Anti-ultraviolet ray mixed color spinning thread and its producing method

An anti-ultraviolet, production method technology, applied in the field of spinning engineering, can solve the problems of unable to meet the personalized and fashionable color requirements, the effect is not long-term, the color is single, etc., and achieves smooth hand feel, good bulkiness, and fiber ratio The effect of low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

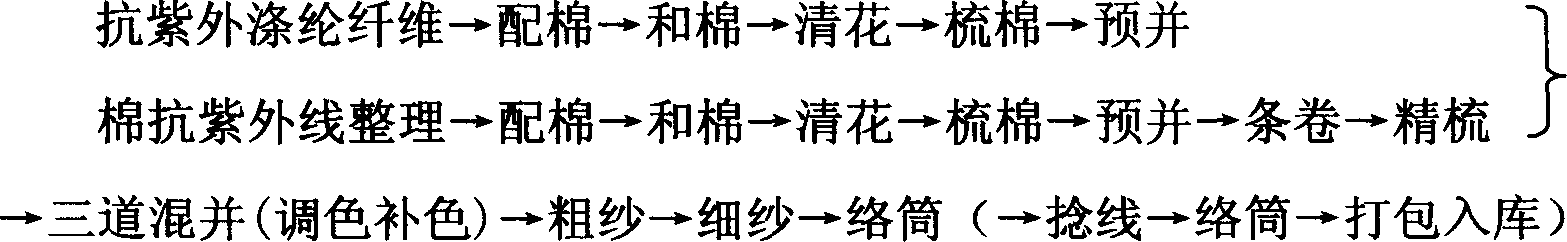

Method used

Image

Examples

Embodiment 1

[0057] 1. Embodiment 1 (original white, bleaching)

[0058] Select 140 kg of cotton loose fiber, put it into a solution with a bath ratio of 1:10 at room temperature, add penetrating agent JFC 2%, scouring agent SA 1%, fluffing agent ERKANTOL NR 1%, adjust pH 10 to 11 with soda ash or tablet ash (bleach Add hydrogen peroxide (10g / L) at 60°C, keep warm at 98°C for 30 minutes, drain the foot water, wash with water, neutralize with acetic acid and wash with water until neutral. After treatment, add anti-ultraviolet finishing agent Leaoshan C liquid 4% and low-temperature fixative SCJ-939 2%, penetrating agent is JFC 5%, Yuanming powder 80g / L, soda ash 6%, after 25 ℃ treatment for 30 minutes, pickling Add 3098 3% hydrophilic soft oil to pH 6-7, adjust pH to 8-9 with soda ash, immerse at 60°C for 30 minutes, dehydrate directly, spray 0.5% antistatic agent TF-480A into the dehydrator, and dry.

Embodiment 2

[0059] 2. Embodiment 2 (whitening or dyeing)

[0060] Select 160 kilograms of cotton sliver loose fibers, put it into a solution with a bath ratio of 1:8 and 2 g / liter of chelating dispersant CT powder (soft water effect) at room temperature, add penetrating agent JFC 2%, scouring agent SA 1% The bulking agent ERKANTOL NR 2%, adjust the pH to 10-11 with soda ash or caustic soda (add hydrogen peroxide 10g / L at 60°C for bleaching), keep warm at 98°C for 30 minutes, let off the corner water, and use the conventional cotton loose fiber dyeing process for post-treatment Add anti-ultraviolet finishing agent Leaoshan C liquid 3% and low-temperature fixing agent SCJ-9393%, the diffusing agent is WA 2%, Yuanming powder 60g / L, soda ash 6%, after 40 ℃ treatment for 30 minutes, pickling to 6~ After 7, add hydrophilic soft oil 3098 3%, color-fixing agent ECO 2%, soak for 30 minutes at 60°C, then dehydrate directly, spray 0.5% antistatic agent 8112 into the dehydrator, and dry.

[0061] Tw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com