Integrated device for controlling wall thickness by digital cam and servo motor

A servo motor and integrated device technology, applied in the field of plastic extrusion and blowing wall thickness control devices, can solve the problems of time lag being easily affected by the outside world, low flexibility, low control accuracy, etc., to improve productivity and product quality, The effect of increasing strength and reducing defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

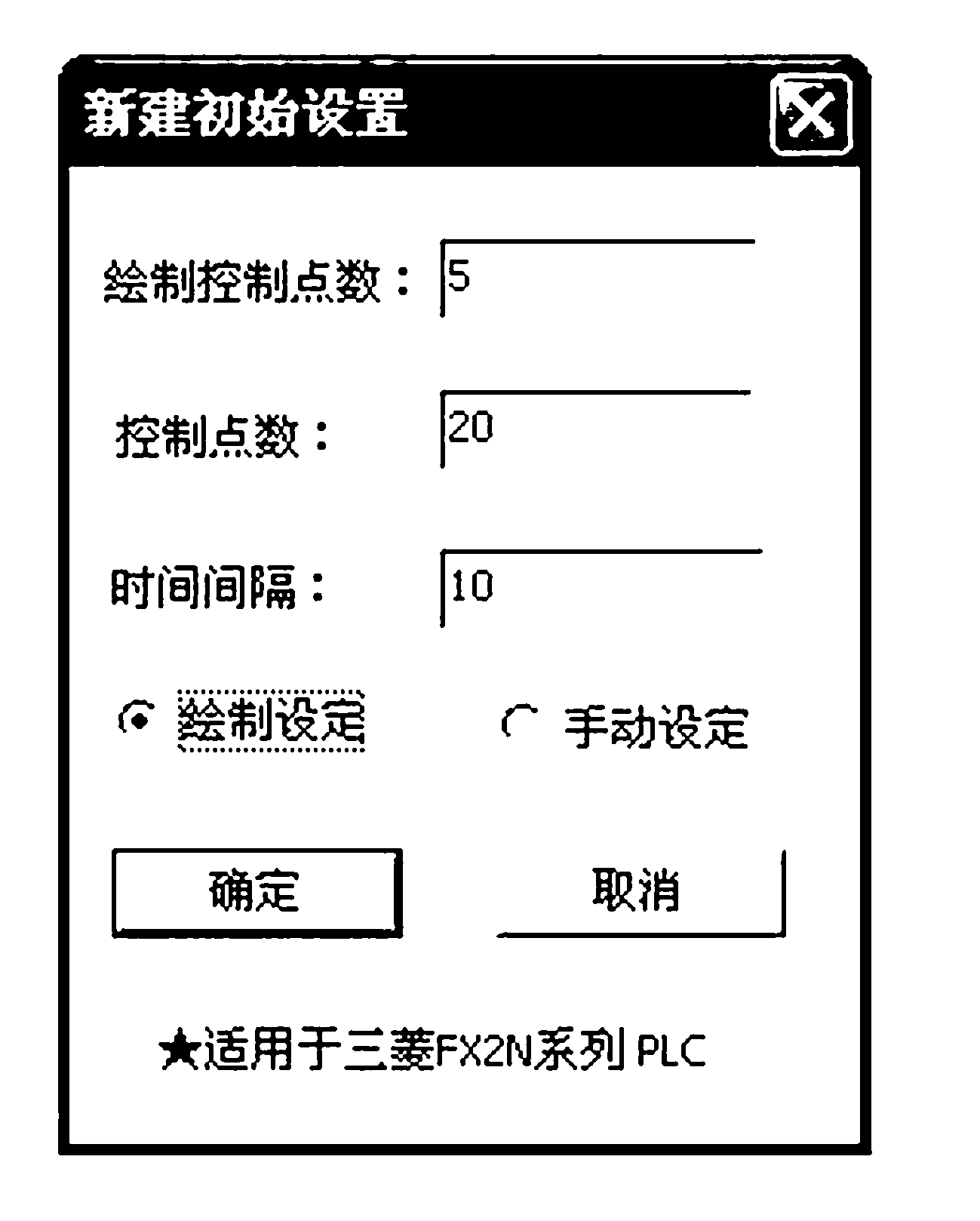

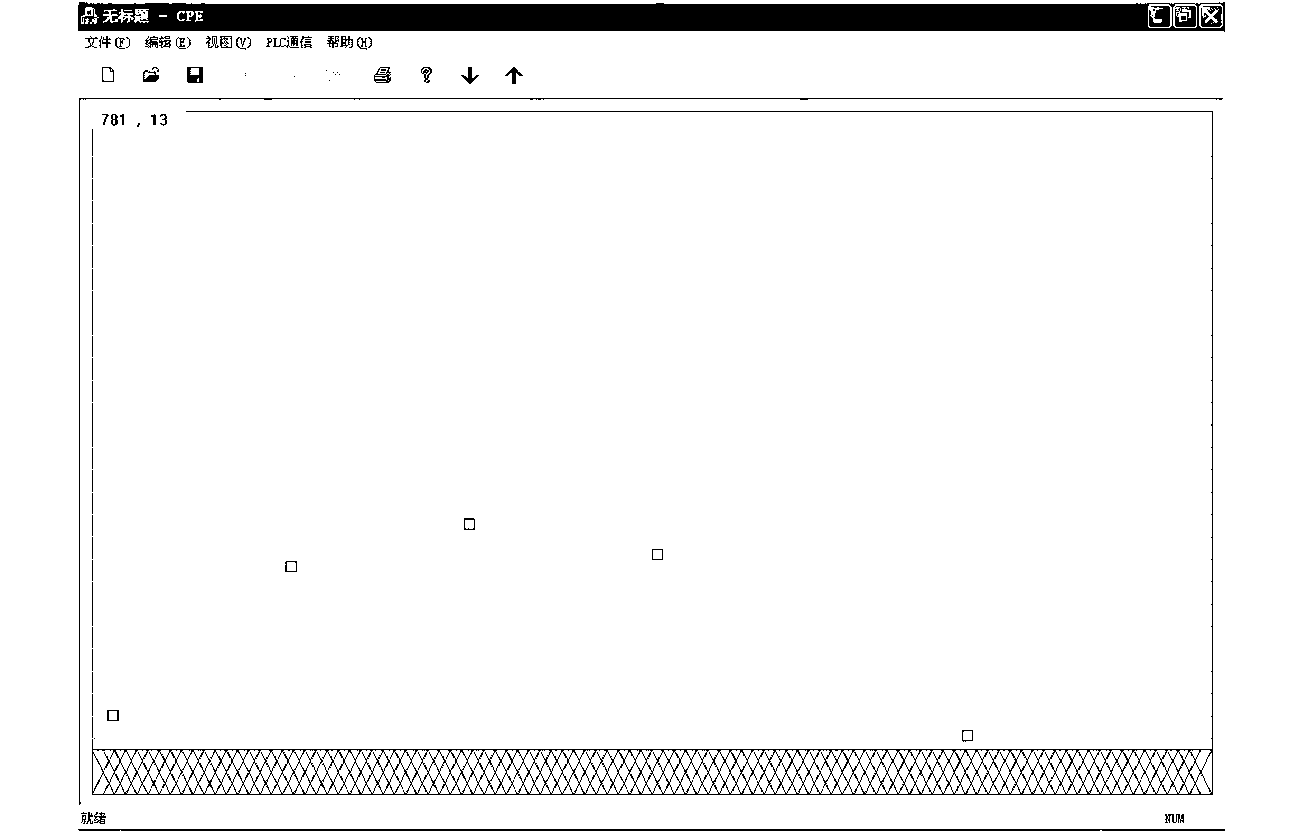

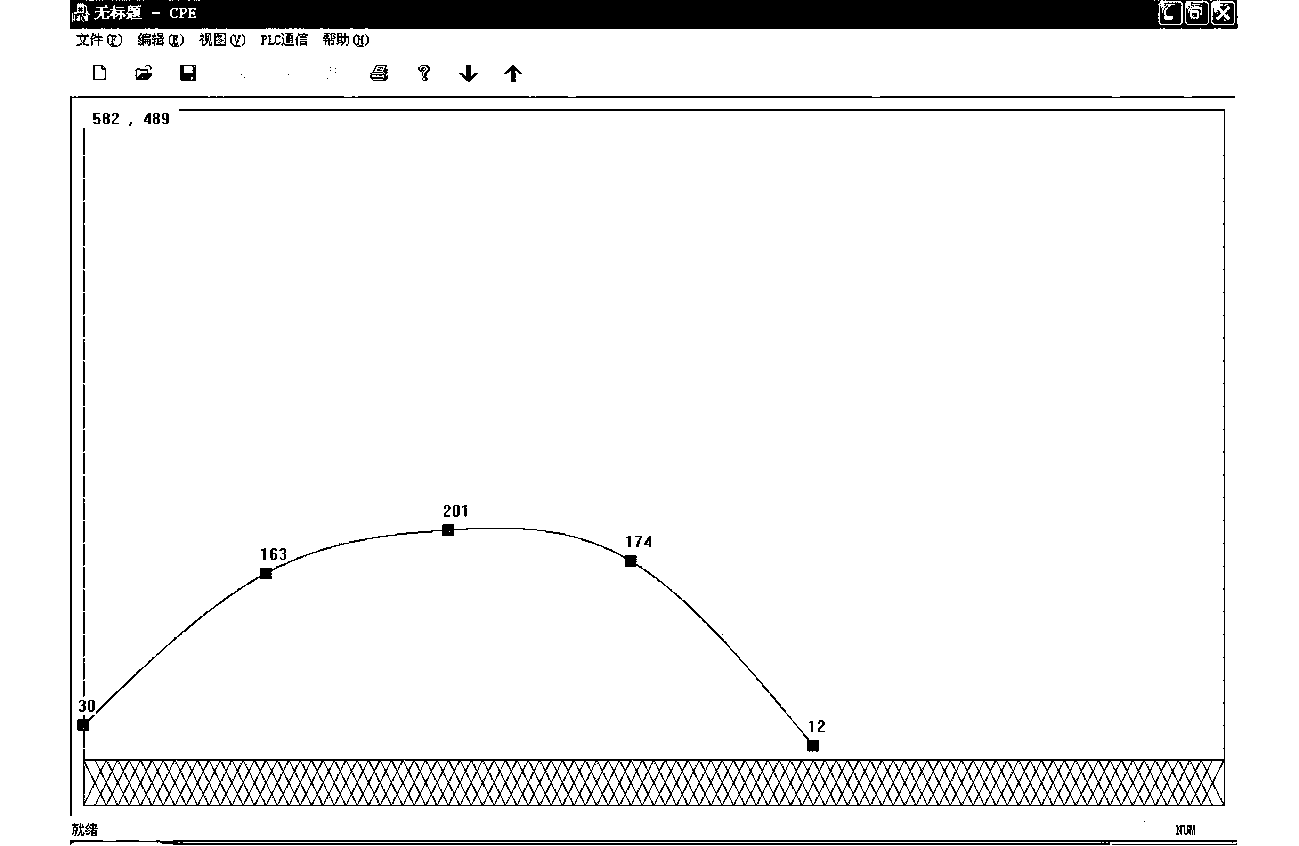

[0031] Such as figure 1 - Figure 7 As shown, this embodiment is an integrated device that uses digital cams and servo motors to control wall thicknesses by changing the shape of digital cams according to different products and extruding and blowing plastic products with different wall thicknesses. The device has the characteristics of fast motion response and high control precision. The digital cam servo motor wall thickness control device includes a digital cam software system 16, a servo motor 1, a ball screw screw pair, an extrusion die head device and a hydraulic gravity balance device 2, and the servo motor 1 is installed on the first fixed support plate 3, and is connected with the ball screw 7 through the flange coupling 17. One end of the ball screw 7 is supported by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com