No-fry highland barley instant noodles and production method thereof

A non-fried, instant noodle technology, applied in the field of food processing, can solve the problems of nutrient failure, failure to form gluten, and difficulty in ensuring hygienic standards, and achieve the effect of convenient eating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The production steps of embodiment 1 non-fried highland barley instant noodles:

[0020] 1. Clean the highland barley to remove sand, dust, straw and other sundries;

[0021] 2. Grind the peeled or unpeeled highland barley directly to more than 80 mesh;

[0022] 3. Adding ingredients and kneading noodles: Add other ingredients (such as ordinary flour, gluten, vitamins, salt, etc.) : Generally 10-20 minutes, shorter in summer and longer in winter.

[0023] 4. Extrude straight noodles with extruding non-expanding equipment, and then use the forming conveyor belt to make corrugated noodles, and then quantitatively cut;

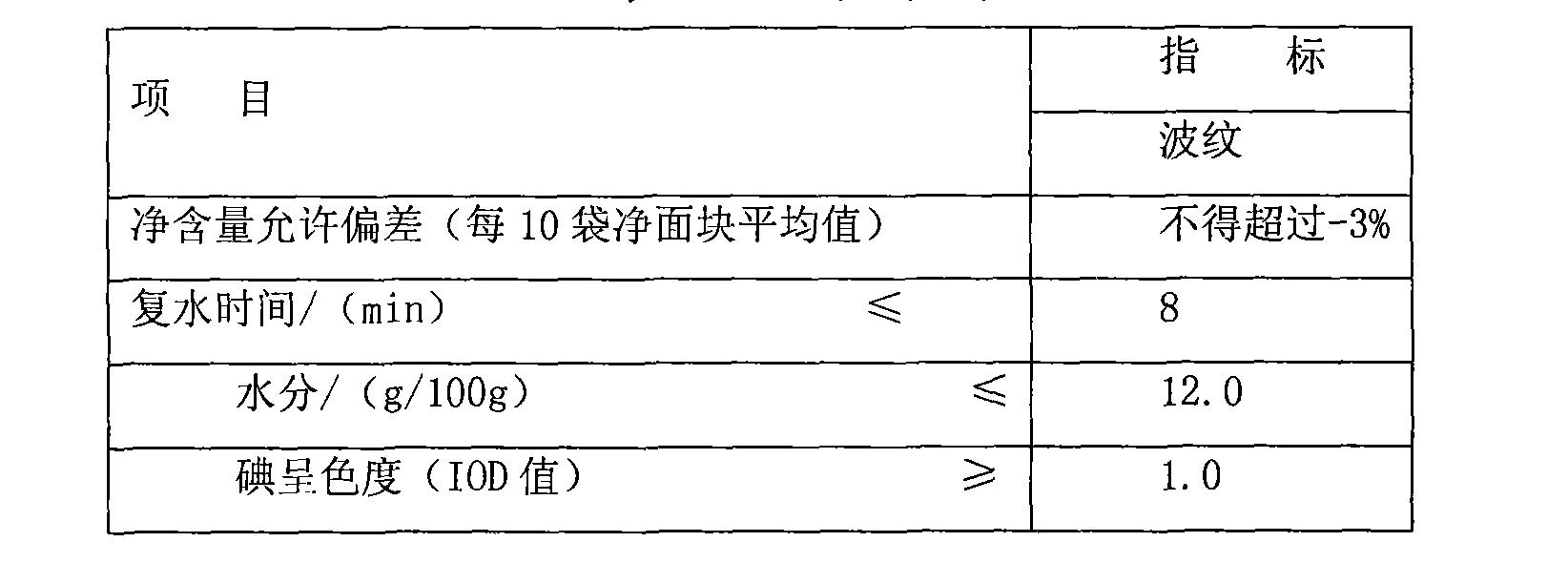

[0024] 5. Cooking temperature is 85°C-100°C, time is 5min-10min; drying temperature is 65°C-95°C until the water content is ≤12%, and then cool with cold air; then put in seasoning bag, pack, seal, code, sterilize, pack Boxes and other processes are completed;

Embodiment 2

[0026] Raw materials: 50 parts of 80-mesh peeled barley flour, 20 parts of flour, 18 parts of buckwheat flour, 10 parts of eggs, 1.5 parts of salt, 30 parts of clean water, 0.2 part of multivitamin, 0.3 part of multivitamin, prepared according to the steps of Example 1.

Embodiment 3

[0028] Raw materials: 100 parts of whole highland barley powder of 100 mesh, 35 parts of clean water, made according to the step of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com