Efficient sludge dewatering flocculant

A technology of sludge dehydration and flocculant, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc. It can solve the problems of excessive heavy metal content, human health hazards, high operating costs, etc., and achieves low preparation costs, low operating costs, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of high-efficiency sludge dewatering flocculant

[0024] 1) Take 100kg of diatomite containing 2% soil bacteria, add 10kg of activated carbon, 20kg of cement and 2kg of organic flocculant (polydimethyldiallylammonium chloride) to it, mix well, and prepare a mixture A;

[0025] 2) Take 16 kg of sodium thiosulfate, 16 kg of iron oxide and 48 kg of calcium sulfate respectively, mix them evenly, and prepare mixture B;

[0026] 3) According to the ratio of mixture B: mixture A is 20:80, add the corresponding proportion of mixture B into mixture A, and mix evenly to prepare high-efficiency sludge dewatering flocculant.

[0027] (2) Pretreatment of sludge and sewage

[0028] Take domestic sewage sludge with a water content of 78.5% by weight, add water to adjust the water content to 92% by weight, and form sewage sludge with a water content (mass percentage, the same below) of 92%.

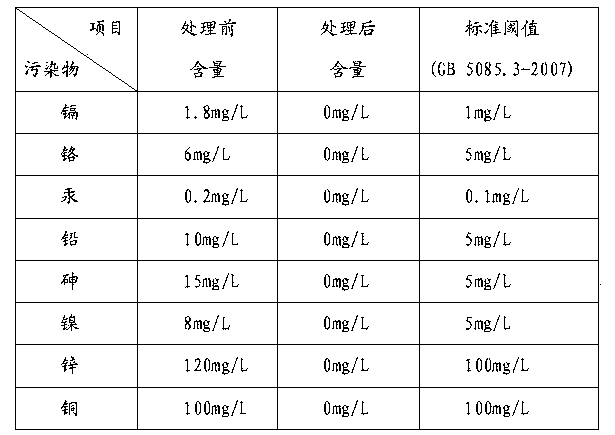

[0029] (3) Comparative experiment of sludge dehydration

[0030] Take comm...

Embodiment 2

[0036] (1) Preparation of high-efficiency sludge dewatering flocculant

[0037] 1) Take 100kg of diatomite containing 3% soil bacteria, add 20kg of activated carbon, 35kg of cement and 4kg of organic flocculant (polydimethyldiallylammonium chloride) to it, mix well, and prepare a mixture A;

[0038] 2) Take 24kg of sodium thiosulfate, 24kg of iron oxide, 72kg of calcium sulfate and 56kg of aluminum sulfate and mix them evenly to make mixture B;

[0039] 3) According to the ratio of mixture B: mixture A is 30:70, add the corresponding proportion of mixture B to mixture A, and mix evenly to prepare high-efficiency sludge dewatering flocculant.

[0040] (2) Pretreatment of sludge and sewage

[0041] Take domestic sewage sludge with a water content of 82.5% by weight, add water to adjust the water content to 95% by weight, and form sewage sludge with a water content of 95%.

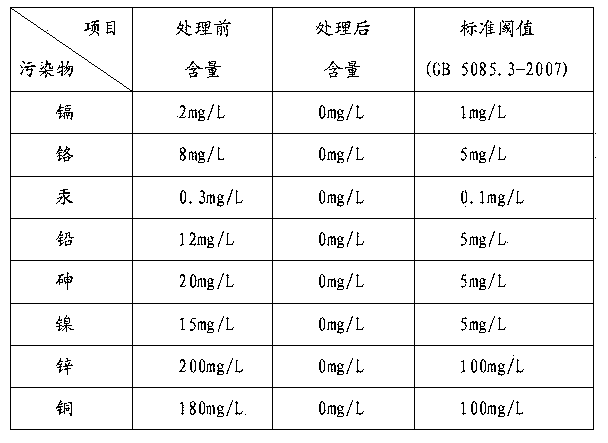

[0042] (3) Comparative experiment of sludge dehydration

[0043] Take commonly used sludge dewatering ag...

Embodiment 3

[0049] (1) Preparation of high-efficiency sludge dewatering flocculant

[0050] 1) Take 100kg of diatomite containing 4% soil bacteria, add 30kg of activated carbon, 50kg of cement and 5kg of organic flocculant (polydimethyldiallylammonium chloride) to it to prepare mixture A;

[0051] 2) Take 30kg of sodium thiosulfate, 28kg of iron oxide, 80kg of calcium sulfate, 80kg of aluminum sulfate and 24kg of alkali metal carbonate (calcium carbonate) and mix them uniformly to prepare mixture B;

[0052] 3) Add mixture B to mixture A and mix evenly to prepare high-efficiency sludge dewatering flocculant.

[0053] (2) Pretreatment of sludge and sewage

[0054] Take printing and dyeing sewage sludge with a water content of 89.3% by weight, add water to adjust the water content to 93% by weight, and form sewage sludge with a water content of 93%.

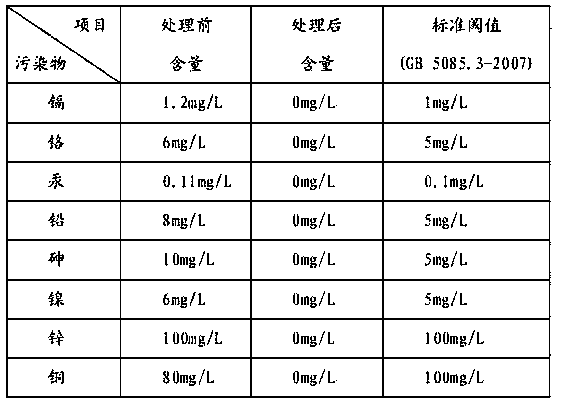

[0055] (3) Comparative experiment of sludge dehydration

[0056] Take commonly used sludge dewatering agent polyferric sulfate (PFS) and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com