Copper foil for current collector of lithium secondary battery

A secondary battery and electrolytic copper foil technology, which is applied in the field of copper foil for lithium secondary battery collectors, can solve problems such as copper foil damage, battery capacity drop, and negative electrode damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] As used in the various figures, similar elements in different views may be given common numerical designations to help the reader understand the various embodiments.

[0033] As used in this specification and claims, the surface roughness is measured in "Rz" standard (JIS B 0601-1994, using an α-type surface roughness and profile measuring instrument manufactured by Kosaka Laboratory Ltd. (Model: SE1700)) is measured and provided, although other systems exist that can be used to measure surface roughness, not all surface roughness measurement systems are equivalent. According to this Rz standard, the results are expressed as the average value of 10 points.

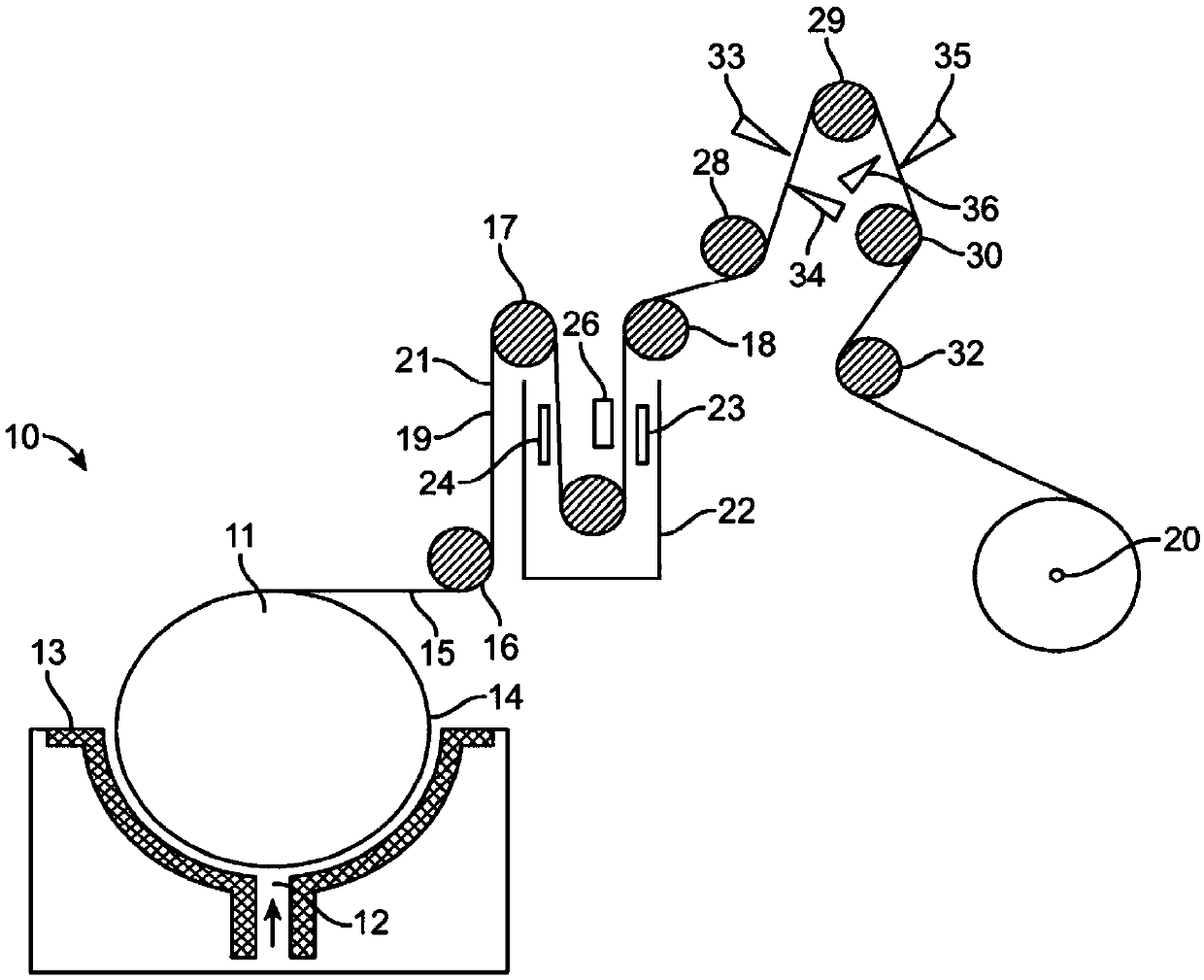

[0034] Such as figure 1 , which illustrates a typical apparatus 10 for manufacturing electrolytic copper foil. A rotatable metal negative roll 11 is placed in a partially submerged position relative to the copper-containing electrolyte 12 . A positive electrode 13 of insoluble metal is placed in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com