Quick-refrigerating type milk-storing cool storage tank

A fast, tank-based technology, applied in dairy processing machinery manufacturing, agricultural and animal husbandry machinery, can solve problems such as poor fresh-keeping effect, high energy consumption, and slow temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below with reference to the drawings and specific embodiments.

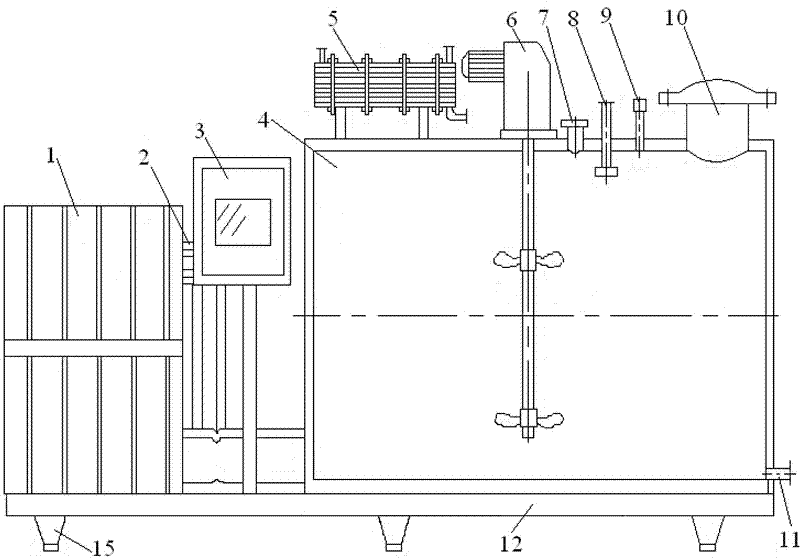

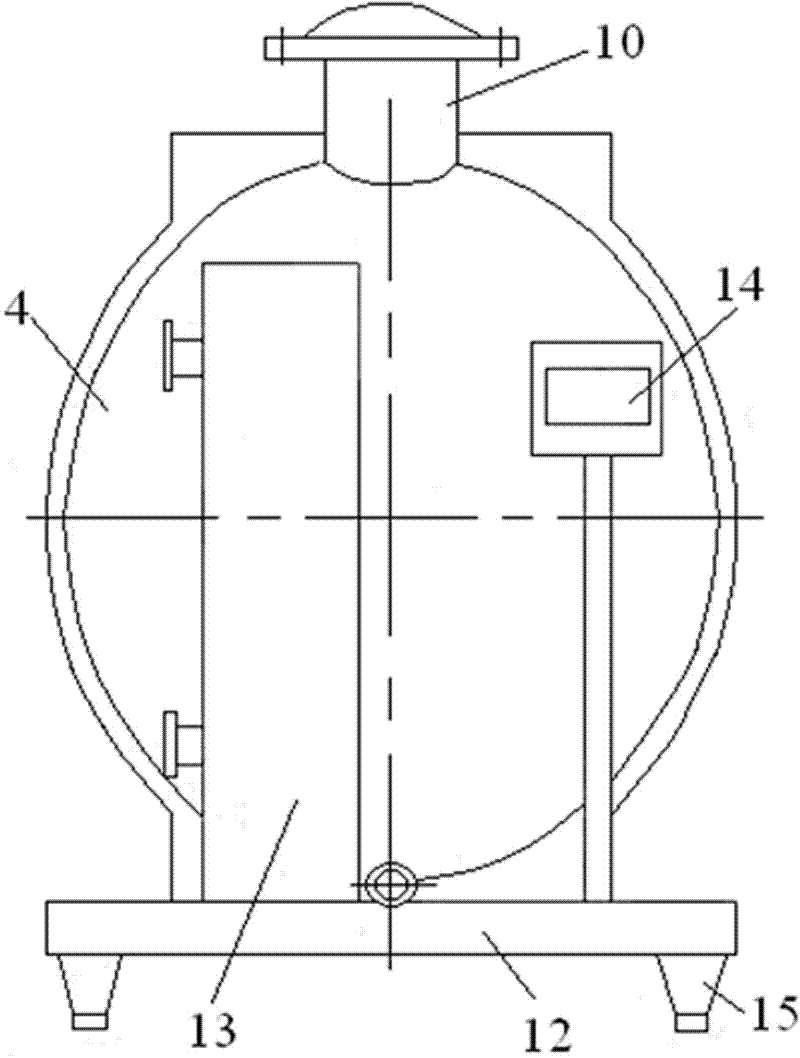

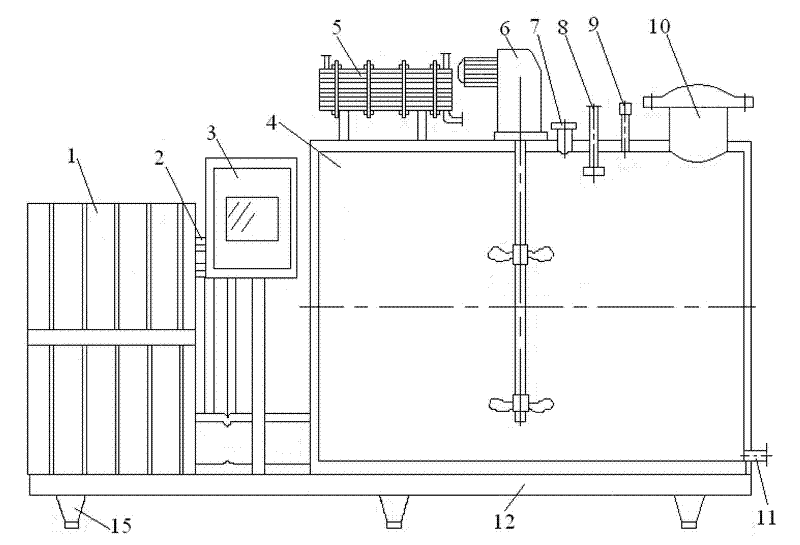

[0014] Most of the existing milk storage refrigerated tanks adopt direct cooling mode. The fresh milk in the milk storage refrigerated tank is cooled by a refrigeration compressor unit and a stirring system, and the temperature of the fresh milk is lowered to 4°C, and then kept fresh at a constant temperature. The temperature of the fresh milk in the milk storage cold storage tank drops slowly, and the cooling time is long. It takes 3 to 3.5 hours to lower the temperature of the fresh milk to a temperature that meets the fresh-keeping requirements, and the fresh-keeping effect is poor. In order to overcome the above-mentioned problems in the prior art, the present invention provides a structure such as figure 1 with figure 2 The fast milk storage cold storage tank shown can quickly cool the fresh milk in a short time and ensure the fresh quality of the fresh ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com