System and method for modulating flue gas with sulfur trioxide

A sulfur trioxide and flue gas technology, applied in chemical instruments and methods, solid separation, electrostatic effect separation, etc., can solve problems such as leakage, complicated process, and blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

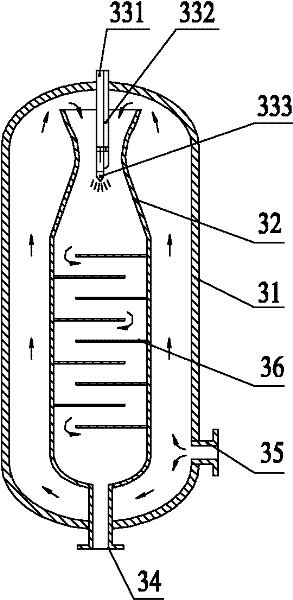

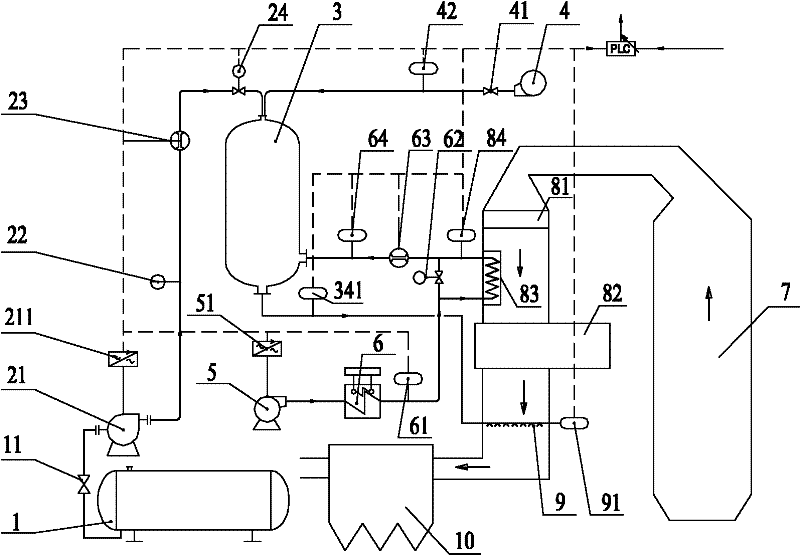

[0024] The sulfur trioxide flue gas conditioning system of the present invention includes a sulfuric acid pyrolysis furnace capable of pyrolyzing sulfuric acid into sulfur trioxide. The structure of the sulfuric acid pyrolysis furnace can refer to figure 1 , figure 1 Schematic diagram of the structure of the sulfuric acid pyrolysis furnace provided for the specific embodiment of the present invention. The sulfuric acid pyrolysis furnace comprises two layers of shells, an outer shell 31 and an inner shell 32, a cavity is formed between the two shells, and the upper end of the inner shell is open; the sulfuric acid pyrolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com