Method for preparing wood-plastic composite plate material through layered lamination method

A wood-plastic composite and board technology, which is applied to flat products, other household appliances, household appliances, etc., can solve the problems of low surface bonding strength, surface gelatinization and blackening, and achieve the purpose of maintaining the original color of wood powder. The method is simple and easy, The effect of shortening the heat pressing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

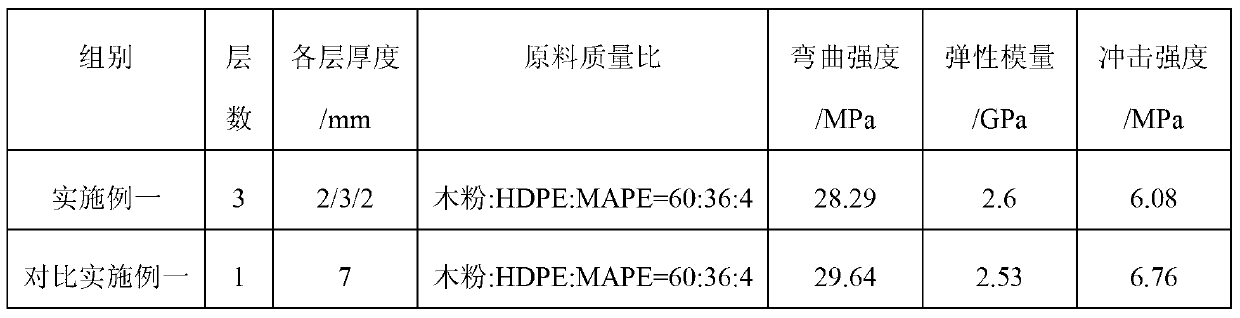

Examples

specific Embodiment approach 1

[0015] Specific implementation mode 1: The method for preparing wood-plastic composite boards by layered lamination method in this implementation mode is implemented according to the following steps:

[0016] 1. Mix biomass fiber, coupling agent, thermoplastic powder or thermoplastic fiber evenly, and then lay it into a core slab with a thickness of 3-4mm. The core slab is placed in a hot press at 170-190°C temperature, 0.5 ~ 2MPa pressure under hot pressing for 3 ~ 5min to obtain the core plate;

[0017] 2. Mix biomass fiber, coupling agent, thermoplastic powder or thermoplastic fiber evenly, pave it into a surface material with a thickness of 2-3 mm, and then lay the surface material on the upper surface of the core board obtained in step 1 and The lower surface is then placed in a hot press at a temperature of 170-190°C and a pressure of 0.5-2 MPa for 3-5 minutes to obtain a hot-pressed wood-plastic composite board;

[0018] 3. Place the hot-pressed wood-plastic composite ...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass ratio of biomass fiber, coupling agent, thermoplastic powder or thermoplastic fiber is 1:(0.05-0.09):(0.5-1.0). Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the biomass fiber is wood fiber, straw scraps, flax chips or bamboo fiber. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com