Method for comprehensive utilization of middle and low grade ferro-sulphur ore and by-production of high-alumina slag and ferrosilicon

A by-product high-aluminum slag and pyrite technology, applied in the field of metallurgy, can solve the problems of surrounding water pollution, single sulfur concentrate product, and sulfur resource utilization rate of less than 58%, and achieve the effect of solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

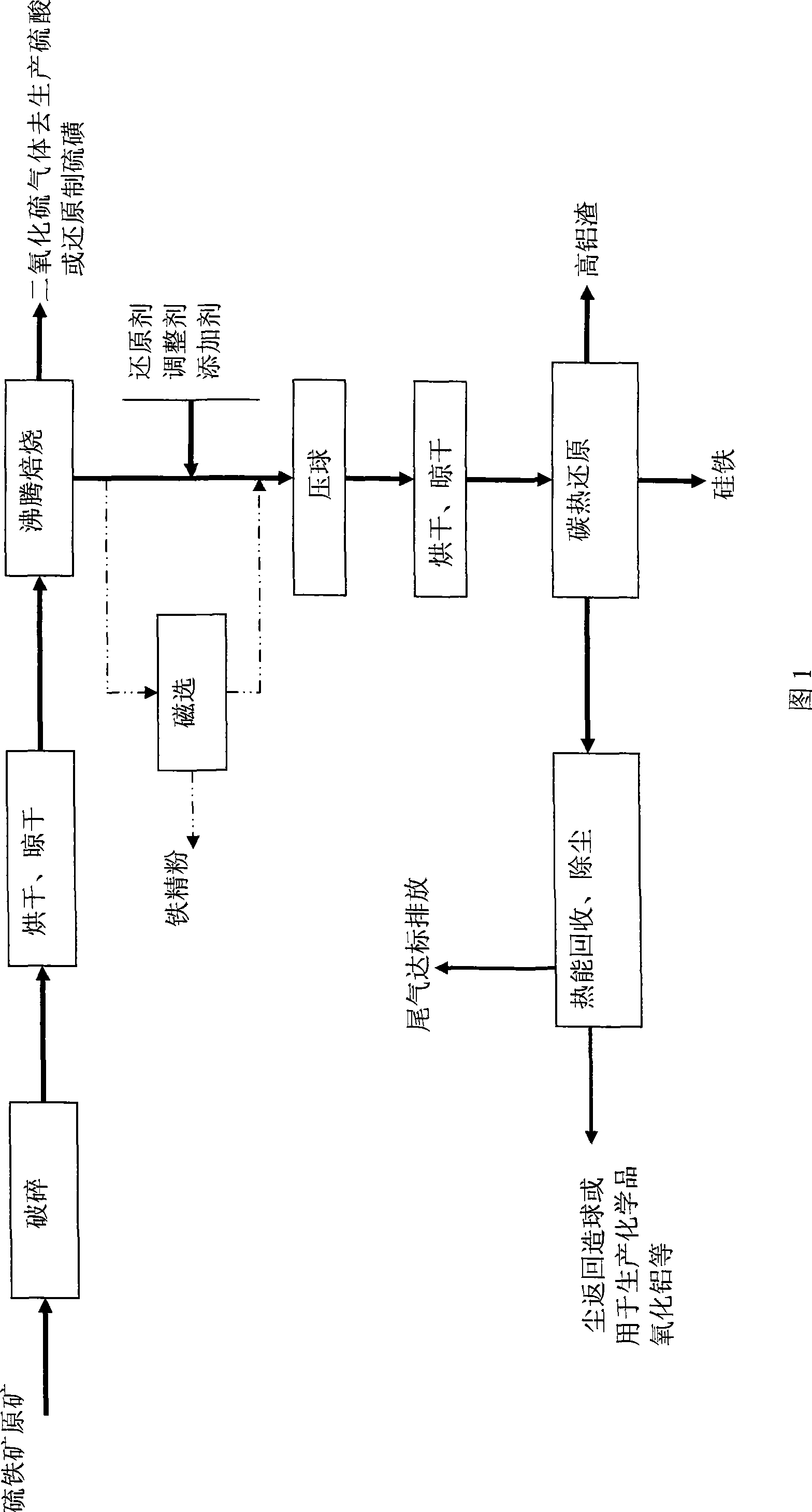

Image

Examples

Embodiment 1

[0017] S: 17-21%, Al 2 o 3 : 27~31%, Fe 2 o 3 : 19-22%, SiO 2 : 32~37%, TiO 2 : 3-6% raw materials with a water content of less than 6%, after being crushed to a size below 4mm, naturally stacked and dried for later use. The prepared raw materials are put into a fluidized furnace for boiling roasting at 850-950°C to obtain gas containing 8-12% of sulfur dioxide and slag containing less than 1% of sulfur. The gas containing sulfur dioxide is used to produce sulfuric acid according to the conventional pyrite acid production process. The main components of slag are S: 0.5-1%, Al 2 o 3 : 28~32% 2, Fe 2 o 3 : 21-23%, SiO 2 : 35-39%, TiO 2 : 4-6%, if ferrosilicon alloy and high-alumina slag of metallurgical deoxidizer brand Si47Fe30 are produced, according to the product and melting temperature requirements, 360 kg of silica with a silicon dioxide content of more than 90% is added to one ton of slag to adjust the composition to meet The composition requirements of the pr...

Embodiment 2

[0019] Homogenized S: 18-21%, Al 2 o 3 : 28~32%, Fe 2 o 3 : 19-22%, SiO 2 : 34-37%, TiO 2 : 4-6% raw materials with a water content of less than 6%, after being crushed to a size below 4mm, naturally stacked and dried for later use. The prepared raw materials are put into a fluidized furnace for magnetic boiling roasting at 900-980 DEG C to obtain gas containing 12-15% of sulfur dioxide and slag containing less than 1% of sulfur. The gas containing sulfur dioxide is used for the boiling reduction of high-sulfur coal to produce sulfur and produce reduced coal slag at the same time. The slag contains 19-21% of ferroferric oxide. Magnetic separation is performed first to obtain iron fine powder containing more than 60% iron. The slag after magnetic separation is added to the coal slag produced by reduction according to its weight 10:1, and its main component is S: 0.6~1%, Al 2 o 3 : 33~38% 2, Fe 3 o 4 : 7-8%, SiO 2 : 42-47%, TiO 2 : 5-7%, if ferrosilicon alloy and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com