Flexible electrochromic device for regulating and controlling near-infrared light and preparation method

A near-infrared light and electrochromic layer technology, which is applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problem of no control advantages in the infrared region

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

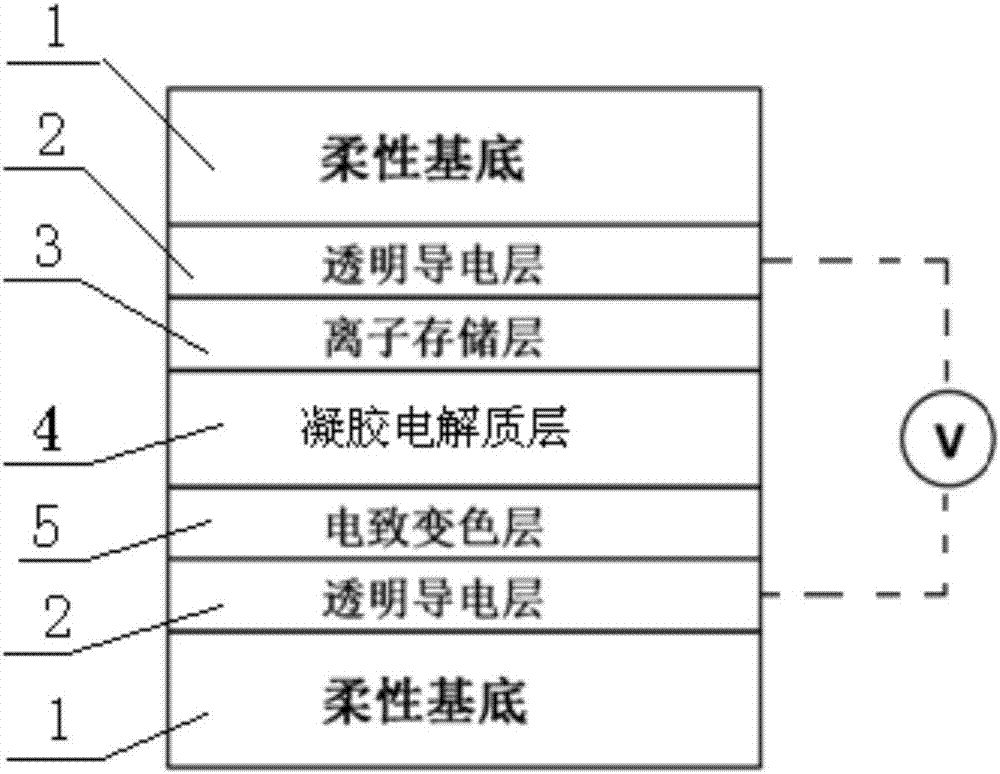

[0020] As described above, a method for preparing a flexible electrochromic device that regulates near-infrared light is characterized in that the steps of preparation are as follows:

[0021] 1. Prepare the counter electrode: the counter electrode is composed of the first layer of transparent flexible substrate 1, the second layer of transparent conductive layer 2 and the third layer of ion storage layer 3, using magnetron sputtering method, chemical vapor deposition method, spray method, extraction Preparation of counter electrode by pull method, electrodeposition method or spin coating method;

[0022] 2. Prepare the working electrode: the working electrode is composed of the fifth electrochromic layer 5, the sixth transparent conductive layer 2 and the seventh flexible substrate 1, using magnetron sputtering method, chemical vapor deposition method, spray method, extraction Preparation of working electrode by pull method, electrodeposition method or spin coating method;

...

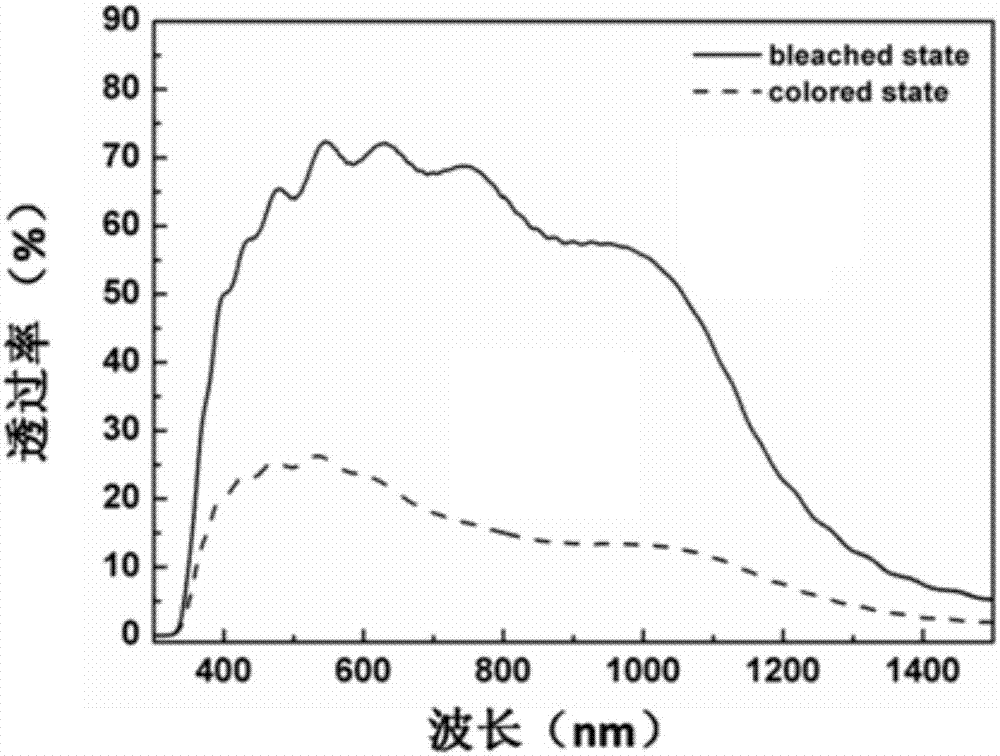

Embodiment 1

[0030] The composition of the flexible device: the transparent flexible substrate is PET, the transparent conductive layer is ITO film, the ion storage layer is PB film, and the gel electrolyte is made of PMMA, LiClO4 and propylene carbonate, the electrochromic layer is WO 3 film;

[0031] Fabrication process of flexible devices:

[0032] Preparation of counter electrode: ITO film is prepared on transparent flexible PET substrate by magnetron sputtering method, PB film is deposited on ITO film by electrodeposition method, the thickness of ITO film is 200nm, and the thickness of PB film is about 100nm;

[0033] Preparation of working electrode: ITO film and WO were sequentially prepared on a transparent flexible PET substrate by magnetron sputtering 3 Thin film, ITO thickness is 200nm, WO 3 The thickness of the film is about 300nm;

[0034] Preparation of gel electrolyte: LiClO 4 Dissolve in propylene carbonate at a concentration of 0.1mol / l to form solution A, dissolve PMM...

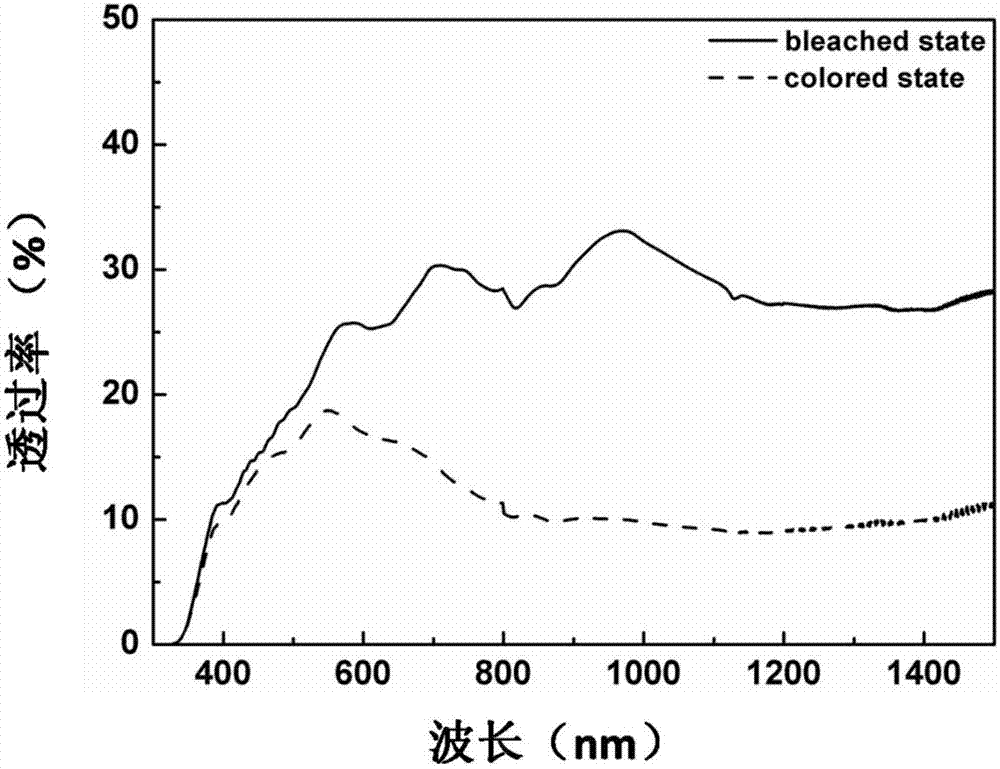

Embodiment 2

[0038] The composition of the flexible device: the transparent flexible substrate is PET, the transparent conductive layer is ITO film, the ion storage layer is NiO film, and the gel electrolyte is made of PMMA, LiClO 4 and propylene carbonate, the electrochromic layer is WO 3 film;

[0039] Fabrication process of flexible devices:

[0040] Preparation of the counter electrode: ITO film and NiO film were sequentially prepared on the transparent flexible PET substrate by magnetron sputtering method, the thickness of the ITO film was 200nm, and the thickness of the NiO film was about 500nm;

[0041] Preparation of working electrode: ITO film and WO were sequentially prepared on a transparent flexible PET substrate by magnetron sputtering 3 Thin film, ITO thickness is 200nm, WO 3 The thickness of the film is about 300nm;

[0042] Preparation of gel electrolyte: LiClO 4 Dissolve in propylene carbonate at a concentration of 0.1mol / l to form solution A, dissolve PMMA in propyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com