 10um account for 65wt%-70wt%.

[0024] The preparation method of the mud that sanitary ceramics is used realizes by following steps:

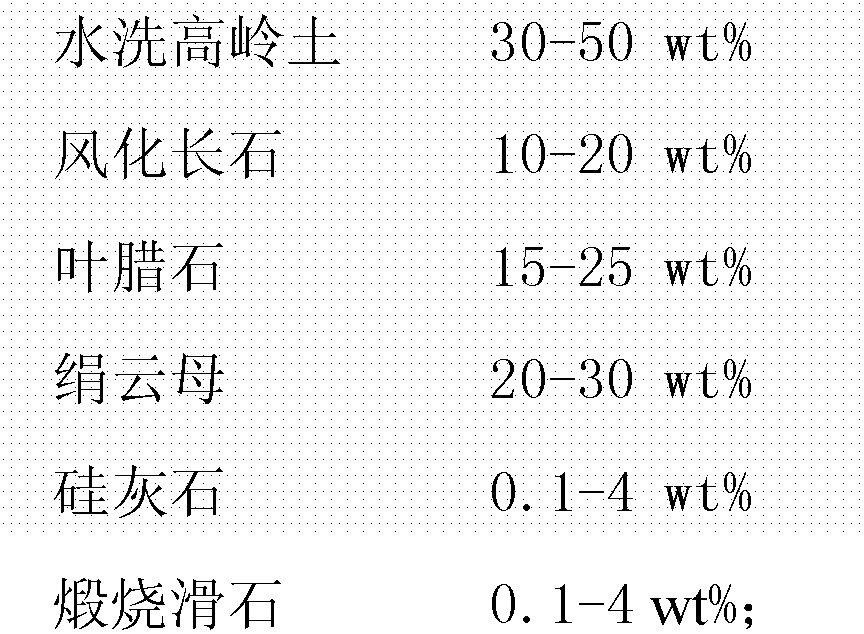

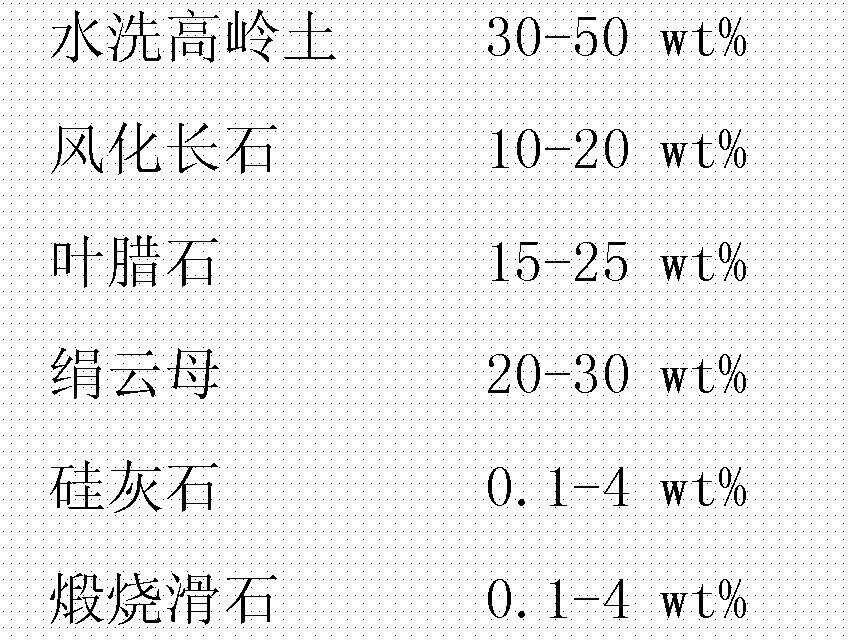

[0025] A. Prepare raw materials: weigh each raw material according to the following ratio:

[0026]

[0027] B, ball milling: add above-mentioned each raw material in the ball mill, and add the water that consumption is 40-45wt% of the total amount of above-mentioned each raw material and carry out ball milling, obtain mud; Wherein, the grinding ball of ball mill adopts high alumina ball, the lining of ball mill The high aluminum lining is used to reduce the impact of the wear of the grind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com