A processing method of a tea flavored dried sweet potato

A processing method and technology of drying sweet potatoes, which are applied in food drying, food ultrasonic treatment, food science, etc., can solve the problems of extending shelf life, dark brown color, sticking into agglomerates, etc., and achieve the effect of extending shelf life, long shelf life and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

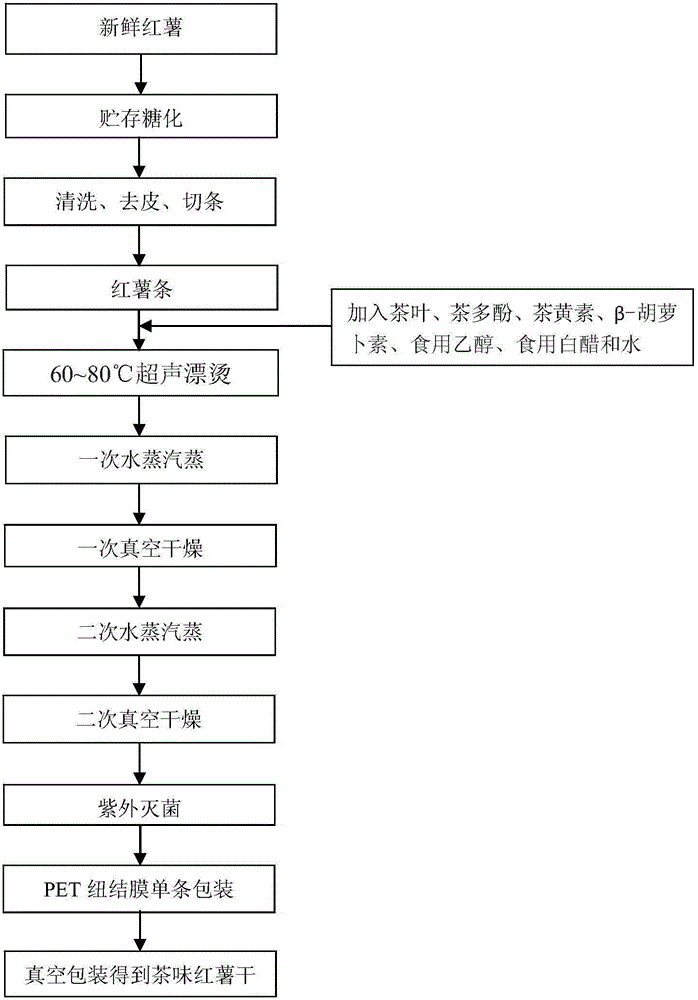

Method used

Image

Examples

Embodiment 1

[0028] (1) Fresh sweet potatoes (100g) were put into ventilated baskets, stacked overhead in a cool and ventilated place indoors, stored at 10°C for saccharification pretreatment for 15 days;

[0029] (2) cleaning, peeling, and cutting the sweet potatoes pretreated through step (1) saccharification to obtain sweet potato strips with a size of 2.5cm×2.5cm×6cm;

[0030] (3) In step (2) gained sweet potato strips, add fresh green tea leaves (3g), tea polyphenols (content 90wt%, 0.5g), theaflavin (0.1g), β-carotene (0.1g), Edible ethanol (purity 95wt%, 10mL), edible white vinegar (4mL) and water (1000mL), in 60 ℃ ultrasonic blanching 10min, drain for subsequent use; Described ultrasonic adopts probe type ultrasonic generation instrument (scientz-1200E ultrasonic cell pulverizer , Ningbo Xinzhi Biotechnology Co., Ltd.);

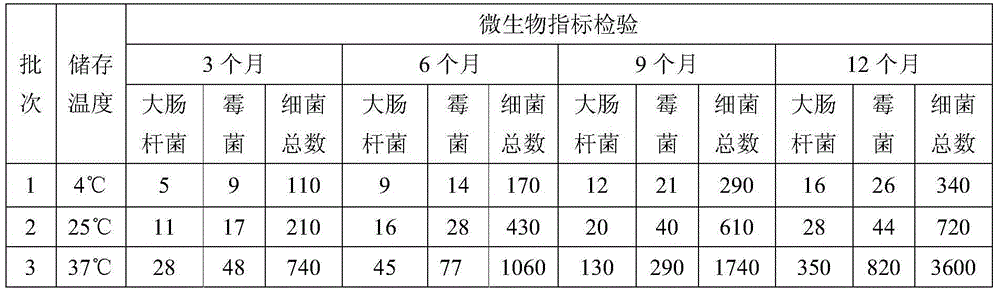

[0031] (4) The sweet potato strips processed in step (3) are carried out sequentially: steam steaming for 30 minutes once, vacuum drying once at 60°C until the m...

Embodiment 2

[0038] (1) Fresh sweet potatoes (100g) were put into ventilated baskets, stacked overhead in a cool and ventilated place indoors, and stored at 15°C for saccharification pretreatment for 10 days;

[0039] (2) cleaning, peeling, and cutting the sweet potatoes pretreated through step (1) saccharification to obtain sweet potato strips with a size of 2.5cm×2.5cm×6cm;

[0040] (3) In step (2) gained sweet potato strips, add fresh green tea leaves (4g), tea polyphenols (content 90wt%, 0.7g), theaflavin (0.2g), β-carotene (0.2g), Edible ethanol (purity 95wt%, 15mL), edible white vinegar (5mL) and water (1000mL), in 65 ℃ ultrasonic blanching 10min, drain for subsequent use; Described ultrasonic adopts probe type ultrasonic generation instrument (scientz-1200E ultrasonic cell pulverizer , Ningbo Xinzhi Biotechnology Co., Ltd.);

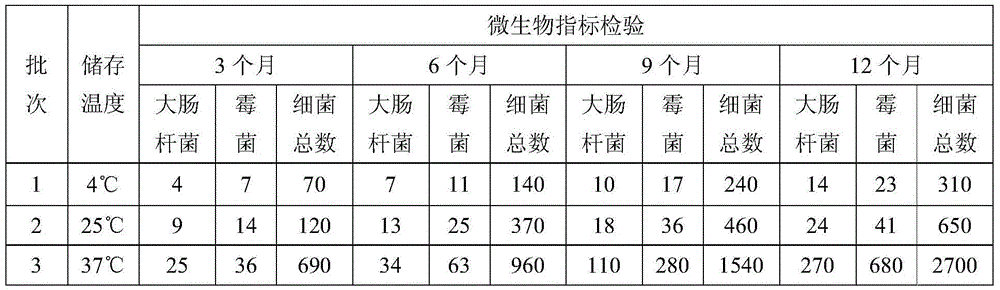

[0041] (4) The sweet potato strips processed in step (3) are carried out sequentially: steam steaming for 40 minutes once, vacuum drying once at 60°C until the...

Embodiment 3

[0048] (1) Fresh sweet potatoes (100g) were put into ventilated baskets, stacked overhead in a cool and ventilated place indoors, and stored at 12°C for saccharification pretreatment for 12 days;

[0049] (2) cleaning, peeling, and cutting the sweet potatoes pretreated through step (1) saccharification to obtain sweet potato strips with a size of 2.5cm×2.5cm×6cm;

[0050] (3) In step (2) gained sweet potato strips, add fresh green tea leaves (5g), tea polyphenols (content 90wt%, 0.7g), theaflavin (0.3g), β-carotene (0.3g), Edible ethanol (purity 95wt%, 15mL), edible white vinegar (5mL) and water (1000mL), in 60 ℃ of ultrasonic blanching 15min, drain for subsequent use; Described ultrasonic adopts probe type ultrasonic generation instrument (scientz-1200E ultrasonic cell pulverizer , Ningbo Xinzhi Biotechnology Co., Ltd.);

[0051] (4) The sweet potato strips treated in step (3) are carried out sequentially: steam steaming for 40 minutes once, vacuum drying once at 60°C until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com