Zinc sulfide nano-belt, preparation and application thereof in preparing anode material of lithium sulfur battery

A positive electrode material, lithium-sulfur battery technology, applied in the direction of zinc sulfide, battery electrodes, lithium batteries, etc., can solve the problems of poor cycle performance, long preparation process, low energy density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

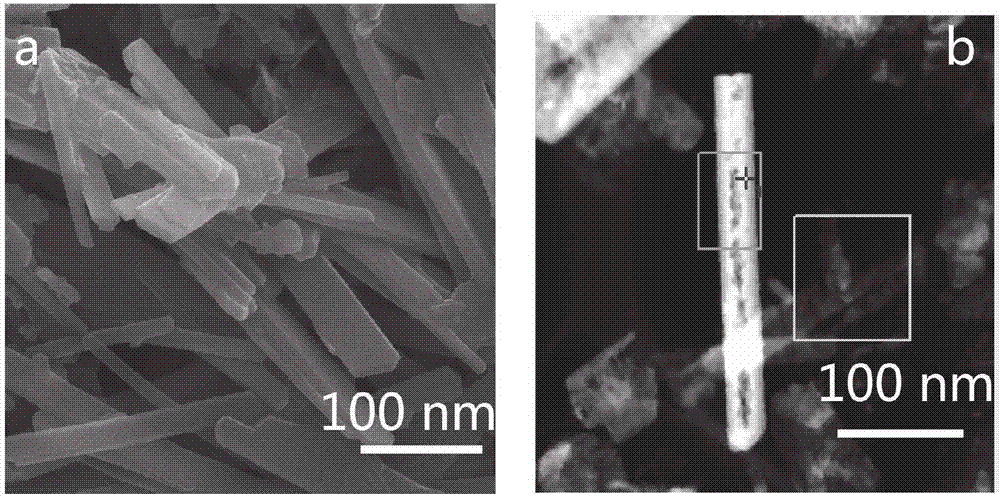

Embodiment 1

[0108] Mix 0.2 gram of zinc chloride with 0.2 gram of thioacetamide (S / Zn molar ratio is 1.8), and 0.08 gram of sodium lauryl sulfate, mix evenly and transfer to a hydrothermal kettle, keep warm at 120°C for 6 hours, and separate the solid and liquid. After drying, the zinc sulfide nanobelt can be prepared; the zinc sulfide nanobelt has a length of 120nm and a diameter of 30nm.

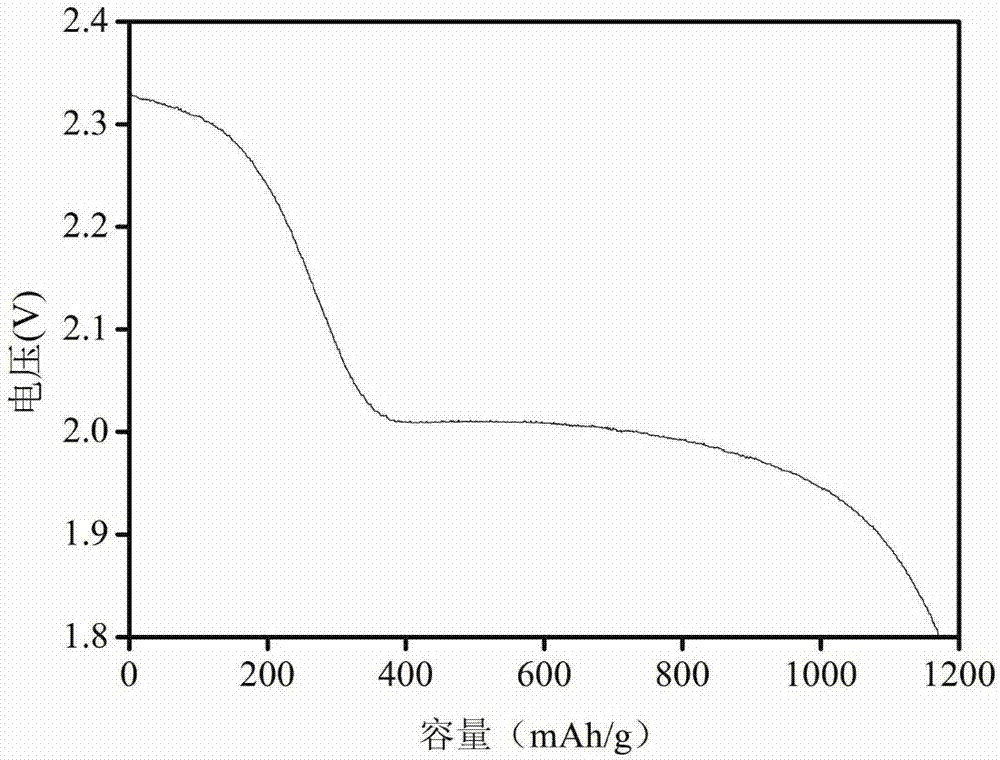

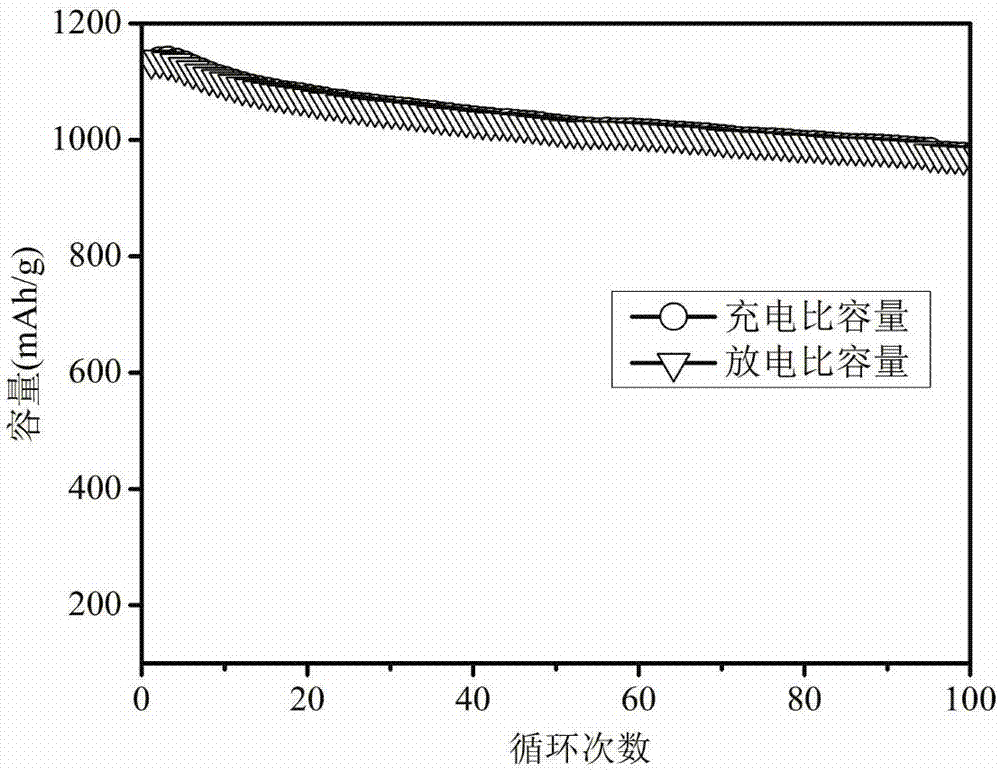

[0109] Disperse the prepared zinc sulfide nanobelts in 500mL of ionized water, add 1 gram of dopamine hydrochloride monomer, then add Tris-buffer to adjust the pH to 8.5, and keep it for 6 hours. The solid product is freeze-dried and transferred to an atmosphere furnace , heated to 600°C under the protection of argon, and kept for 1 hour. The product was added into 200 ml of ferric chloride solution with a concentration of 10% and stirred overnight (12 hours), and the obtained product was dried at 60°C. Its actual sulfur content is 50wt.% by thermogravimetric test. Gained composite positive electrod...

Embodiment 2

[0112] Mix 0.2 gram of zinc chloride with 0.4 gram of thioacetamide (S / Zn molar ratio is 3.6), and 0.1 gram of sodium lauryl sulfate, and transfer them to a hydrothermal kettle, keep the temperature at 180° C. for 6 hours, and separate the solid and liquid. And after drying, the zinc sulfide nanobelt can be obtained, the length of which is 150nm, and the diameter is 60nm.

[0113] Disperse the prepared zinc sulfide nanobelts in 500mL of ionized water, add 3 grams of dopamine hydrochloride monomer, then add Tris-buffer to adjust the pH to 8.8, and keep it for 6 hours. The solid product is freeze-dried and transferred to an atmosphere furnace , heated to 800°C under the protection of argon, and kept for 5 hours. Add the product into 500 ml of ferric chloride solution with a concentration of 15%, stir overnight (12 hours), and dry the obtained product at 60°C. Gained composite positive electrode material, conductive carbon black, polyvinylidene fluoride (PVDF) are uniformly mixe...

Embodiment 3

[0116] Mix 0.2 gram of zinc chloride with 0.5 gram of thioacetamide (S / Zn molar ratio is 4.5), and 0.1 gram of sodium lauryl sulfate, mix evenly and transfer to a hydrothermal kettle, keep the temperature at 200°C for 10 hours, and separate the solid and liquid. And after drying, the zinc sulfide nanobelt can be obtained, the length of which is 180nm, and the diameter is 40nm.

[0117] Disperse the prepared zinc sulfide nanobelts in 500mL of ionized water, add 4 grams of dopamine hydrochloride monomer, then add Tris-buffer to adjust the pH to 8.5, and keep it for 12 hours. The solid product is freeze-dried and transferred to an atmosphere furnace , heated to 800°C under the protection of argon, and kept for 5 hours. The product was added into 500 ml of iron sulfide solution with a concentration of 30% and stirred overnight (12 hours), and the obtained product was dried at 60°C. The actual sulfur content is 70.8wt.% by thermogravimetric test. Gained composite positive electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com